Patents

Literature

93results about How to "Eliminate Chroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

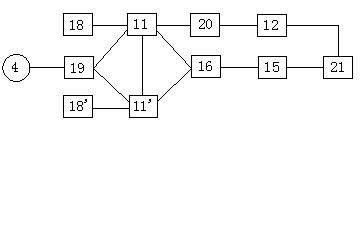

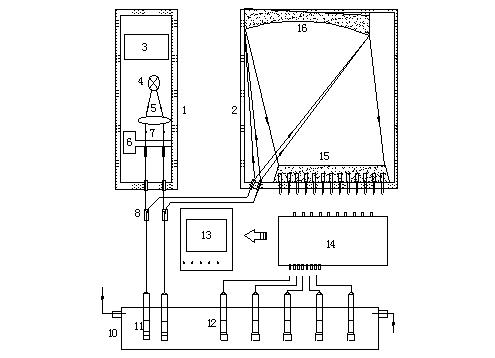

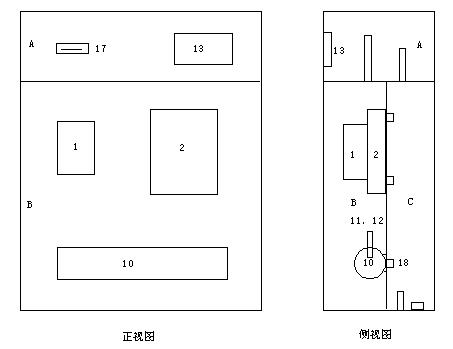

Complex monitor for automatically monitoring multiple parameters of water on line

InactiveCN102661923AEconomic savingsNo secondary pollutionColor/spectral properties measurementsMaterial electrochemical variablesPrincipal component analysisUv vis absorbance

The invention discloses a method for automatically monitoring water quality indexes on line and a device for implementing the method. A method of combining an ultraviolet and visible spectroscopy and various sensors is adopted, dozens of water quality indexes including chemical oxygen demand and ammonia nitrogen can be measured at one time, measurement indexes can be configured in a building block mode according to requirements, and chemical agents are not required. According to the device, the constructed digital optical fiber spectrometer is taken as a core, ultraviolet and visible absorption spectrum data of a water sample is processed in a mode of sequentially combining wavelet de-noising, principal component analysis and a support vector machine, and water quality indexes such as chemical oxygen demand and biochemical oxygen demand of water are acquired. Various physical and electrochemical sensors acquire water quality indexes such as ammonia nitrogen, dissolved oxygen and conductivity. All hardware and software for implementing the method is put in a cabinet to form the device, and the device analyzes the introduced water sample under the control of an embedded industrial control computer system, and automatically monitors the water quality indexes in real time.

