SAGD (steam-assisted gravity drainage) super-heavy oil high-temperature flash-evaporation dehydration method

A technology for flash dehydration and super-heavy oil, which is applied in the fields of hydrocarbon oil dehydration, dehydration/demulsification by chemical methods, etc. The effect of thinner consumption, shorter dehydration time, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

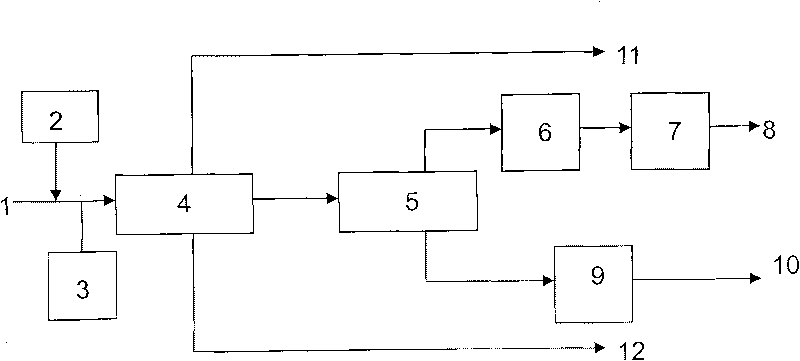

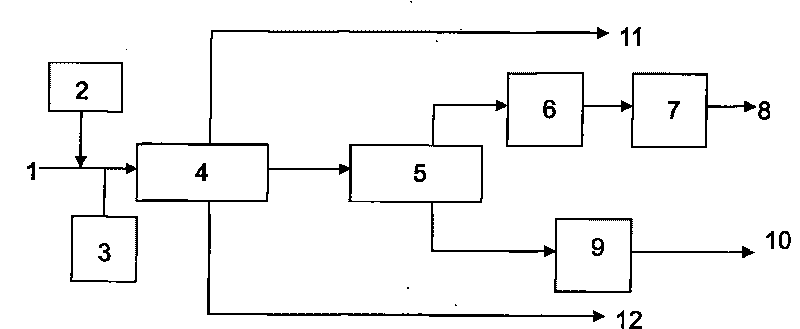

[0009] In the attached picture:

[0010] The production fluid 1 of SAGD high-temperature ultra-heavy oil from the well station is degassed and collected and transported into the three-phase separator 4 with a multi-stage centrifugal pump. Before the production fluid enters the three-phase separator 4, it is first added by the dosing device 2 The high-temperature demulsifier of 200mg / l~300mg / l enters the inlet pipeline of the three-phase separator 4, and at the same time, the high-temperature sampling device 3 is used to sample and analyze the water content of the produced liquid, and an inert gas of a certain pressure is added to the three-phase separator 4, Make the pressure in the three-phase separator 4 higher than the saturated vapor pressure of water at the dehydration temperature by 0.1MPa to 0.3MPa, and the production fluid added with the demulsifier is settled in the three-phase separator 4 for 1hr to 3hr to achieve preliminary oil-water separation and demulsification s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com