Multifunctional scouring agent for continuous steaming scouring and bleaching of cotton knit and preparation method of multifunctional scouring agent

A cotton knitting and multifunctional technology, which is applied in the field of continuous steaming, scouring and bleaching of cotton knitting and its preparation field, can solve the problems of high sewage treatment cost, large energy consumption, and large fabric damage, and achieve excellent sequestration Combined dispersing ability, high strength retention rate, good whiteness and capillary effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

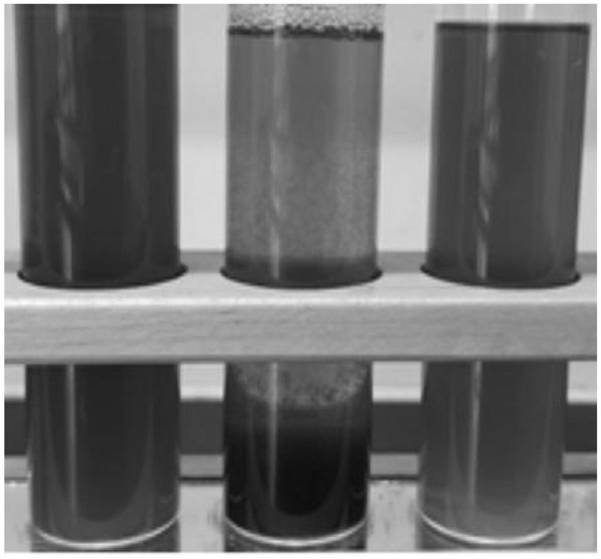

Image

Examples

Embodiment 1

[0025] A method for preparing a multifunctional scouring agent for continuous steaming, scouring and bleaching of cotton knitting, comprising the following steps:

[0026] (1) In parts by mass, 8 parts of sodium gluconate, 4 parts of magnesium sulfate, 7 parts of tetrasodium iminodisuccinate, 20 parts of sodium polyhydroxycarboxylate, 18 parts of deionized water and Heat up the reaction vessel to 65°C, start stirring (frequency 100), and stir for 30 minutes until the material is completely dissolved;

[0027] (2) 20 parts of the solution prepared in step (1) and 20 parts of isomeric decanol polyoxyethylene ether (5EO) and 10 parts of isomeric tridecyl alcohol polyoxyethylene ether (6EO) of the formula amount, the present invention is synthesized The environmental-friendly phosphorus-free chelating dispersant maleic anhydride and 12 parts of acrylic acid copolymer obtained by the reaction were incubated at 55°C for 1 hour, and then cooled to below 30°C by cooling circulating wa...

Embodiment 2

[0029] A method for preparing a multifunctional scouring agent for continuous steaming, scouring and bleaching of cotton knitting, comprising the following steps:

[0030] (1) In terms of parts by mass, respectively add 6 parts of sodium gluconate, 6 parts of magnesium sulfate, 8 parts of tetrasodium iminodisuccinate, 22 parts of sodium polyhydroxycarboxylate, 18 parts of deionized water and Heat up the reaction vessel to 70°C, start stirring (frequency 100), and stir for 30 minutes until the material is completely dissolved;

[0031] (2) 15 parts of isomerized decanol polyoxyethylene ethers (5EO) and 15 parts of isomeric tridecyl alcohol polyoxyethylene ethers (6EO) of the solution prepared in step (1) and formula quantity, maleic anhydride and 10 parts of acrylic acid copolymer are kept at 50°C for 1 hour, and then the cooling cycle water is turned on to quickly cool down to below 30°C, and 2 parts of functional additives are added to obtain a multifunctional scouring agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com