Owner:SICHUAN BELAM TECH

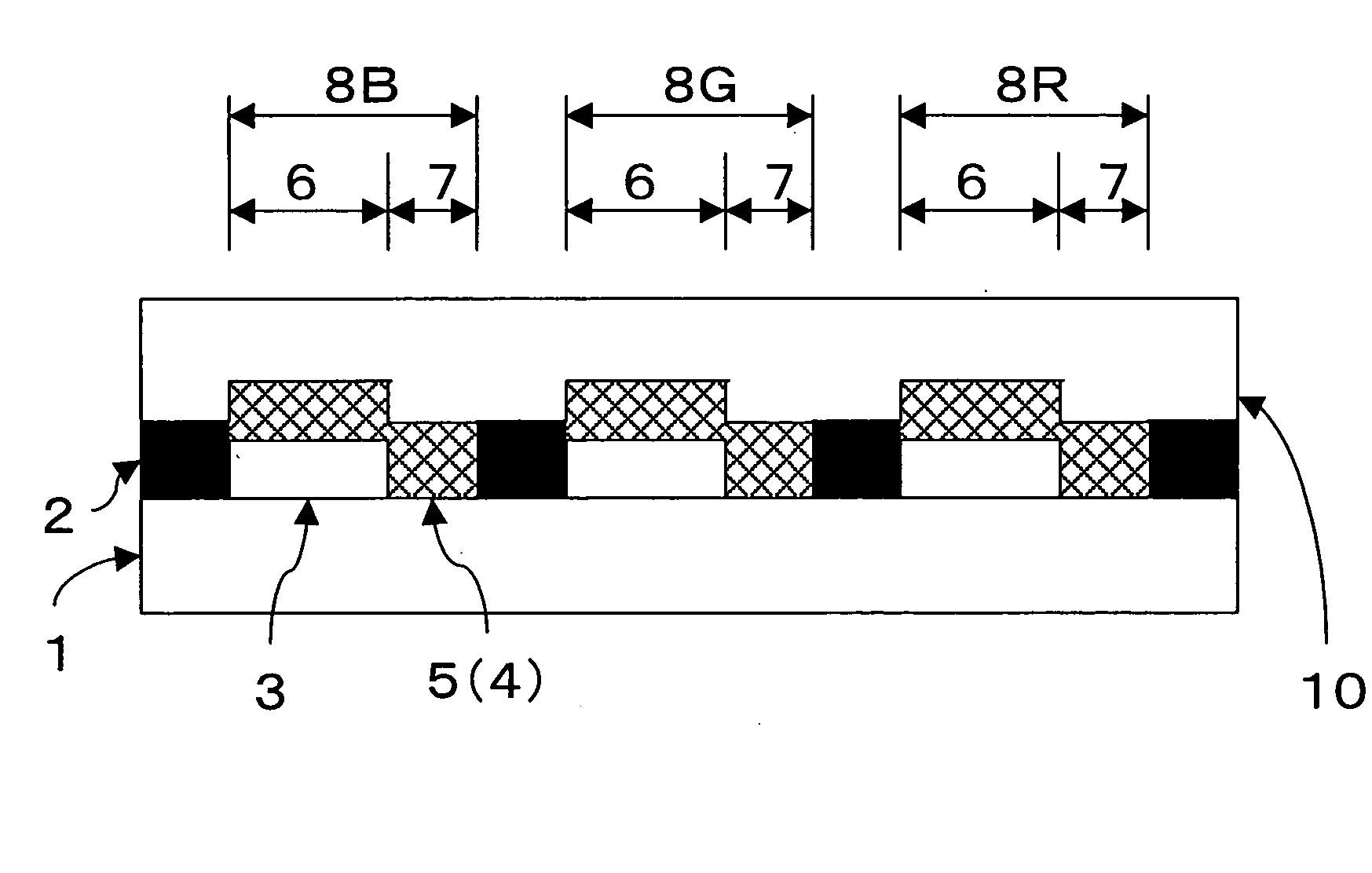

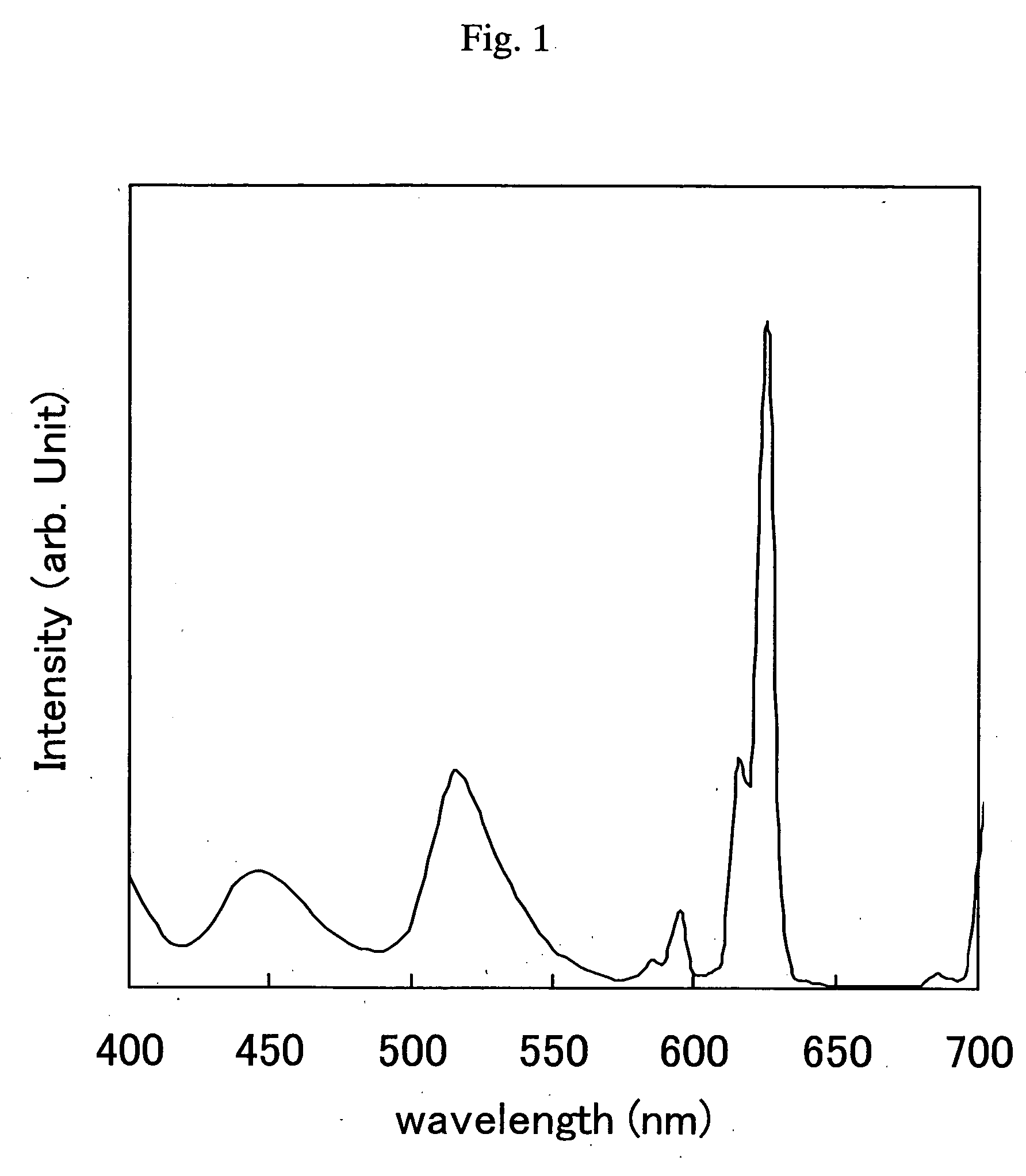

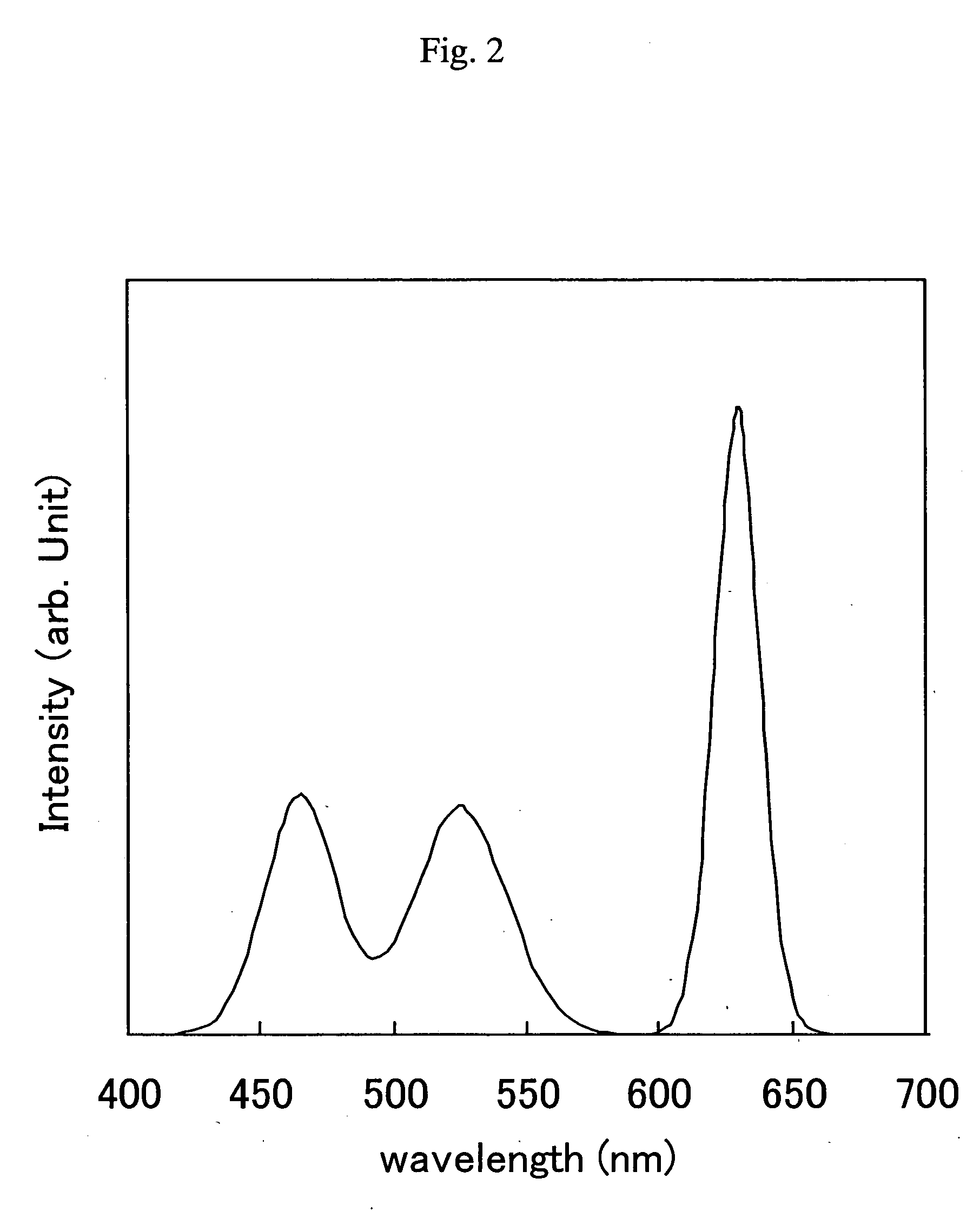

Color filter for liquid crystal display and semitransmission liquid crystal display

InactiveUS20050110923A1High color reproductionImprove featuresOptical filtersNon-linear opticsLiquid-crystal displayDisplay device

The present invention provides a low-cost transflective liquid crystal display exhibiting high color reproducibility in a transmissive display and excellent characteristics (color reproducibility and brightness) in a reflective display. Also, the present invention provides a color filter for a bright transflective liquid crystal display. The transflective liquid crystal display includes a pair of substrates disposed opposite to each other with a liquid crystal layer held therebetween, a reflection means using ambient light as a light source, and a backlight source. The transflective liquid crystal display further includes a color filter having a transmissive region and a reflective region which are provided in each picture element of the color filter and which have colored layers comprising a single material, and a three-peak type LED backlight source.

Owner:TORAY IND INC

Method for processing high-concentration wastewater containing alkaline mud

ActiveCN101693579ALow toxicityReduce loadTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAerobic treatment systemHigh concentration

The invention discloses a method for processing wastewater containing alkaline mud with high COD concentration, high toxicity, low biodegradability and high chroma. In the invention, a micro-electrolysis pretreatment, and flocculating and decoloring process are adopted to reduce the COD concentration and chroma and improve the biodegradability, thus providing precondition for the subsequent acidified hydrolysis and aerobic treatment system to further eliminate alkaline mud contamination load; and the yielding water is deposited by a deposition pool and discharged after disinfection. In the invention, the COD concentration (80,000-300,000mg / L) and the chroma (12,500-50,000 times) of inflowing water are improved to maximum degree, stability for the running of system is considered sufficiently, a large amount of diluted water required in the running process is saved, the yielding water can be directly exhausted to urban sewage pipelines, received by waterbody or combined in other treatment systems for treatment, and can comply with the recycling standard. In the whole treatment process, the secondary pollution is not generated, the total emission amount of COD is reduced, the whole system runs conveniently and quickly, and the investment and running expense is far lower than that of the traditional film treatment system.

