Pretreatment method of superfine denier nylon fabric

A technology of ultra-fine denier and nylon, which is applied in the direction of textiles, papermaking, and dry-cleaning fiber products. It can solve the problems of easy abrasion during high-speed operation, uneven stress release in fibers, and large tension and mechanical rubbing force. Avoid batch-to-batch quality differences, good anti-sizing ability and sufficient time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

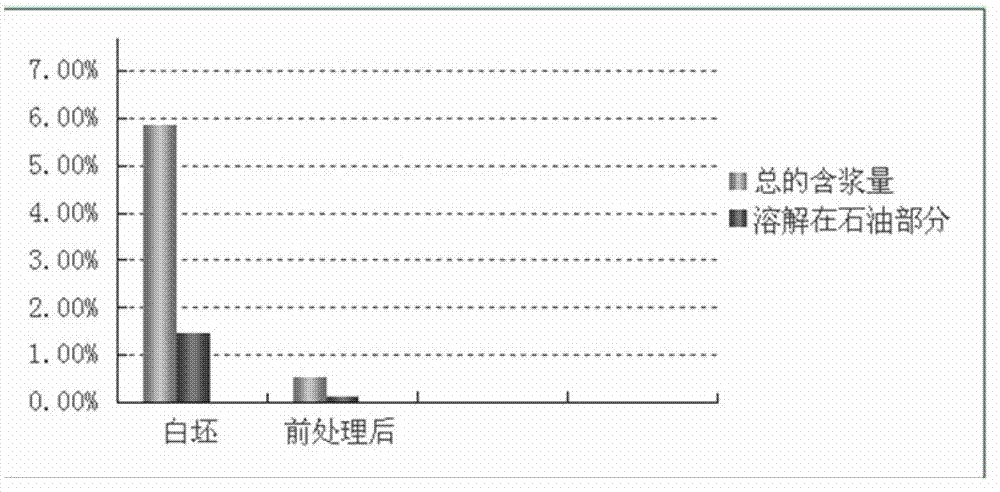

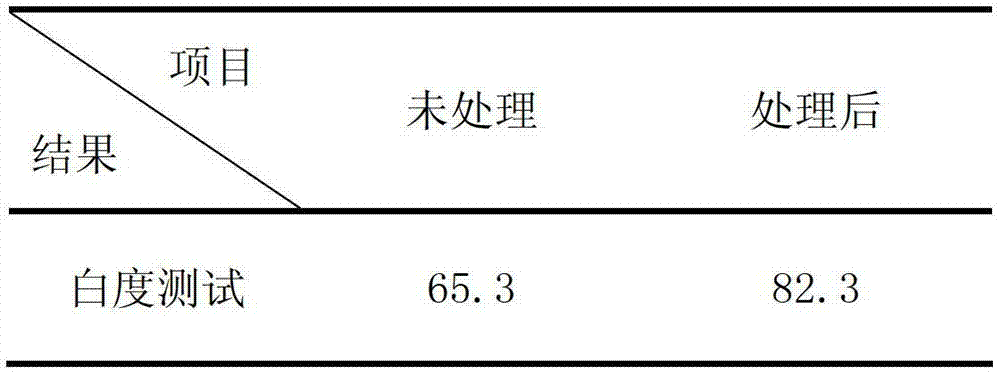

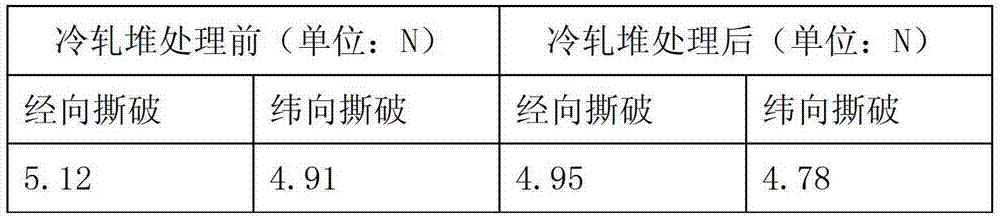

[0012] Example 1: The white base of ultra-fine denier nylon fabric used in this embodiment: warp direction: 15D / 12f nylon low elastic yarn; weft direction: 20D / 24f nylon filament; door width 162cm; square meter weight 33g / m 2 .

[0013] The pretreatment of superfine denier nylon fabric is carried out in the following steps in the present embodiment:

[0014] S1. Using the HLM2082 cold batch machine, under the conditions of reaction temperature of 45°C and vehicle speed of 50m / min, cold pad batch treatment is carried out on the white blank of ultra-fine denier nylon fabric with cold stack liquid, and the ultra-fine denier nylon fabric is completed The pre-treatment; wherein the cold stack fluid described in step 2 is composed of 32% liquid caustic soda, degreasing agent TF-126A, hydrogen peroxide, high-efficiency refining penetrating agent TF-125D, chelating dispersant TF-510C, environmental protection low alkali cold stack king HLD -100, desizing agent M-1011 and water; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com