Preparation method of carbon/carbon composite thermal insulation material containing anti-oxidization coating

A thermal insulation material and carbon composite technology, which is applied in the fields of carbon/carbon composite thermal insulation molding materials, polysilicon ingot furnaces and monocrystalline silicon Czochralski furnaces, can solve the problems of carbon volatilization and oxidation without improving and heat insulation Performance, dust generation is not ideal, service life is not ideal, the surface layer is not densified, etc., to achieve the effect of improving product production efficiency, increasing production processes, and reducing dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

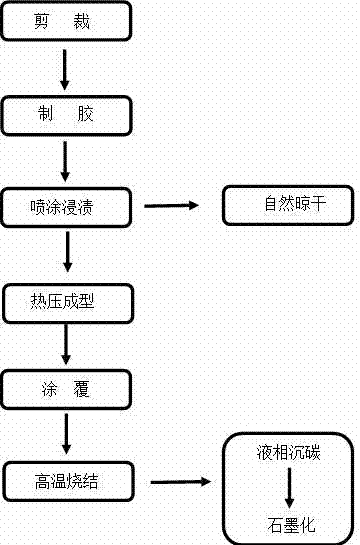

[0018] The embodiment of the present invention proposes a better method for preparing a carbon / carbon thermal insulation material containing an anti-oxidation coating, which improves the performance of the thermal insulation material and mainly includes:

[0019] (1) Cutting: Cut several pieces of polyacrylonitrile carbon fiber soft felt of the required size, as the embryo body for the preparation of thermal insulation materials.

[0020] (2) Glue making: Mix soluble thermosetting phenolic resin and 99% analytical pure alcohol according to the ratio of 1:1 by weight, stir evenly, and set aside.

[0021] (3) Spray impregnation: Spray and impregnate according to the weight ratio of felt and colloid of 1:3. Spray the colloid in (2) on both sides of each felt in (1) evenly and in equal proportions by mechanical spraying method, and then place it in a ventilated place to let the alcohol volatilize naturally.

[0022] (4) Hot press forming: spread the release paper on the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com