Owner:TONGJI UNIV +1

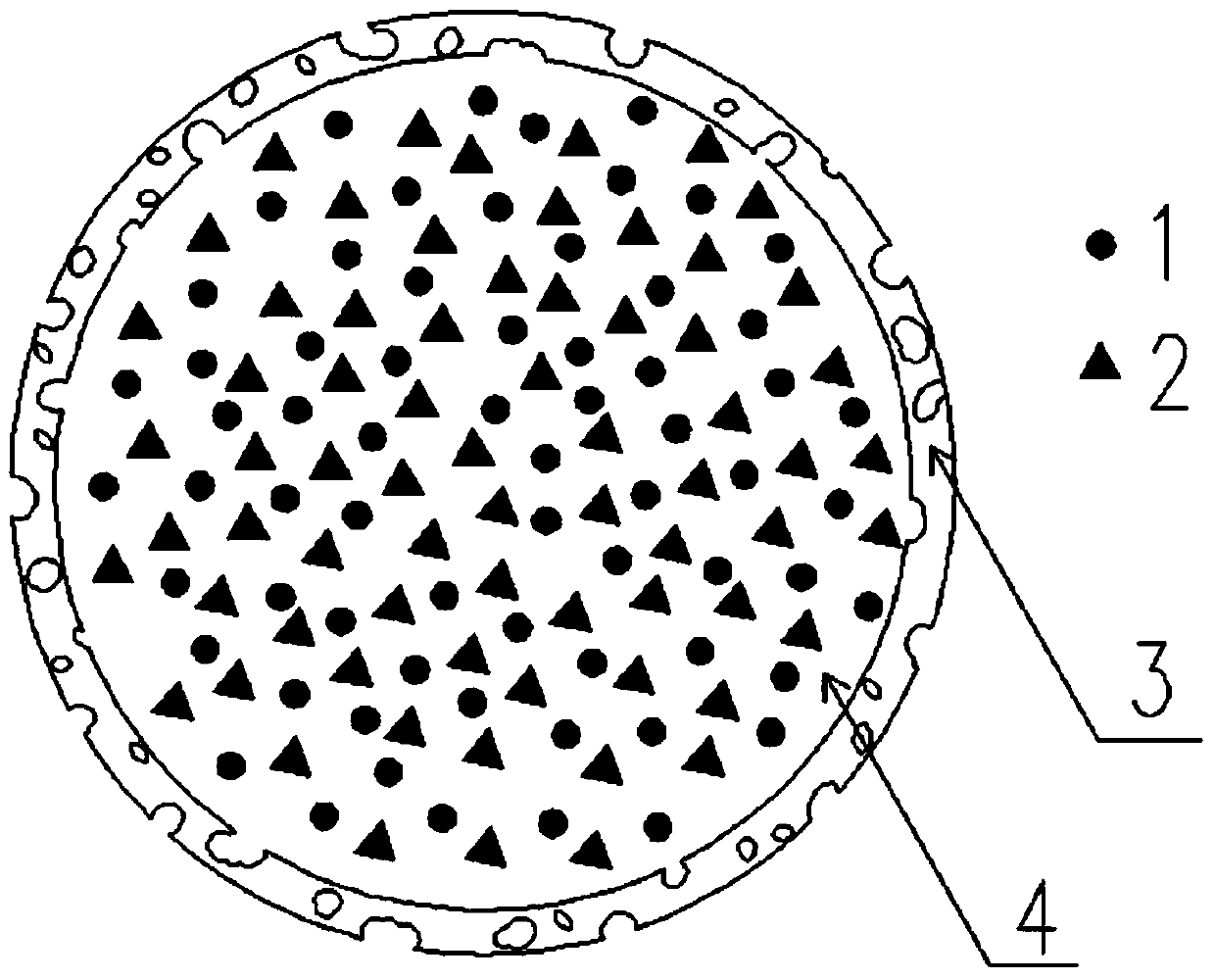

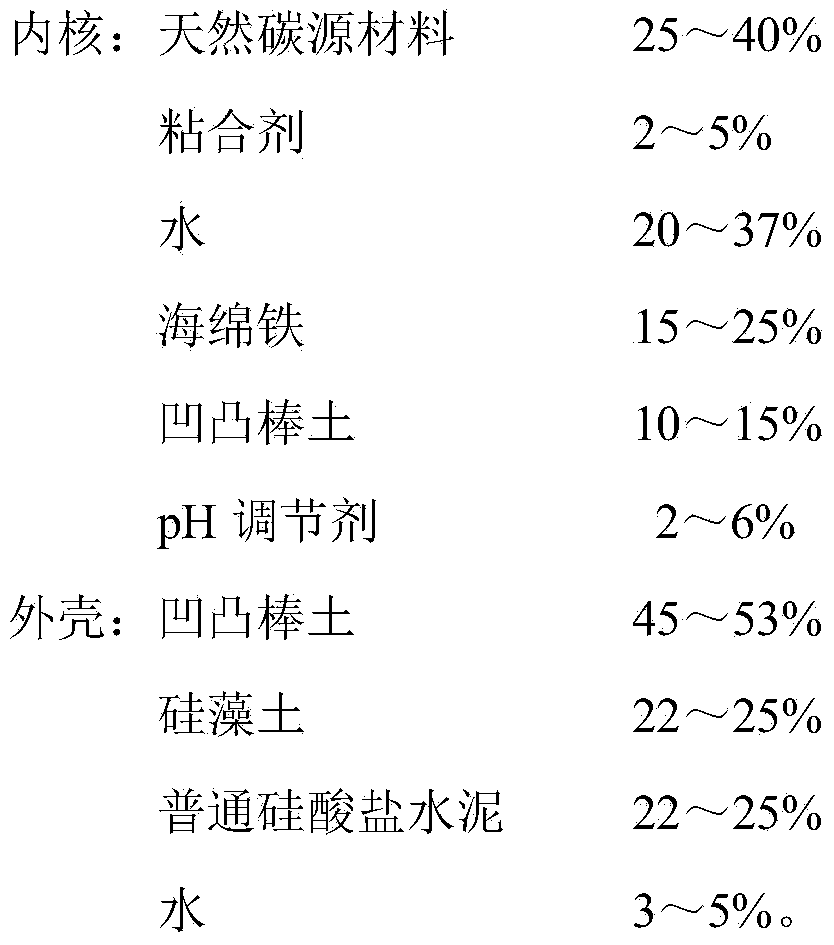

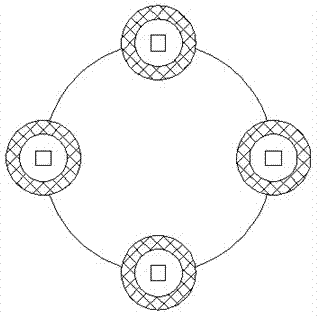

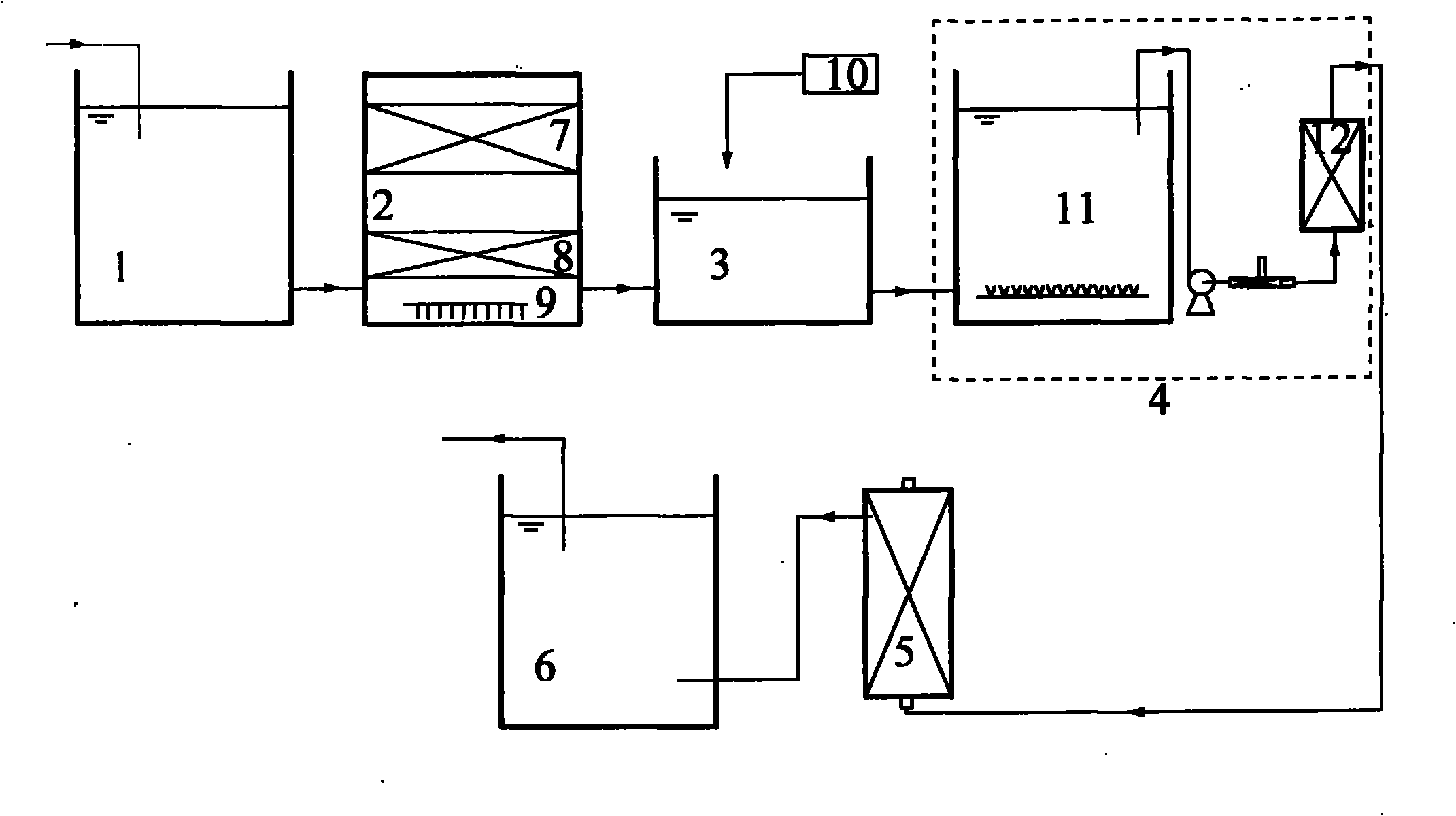

Carbon-iron microbattery slow-release carbon source filler and preparation method thereof

InactiveCN103723824AEliminate ChromaImprove biodegradabilityTreatment with anaerobic digestion processesAdhesivePortland cement

The invention discloses a carbon-iron microbattery slow-release carbon source filler and a preparation method thereof, belonging to the field of restoration of underground water pollution. The carbon-iron microbattery slow-release carbon source filler is composed of an inner core and an outer shell, wherein the inner core is made from organic carbon source mixed materials, and the outer shell is prepared from cement and high-permeability raw materials. The inner core is prepared from the following components in percentage by mass: 25-40% of natural carbon source material, 2-5% of adhesive, 20-37% of water, 15-25% of spongy iron, 10-15% of attapulgite and 2-6% of pH regulator; and the outer shell is prepared from the following components in percentage by mass: 45-53% of attapulgite, 22-25% of kieselguhr, 22-25% of ordinary Portland cement and 3-5% of water. By using the filler and method, the particle strength of the inner core can be enhanced to 70-105N / particle, and the thickness of the slow-release outer shell is lowered to 1-1.5 mm, so that the carbon-iron can be uniformly distributed in the material.

Owner:NANJING UNIV

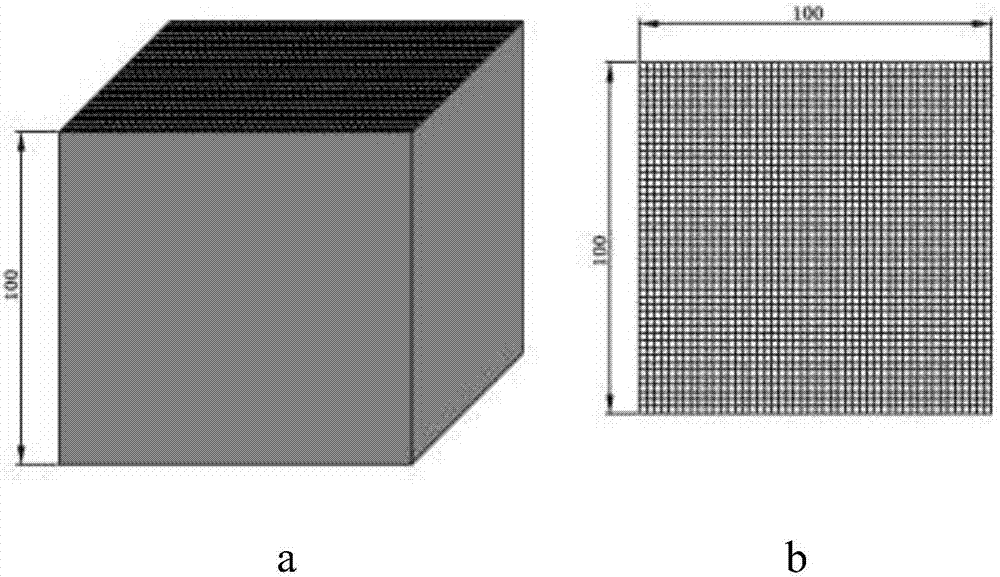

Modified polyurethane suspended filler and preparation method and application thereof

ActiveCN104961227AImprove and optimize the ecosystemImprove effectivenessSustainable biological treatmentBiological water/sewage treatmentActivated carbonPorosity

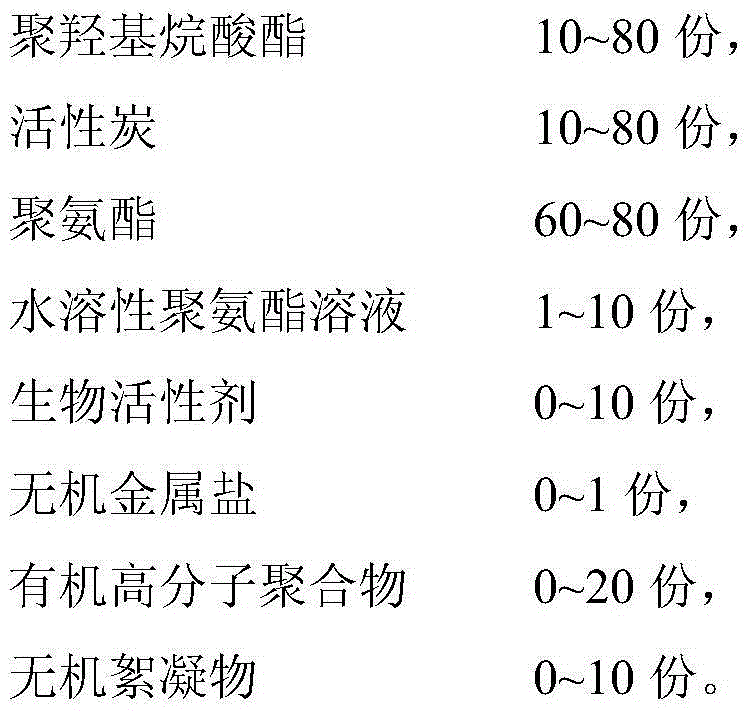

The invention discloses modified polyurethane suspended filler which comprises, by weight, 10 parts to 80 parts of polyhydroxyalkanoate, 10 parts to 80 parts of activated carbon, 60 parts to 80 parts of polyurethane, 1 part to 10 parts of water-soluble polyurethane solutions, 0 part to 10 parts of bioactivator, 0 part to 1 part of inorganic metal salt, 0 part to 20 parts of organic high-molecular polymer and 0 part to 10 parts of inorganic flocculate. A preparation method of the modified polyurethane suspended filler includes the steps of taking the 10 parts to 80 parts of polyhydroxyalkanoate, the 10 parts to 80 parts of activated carbon, the 0 part to 10 parts of bioactivator, the 0 part to 1 part of inorganic metal salt, the 0 part to 20 parts of organic high-molecular polymer and the 0 part to 10 parts of inorganic flocculate, dissolving the mixture in the 1 part to 10 parts of water-soluble polyurethane solutions, soaking the 60 parts to 80 parts of polyurethane in the solution to obtain the loaded polyurethane suspended filler, and conducting secondary drying after primary drying is conducted to obtain the modified polyurethane suspended filler. The modified polyurethane suspended filler has the advantages of being high in porosity and large in specific area.

