Soybean milk grinder rotor and soybean milk grinder

A refiner, rotor technology, applied in pulp beating/refining methods, textile and papermaking, fiber raw material processing, etc., to achieve the effect of reducing downtime, extending service life, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

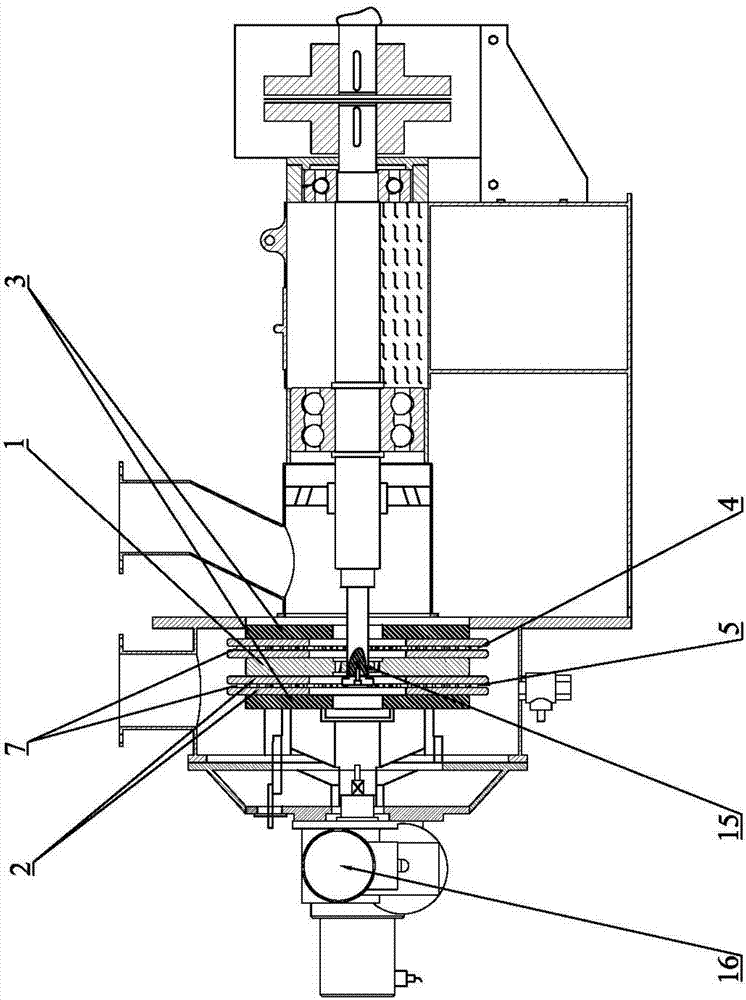

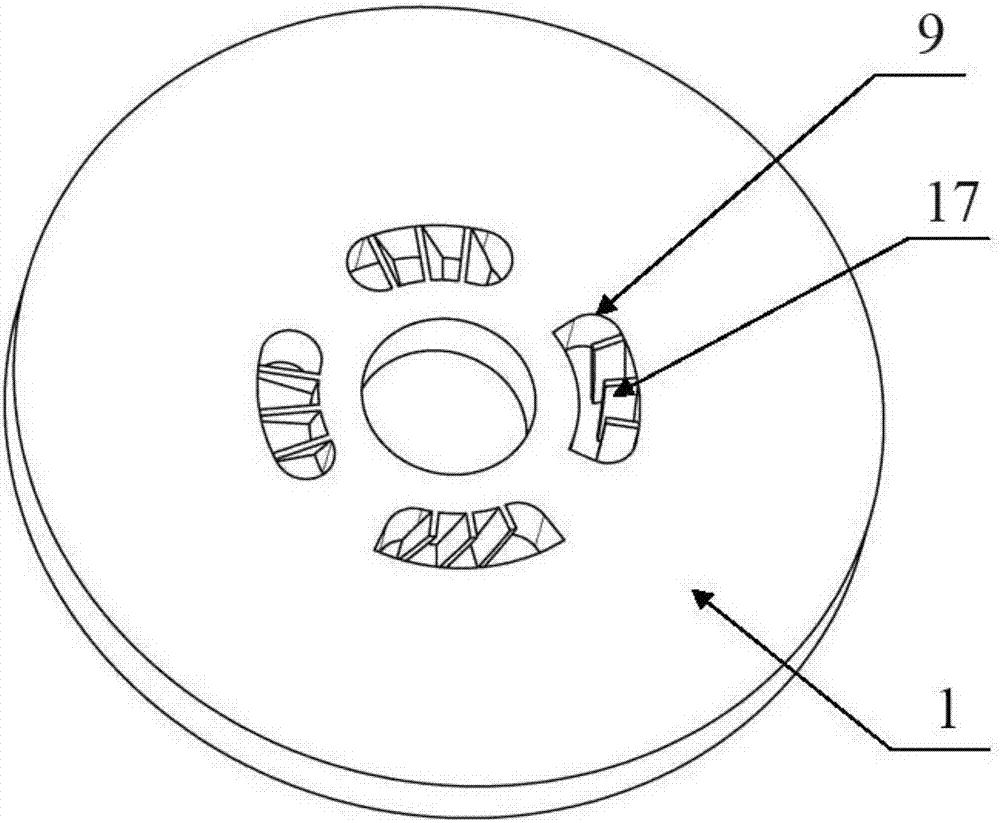

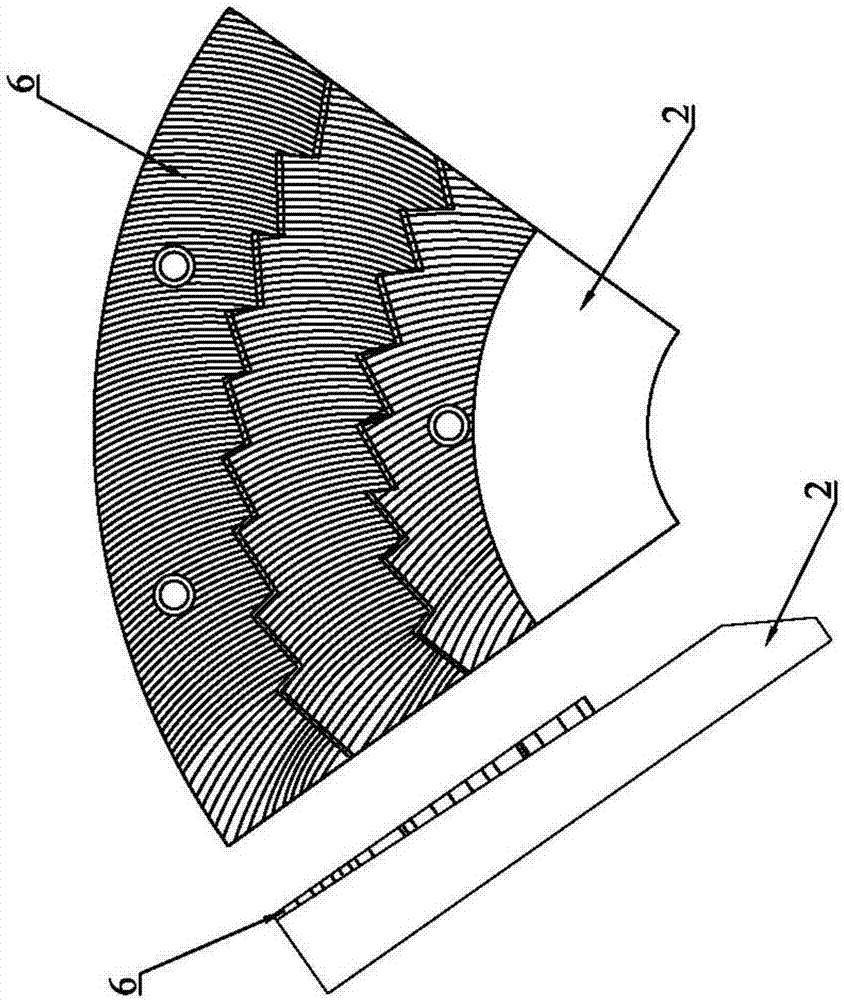

[0029] According to a first embodiment of the invention, the double disc refiner has such figure 1 The main configuration shown. The refiner rotor includes: a rotor main body 1, the rotor main body 1 has a drive motor side 4 facing the drive motor when installed and a gap adjustment side 5 facing away from the drive motor (the side of the refiner door is equipped with a gap adjustment device 16 ), both sides of the rotor main body 1 are arranged with grinding discs 2 with several grinding blades 6; two stators, the rotor main body 1 is designed to be suitable for rotating between these two stators 3, wherein, Each of the stators 3 is provided with a grinding disc 2 with a sharpening edge 6 on the side facing the rotor main body 1, whereby the rotor main body 1 on the drive motor side 4 and the gap adjustment side 5 are respectively provided by the rotor The main body 1 and the corresponding stator 3 form a refining zone 7; wherein said rotor main body 1 is designed to be adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com