Patents

Literature

68results about How to "Save industrial water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

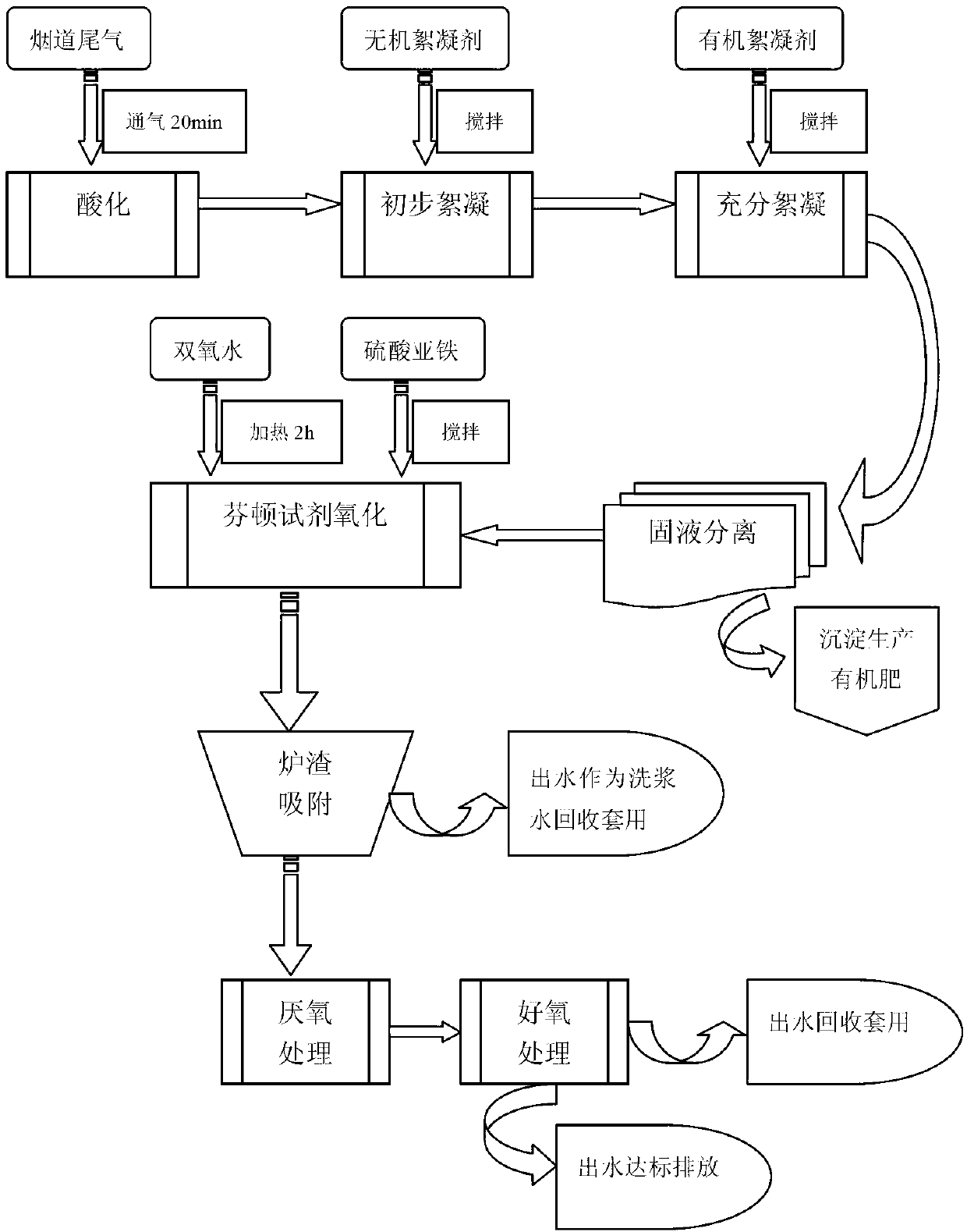

Process and equipment for dust collection and heat recovery by converter gas dry method

InactiveCN101942538ASave industrial waterMaximum recyclingManufacturing convertersIncreasing energy efficiencyBaghouseSpark arrestor

The invention provides an optimized process scheme and equipment aiming at the problems existing in the recovery technology of the conventional converter gas dry method. In the process scheme and the equipment, physical sensible heat between 800-1,000 DEG C and 200 DEG C of converter gas is recovered by using a high-efficient heat pipe exhaust-heat boiler, and hidden danger of system explosion is eliminated by using a spark arrestor at the same time. A nitrogen pulse bag-type dust collector replaces an electrostatic dust collector, so that the equipment has the advantages of simple structure, low fault rate and high dust collection efficiency. Compared with the recovery technology of the conventional converter gas dry method, the process scheme and equipment have obvious improvements on benefits, which are shown as reduction in dust emission load, reduction in energy and water consumption, increase in steam recovery, small equipment investment, safe and reliable process and the like.

Owner:北京国华新兴节能环保科技有限公司

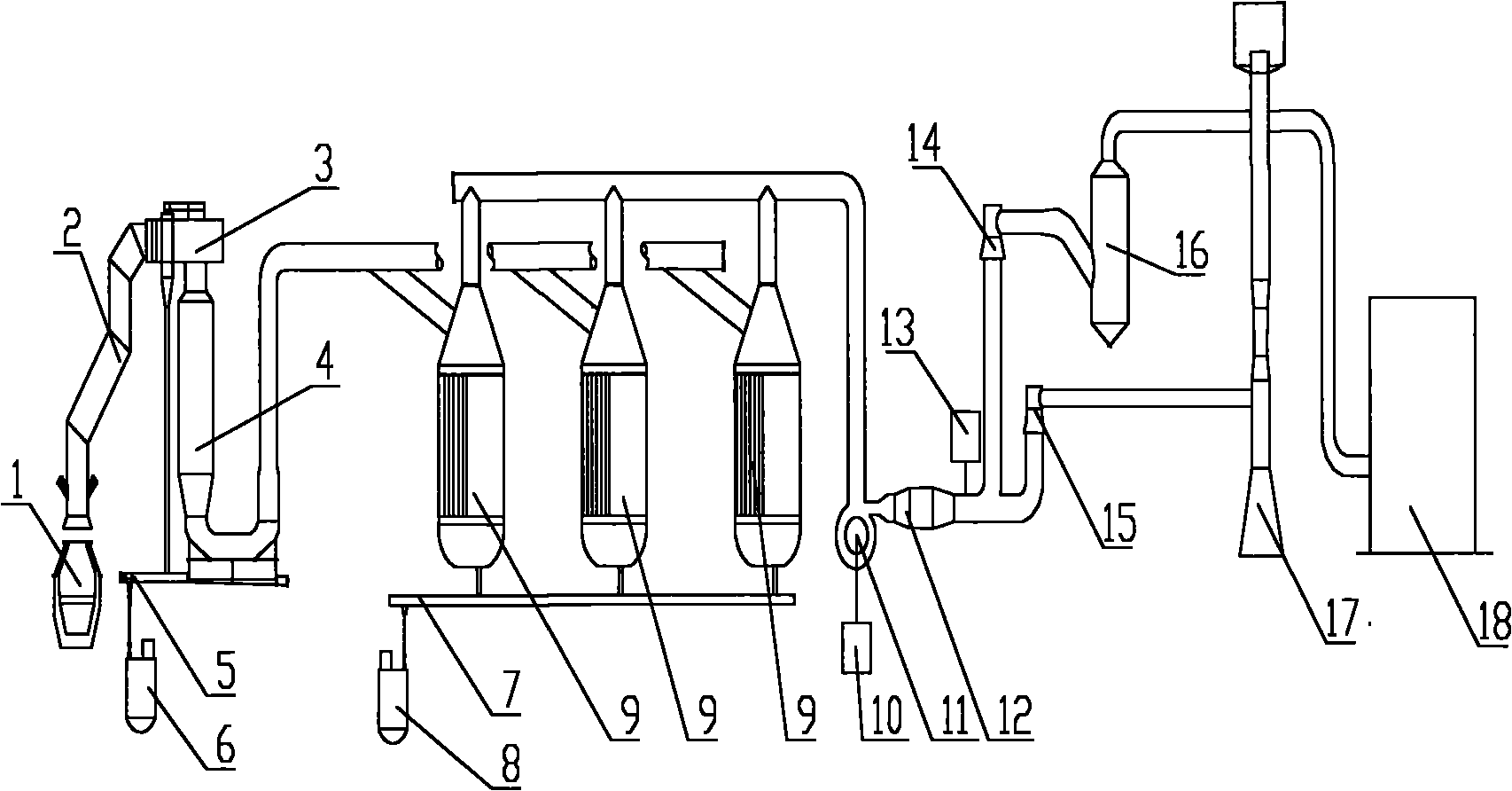

Method for comprehensively treating and utilizing dissolving pulp black liquor

ActiveCN102992553AEmission reductionEliminate ChromaTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemical oxygen demandSlag

The invention belongs to the technical field of biochemical environmental protection and provides a method for comprehensively treating and utilizing dissolving pulp black liquor. The method comprises the steps of (1) acidification, (2) flocculation, (3) oxidation, (4) adsorption and (5) biochemical treatment and further achieves sewage discharge up to the standard. By means of the method for comprehensively treating and utilizing the dissolving pulp black liquor, flue tail gas, slag and other wastes can be completely utilized, treatment cost is saved remarkably while emission of the three wastes is reduced, flocculated precipitate can serve as a raw material for producing organic fertilizers, considerable economic benefit is produced, chemical oxygen demand (COD) of water subjected to adsorption treatment is reduced by more than 85%, chroma is reduced by more than 99%, and the water can be recycled and can be subjected to biochemical treatment and then discharge up to the standard. The method is reasonable in process, low in cost and easy to implement, and has good economic benefit, environmental benefit and social benefit.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

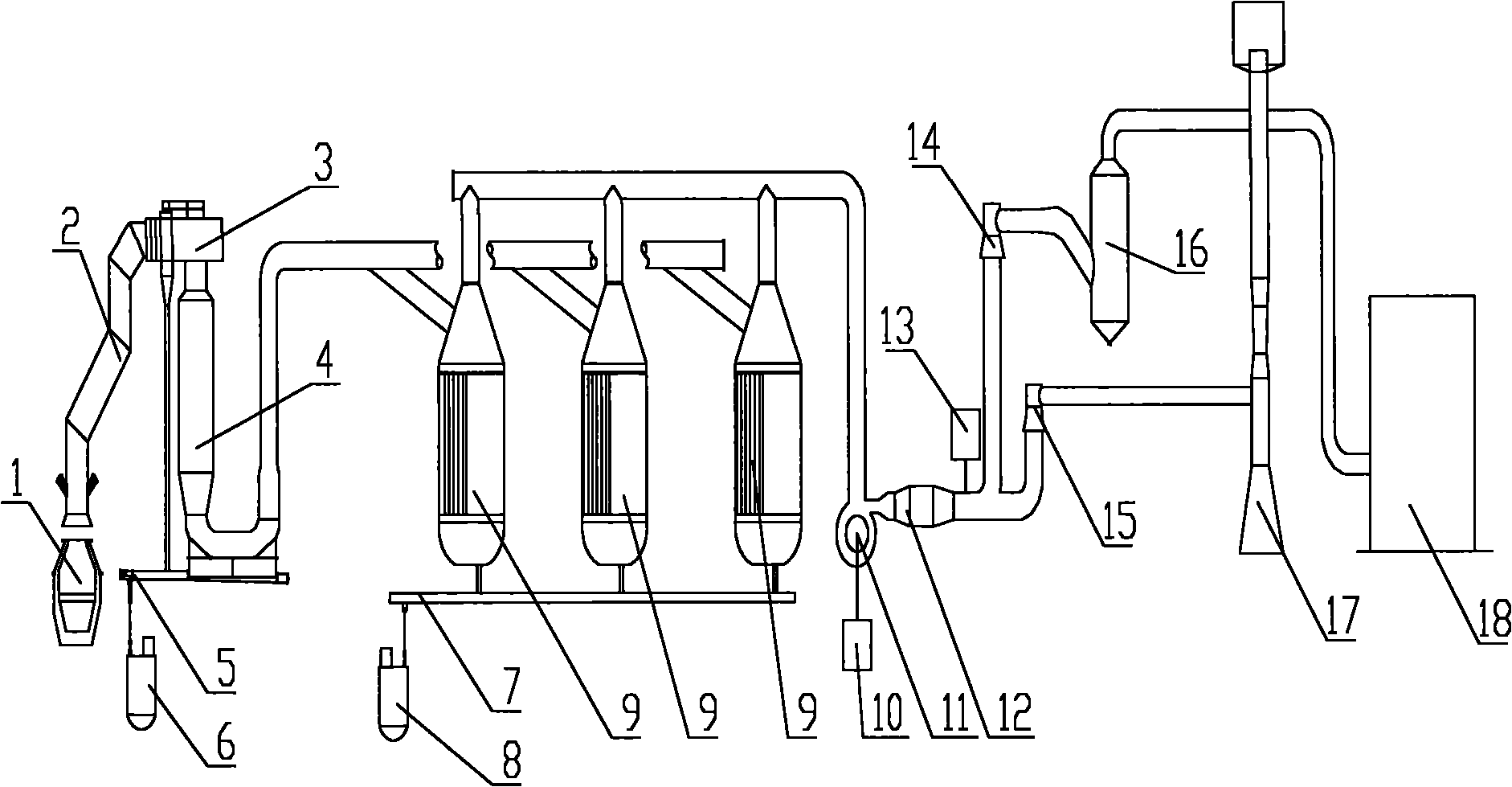

Full dry purification and residual heat utilization equipment and method for converter gas

InactiveCN101492756ALess dustLess waterIncreasing energy efficiencyManufacturing convertersSuperheated steamMoisture

The invention provides devices for purifying converter gas by dry process and using afterheat of the converter gas and a method thereof. In a converting period, waste gas exhausted from the converter is cooled by a movable gas hood and a vaporizing cooling duct, then is sent into a gravity dust collector to reduce dust content thereof, is conducted into a flue and then to an afterburning afterheat boiler; the afterburning afterheat boiler generates overheated vapor by using large quantity of sensible heat of the converter gas and sends the converter gas after being cooled into a bag dust collector through the flue to purify; the purified converter gas is sent to a draft fan to be pressurized through the flue, then passes through a three-way valve, and is sent to a converter gas cabinet; in a non-blowing period of the converter, converter gas is not generated; afterburning afterheat boiler burns a certain amount of blast furnace gas to stabilize load thereof and vapor yield. The three-way valve is switched to cause the afterheat boiler waster gas exhausted from the draft fan to flow to a waste gas discharging chimney. The converter gas processed by the method and devices has very low dust and moisture contents and is an ideal purified gas. During the operation process, large quantity of industrial water is saved, and large quantity of secondary energy is recycled.