Owner:HEFEI JIKUN ENVIRONMENTAL PROTECTION TECH CO LTD

Method for decolorizing sulfuric acid by using hydrogen peroxide

InactiveCN102757021ANo change in qualityEliminate ChromaSulfur-trioxide/sulfuric-acidFlue gasEconomic benefits

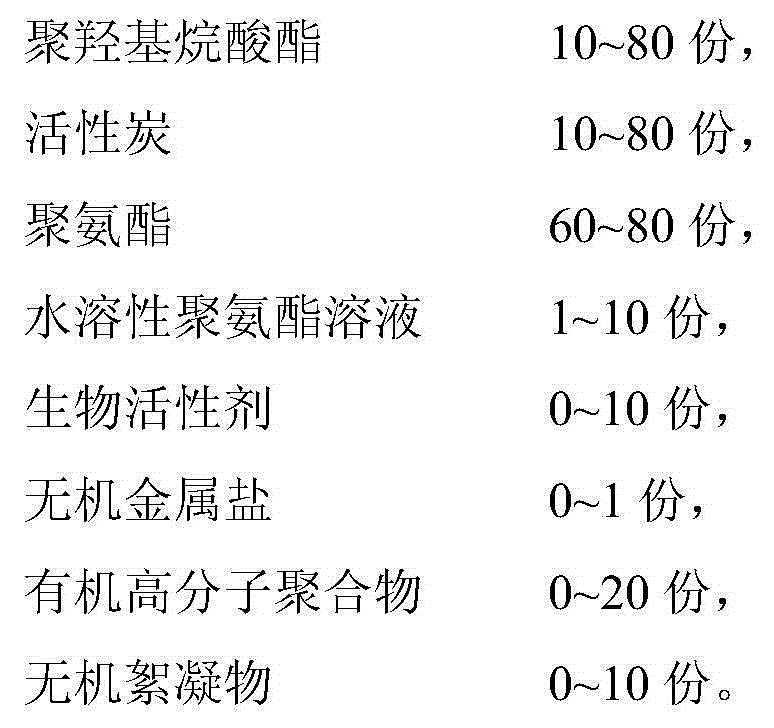

The invention relates to a method for decolorizing sulfuric acid by using hydrogen peroxide. The method includes the following steps of injecting a hydrogen peroxide solution to the sulfuric acid in a closed sulfuric acid decolorizing tank at a speed of 6-18L / min*t with a volume ratio of the sulfuric acid to the hydrogen peroxide solution being 100: (6-22); and simultaneously continuously stirring a mixture at a speed of 8-15 revolutions per minute to obtain the finished sulfuric acid. By means of the hydrogen peroxide solution, the method is strong in oxidizability, good in selectivity, simple in process, convenient, flexible and capable of decolorizing tawny or black brown sulfuric acid; under acidic conditions, reduzate of the hydrogen peroxide is water, other metal ions can not added to the sulfuric acid finished product, and the quality of the sulfuric acid finished product can not be changed; therefore, the problem that the chromaticity and the transparency of the sulfuric acid finished product prepared by gypsum flue gases can't reach the standard can be eliminated, the quality of gypsum flue gas acid can reach the standard of high-class products of industrial concentrated sulfuric acid, the market competitiveness of the gypsum acid is improved, and economic benefits of enterprises are increased.

Owner:刘立文

Organic waste water processing method

ActiveCN101139154ARelease influenceEfficient removalTreatment with anaerobic digestion processesMultistage water/sewage treatmentNitrogenMembrane bioreactor

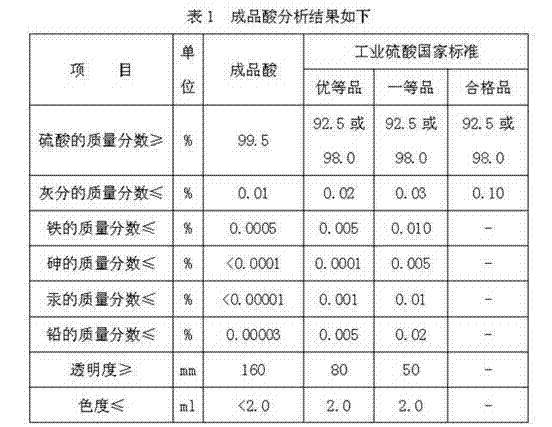

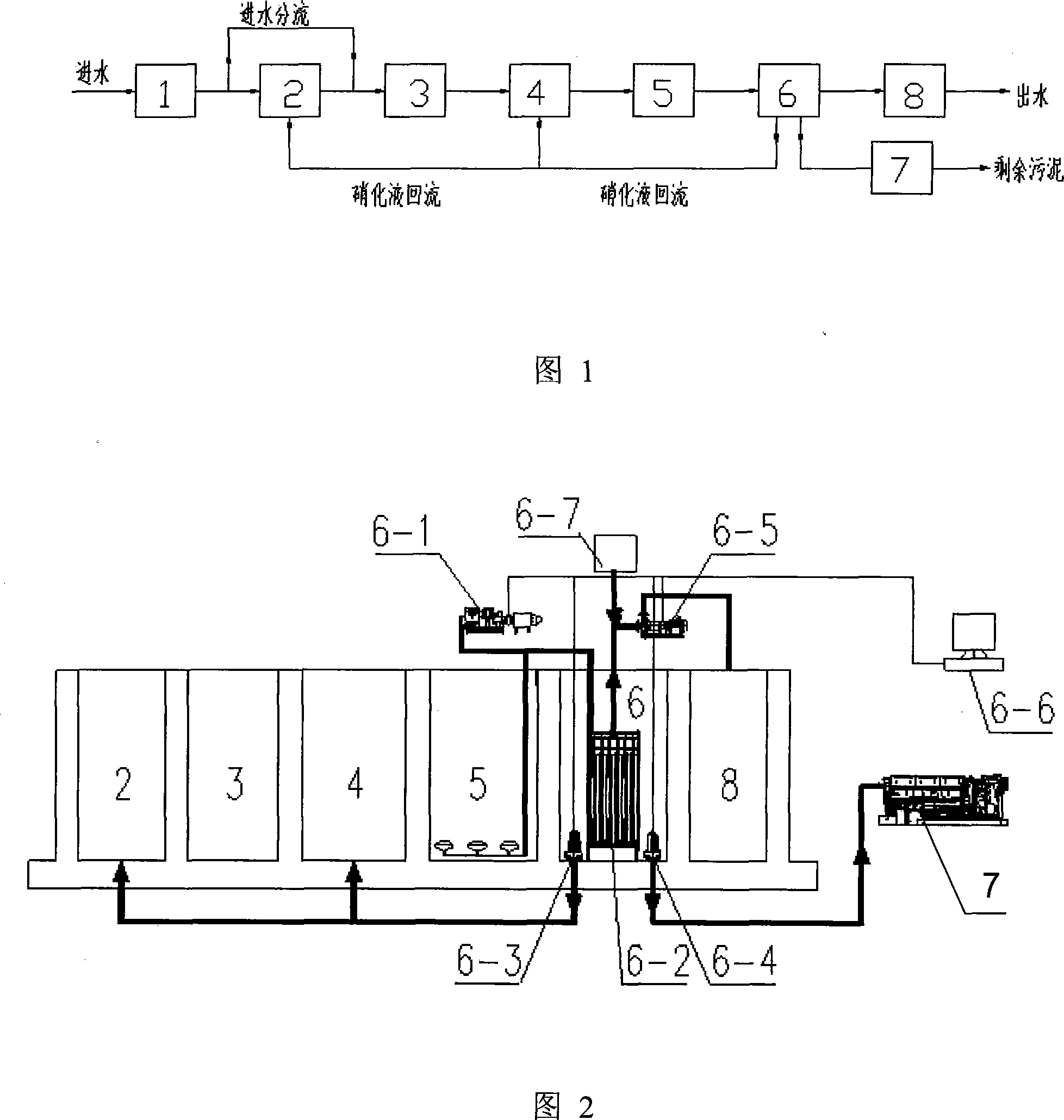

The present invention relates to an organic wastewater treatment method of membrane bioreactor, which has dephosphorization and denitriding functions. The method is provided with an oxygen-poor pool before the typical anaerobic-oxygen-poor-aerobic dephosphorization and denitriding method and provided with an aerobic pool adopting integrated membrane bioreactor behind the method. The method of the present invention not only has the advantages of the membrane bioreactor, but also can more completely remove organic contaminations, dephosphorize and denitride as well as eliminate the chroma of yielding water efficiently. The present invention is a method to reach the regenerated water standard of high quality by one time treatment of wastewater.

