Flue gas desulfurization method and device

A desulfurization device and flue gas technology, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of separation and high cost, high corrosion, low efficiency, etc. perfect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

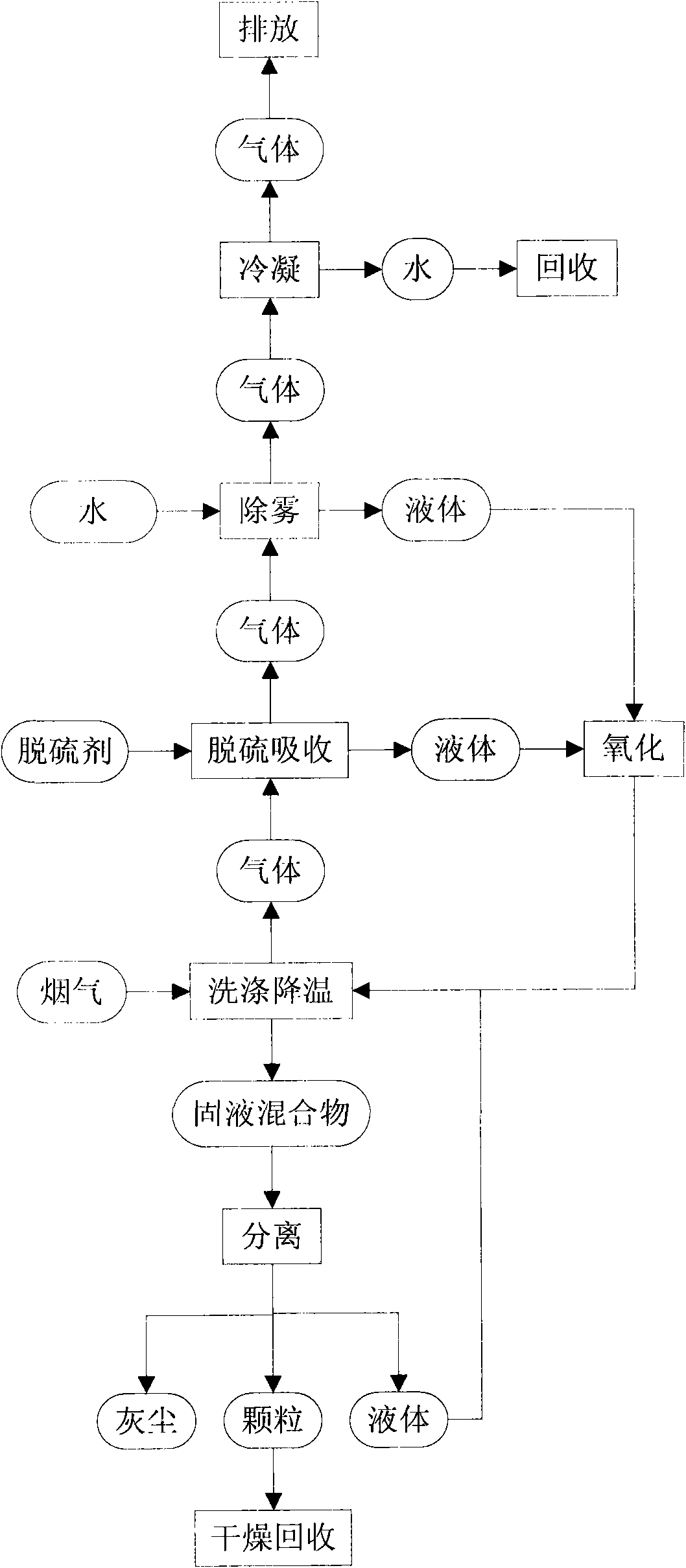

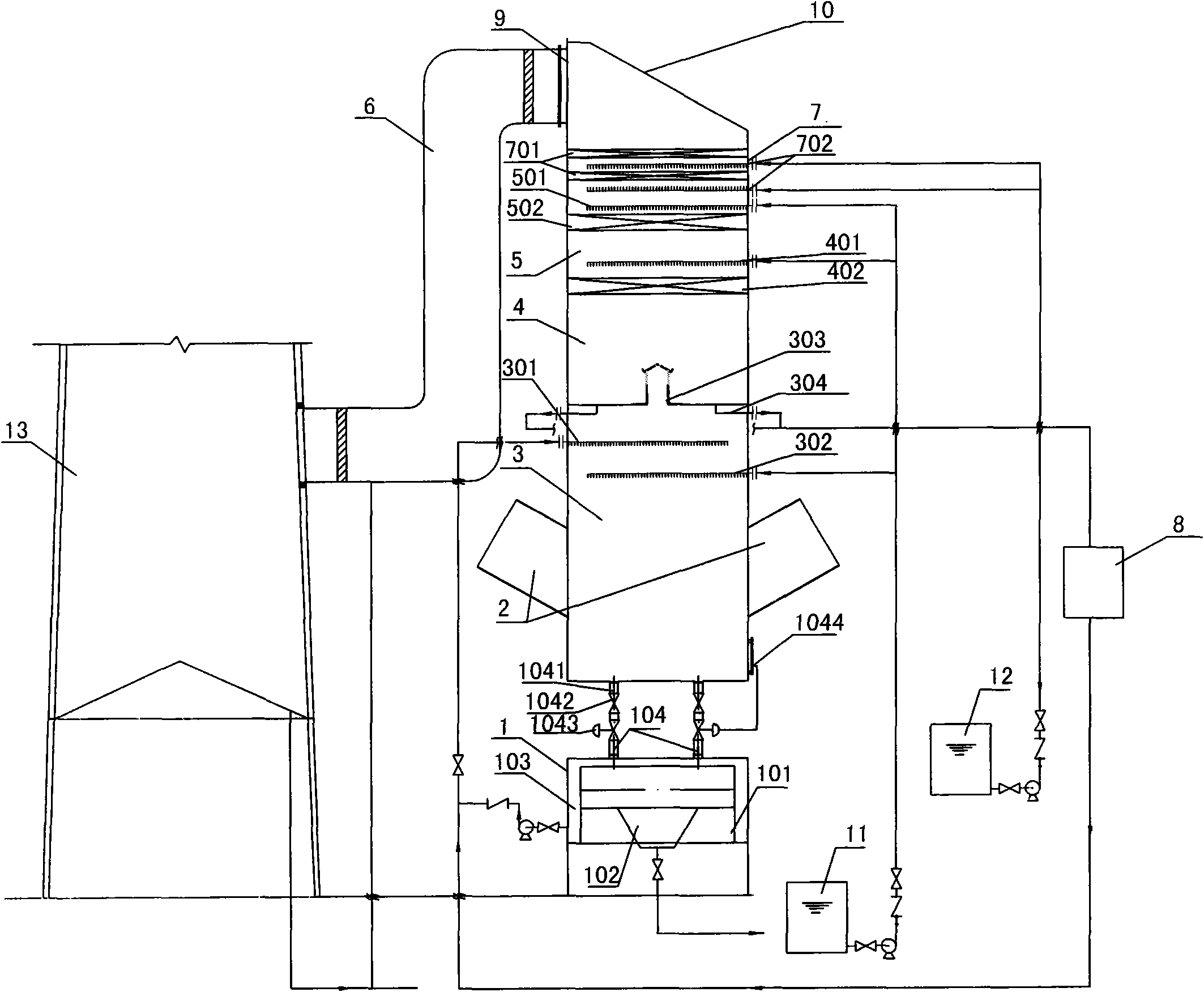

[0052] A 240t / h coal-fired high-pressure boiler with a flue gas volume of 350,000Nm 3 / h, boiler coal consumption 58t / h, flue gas sulfur dioxide content 3000mg / Nm 3 , exhaust gas temperature 145℃, dust content after electrostatic precipitator 250mg / Nm 3 , the desulfurization tower adopts the packing structure and is divided into five zones and four stages of spraying (as attached figure 2 shown).

