Forming method of positive pole piece of lithium ion power battery

A technology of positive pole piece and power battery, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of short circuit in the battery cell, difficult alignment of front and back sides, and difficulty in die cutting, so as to improve electrical performance and safety. performance, reduce self-discharge defects, and improve the effect of material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

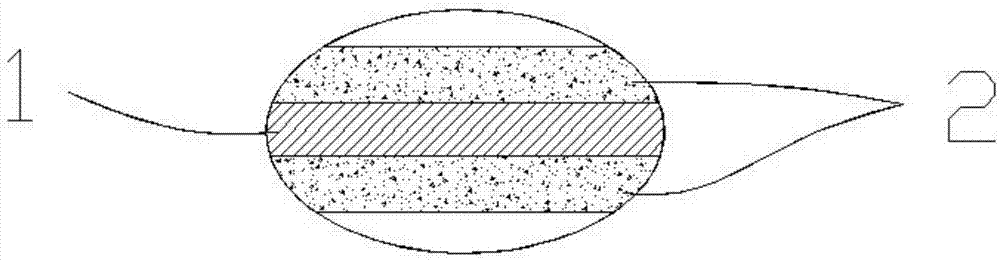

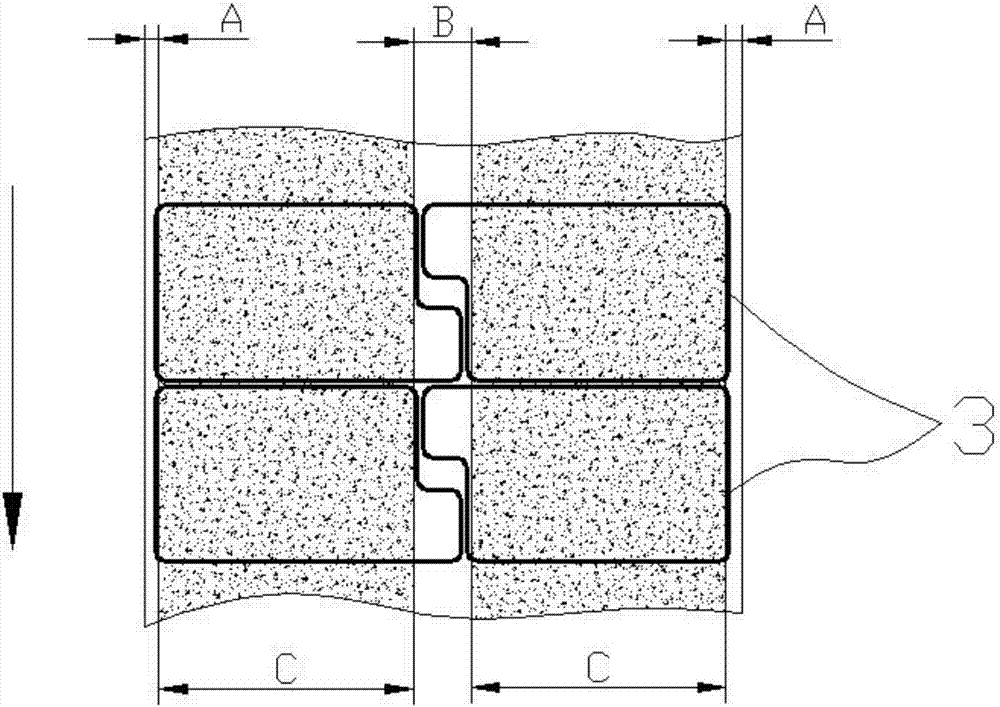

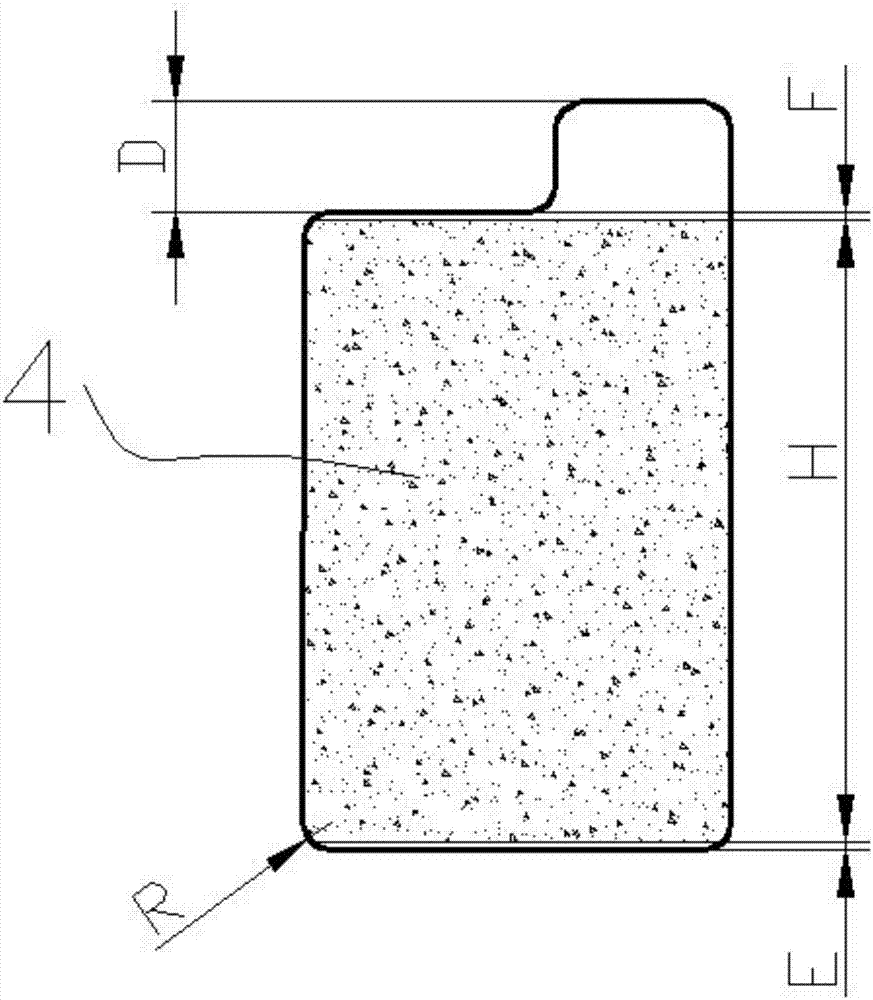

[0020] Such as figure 1 As shown, a positive pole piece for a lithium ion battery provided by an embodiment of the present invention includes a current collector aluminum foil 1 and a positive electrode active material 2 coated on both sides. Refer to figure 1 , figure 2 As shown, the position of the positive and negative double-sided coating area is the same, and the coating method is adopted figure 2 The coating direction is shown for continuous coating, the coating area of the positive pole piece is distributed symmetrically, and the coating width is C (50~300mm). The two sides and the middle of the coating area are provided with blank areas, and the width of both sides is blank All are A (3~5mm). When the width of the die is greater than the width of the coating, the pole piece can be left blank on both sides after forming and will not cut to the dressing area. If the width of the die is less than the coating width, the pole piece will be formed Without any white space, t...

Embodiment 2

[0022] Such as figure 1 As shown, an embodiment of the present invention provides a positive pole piece for a lithium-ion battery. The large roll of the positive pole piece is continuously coated with symmetrical blanks in the middle, and the coating area is located on the front and back sides of the positive pole piece body with symmetrical positions. The width of the coating zone is smaller than the width of the die, and the two sides form a left-right symmetrical blank area with a width of 4mm; the pole piece punching arrangement adopts a rotary compact arrangement, and the common blank area leads to the lugs and the lead poles. The length of the ear is 2mm shorter than the width of the blank area; the tab and the pole piece body are integrated with rounded corners, and die cutting is adopted. When the die is punched, there are blank areas at the head and tail of the coating area as a safety boundary , Its width is 1mm.

[0023] The method for forming the positive pole piece o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com