Owner:BEIJING ORIGINWATER TECH CO LTD

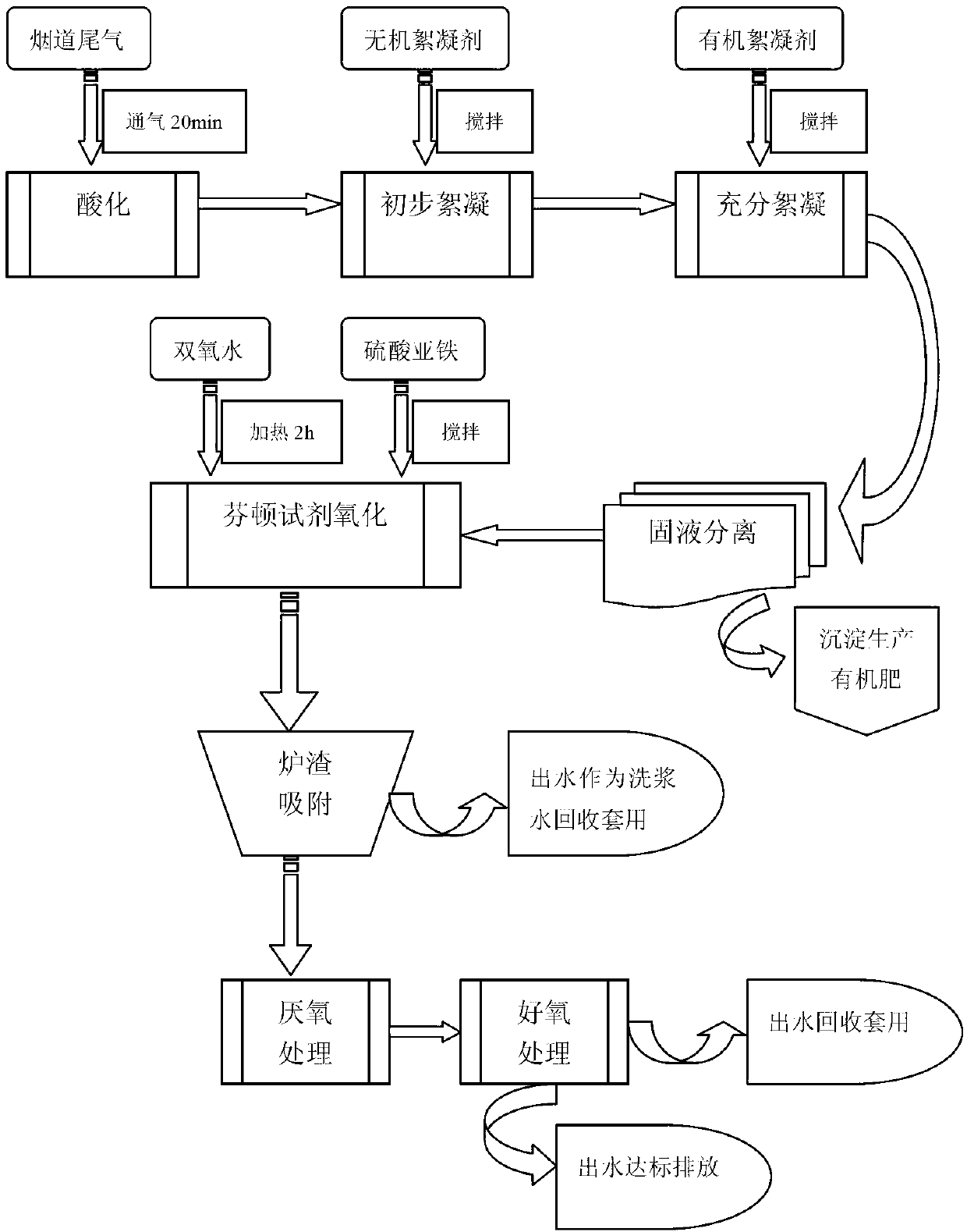

Method for comprehensively treating and utilizing dissolving pulp black liquor

ActiveCN102992553AEmission reductionEliminate ChromaTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemical oxygen demandSlag

The invention belongs to the technical field of biochemical environmental protection and provides a method for comprehensively treating and utilizing dissolving pulp black liquor. The method comprises the steps of (1) acidification, (2) flocculation, (3) oxidation, (4) adsorption and (5) biochemical treatment and further achieves sewage discharge up to the standard. By means of the method for comprehensively treating and utilizing the dissolving pulp black liquor, flue tail gas, slag and other wastes can be completely utilized, treatment cost is saved remarkably while emission of the three wastes is reduced, flocculated precipitate can serve as a raw material for producing organic fertilizers, considerable economic benefit is produced, chemical oxygen demand (COD) of water subjected to adsorption treatment is reduced by more than 85%, chroma is reduced by more than 99%, and the water can be recycled and can be subjected to biochemical treatment and then discharge up to the standard. The method is reasonable in process, low in cost and easy to implement, and has good economic benefit, environmental benefit and social benefit.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