Owner:袁长胜

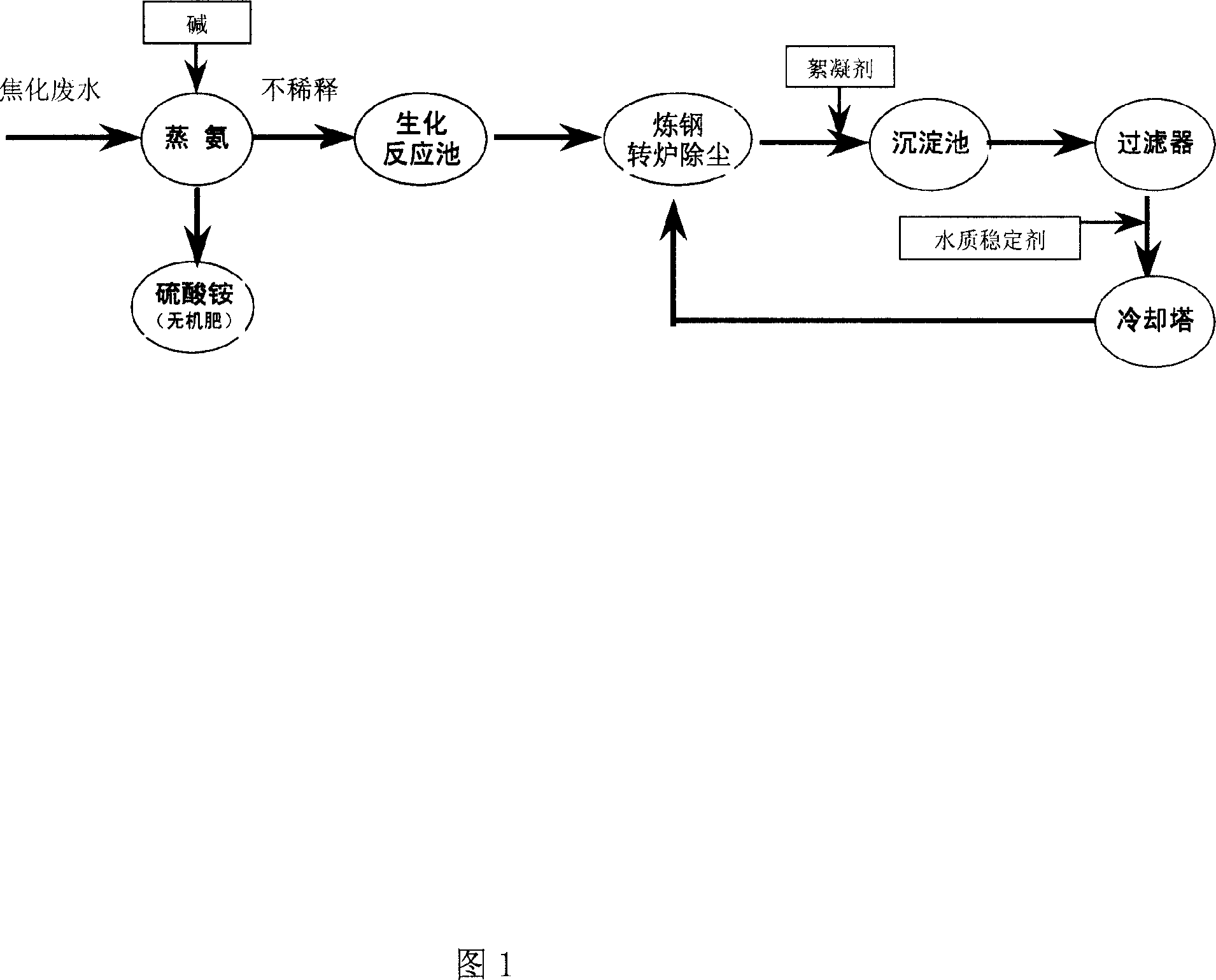

Coking waste water zero discharge treatment process

InactiveCN1948188AAchieving "Zero Emissions"Realize "Zero Emissions"Multistage water/sewage treatmentWater/sewage treatment by degassingDistillationWater quality

The present invention relates to a pyrogenic waste water zero discharge treatment process. It is characterized by that said process includes the following steps: making the pyrogenic waste water undergo the process of primary ammonia distillation treatment, then making biochemical treatment, and making the treated waste water be directly returned into the dust-removing system of steel-smelting converter, utilizing converter smoke dust and flue gas to further degrade the pollutants of amino nitrogen, phenol, cyanogens and COD in the pyrogenic waste water under the high temperature condition, and making the discharged water undergo the processes of flocculating settling, filtering and water quality stabilization so as to attain the discharge requirement.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

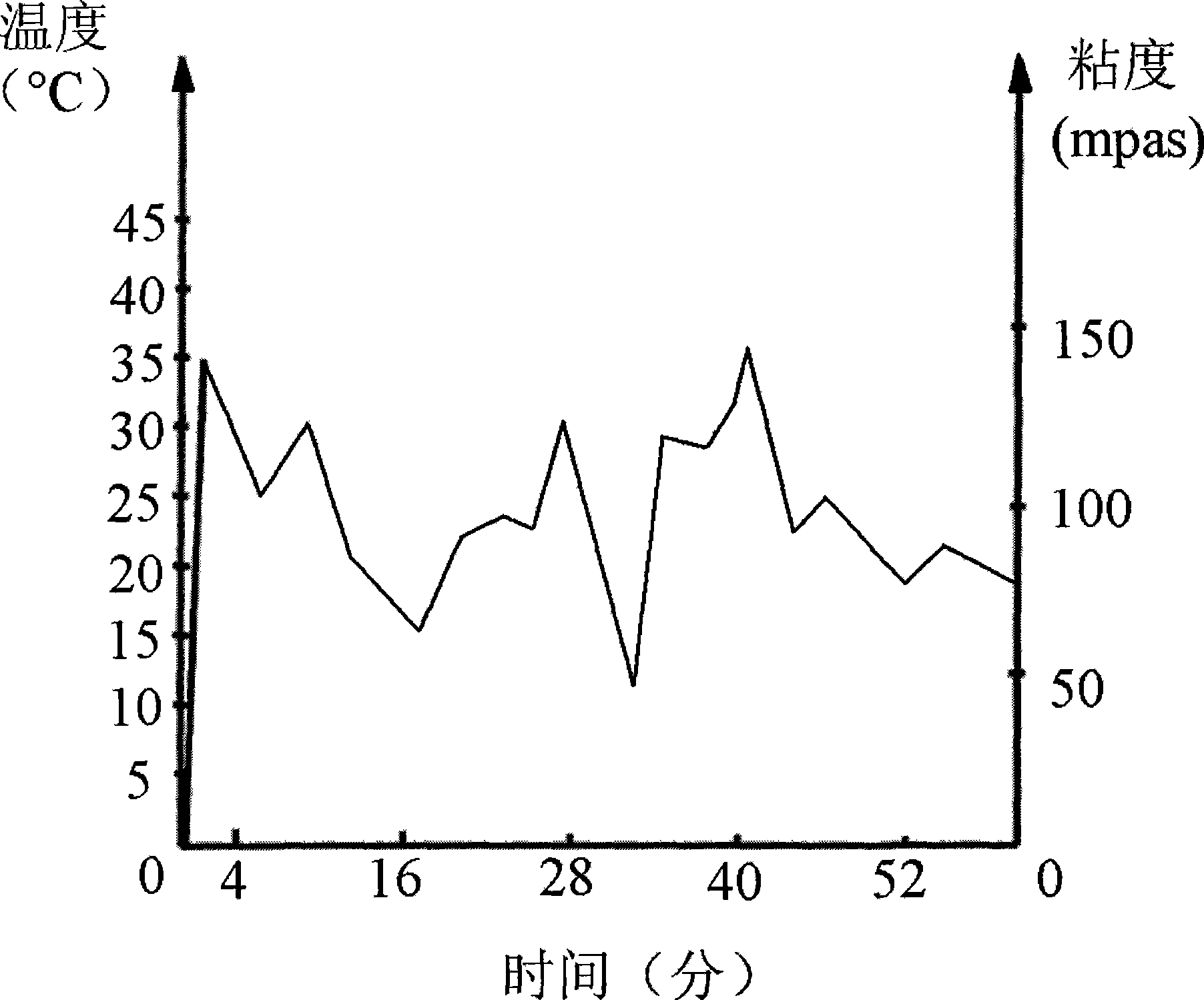

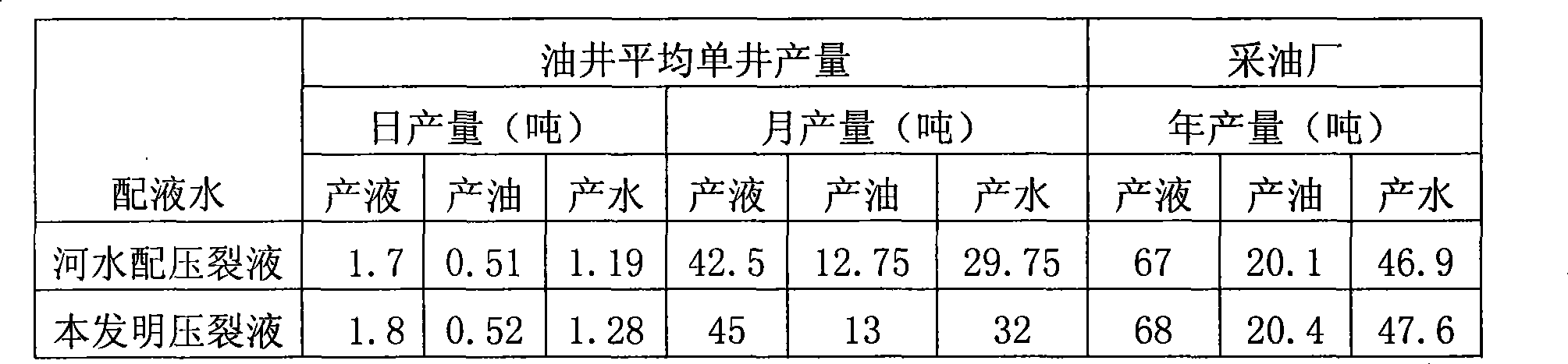

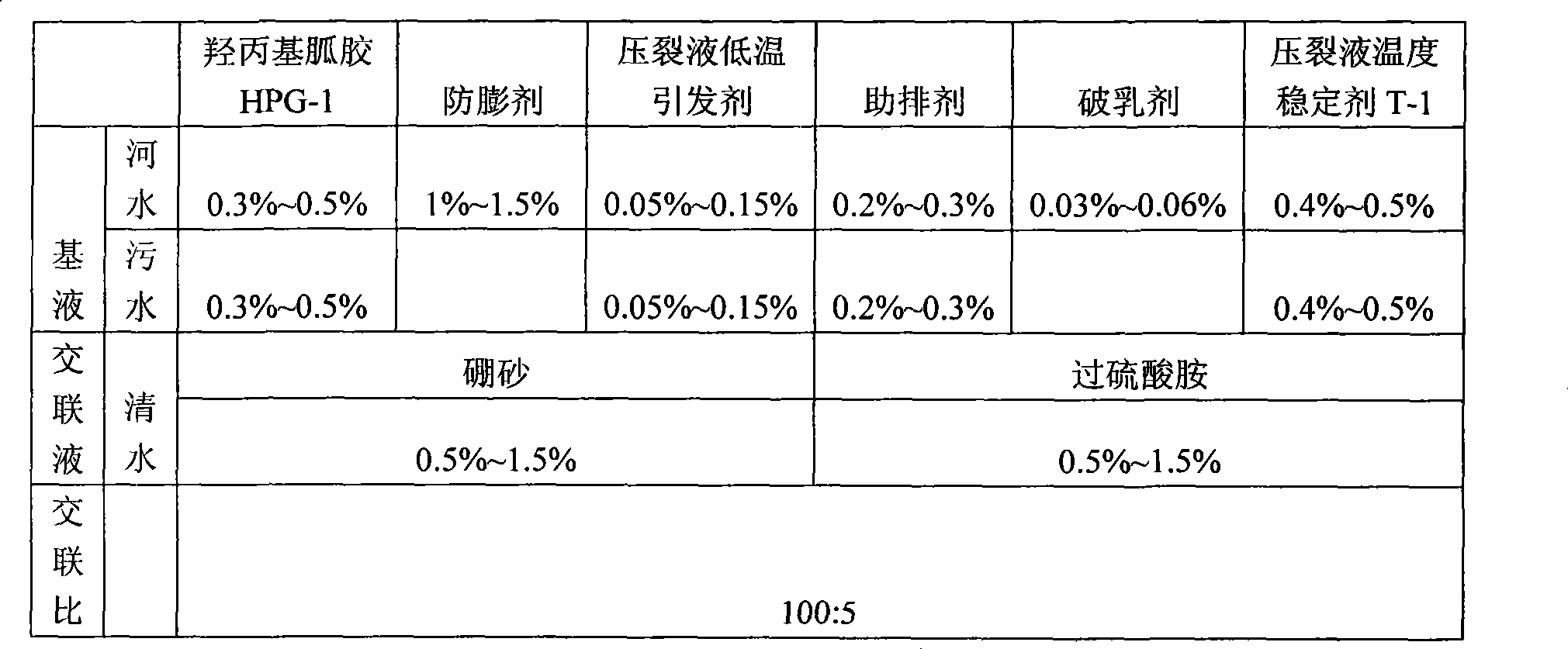

Fracture liquid and preparation method thereof

InactiveCN101381598AHigh salinityGood compatibilityDrilling compositionSweep efficiencyFracturing fluid

The invention discloses fracturing fluid and a preparation method thereof. The fracturing fluid is formed by mixing base fluid and crosslinked fluid according to the crosslinking ratio of 100 to 5; the base fluid consists of the following compositions according to mass percentage: 03 to 0.5 percent of hydroxypropyl guanidine gum HPG-1, 0.4 to 0.5 percent of a temperature stabilizer for the fracturing fluid, 0.05 to 0.15 percent of a low temperature evocating agent for the fracturing fluid, 0.2 to 0.3 percent of a cleanup additive and the balance being sewage water from a crude oil layer; and the crosslinked fluid consists of the following compositions according to mass percentage: 0.5 to 1.5 percent of borax, 0.5 to 1.5 percent of ammonium persulfate and the balance being clear water. The method for preparing the fracturing fluid comprises the following steps: the prepared base fluid and the prepared fracturing fluid are respectively placed for 100 to 120 minutes and are mixed according to the crosslinking rate of 100 to 5 to form the fracturing fluid. The method adopts the sewage water for matching the fracturing fluid, saves cost, has small pollution to the environment and improves the wave and volume of a water-driven reservoir and the oil-sweeping efficiency.

