Automatic bag breaking discharge device

A unloading device and bag breaking technology, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc., can solve the problems of incomplete bag breaking and unloading, large dust production, low efficiency, etc., and achieve good dust control effect, The effect of small dust production and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

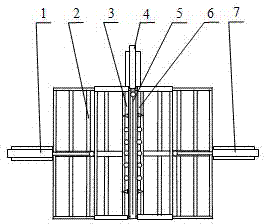

[0021] An automatic bag breaking and unloading device. Such as figure 1 As shown, the device includes a bag breaking cutter frame 2, a left bag breaking cutter 3, a bag cutting cutter 5 and a right bag breaking cutter 6.

[0022] Such as figure 1 As shown, a bag cutting tool 5 is installed in the middle position of the upper plane of the bag breaking tool frame 2 along the front and rear directions, and the left and right sides of the bag cutting tool 5 are correspondingly equipped with a left bag breaking tool 3 and a right bag breaking tool 6 , the left bag breaking tool 3 and the right bag breaking tool 6 are symmetrically arranged on the upper plane of the bag breaking tool frame 2. The working end of the piston rod of the bag cutting tool cylinder 4 is hinged with the bag cutting tool 5, the working end of the piston rod of the left bag breaking cylinder 1 is hinged with the left bag breaking tool 3, and the working end of the piston rod of the right bag breaking cy...

Embodiment 2

[0027] An automatic bag breaking and unloading device. Except following technical parameter, all the other are with embodiment 1:

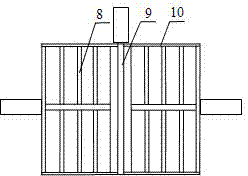

[0028] The sieve plate 8 is evenly provided with bar-shaped sieve holes, the width of the bar-shaped sieve holes is 20-30mm, and the sum of the hole areas of the bar-shaped sieve holes is 60-80% of the area of the sieve plate 8;

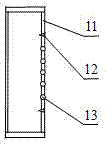

[0029] Steel nails 13 are evenly installed between the two triangular blades 12, and the number of steel nails 13 is 6 to 9;

[0030] The length of knife body is 80~85% of the cutter groove 9 lengths of bag breaking cutter frame 2.

[0031] This embodiment has the following positive effects:

[0032] 1) In this specific embodiment, a bag cutting tool 5 is installed in the middle position of the upper plane of the bag breaking tool frame 2 along the front and rear directions, and the left and right sides of the bag cutting tool 5 are correspondingly equipped with a left bag breaking tool 3 and a right side. The bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com