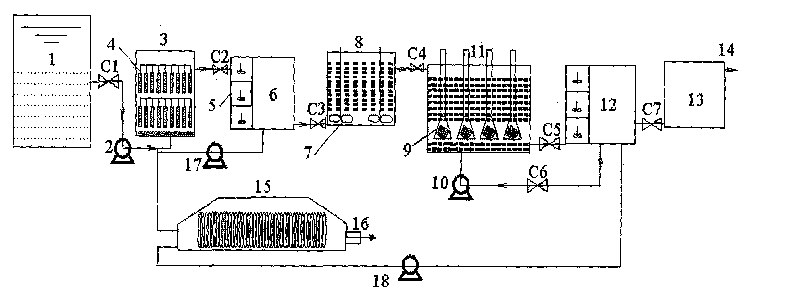

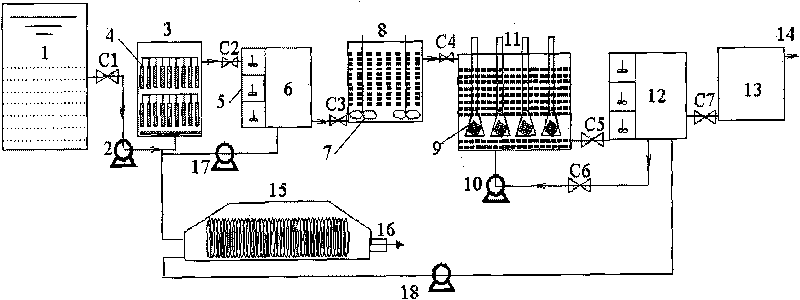

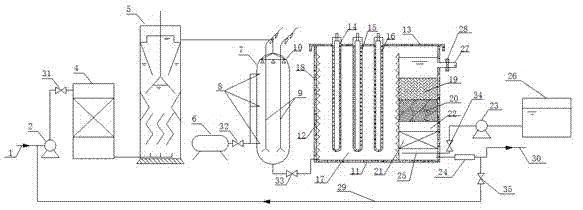

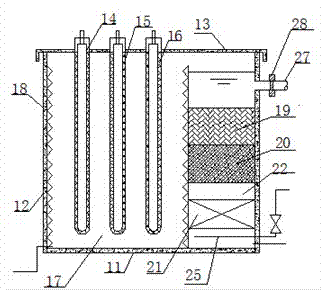

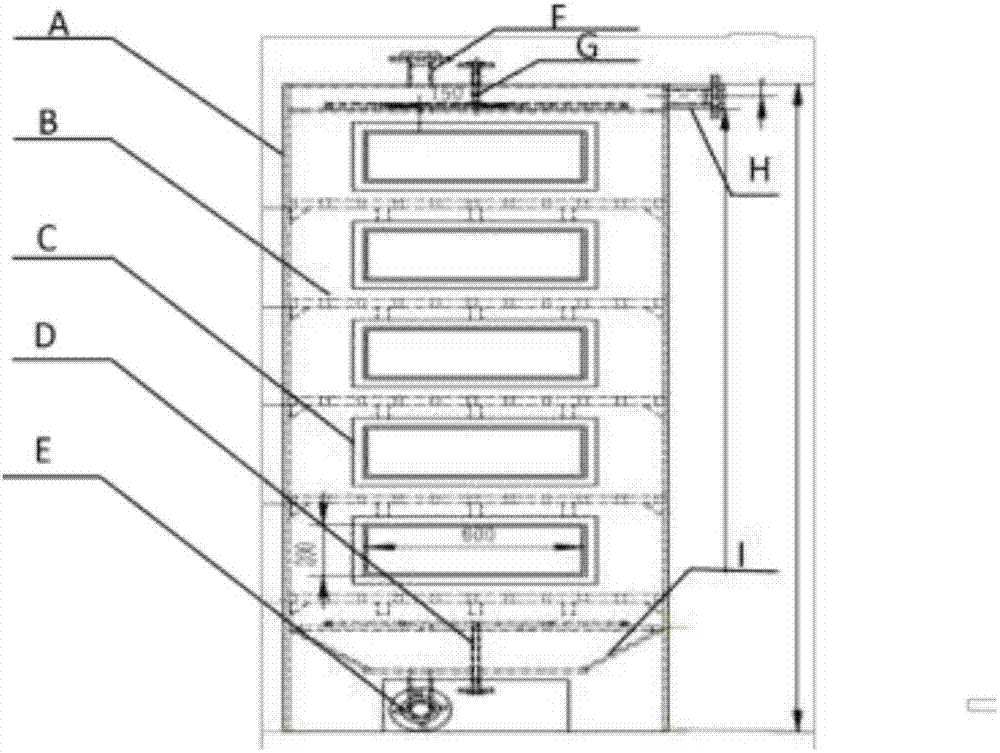

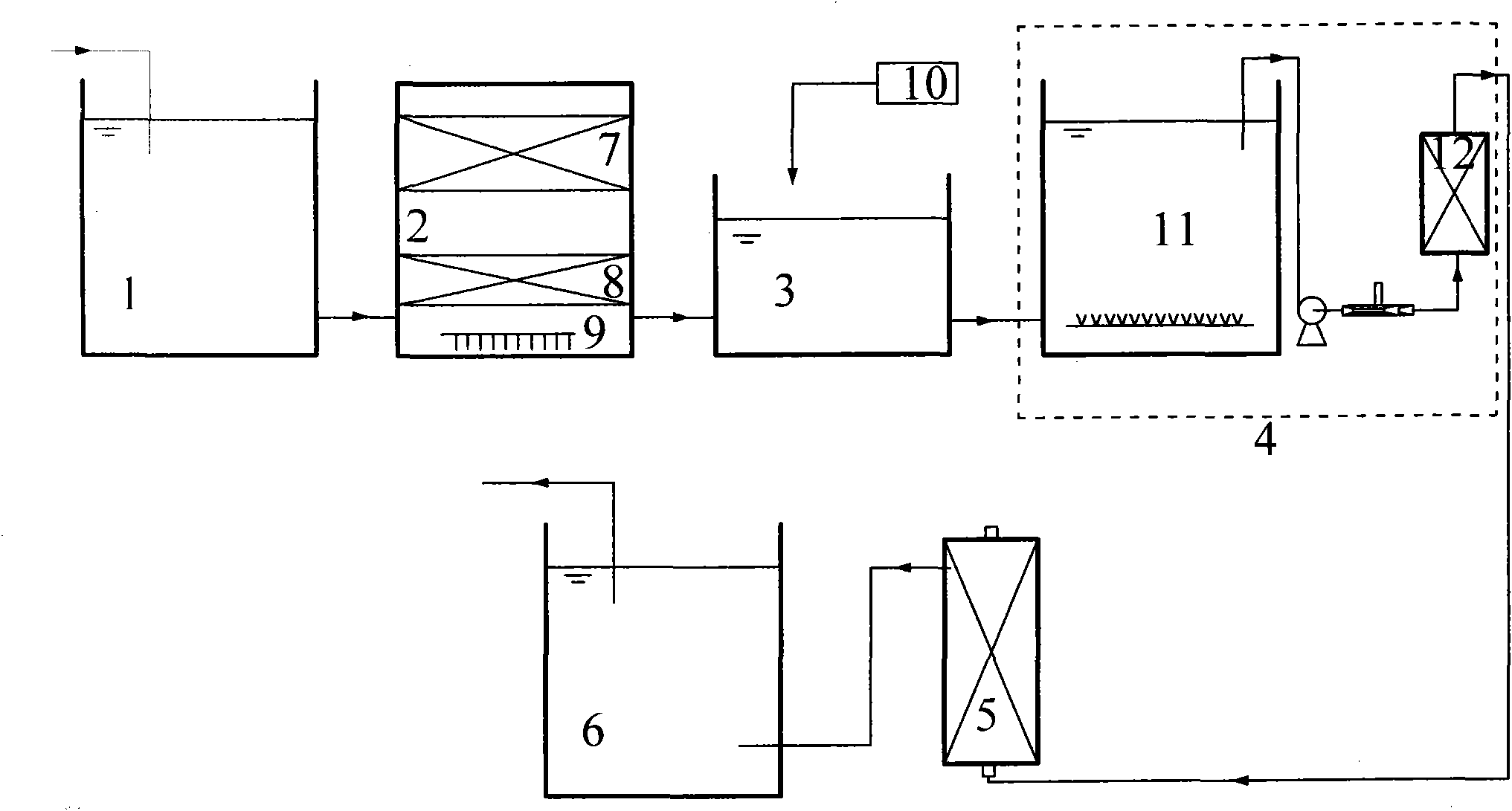

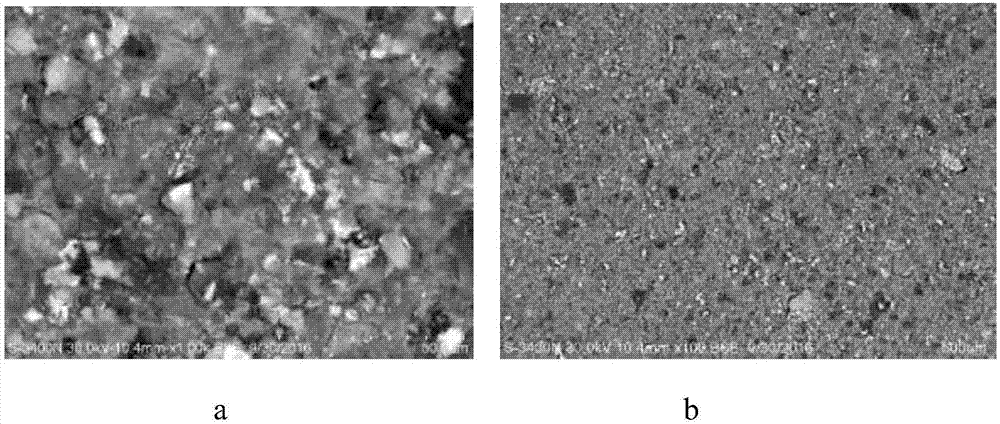

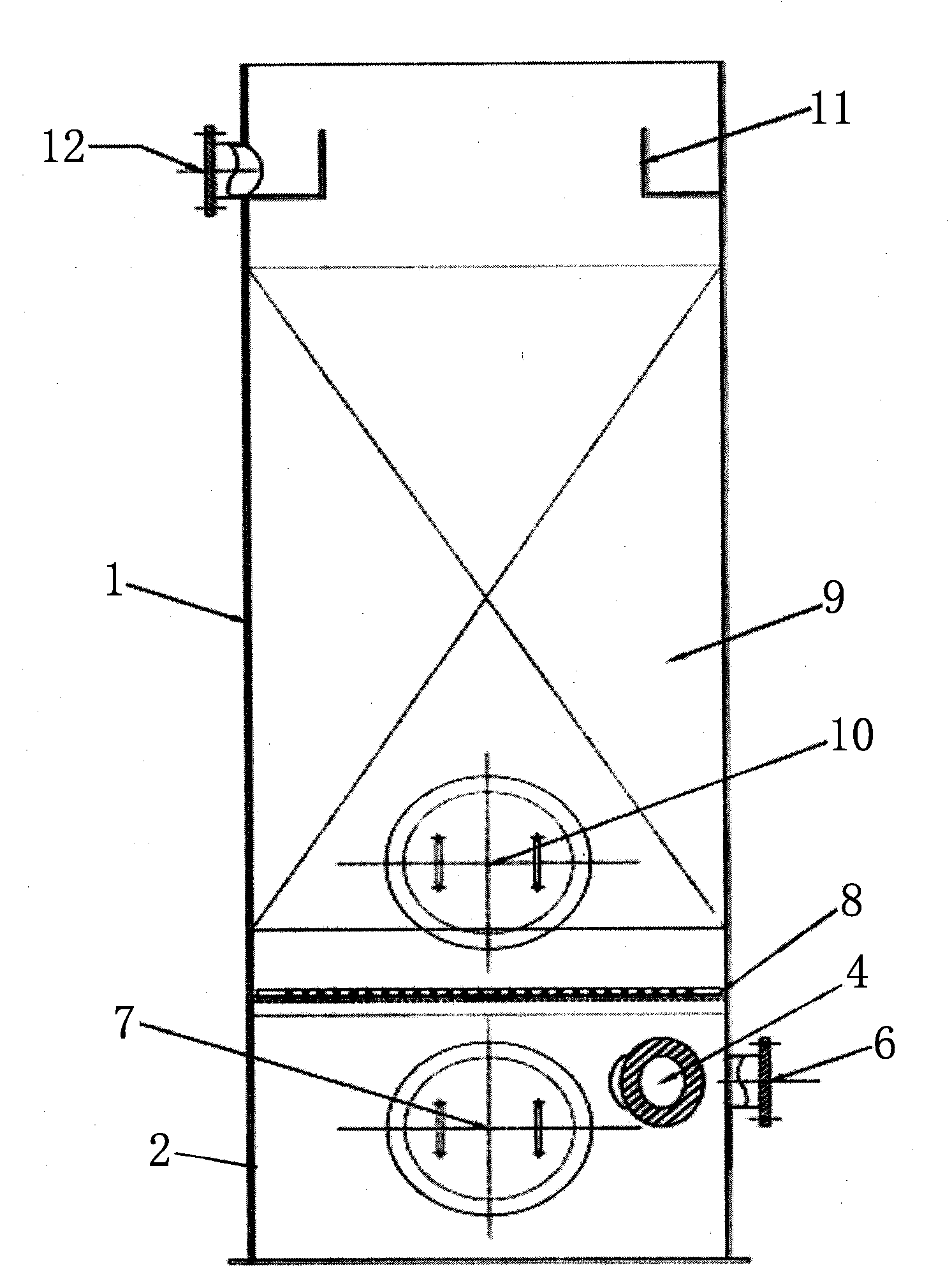

Combined apparatus for advanced treatment of high concentration organic waste water

InactiveCN102730906AUniform water qualityUniform water volumeWater/sewage treatment by irradiationTreatment with anaerobic digestion processesHigh concentrationPhotocatalytic reaction

The invention relates to a combined apparatus for advanced treatment of high concentration organic waste water. The apparatus comprises a pretreatment buffer tank, an anaerobic reactor, a pressurized aeration stirring system, a photocatalytic reactor, a filter chamber, a backwashing system, a back flow line pipe system and the like. Preliminary treatment of high concentration organic waste water is carried out by using an anaerobic method after waste water is pretreated, then advanced treatment of primary treated water is carried out by using a photocatalysis method, and furthermore, effluentis filtered with the filter chamber. The apparatus provided in the invention can both profoundly remove high concentration organic matters and ferro-manganese ions in waste water and prevent secondary pollution, has the advantages of small energy consumption, high efficiency, a good effect and the like, is applicable to treatment of high concentration organic waste water and can guarantee stable and highly efficient water yielding and the quality of reused water.