Owner:YANCHANG OIL FIELD

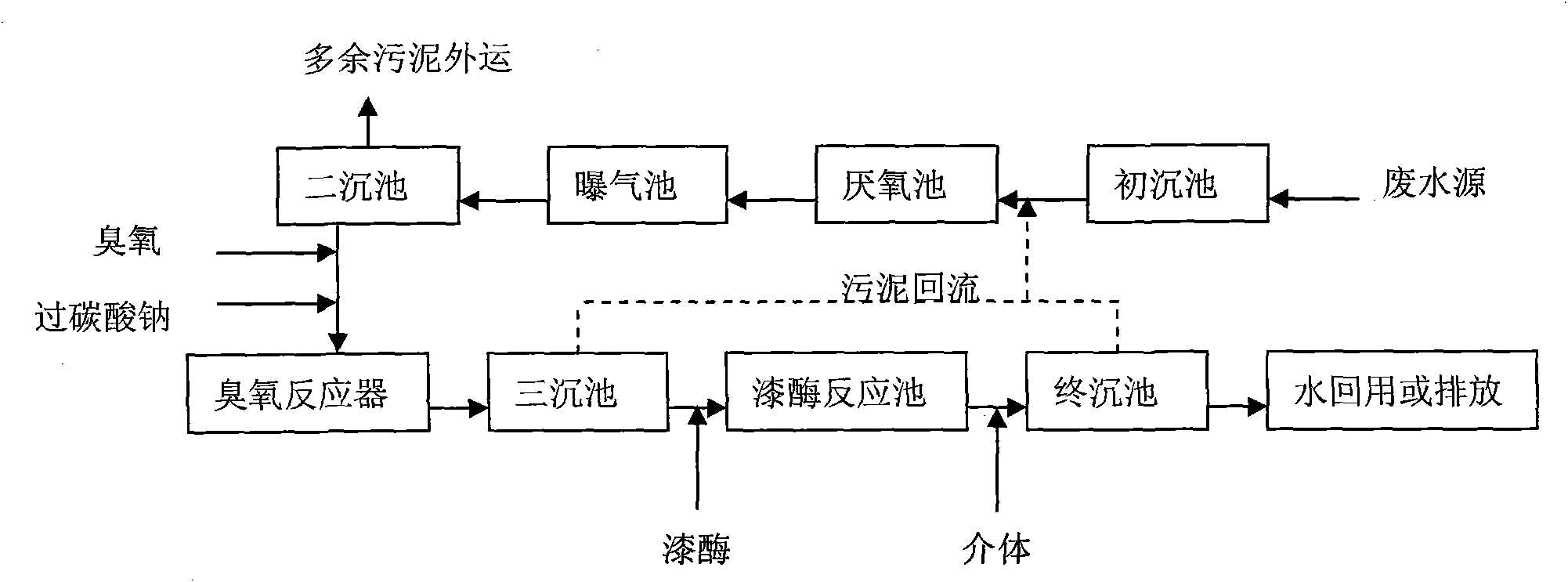

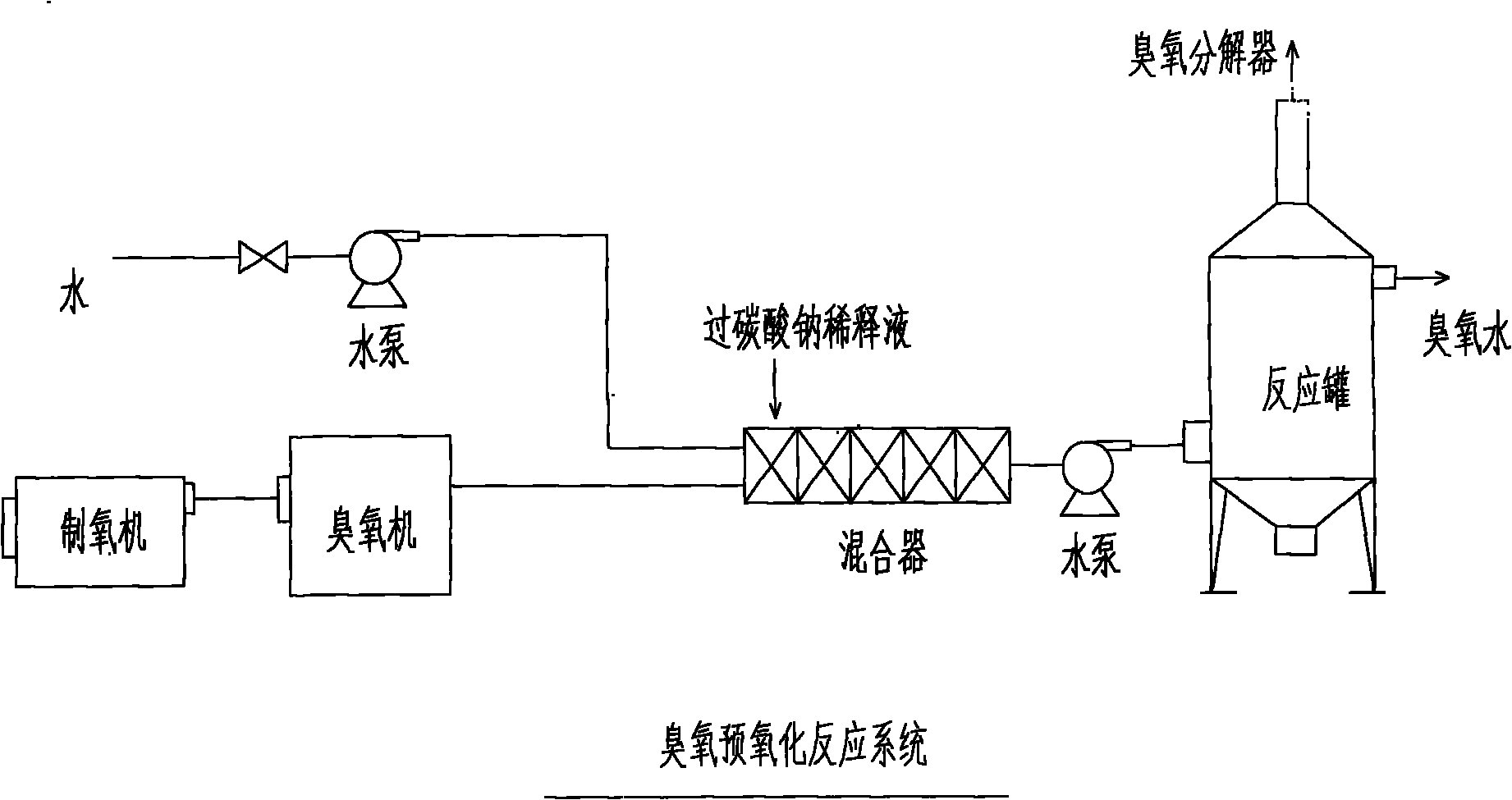

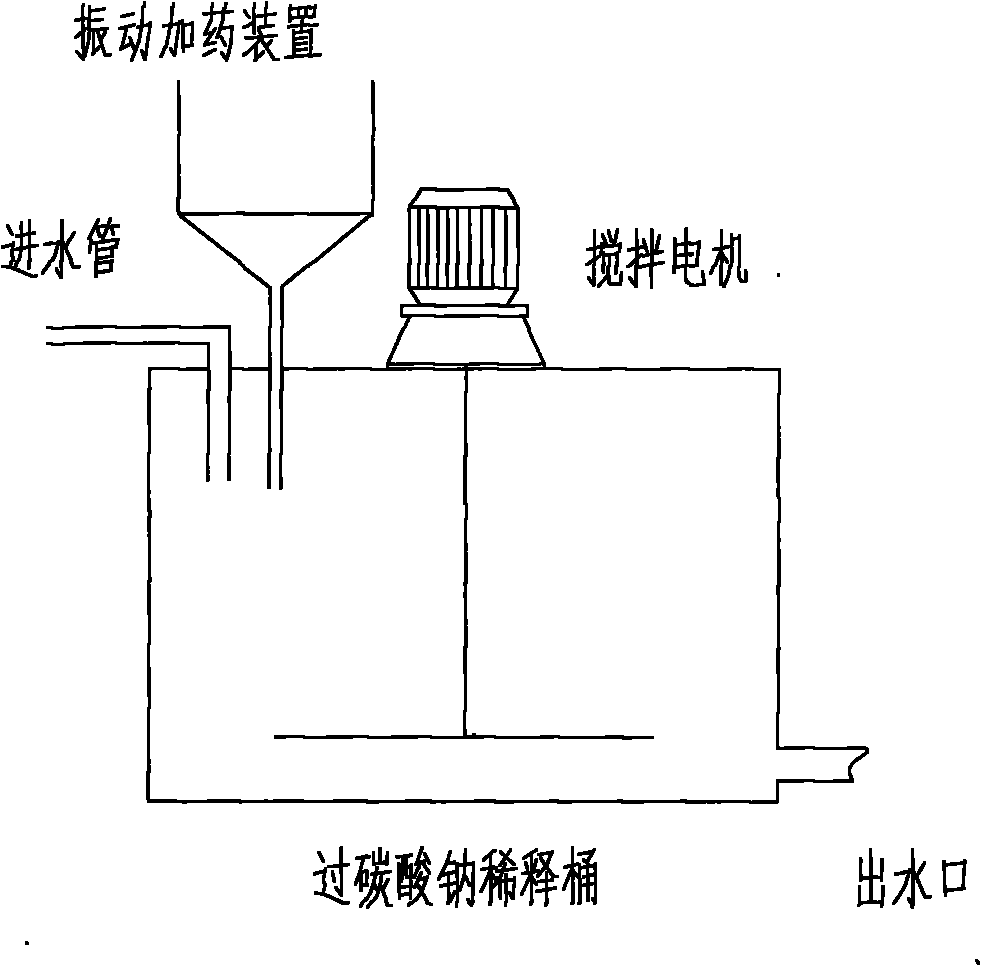

Ozone pre-oxidation and laccase advanced water treatment method

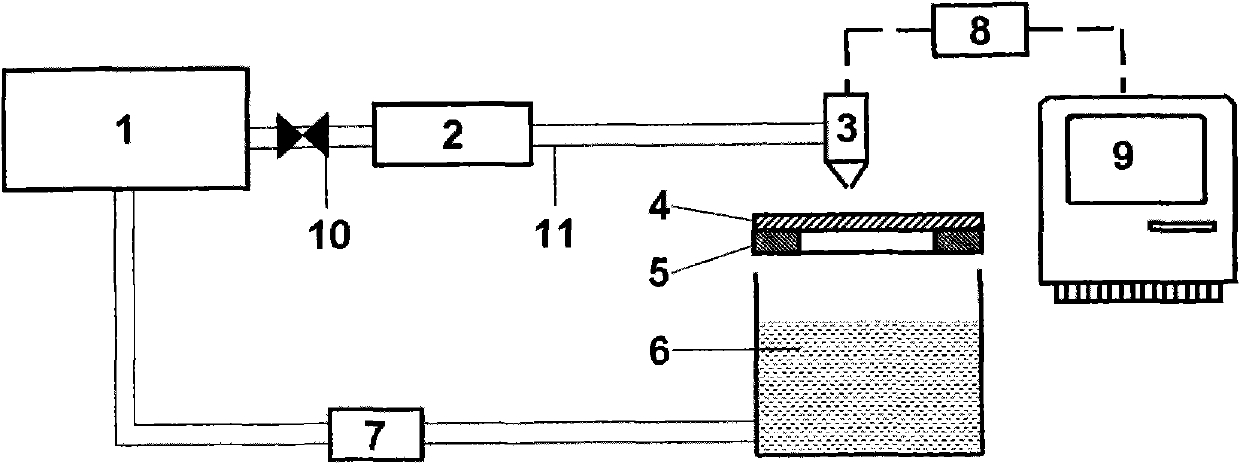

ActiveCN101817622AReduce chromaImprove biodegradabilityMultistage water/sewage treatmentDecompositionTherapeutic effect

The invention relates to an ozone pre-oxidation and laccase advanced water treatment method, which comprises the following steps of: mixing waste water, ozone and sodium percarbonate in a mixer; adding the mixture in an ozone reactor device for stirred reaction; making the mixture enter a tertiary sedimentation basin for solid-liquid separation; adding the separated supernate and laccase into a laccase reaction tank, and fully mixing the laccase with the waste water for reaction; mixing the diluted mediator and the effluent from the laccase reaction tank, and performing flocculent settling solid-liquid separation on the mixture in a final sedimentation basin; and performing anaerobic and aerobic biochemical treatment on the effluent. The method overcomes the defects of over-high cost, low efficiency of enzyme treatment, high enzyme consumption, difficult sedimentation and separation of enzyme per se, and the like. The method only makes two processing units of ozone pre-oxidation and laccase-mediator catalytic polymerization achieve good mutual acceleration and gradient treatment effects, accelerates decomposition of O3 to make micro-flocculation effect of the ozone pre-oxidation in the optimized pH value range, is favorable for reducing the coagulant consumption, can recycle the waste water, and has scale application.

Owner:NANJING SHENKELONG ENVIRONMENTAL PROTECTION

Method for extracting geniposide from gardenia yellow pigment waste liquor

ActiveCN103087129AIncrease profitAchieve zero emissionsSugar derivativesSugar derivatives preparationIsobutanolReverse osmosis

The invention discloses a method for extracting geniposide from gardenia yellow pigment waste liquor, which mainly comprises the following steps: concentrating gardenia yellow pigment waste liquor used as a raw material through a reverse osmosis membrane, extracting with isobutanol, decolorizing with active carbon, concentrating, performing crystallization purification twice, and finally drying. The invention can solve the waste problem that the gardenia effective component can not be economically and effectively recovered from the gardenia yellow pigment producing waste liquor in an environment-friendly way.

Owner:广西山云生化科技股份有限公司

Non-phosphorus pretreatment filming agent for recirculating cooling water system and preparation and application method thereof

ActiveCN105112900ALow costGood synergyMetallic material coating processesPollutionConsumptive water use

The invention relates to a non-phosphorus pretreatment filming agent for a recirculating cooling water system and a preparation and application method thereof and belongs to the technical field of water treatment. The non-phosphorus pretreatment filming agent for the recirculating cooling water system is composed of, by weight, 5%-15% of sodium glutamate, 15%-30% of sodium gluconate, 20%-40% of hydrolytic polymaleic anhydride, 1%-10% of zinc sulfate, 1%-3% of concentrated sulfuric acid, and the balance deionized water. The non-phosphorus pretreatment filming agent for the recirculating cooling water system is low in cost, environmentally friendly, free of pollution and high in film forming speed; a formed film is even and compact; the pH value does not need to be regulated in the pretreatment filming process; pollution discharging is not needed after pretreatment filming is completed, and the process can be directly transferred into normal operation so that a large amount of industrial water can be saved; meanwhile, the invention provides the simple and convenient preparation and application method.

