Full dry purification and residual heat utilization equipment and method for converter gas

A converter gas and all-dry technology, which is applied in the field of converter gas purification, can solve the problems of waste of secondary energy, excessive dust content of converter gas, and consumption of industrial water, so as to save industrial water, eliminate potential safety hazards, and reduce water content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

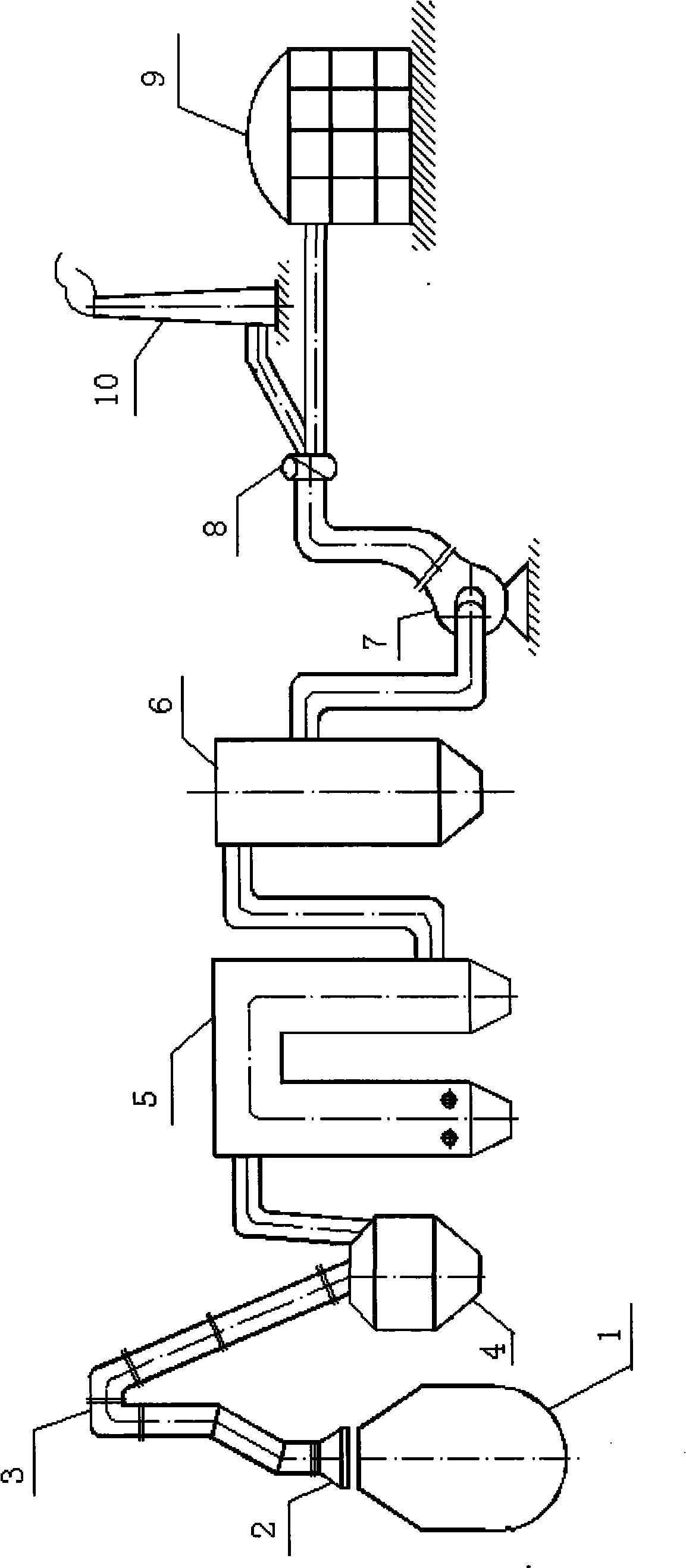

[0009] As shown in the figure, during the blowing period, the raw coal gas at about 1600 °C discharged from the converter 1 is cooled to about 900 °C through the movable hood 2 and the vaporization cooling flue 3, and then sent to the gravity dust collector 4 to reduce the dust content to 10~20g / Nm 3 , and then lead to the supplementary combustion waste heat boiler 5 through the flue. The supplementary combustion waste heat boiler 5 is composed of a blast furnace gas combustion chamber, a radiant heating surface and a convective heating surface. The blast furnace gas combustion volume of the waste heat boiler is reversely adjusted according to the flow rate of the converter gas sent to the waste heat boiler. During the converter blowing period, the converter gas production volume is the largest, and the post-combustion waste heat boiler 5 burner blast furnace gas combustion volume is the smallest; During the non-blowing period of the converter, the amount of converter gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com