Owner:HOHAI UNIV

Processing method of garbage leachate

InactiveCN102329023ALow toxicityReduce loadMultistage water/sewage treatmentWater/sewage treatment by oxidationLitterCalcium hypochlorite

The invention relates to a processing method of garbage leachate, which comprises the following steps: 1) adding sodium hypochlorite into garbage leachate to carry out preoxidation; 2) adding ferrous iron and hydroxide, stirring, and separating out the supernatant; and 3) adding ferrous iron and hydrogen peroxide into the supernatant, stirring, and regulating the pH value of the effluent water to reach the standard. Aiming at the garbage leachate after biochemical treatment, the invention is composed of sodium hypochlorite reinforced ferrous iron coagulation and Fenton technique. The sodium hypochlorite reinforced ferrous iron coagulation can remove nondegradable organic substances in the leachate, and generate active chlorine to effectively remove ammonia nitrogen. In the Fenton technique, ferrous iron and hydrogen peroxide in a certain proportion are added to generate hydroxy free radicals, thereby further oxidizing the organic substances and implementing partial mineralization, lowering the toxicity of the leachate and enhancing the biochemical quality of the leachate.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

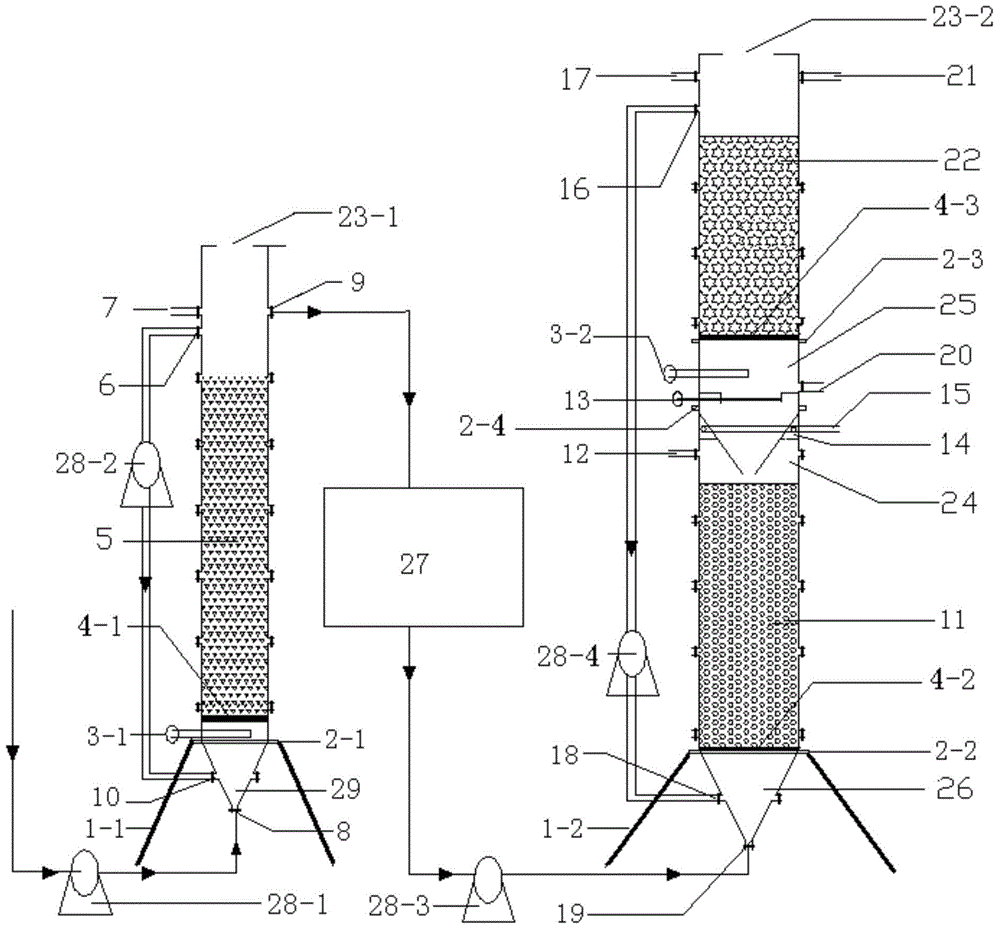

Process and device for treating tetracycline antibiotic wastewater

ActiveCN104445814AExtended service lifeNot easily oxidizedTreatment by combined electrochemical biological processesMultistage water/sewage treatmentElectrolysisOxygen

The invention discloses a process and a device for treating tetracycline antibiotic wastewater. The process comprises a pretreatment step and an anaerobic / aerobiotic treatment step; the pretreatment step comprises performing electrolytic treatment by taking ferric carbon microelectrolysis ceramsite as a filler; the anaerobic / aerobiotic treatment step comprises orderly performing anaerobic treatment and aerobiotic treatment on the wastewater treated by virtue of the pretreatment step, and fly ash ceramsite is taken as a filler for the anaerobic treatment, and sludge ceramsite is taken as a filler for the aerobiotic treatment. The invention also discloses the device for the process. According to the process and the device for treating the tetracycline antibiotic wastewater, the multi-stage treatment process is simplified, the capital investment is greatly reduced and the capital is saved; and the own characteristics of the wastewater are thoroughly utilized, and the dosage of a chemical agent is reduced, and therefore, secondary pollution is reduced while the cost is saved.

Owner:SHANDONG UNIV

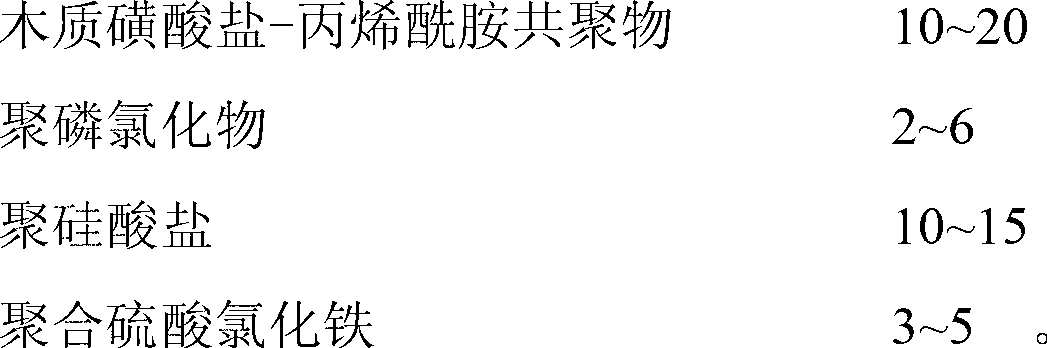

Slaughter wastewater flocculating agent

InactiveCN102992463ARemove chromaEfficient removalWater/sewage treatment by flocculation/precipitationSulfuric acidEnvironmental geology

The invention provides a slaughter wastewater flocculating agent which is formed by the following components in parts by weight: 10-20 parts of lignosulphonate-acrylamide copolymer, 2-6 parts of polyphosphorus chloride, 10-15 parts of polysilicate and 3-5 parts of polyferric chloride sulfate. According to the slaughter wastewater flocculating agent, the polysilicate is aluminum polysilicate or iron polysilicate; and the polyphosphorus chloride is polyphosphorus aluminum chloride or polyphosphorus iron chloride.

Owner:洪仁作

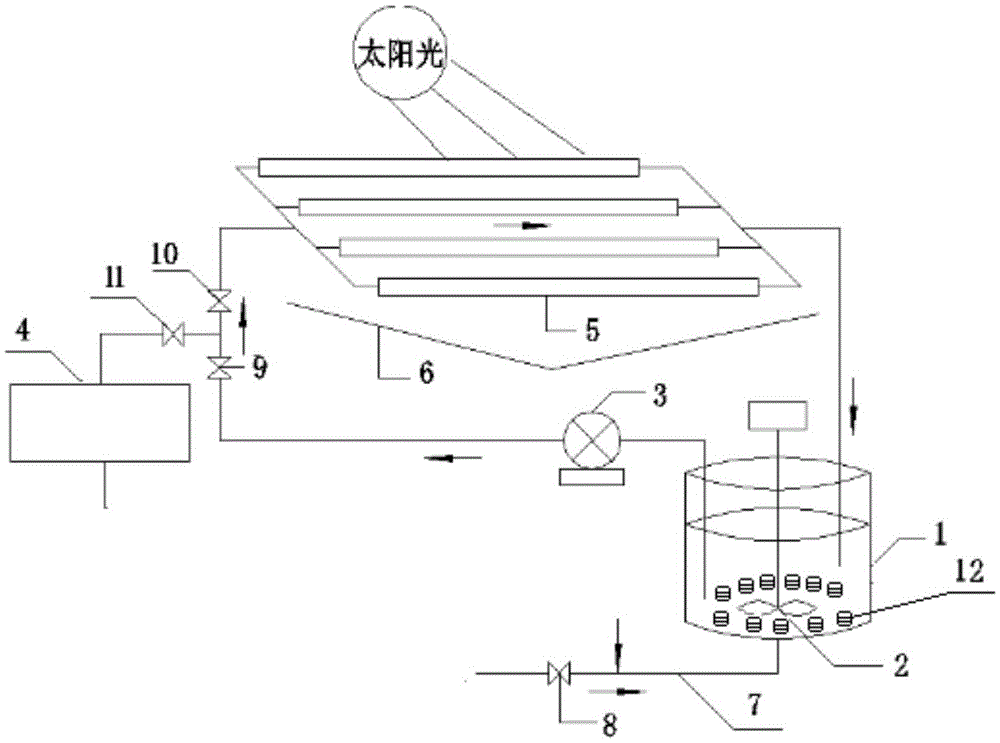

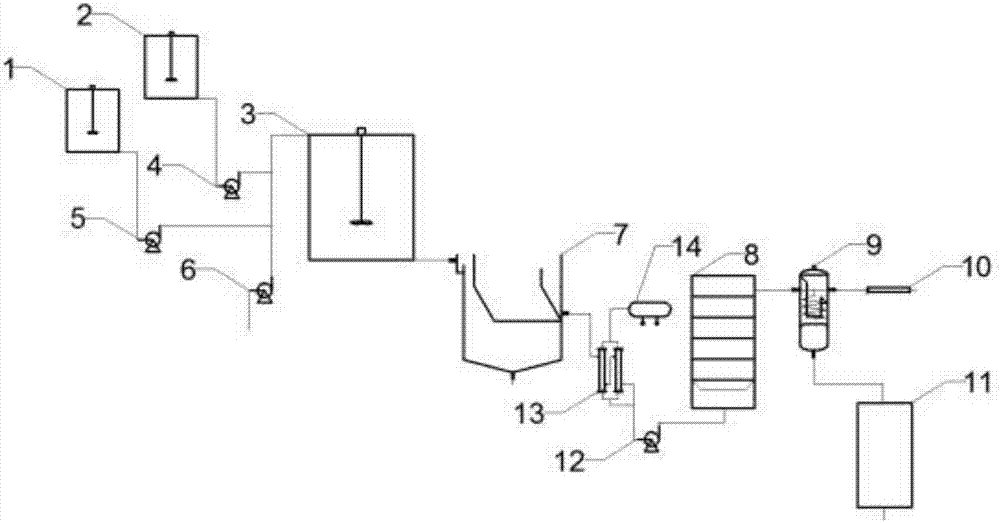

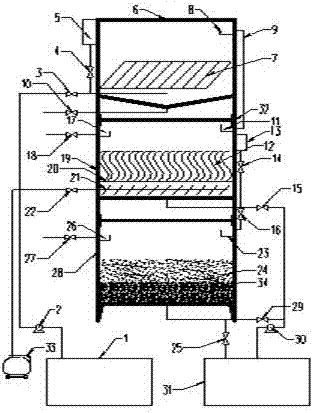

Light-Fenton catalytic oxidation coal chemical industry wastewater deep treatment system and coal chemical industry wastewater treatment method thereof

ActiveCN105645506AEnhance light absorptionDo·OHWater treatment parameter controlWater/sewage treatment by irradiationSludgeCatalytic oxidation

The invention discloses a light-Fenton catalytic oxidation coal chemical industry wastewater deep treatment system and a coal chemical industry wastewater treatment method thereof, relates to a coal chemical industry wastewater deep treatment system and the coal chemical industry wastewater treatment method thereof, and aims to solve the problems of high cost, low efficiency, serious sludge accumulation and poor treatment effect in the existing coal chemical industry wastewater deep treating process. The system disclosed by the invention consists of a water inlet system, a chemical inlet system, a photoreaction treatment system and a cyclic water system. Sunshine is adopted as a light source of the system; under the catalytic reaction of TiO2, except that part of pollutants can be directly decomposed, a hydroxyl complex of iron has high light absorption property, and can absorb light and perform photolysis to generate more .OH; the reaction speed is high. Illumination can also enhance the reduction of Fe<3+> and improve the concentration of Fe<2+>, and is beneficial to the catalytic decomposition of H2O2, so that the removal effect of pollutants is improved, the removal rate of COD and ammonia nitrogen reaches over 90 percent, and chrominance is also removed greatly.

