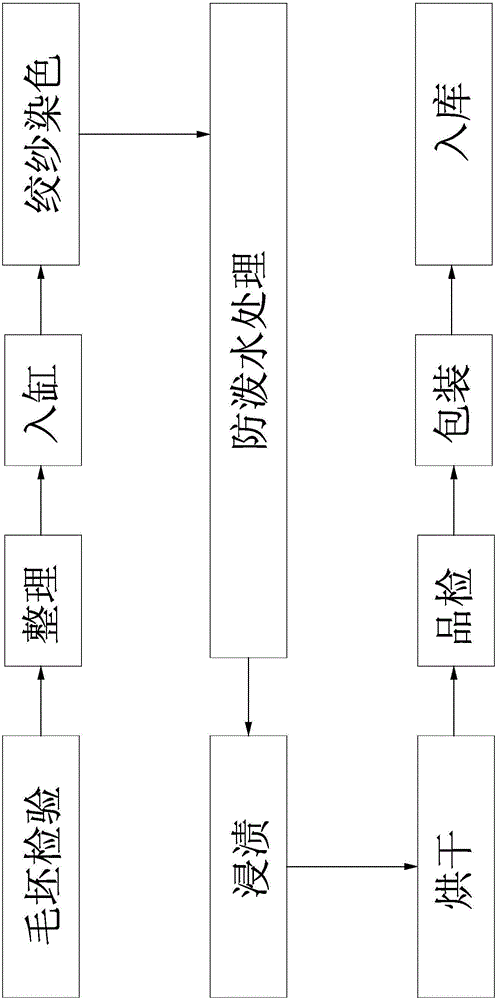

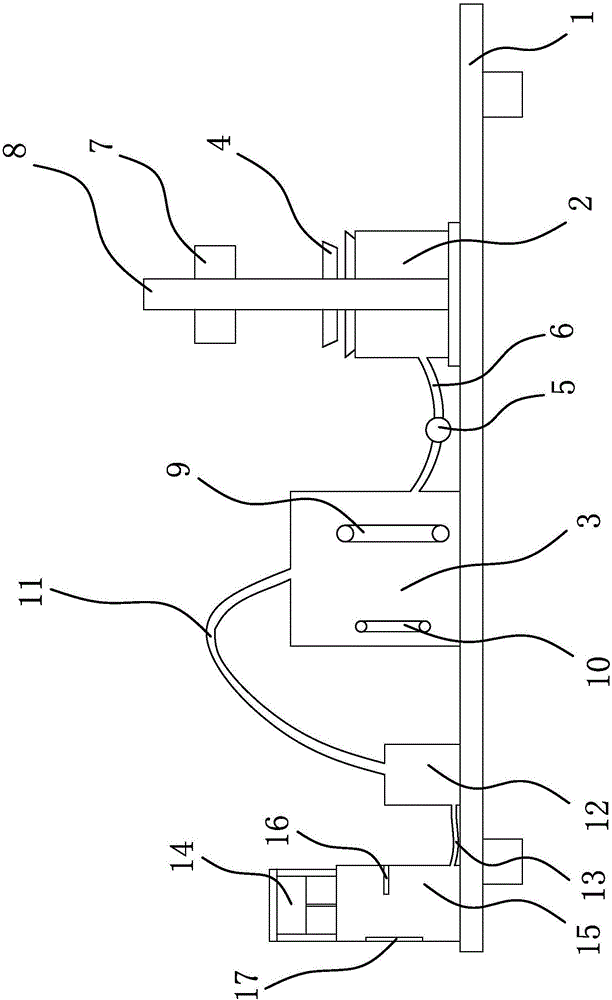

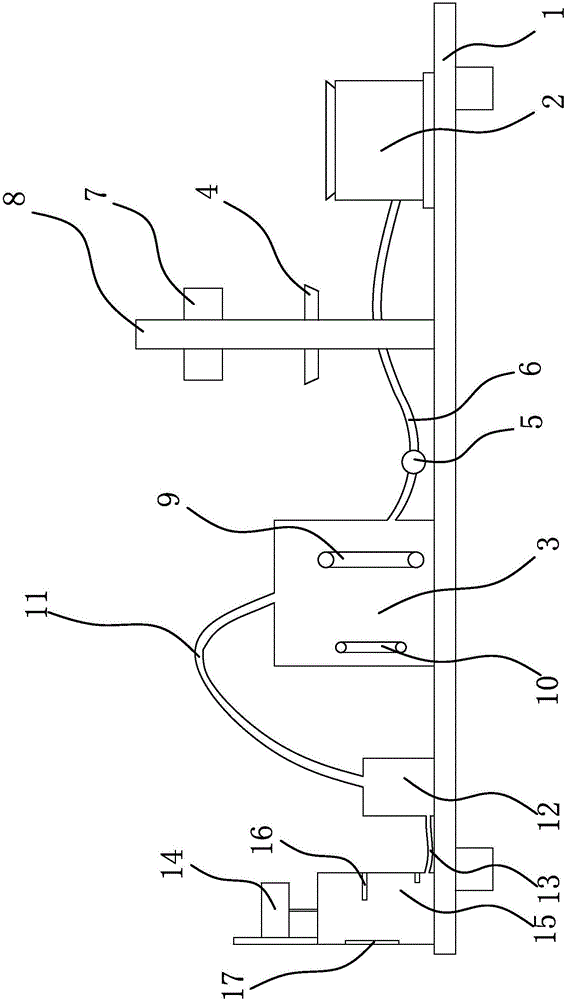

Dyeing and finishing technology with waterproof performance yarn and automatic impregnation machine

An impregnating machine and yarn technology, applied in textile processing machine accessories, textile material processing, and textile material processing equipment configuration, etc., can solve the problems of insufficient impregnation, low impregnation efficiency, etc. Finishing steps, the effect of reducing industrial water use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Immerse the nylon yarn in 120g / L C4 fluorine series water repellent working solution for 30 minutes, dehydrate, control the liquid retention rate at about 30%, and dry at 100°C for 10 minutes. Initial spray test score of 95 (ISO class 4), reduced to 80 (ISO class 3) after 3 standard home washes and dries, and further reduced to 80 (ISO class 3) after 5 washes.

Embodiment 2

[0067] Nylon nitrile yarns were dipped in 120g / L C4 fluorine series water repellent working solution concentration for 30 minutes, dehydrated, and the liquid retention rate was controlled at about 30%. The drying temperature was 100°C and the drying time was 10 minutes. The initial spray test score can reach AATCC 95 points, and it will drop to 80 points (ISO level 3) after 5 washes.

Embodiment 3

[0069] Immerse the nylon yarn in 120g / L C4 fluorine series water repellent working solution concentration for 30 minutes, dehydrate, control the liquid retention rate at about 30%, and dry at 100°C for 25 minutes. The initial spray test score of the fabric reached AATCC standard 95 points (ISO level 4), after 3 standard household washings, the water repellency performance was reduced to 900 points (ISO level 4), and after 5 washings it was still 85 points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com