Method for comprehensively treating and utilizing dissolving pulp black liquor

A technology for comprehensive treatment and dissolving pulp, applied in chemical instruments and methods, processing wastewater treatment, adsorption water/sewage treatment, etc., to achieve the effect of saving treatment costs, good economic benefits, and reducing pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

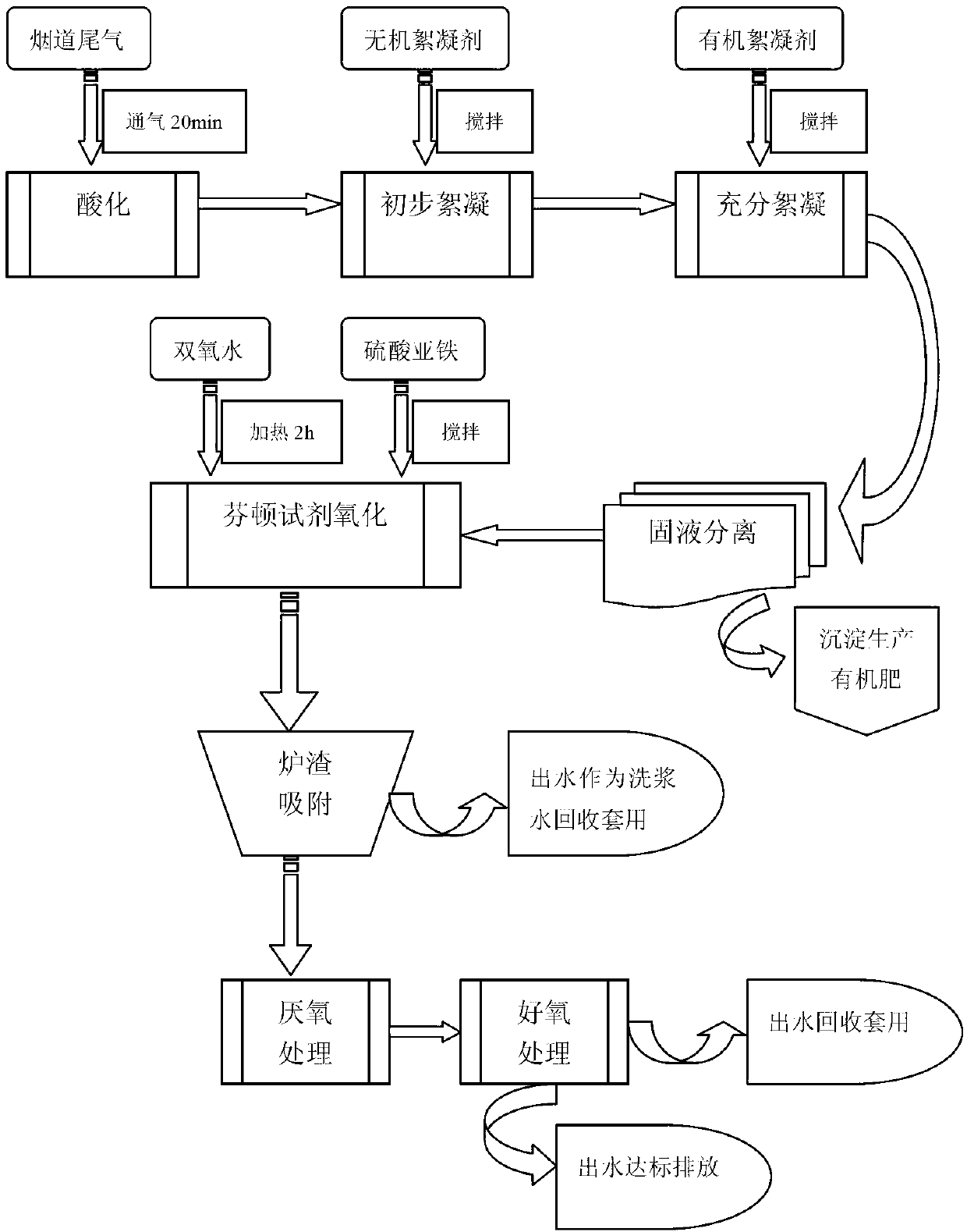

Method used

Image

Examples

Embodiment 1

[0050] Comprehensive treatment and utilization of dissolving pulp black liquor (applicable to effluent recovery)

[0051] The pH of the black liquor to be treated: 12.99, COD: 14736mg / L, chromaticity: 2500, volume: 1m 3 ;

[0052] Into the black liquor, the total amount of sulfur dioxide, carbon dioxide and nitrogen oxides is 2000mg / m 3 Left and right flue gas, time 20min, black liquor pH drops to 9.0, COD drops to 12089mg / L, chroma drops to 2300;

[0053] Prepare a polyaluminum ferric sulfate solution with a mass fraction of 10%, add 20kg of the solution to the wastewater, and stir for 3 minutes;

[0054] Prepare anionic polyacrylamide TSG-820 with a mass fraction of 1‰, add 20kg of the solution to the wastewater, and stir for 5 minutes. After the above two steps of flocculation, the COD of the black liquor will be reduced to 9690mg / L, and the chromaticity will be reduced to 2000;

[0055] Plate and frame filter press, collect flocculation sediment, and produce organic fer...

Embodiment 2

[0062] Comprehensive treatment and utilization of dissolving pulp black liquor (applicable to effluent recovery)

[0063] The pH of the black liquor to be treated: 12.99, COD: 14736mg / L, chromaticity: 2500, volume: 1m 3 ;

[0064] The total amount of sulfur dioxide, carbon dioxide and nitrogen oxides shall be 2000mg / m 3 The left and right flue gas is passed into the wastewater through the pipeline, and the aeration time is 20 minutes, the pH drops to 9.0, the COD drops to 12089mg / L, and the chromaticity drops to 2300;

[0065] Add 20 kg of prepared polyaluminum chloride solution with a mass fraction of 15% to the waste water, and stir for 3 min;

[0066] Add 20 kg of prepared non-ionic polyacrylamide TS-45 solution with a mass fraction of 2‰ to the wastewater, stir for 5 minutes, and after two-step flocculation treatment, the COD of the black liquor will be reduced to 9527 mg / L, and the chromaticity will be reduced to 1900;

[0067] Belt filter press is used for solid-liqui...

Embodiment 3

[0074] Comprehensive treatment and utilization of dissolving pulp black liquor (terminal effluent up to standard discharge)

[0075] The pH of the black liquor to be treated: 12.99, COD: 14736mg / L, chromaticity: 2500, volume: 1m 3 ;

[0076] Into the black liquor, the total amount of sulfur dioxide, carbon dioxide and nitrogen oxides is 2000mg / m 3 Left and right flue gas, the ventilation time is 20min, the pH drops to 9.0, the COD drops to 12089mg / L, and the chromaticity drops to 2300;

[0077] Prepare a polyaluminum ferric sulfate solution with a mass fraction of 5%, add 20kg of the solution to the waste water, and stir for 3 minutes;

[0078] Prepare anionic polyacrylamide TSG-825 with a mass fraction of 0.5‰, add 20kg of the solution to the wastewater, and stir for 5 minutes. After the above two steps of flocculation treatment, the COD of the black liquor will drop to 9862mg / L, and the chroma will drop to 2050;

[0079] Disc-type centrifugation collects flocculation and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com