Owner:INLEN CHEM TECH +1

Method for preparing micro-phosphor anti-scaling corrosion inhibitor

InactiveCN102351326AEmission reductionSave industrial waterScale removal and water softeningCorrosion inhibitorWater treatment

The invention provides a method for preparing a micro-phosphor anti-scaling corrosion inhibitor, and belongs to the technical field of industrial recycling cooling water treatment. The following raw materials used in the method comprises in parts by weight: 25 to 50 parts of deionized water, 1 to 4 parts of phosphono acid, 50 to 60 parts of polycarboxylic acid, 1 to 3 parts of zinc salt, and 1 to 4 parts of copper corrosion inhibitor. The method comprises a step of mixing the raw materials in a reaction kettle according to a preset proportion to prepare the required micro-phosphor anti-scaling corrosion inhibitor. The corrosion inhibitor is an environmentally-friendly economical product, does not have emission of 'the three wastes' in a production process, guarantees concentration rate of industrial recycling cooling water to be over 5 times, saves massive industrial water, and realizes that the emission of total phosphor in the recycling water is less than the primary-grade standard of the maximum permissible concentration in China, so that the aims of protecting environment and saving energy are achieved.

Owner:SHANDONG TIANQING TECH DEV

Geling soup and its preparing method

InactiveCN1820648AIncrease economic incomeChange coolnessFood preparationPlant ingredientsBiologyDioscorea polystachya

The present invention discloses a kind of health food, named as Gelinggeng soup, and its production process. The health food is produced with kudzu vine root and tuckahoe in certain weight ratio as materials, and the materials may also contain Chinese yam and lotus seed. The production process is the following steps: washing, cutting, stoving and crushing the materials into thick grains separately; fine crushing to 120-150 mesh; mixing the powdered materials; wet pelletizing into 70-80 mesh grains; sterilizing and stoving; and packing to obtain the finished product. The health food has the nutritious values and medicinal values of the materials well maintained, and is easy to absorb and suitable for all people.

Owner:HONGTOUMA FOOD LONGYAN CITY FUJIAN PROV

Catalyst for treating benzene series organic waste-gas or waste-water by using low temp. and dry method, prepn. method and application thereof

InactiveCN1792438AImprove adsorption capacityMild conditions for catalytic oxidationDispersed particle separationCatalyst activation/preparationBenzoic acidBenzene

A catalyst for treating the benzene contained organic waste gas and the benzene and benzoate contained sewage by low-temp dry method contains metal (1-10 Wt%) chosen from Cu, Fe, V and Co, and activated carbon (90-99 Wt%) as carrier. Its application includes such steps as passing said waste gas or sewage through said catalyst while adsorbing, drying, filling oxidizing gas and reaction.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for treating aniline waste water by absorption-low temperature dry method

ActiveCN101264996AImprove adsorption capacityEfficient removalMultistage water/sewage treatmentNature of treatment waterContinuous useCatalytic oxidation

A low temperature dry treatment method of aniline wastewater by adsorption comprises the steps of feeding aniline wastewater into a fixed-bed reactor filled with adsorption-catalyst until the aniline concentration in the effluent wastewater after adsorption is 4.9 mg / L, discharging residual water in the reactor, introducing oxidizing gas with oxygen volumetric concentration of 4-6% and air speed of 500-2,000 h<-1>, reacting at 100-400 DEG C for 1-10 hours, and using the adsorption-catalyst after catalytic oxidation on the next stage of adsorption-catalytic oxidation. The inventive method can efficiently remove aniline pollutant from wastewater; and has the advantages of no secondary pollution, reusability of adsorption-catalyst, and low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for resource utilization of water-containing sludge

InactiveCN103396019AAchieve harmless treatmentMeet application requirementsCement productionProduction lineSludge

The invention discloses a method for resource utilization of water-containing sludge. At a section from a raw material shed or a raw material warehouse to a raw material vertical milling area in a dry-method cement production line, water-containing sludge is mixed into raw material or put in a vertical mill, so as to adjust the comprehensive water content and the material plasticity of raw materials and the vertically milled material of the raw material to 3wt% to 15wt%; and the sludge-containing raw material powder which is prepared from the vertically milled raw material is fed into a cement kiln system so as to be calcined into cement clinker. According to the method, based on such natural characteristics of water-containing sludge as high water content, the flocculence structure, the plasticviscosity, water content and plasticity required by the vertically milled material can be provided, the application requirements of the raw material vertical mill are met, the purpose of resource utilization of the water-containing sludge is reached, the method is simple, feasible, practical and low in investment, the harmless treatment of water-containing sludge is realized, the investment in technical transformation of the method is small, the utilization amount of the sludge is large, and good benefits and optimal economy are achieved.

Owner:尹无忌

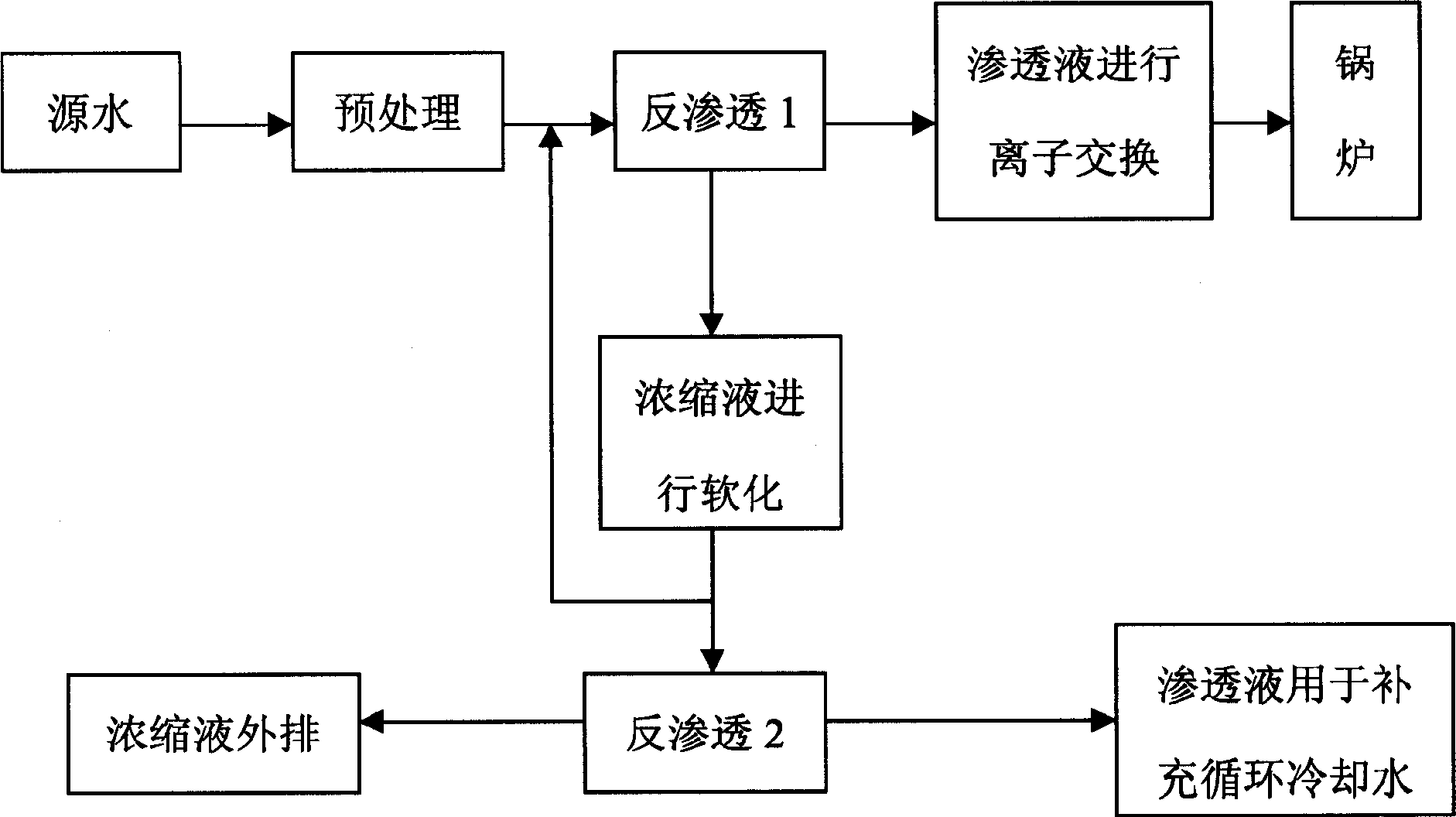

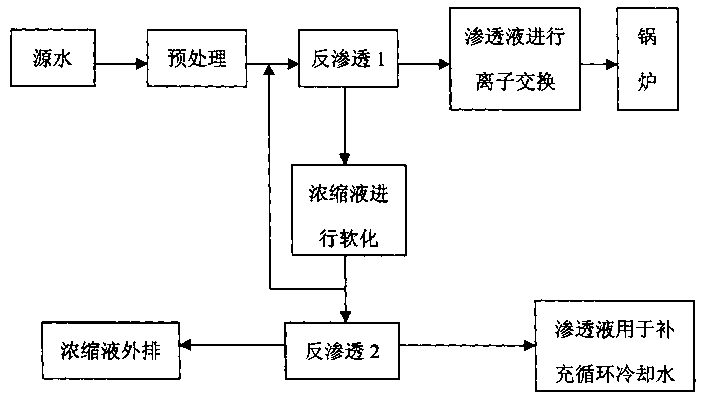

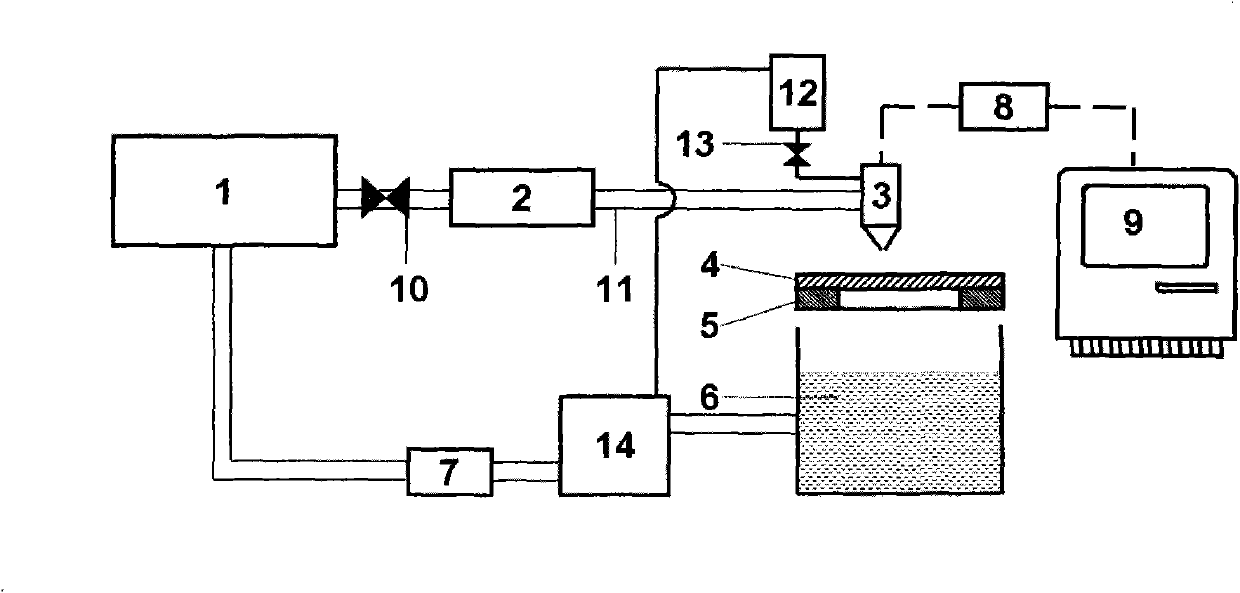

Method for comprehensive treatment and utilization of industrial water

InactiveCN1448348AHigh recovery rateImprove water qualityMultistage water/sewage treatmentIon exchangeWater quality

The present invention aims at raising the utilization rate of industrial water. The scheme of the present invention includes reverse osmose and ion exchange combining desalting process to prepare water for steam boiler. Of the concentrated liquid of reverse osmose after being softened, one part is returned to reverse osmose treatment to raise the water recovering rate while the other part is reverse osmose treated with the permeated liquid after being treated is used to replace fresh water to replenish circular water. This can improve water quality in circular water system while saving fresh water consumption. The method of the present invention can raise water utilizing rate and is suitable for plants with both steam boiler and circular cooling water system.

Owner:CHINA PETROLEUM & CHEM CORP +1

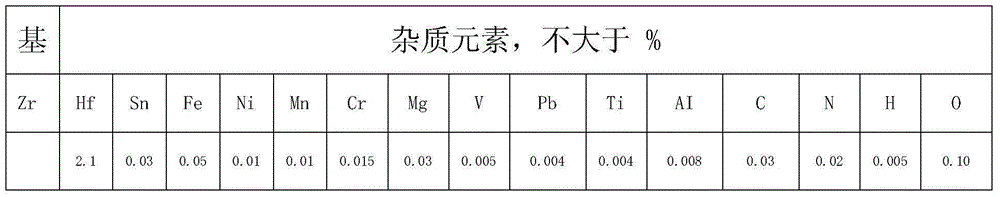

Production method of zirconium and zirconium alloy strip coil

ActiveCN105032974ASolve the problem that cannot be rolled into coils by hot rollingSolution not easy to removeProduction lineNuclear power

The invention provides a production method of a zirconium and zirconium alloy strip coil. The production method comprises the steps that a zirconium or zirconium alloy strip blank is heated in a heating furnace before production and is rolled on a steekle mill or a tandem rolling unit to the thickness that the blank can be transferred to a cold mill to be rolled, and the blank is directly coiled; surface treatment is carried out on a hot-rolling zirconium coil obtained through rolling on a continuous annealing-shot blasting-acid pickling production line, and a zirconium strip obtained after surface treatment is a smooth and clean zirconium strip which is in the metal natural color and free of oxide skin or harmful air suction layers; then a cold mill unit is adopted for carrying out cold rolling on the zirconium strip to obtain a thin strip, and cold rolling is carried out after annealing is carried out in an on-line annealing or vacuum annealing manner in the process of cold rolling; and finally various finished zirconium or zirconium alloy thin strip products of target thickness are obtained in a rolled manner. According to the production method, the cost is low, the product quality is good, and the rate of the finished products is improved by more than 15%; the requirements of nuclear power, chemical engineering and other aspects for thin zirconium materials and zirconium strips for thin-wall zirconium pipe welding can be completely met; and energy saving and consumption reduction are achieved, and high practical value is achieved.

