Method for treating metallurgical wastewater by nanofiltration-freezing denitration process

A technology of freezing denitrification and nanofiltration, applied in metallurgical wastewater treatment, frozen water/sewage treatment, sedimentation treatment, etc., to achieve the effect of saving industrial water, low energy consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

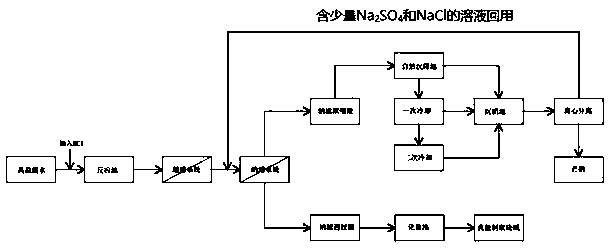

Method used

Image

Examples

Embodiment 1

[0034] (1) Pretreatment

[0035] Pipeline the untreated metallurgical wastewater into the reaction pool, add 14.5t of hydrochloric acid with a mass fraction of 20% to the reaction pool every hour, and continue to add hydrochloric acid to adjust the pH of the metallurgical wastewater to 6~7 after fully reacting.

[0036] (2) Ultrafiltration

[0037] The PH-adjusted metallurgical wastewater is sent to the ultrafiltration system through the pipeline, and the large particles of impurities are intercepted, and the ultrafiltration permeate enters the nanofiltration system.

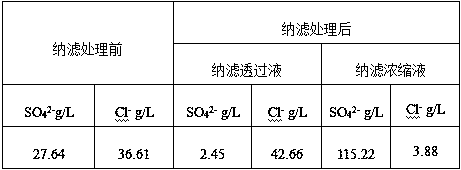

[0038] (3) Nanofiltration

[0039] The nanofiltration membrane module can be commonly used in the market, and the D series produced by GE is preferred. The obtained ultrafiltration permeate enters the nanofiltration membrane module through a booster pump at 3.5Mpa, and the temperature of the feed liquid is 25°C. After being processed by the nanofiltration system, the obtained nanofiltration permeate mainly con...

Embodiment 2

[0048] (1) Pretreatment

[0049] Pipeline the untreated metallurgical wastewater into the reaction pool, add 11.6t of hydrochloric acid with a mass fraction of 25% to the reaction pool every hour, and continue to add hydrochloric acid to adjust the pH of the metallurgical wastewater to 6~7 after the reaction is complete.

[0050] (2) Ultrafiltration

[0051] The PH-adjusted metallurgical wastewater is sent to the ultrafiltration system through the pipeline, and the large particles of impurities are intercepted, and the ultrafiltration permeate enters the nanofiltration system.

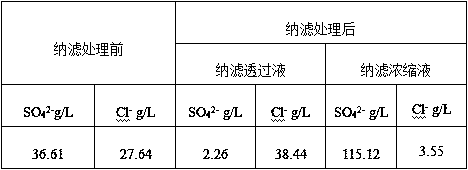

[0052] (3) Nanofiltration

[0053] The nanofiltration membrane module can be commonly used in the market, and the D series produced by GE is preferred. The obtained ultrafiltration permeate enters the nanofiltration membrane module through the booster pump at 3.5Mpa, and the temperature of the feed liquid is 25°C. After being treated by the nanofiltration system, the obtained nanofiltration permeate ...

Embodiment 3

[0062] (1) Pretreatment

[0063] Pipeline the untreated metallurgical wastewater into the reaction pool, add 9.7t of hydrochloric acid with a mass fraction of 30% to the reaction pool every hour, and continue to add hydrochloric acid to adjust the pH of the metallurgical wastewater to 6~7 after the reaction is complete.

[0064] (2) Ultrafiltration

[0065] The PH-adjusted metallurgical wastewater is sent to the ultrafiltration system through the pipeline, and the large particles of impurities are intercepted, and the ultrafiltration permeate enters the nanofiltration system.

[0066] (3) Nanofiltration

[0067] The nanofiltration membrane module can be commonly used in the market, and the D series produced by GE is preferred. The obtained ultrafiltration permeate enters the nanofiltration membrane module through a booster pump at 3.5Mpa, and the temperature of the feed liquid is 25°C. After being processed by the nanofiltration system, the obtained nanofiltration permeate m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com