[0053] combine figure 1 with 2 As shown, the flue gas desulfurization process of the present embodiment is as follows:

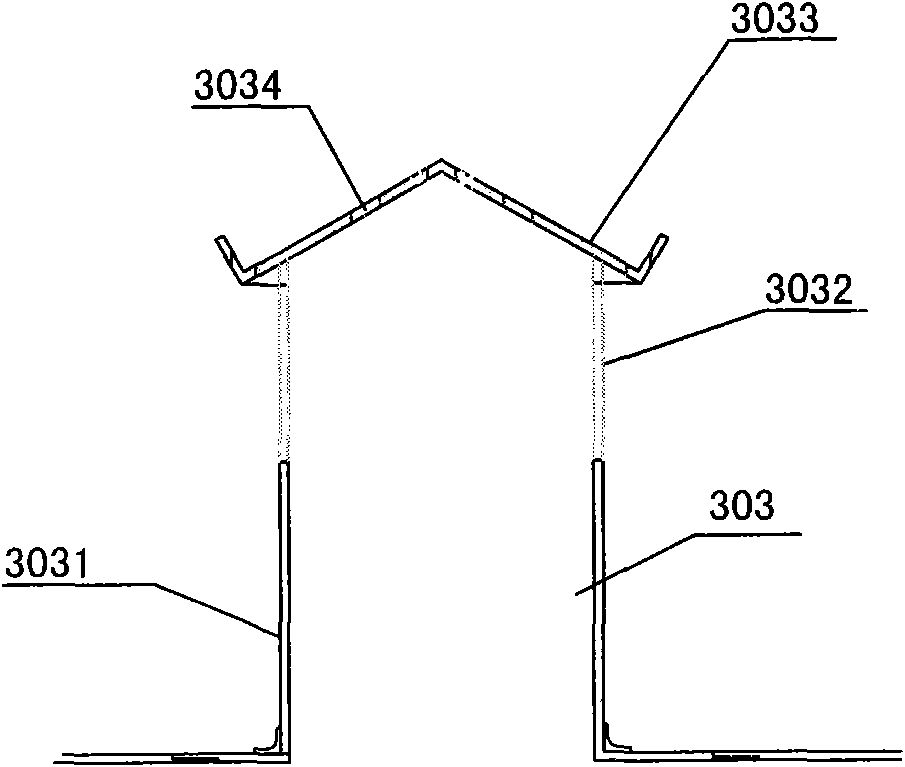

[0054] 1) Washing and cooling: the flue gas (temperature 135-145°C) after electric dust removal is supplied to the concentrated dust removal area 3 of the desulfurization tower 10 through the flue gas inlet 2, and the spray device 301 on the top of the concentrated dust removal area 3 sprays the flue gas Spray the aqueous solution containing ammonium sulfate and the like returned in the subsequent steps, and contact the gas and liquid countercurrently to was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com