Owner:BAOJI TUPENG METAL MATERIALS CO LTD

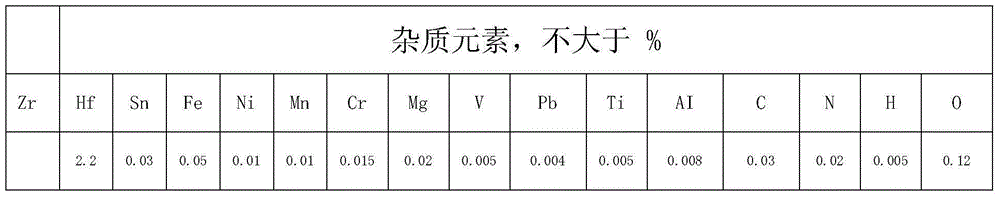

Water cooling mechanism with buffering and self-circulating device

ActiveCN104089445APlay a protective effectImprove cooling effectLighting and heating apparatusEnergy industryWater storage tankEngineering

The invention aims to provide a water cooling mechanism with a buffering and self-circulating device. According to the technical scheme, the water cooling mechanism is composed of a water tank, a water pump, a main valve, a cooling water storage bin, a filter device, a naturally cooling bin, a conveying belt and a cooling water storage tank. A water pumping pipe and a water supply pipe are arranged on the water pump. A water cooling bin, a water storage buffering device, a water inlet pipe and a water outlet pipe are further arranged on the cooling water storage bin. According to the water cooling mechanism, the water storage buffering device is arranged on the cooling water storage bin, the inner structure of the water storage buffering device is in a multiple-layer-net shape, pumped cold water can be well delivered in a distributed mode, and the water cooling bin is protected; cold water entering the cooling water storage bin in the distributed mode forms a backflow mechanism in the cooling water storage bin, after being filtered, the cold water entering the cooling water storage bin in the distributed mode flows back to the cooling water storage tank from a return pipe, and then a complete water cooling circulation mechanism is formed. The water cooling mechanism with the buffering and self-circulating device saves energy, is environmentally friendly, reduces industrial water consumption greatly and reduces cost for an enterprise.

Owner:TIANJIN JINHAIHE TECH

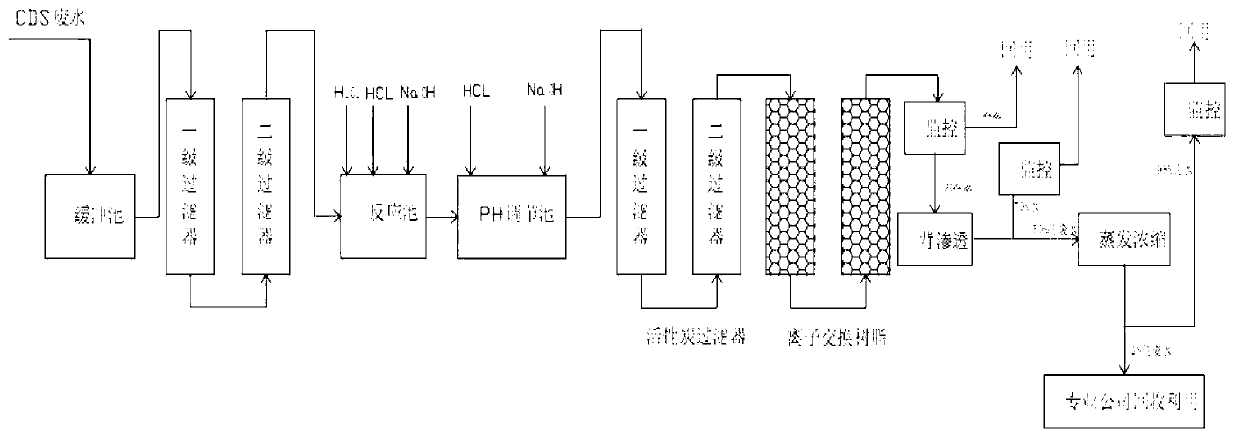

Method for recycling and utilizing CdS waste liquor produced in production process of copper indium gallium selenide (CIGS) film solar cell

ActiveCN102887603AReduce energy consumptionAchieving zero emissionsCadmium sulfidesWater/sewage treatment by ion-exchangeActivated carbonIndustrial waste water

The invention discloses a method for recycling and utilizing CdS waste liquor produced in the production process of a copper indium gallium selenide (CIGS) film solar cell, wherein the method comprises the following steps of: (1) filtering the cadmium sulphide in the waste liquor; (2) performing oxidation treatment; (3) adsorbing the waste liquor with an active carbon filter; (4) carrying out ion exchange adsorption; (5) monitoring the waste liquor subjected to the ion exchange adsorption; and (6) vaporizing and concentrating the waste liquor. The method provided by the invention has the beneficial effects that a large number of industrial wastewater comprising CdS particles produced in the production process of the CIGS film solar cell is subject to a multi-stage continuous waste liquor treatment processes such as secondary filtering, oxidation treatment, activated carbon adsorption, ion exchange, back penetration and concentration evaporation, thereby realizing the zero discharge of the cadmium-containing industrial wastewater and effectively saving the industrial water; the filtering membrane and the ion exchanging agent in the treatment device are periodically recycled and exchanged to effectively reduce the energy consumption in the treatment of the waste liquor.

Owner:ZHEJIANG SHANGYUE OPTOELECTRONICS TECH

Circulating water treating agent and preparation method thereof

ActiveCN104402130ASave industrial waterExcellent scale and corrosion inhibition performanceSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsTotal phosphorusChemistry

The invention relates to a circulating water treating agent and a preparation method thereof. The circulating water treating agent is composed of the following raw materials in parts by weight: 10-13 parts of phosphono carboxylic acid, 35-40 parts of polycarboxylic acid, 5-7 parts of zinc salt, 3-5 parts of copper corrosion inhibitor, 5-17 parts of polyepoxysuccinic acid, 3-16 parts of sodium salicylate, 5-8 parts of sodium tungstate, 1-3 parts of iron trichloride and 70-150 parts of deionized water. The raw materials are mixed in a reaction kettle according to the preset proportion to obtain the circulating water treating agent. No three wastes are discharged in the circulating water treating agent production process; the total phosphorus discharge in the circulating water is less than the maximum allowable discharge concentration in national primary standard; and the circulating water treating agent has excellent scale and corrosion inhibition performance.

Owner:CHONGQING WANLILAI CHEM

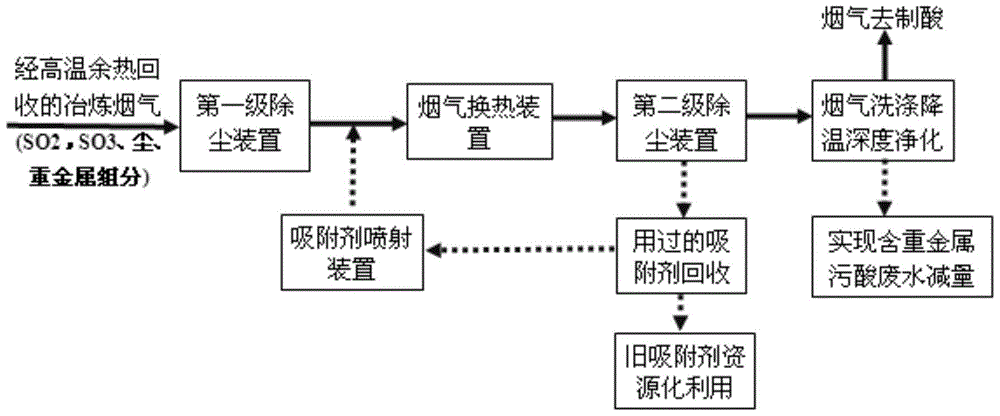

A method for dry removal of sulfur trioxide and heavy metals from flue gas from acid smelting in non-ferrous smelting

The invention relates to a dry-type removing method for sulfur trioxide and heavy metals in nonferrous smelting acid-making flue gas. The method comprises the following steps: primarily recovering heat of nonferrous smelting flue gas through a high-temperature heat recovery boiler and carrying out first-stage dust removal through a first-stage dust removal device so as to remove more than 90% of gas dust in the flue gas; then directly jetting, from a flue, the powder of an absorbent capable of adsorbing / absorbing SO3 and heavy-metal components into the flue gas having undergone the first-stage dust removal, and carrying out absorption reaction; then cooling the flue gas containing the absorbent by utilizing a flue gas heat-exchange device so as to allow SO3 and heavy metals to be effectively trapped and collected by the absorbent and part of volatile heavy metals to be condensed through induction; and finally, trapping and collecting the absorbent having absorbed SO3 and the heavy metals and granular heavy metals via a second-stage dust removal device. Compared with the prior art, the dry-type removing method provided by the invention can effectively remove the heavy metal components and SO3 in the flue gas from upstream and reduces the concentration of sulfuric acid and the contents of heavy metals in washing wastewater.

Owner:SHANGHAI JIAOTONG UNIV

Liquid metal knife cutting system

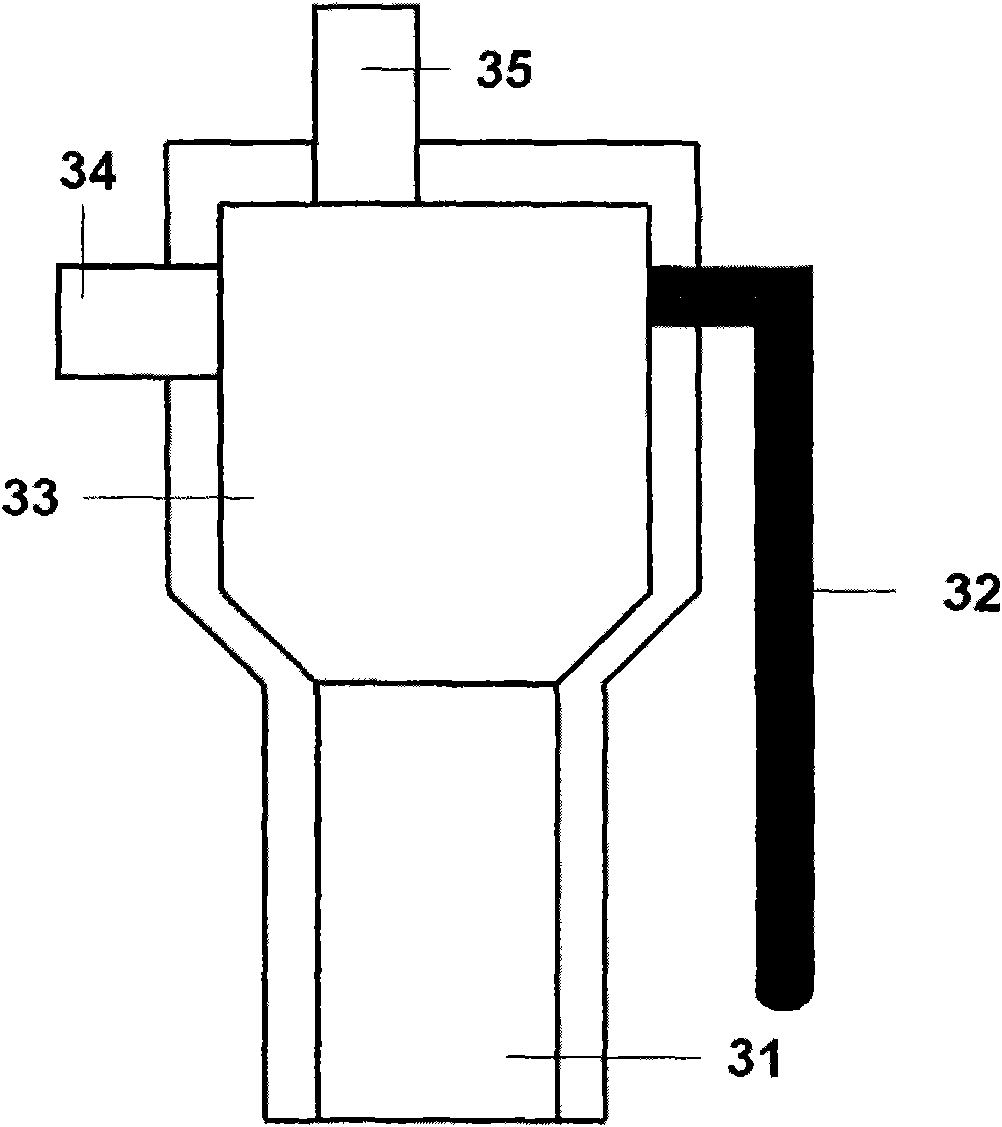

ActiveCN102554798AAchieve the purpose of cuttingWon't happenAbrasive blasting machinesNumerical controlSpray nozzle

A liquid metal knife cutting system comprises a cutting device, wherein the cutting device comprises a cutting nozzle and a rectification cavity communicated with the upper end of the cutting nozzle. An inlet pipe communicated with the pressure pump outlet through a hose is installed on the lateral wall of the rectification cavity, a miniature camera is installed on an observation hole on the lateral wall of the rectification cavity, and the pressure pump inlet is communicated with the liquid metal storage tank outlet. A workbench is arranged below the cutting nozzle, a recycle container is arranged below the workbench, a connection pipeline at the lower portion of the recycle container is communicated with the storage tank bottom, and a recycle pump is installed on the pipeline of the recycle container. A numerical control table comprises a processor and a data base, wherein the processor is used for calculating relevant cutting parameters in cutting, and the data base is used for recording the cutting parameters corresponding to cutting materials and cutting results. The cutting nozzle of the cutting device is coaxial with a motor shaft, and a motor receives operation commands given out by the numerical control table and controls a cutting path of the cutting nozzle of the cutting device according to the commands to complete cutting of a workpiece to be cut. The cutting system is high in cutting accuracy, stable, low in noise, energy-saving and environment-friendly.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

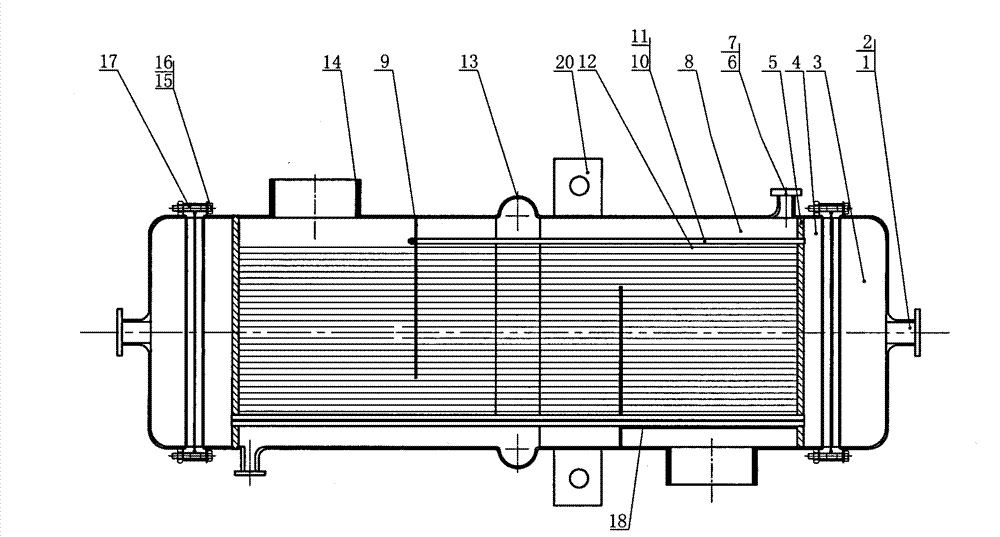

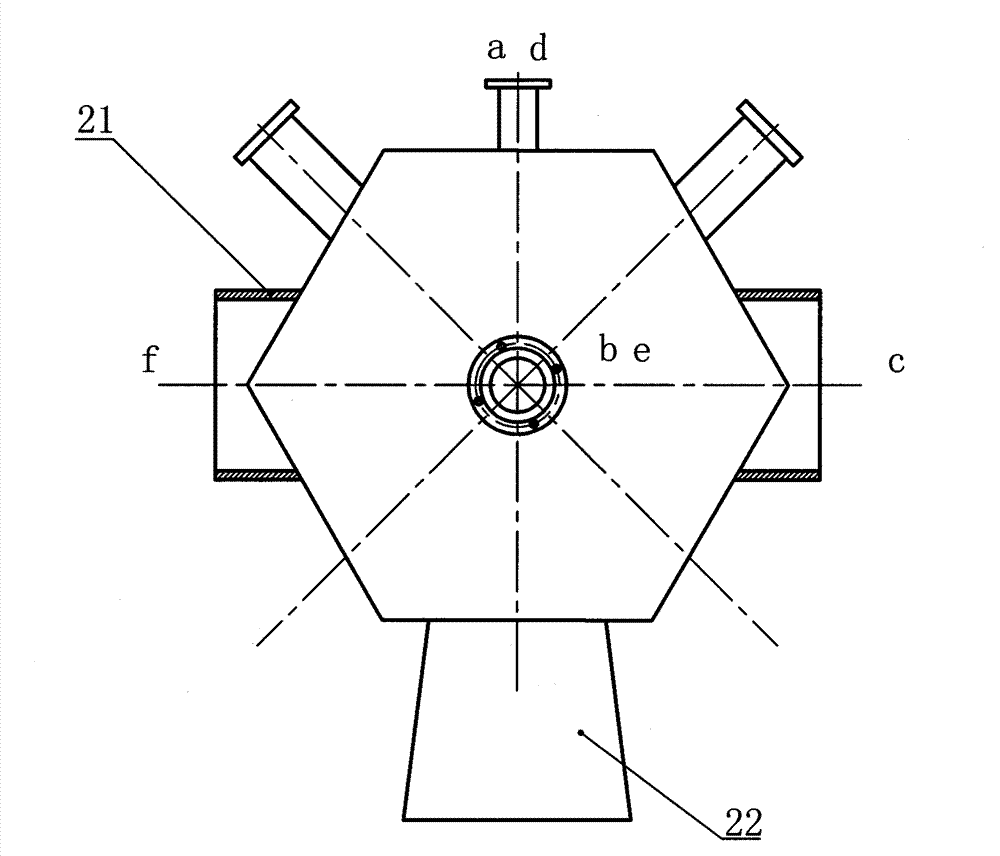

Novel air cooler

InactiveCN102901379ASpeed up circulationReduce pollutionHeat exchanger casingsStationary tubular conduit assembliesPetrochemicalIndustrial water

The invention aims at providing a novel air cooler and belongs to the technical field of chemical devices. The novel air cooler is composed of a barrel (8), heat exchanging pipes, inlets and outlets, a plurality of the heat exchanging pipes are arranged in the barrel through a pipe plate (5), a plurality of the inlets and the outlets are arranged on the outer side of the barrel, and the inlets and the outlets face different directions; an a inlet and a d outlet are symmetrically arranged on two round side surfaces of the barrel, a c air inlet and an f air outlet are horizontally arranged on the two side surfaces of the barrel, a b air exhaust port and an e water discharging port are vertically arranged through the c air inlet and the f air outlet, an opening connection pipe and a flange are sequentially arranged at positions of a 45 degree angle and a 315 degree angle, and the 45 degree angle and the 315 degree angle are formed by the fact that the a inlet and the d outlet are used as a center, and the b air exhaust port and the e water discharging port are used as a 0 degree to rotate the barrel in a clockwise direction. Hot fluids in the pipe are subjected to heat exchanging through air outside the heat exchanging pipes (12) to achieve functions of cooling and condensing, and the novel air cooler is widely used in oil refining and condensing of steam at petrochemical engineering tower tops and is capable of saving a large amount of industrial water and reducing environment pollution.

Owner:夏亚飞

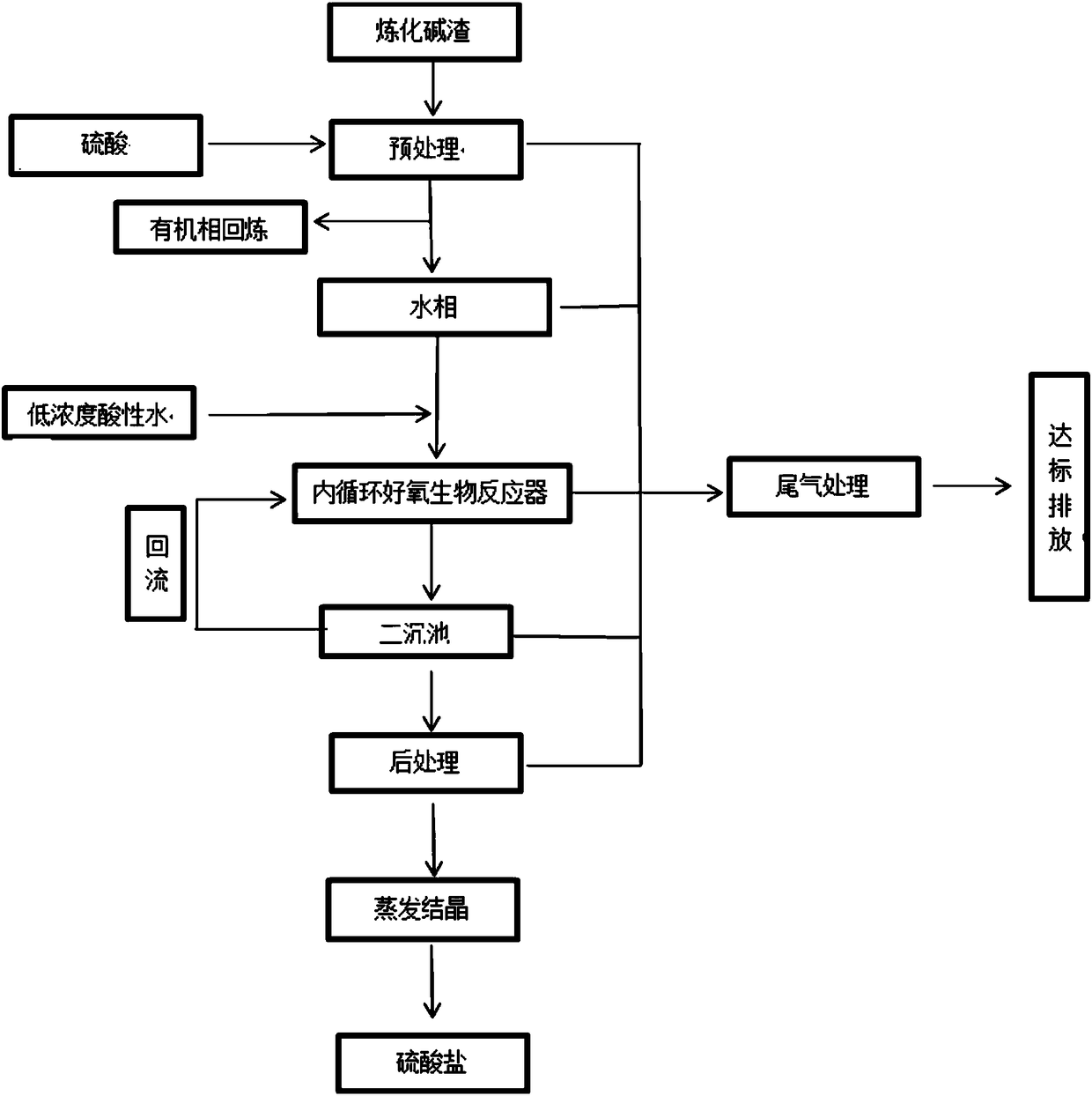

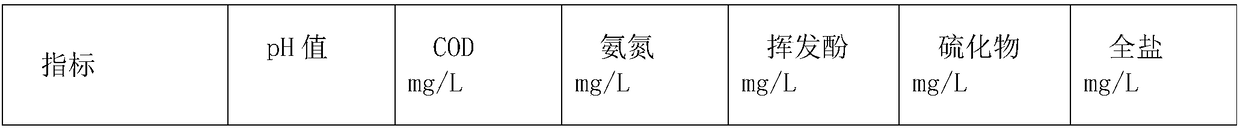

Resource comprehensive utilization method of refining alkaline slag

ActiveCN108529819AAvoid introducingQuality assuranceTreatment using aerobic processesWater treatment compoundsSocial benefitsSlag

The invention belongs to the technical field of biochemical environment protection, and concretely provides a resource comprehensive utilization method of refining alkaline slag. The method mainly ischaracterized in that the refining alkaline slag is subjected to pretreatment, biochemical treatment, post treatment, evaporative crystallization and tail gas treatment to finally realize the organicphase reprocessing utilization; the tail gas is exhausted in a standard reaching way; meanwhile, sodium sulfate products are recovered at the same time; the utilization maximization of resources is realized. The method provided by the invention has the advantages that the process is reasonable; the cost is low; the implementation is easy; good economic benefits, environment benefits and social benefits are realized.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Corrosion inhibition antiscale agent

InactiveCN105948282ANo pollution in the processNo toxicitySpecific water treatment objectivesTreatment using complexing/solubilising chemicalsNuclear chemistryPollution

The invention relates to a corrosion inhibition antiscale agent which is composed of, by weight, 50-60 parts of anhydrous sodium carbonate, 5-10 parts of sodium tripolyphosphate, 5-10 parts of sodium hexametaphosphate and 20-40 parts of sodium humate. The corrosion inhibition antiscale agent is free of pollution to the environment, free of toxicity, small in consumption, convenient to use and low in price.

Owner:范博琳

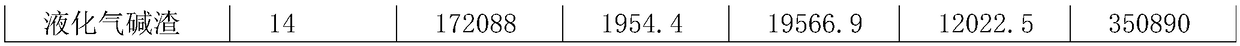

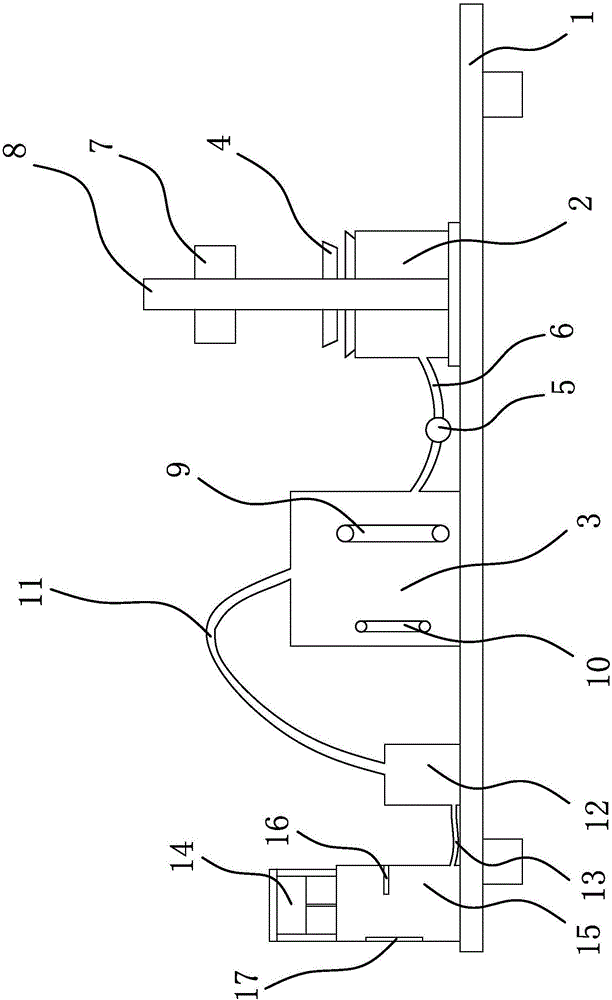

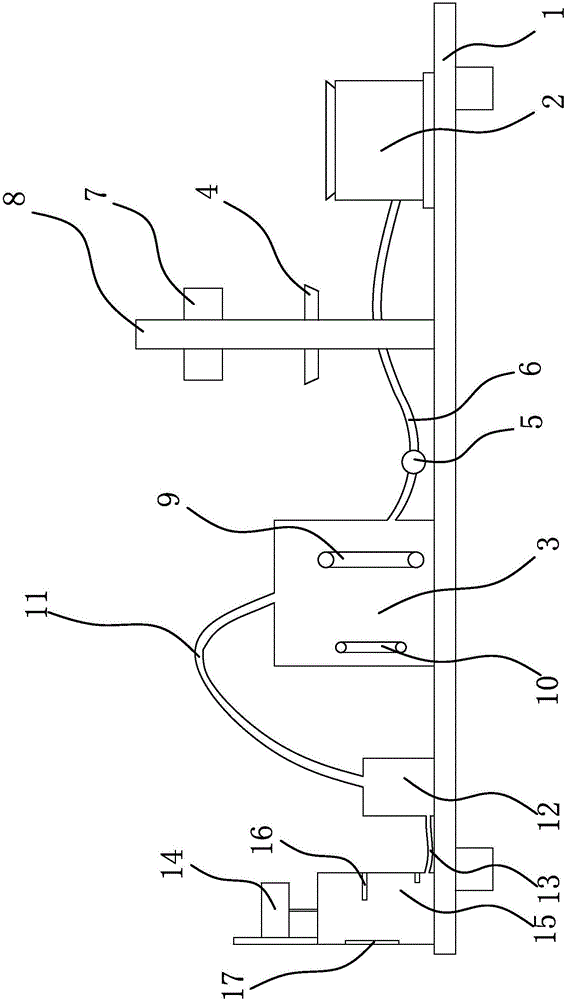

Dyeing and finishing technology with waterproof performance yarn and automatic impregnation machine

ActiveCN106087301ADirect effectGood effectTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnState of art

The invention provides a dyeing and finishing technology with waterproof performance yarn and automatic impregnation machine thereof, and belongs to the technical field of textile machines. The problems that existing yarn impregnation is not sufficient enough, and no dyeing and finishing technology with the waterproof performance exists are solved. The dyeing and finishing technology with the waterproof performance yarn comprises the following steps that A, blank inspection; B arranging; C, cylinder entry; D, skein dyeing; E, water repellent treatment; F, impregnation; G, drying; H, product inspection; I, packaging; J, storage. The automatic impregnation machine for the dyeing and finishing technology comprises a workbench. A knotting cylinder is arranged on one side of the workbench. A sliding positioning mechanism which can slide relatively is arranged between the knotting cylinder and the workbench. A stand column is fixed to the workbench. A lifting mechanism which enables a compression plate to move up and down is arranged between the stand column and the compression plate. The dyeing and finishing technology has the advantages of being high in dyeing efficiency, sufficient in impregnation and the like.

Owner:ZHEJIANG YINGSHANHONG TEXTILE TECH CO LTD

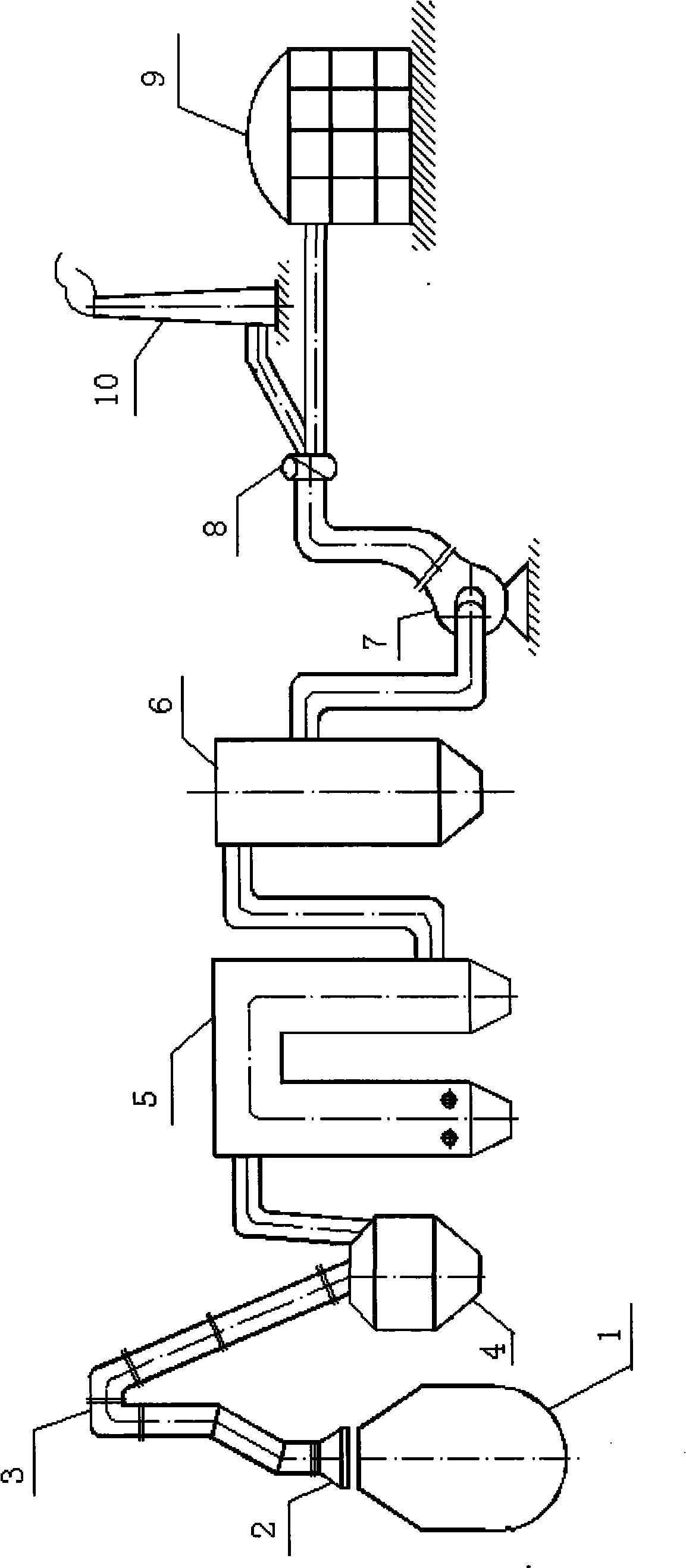

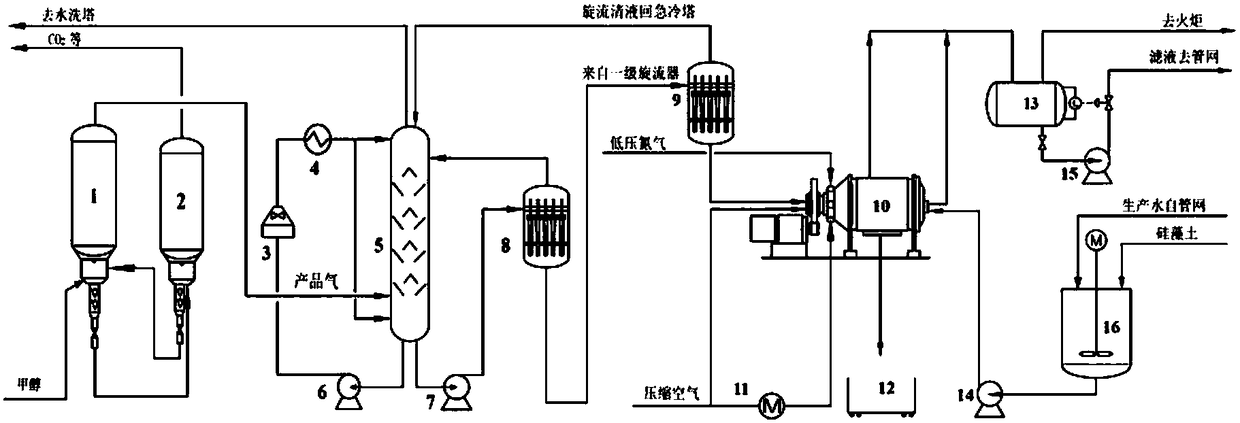

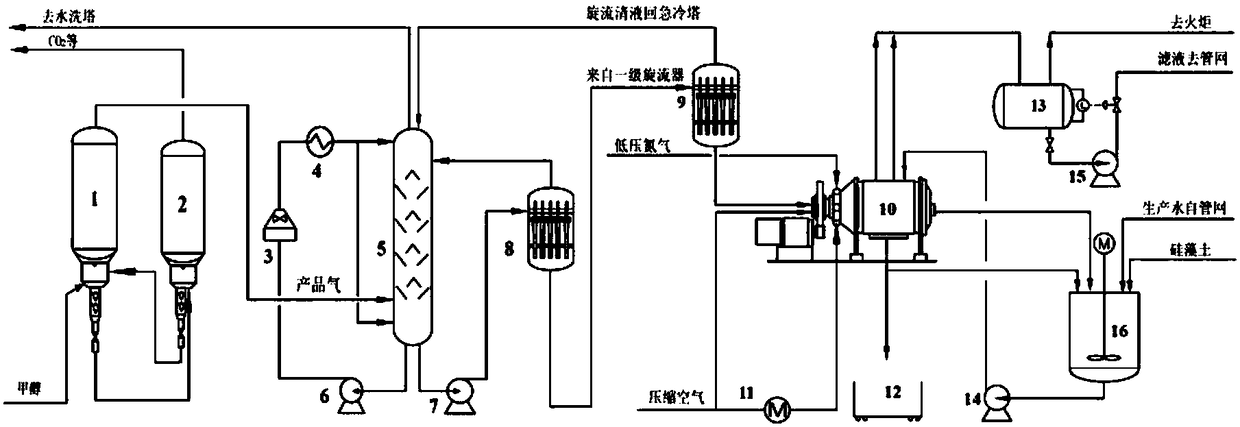

Pre-coating material efficiency increasing and consumption reducing method and pre-coating material efficiency increasing and consumption reducing apparatus in MTO quenching water pre-coating pressure filtration separation system

InactiveCN108325273ASave industrial waterLow solid contentHydrocarbon from oxygen organic compoundsFiltration separationCycloneFilter press

The present invention relates to a pre-coating material efficiency increasing and consumption reducing method and a pre-coating material efficiency increasing and consumption reducing apparatus in anMTO quenching water pre-coating pressure filtration separation system, and provides a pre-coating material efficiency increasing and consumption reducing method in an MTO quenching water pre-coating pressure filtration separation system, wherein the pre-coating material efficiency increasing and consumption reducing method comprises that (i) an auxiliary filtration agent is added to an auxiliary filtration agent stirring tank (16), the obtained material is fed into to the pre-coating unit chamber of a filter press (10), and a pre-coating is formed on a filtration cloth; (ii) a catalyst suspension concentrated by a two-stage cyclone (9) enters the filter press (10), and filtering is performed on the pre-coating; (iii) at the early stage of filtration, the filter cake returns to the auxiliary filtration agent stirring tank (16), and is mixed with the auxiliary filtration agent so as to be used as the new auxiliary filtration agent, and the new auxiliary filtration agent enters the next cycle of the auxiliary filtration process; (iiii) the filtration specific resistance of the pre-coating is increased after the cycle is performed for a certain time, and when the pressure of a filtrateinlet is increased to achieve a set value, a material discharge port is switched to a filter cake collection tank (12) so as to discharge the filter cake. The invention further provides a pre-coatingmaterial efficiency increasing and consumption reducing apparatus in an MTO quenching water pre-coating pressure filtration separation system.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

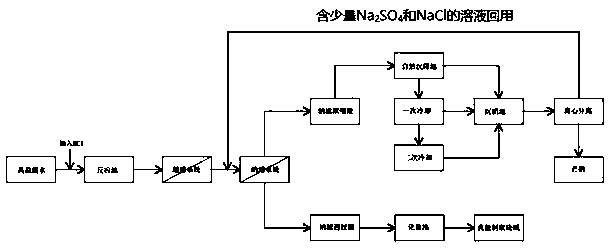

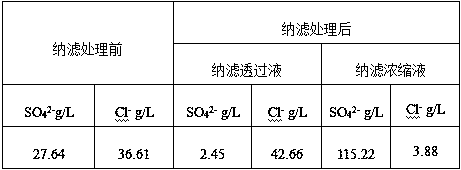

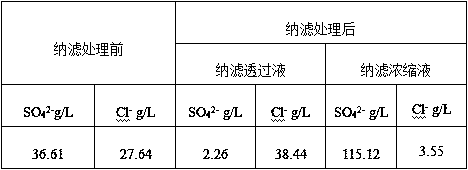

Method for treating metallurgical wastewater by nanofiltration-freezing denitration process

InactiveCN109399845AAvoid introducingEliminate the crystallization stepWater/sewage treatment by centrifugal separationWaste water treatment from metallurgical processCentrifugationWastewater

The invention discloses a method for treating metallurgical wastewater by a nanofiltration-freezing denitration process. The method comprises the steps of feeding untreated metallurgical wastewater into a reaction tank through a pipeline and adding HCl in the reaction tank to remove HCO3- and CO32- from the metallurgical wastewater; after the reaction, treating the metallurgical wastewater throughan ultrafiltration system and a nanofiltration system sequentially, and delivering the obtained nanofiltration concentrate to a freezing denitration system through the pipeline for freezing denitration treatment; introducing the concentrate subjected to the freezing denitration treatment to a centrifugation separation section to separate generated sodium sulfate crystals, and making a small amount of the solution generated by centrifugation separation return to the ultrafiltration system for reuse; introducing the obtained nanofiltration permeate to a salt pool through the pipeline, and adding a certain amount of chlorine to prepare caustic soda. The method has the advantages of being simple in process, low in energy consumption and capable of treating the metallurgical wastewater generated by a chemical plant economically and effectively and achieving recycling of the wastewater.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Evaporative crystallization system

InactiveCN113184933AAvoid cloggingReduce lossesWater/sewage treatment by heatingSalt depositPhysical chemistry

The invention relates to the technical field of coal chemical industry wastewater treatment, and discloses an evaporative crystallization system which comprises an evaporator and a solid-liquid separator, the evaporator is provided with a salt collecting chamber, a first crystal slurry outlet and a slurry turning opening, the first crystal slurry outlet and the slurry turning opening communicate with the salt collecting chamber, and the solid-liquid separator is provided with a first crystal slurry inlet, a first mother liquor outlet and a crystallized salt outlet. A first crystal slurry inlet of the solid-liquid separator communicates with a first crystal slurry outlet of the evaporator, the solid-liquid separator is used for separating crystalslurry entering the solid-liquid separator into mother liquor and crystal salt, and the first mother liquor outlet communicates with the slurry turning opening to be used for introducing the separated mother liquor into the salt collecting chamber so as to disturb crystal slurry in the salt collecting chamber. The evaporative crystallization system has the function of preventing blockage caused by deposition and hardening of salt particles at the bottom of the salt collecting chamber.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD

Method for utilizing mineral separation backwater in magnesite reverse flotation desilicification

InactiveCN104176854AThe utilization method of ore dressing backwater is simpleThe utilization method of ore dressing backwater is easyMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationActivated carbonEngineering

The invention provides a method for utilizing mineral separation backwater in magnesite reverse flotation desilicification, which comprises the following steps: (1) introducing mineral separation backwater into a regulating tank, wherein the tank wall of the outflow end of the regulating tank is lower than the tank walls of the other three sides; (2) sending the mineral separation backwater into a stirring reaction tank through the outflow end of the regulating tank, adding a coagulating agent into the reaction tank, and stirring; (3) transferring the liquid obtained in the step (2) into a precipitation tank of which the bottom surface is a slope, standing for 6-12 hours, and discharging solid particles on the bottom; continuing standing for 12-24 hours, and discharging the water layer between the bottom layer and the plane at the highest point of the slope; (4) filtering out sand from the water, pumping into an adsorption tank, and adsorbing with activated carbon for 2-4 hours; and (5) pumping the adsorbed liquid into a reuse water tank, and carrying out reverse flotation on the backwater. The method is simple and easy to implement, has the advantages of low treatment cost and short treatment period, and can be widely industrialized in industry.

Owner:营口东吉科技(集团)有限公司

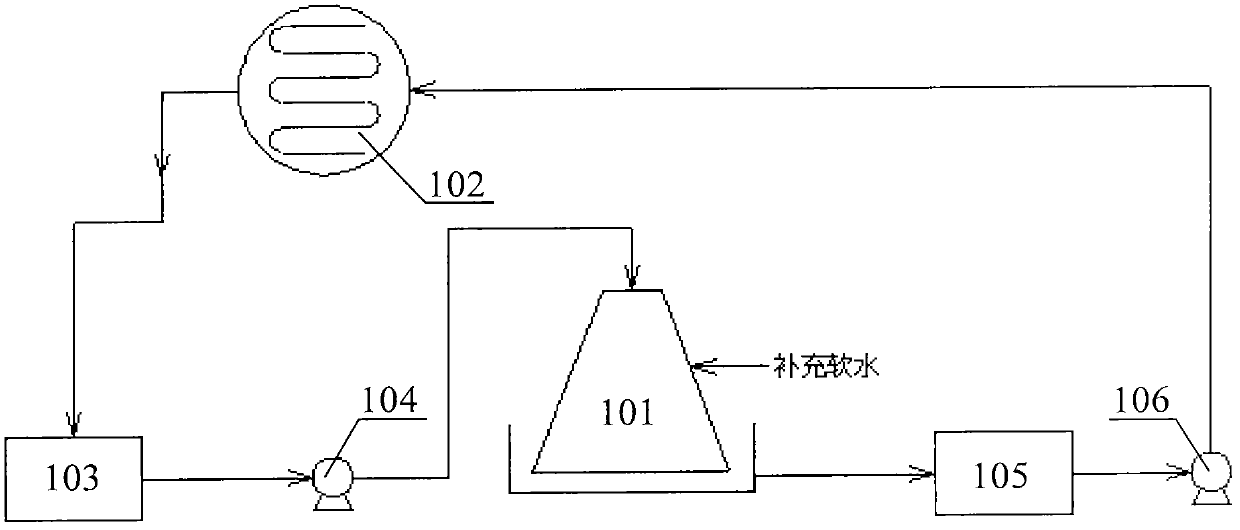

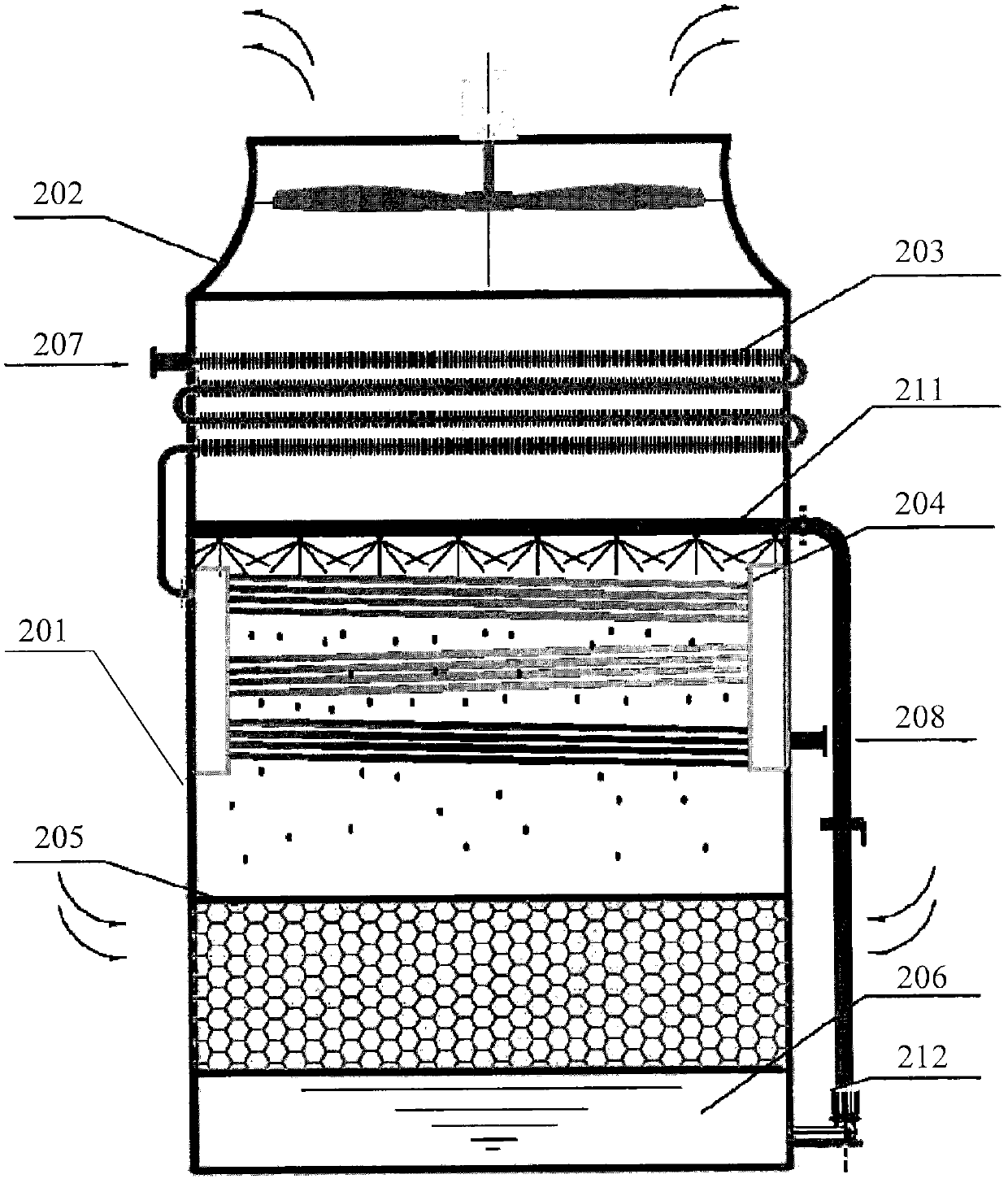

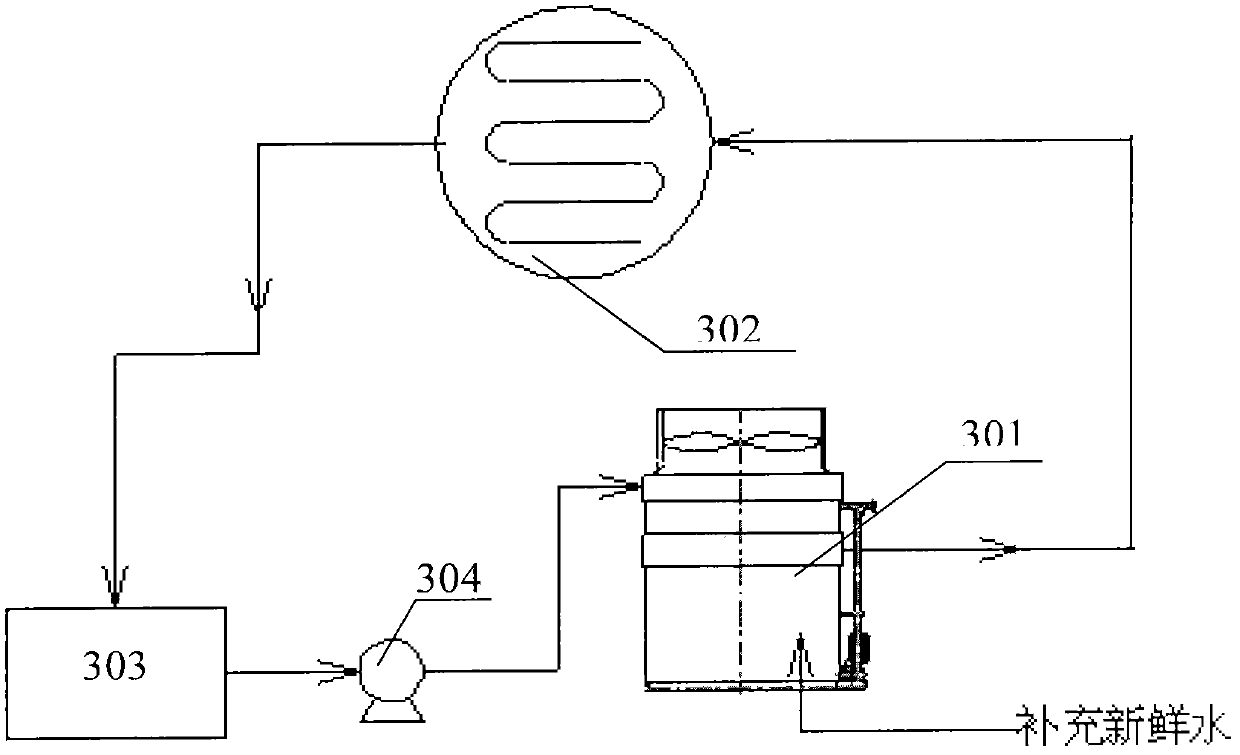

Combination air cooler and circulating cooling water system based on same and method

InactiveCN102564160AImprove thermal efficiencyReduce cloggingStationary conduit assembliesElectricityEvaporation

The invention discloses a combination air cooler, a circulating cooling water system based on the air cooler and a method. The combination air cooler comprises a case, a wet and cold portion, an air inlet, a spraying water tank, a technical medium outlet, a dry and cold portion, a hyperbolic air duct and a technological medium inlet, the wet and cold portion, the air inlet and the spraying water tank are sequentially arranged in the case from top to bottom, the technological medium outlet is positioned on one side of the case and led out from the wet and cold portion, the wet and cold portion sequentially consists of a spraying system and an evaporation cooling tube bundle from top to bottom, the evaporation cooling tube bundle consists of heat exchange tubes which are obliquely arranged, an included angle is formed between each heat exchange tube and the horizontal plane, the dry and cold portion is positioned above the wet and cold portion, the hyperbolic air duct is arranged above the dry and cold portion, and the technological medium inlet is positioned on one side of the case and led into the dry and cold portion. The circulating cooling water system based on the air cooler consists of a technological device cooler, a water pool, a circulating water pump and the combination air cooler which are sequentially connected along a circulating direction of sealed circulating technological media in the circulating cooling water system. The combination air cooler, the circulating cooling water system and the method have the advantages that electricity consumption and water consumption are saved during production, and an energy conservation effect is realized.

Owner:奥福科技有限公司

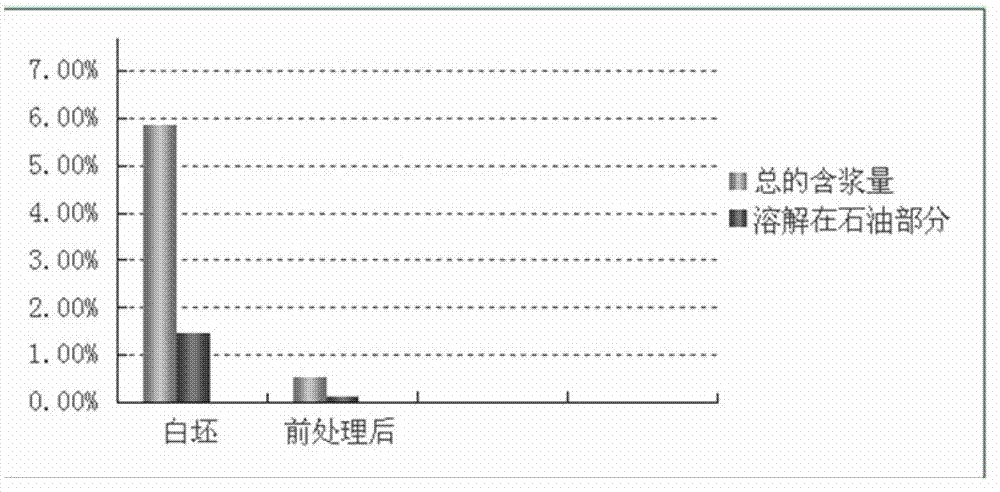

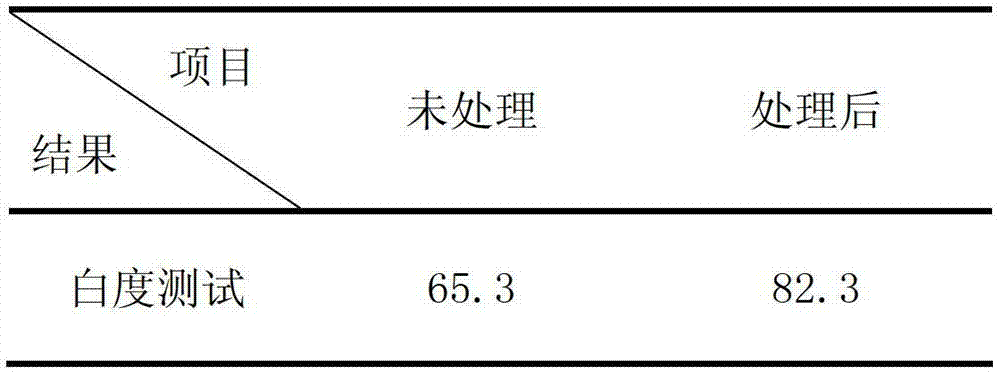

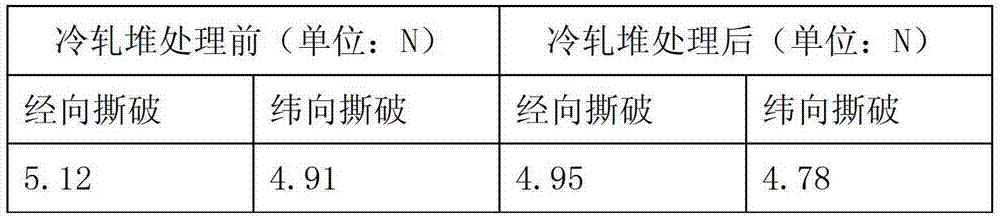

Pretreatment method of superfine denier nylon fabric

ActiveCN103114430BStability is soft and uniformImprove cleanlinessDry-cleaning apparatus for textilesBatch processingPretreatment method

The invention discloses a pretreatment method of superfine denier nylon fabric, and belongs to the field of the processing of superfine denier nylon fabric. The method solves the technical problems that the strength of gray fabric is highly damaged by the existing pretreatment method of superfine denier nylon fabric, the feeling is not fluffy, and drape is easy to produce. The method comprises the following steps of: firstly, performing cold pad-batch processing to grey of superfine denier nylon fabric with cold batch liquid under the conditions that the reaction temperature is 40 to 45 DEG C and the lathing speed is 50 to 55m / min, and secondly, laying the grey of the superfine denier nylon fabric processed in the first step in an open-width desizing machine, and performing cold batch desizing processing with pad-batch desizing liquid under conditions that the reaction temperature is 95 to 98 DEG C and the lathing speed is 60 to 55m / min, so as to accomplish the pretreatment of the superfine denier nylon fabric. The method is applied to the pretreatment of superfine denier nylon fabric.

Owner:SHENGHONG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com