Owner:广州市创景市政工程设计有限公司

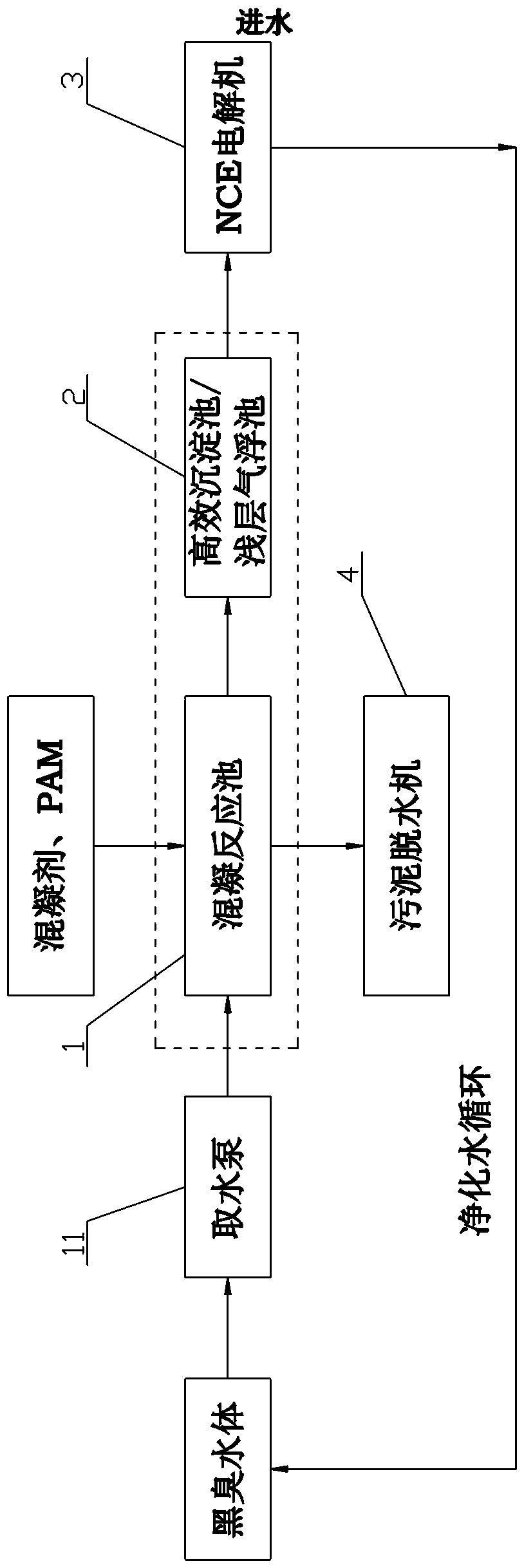

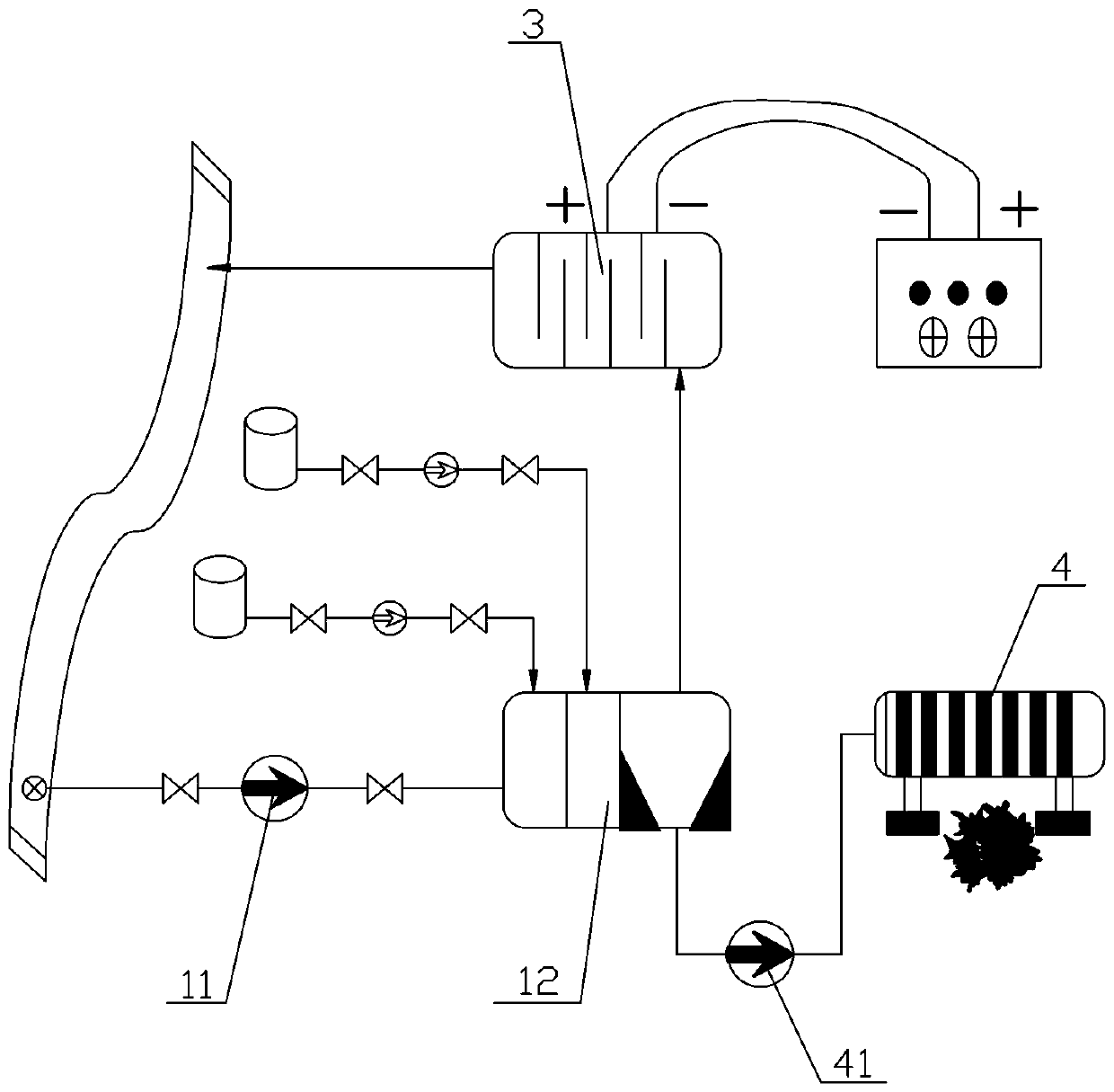

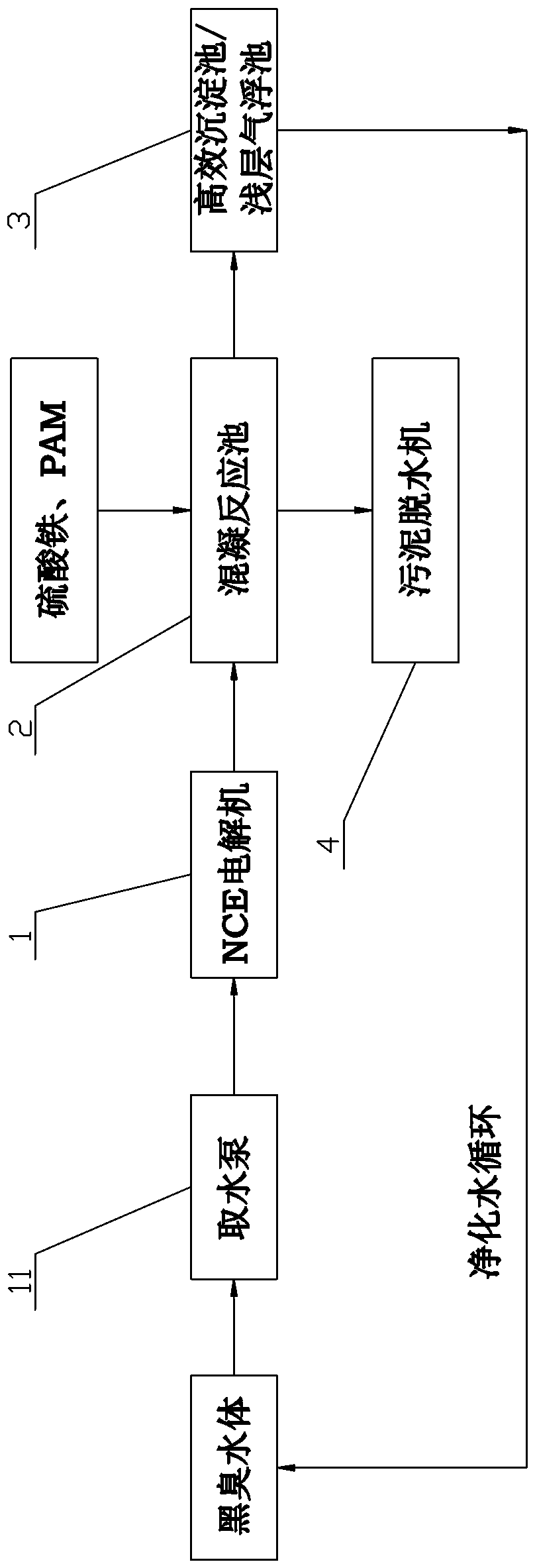

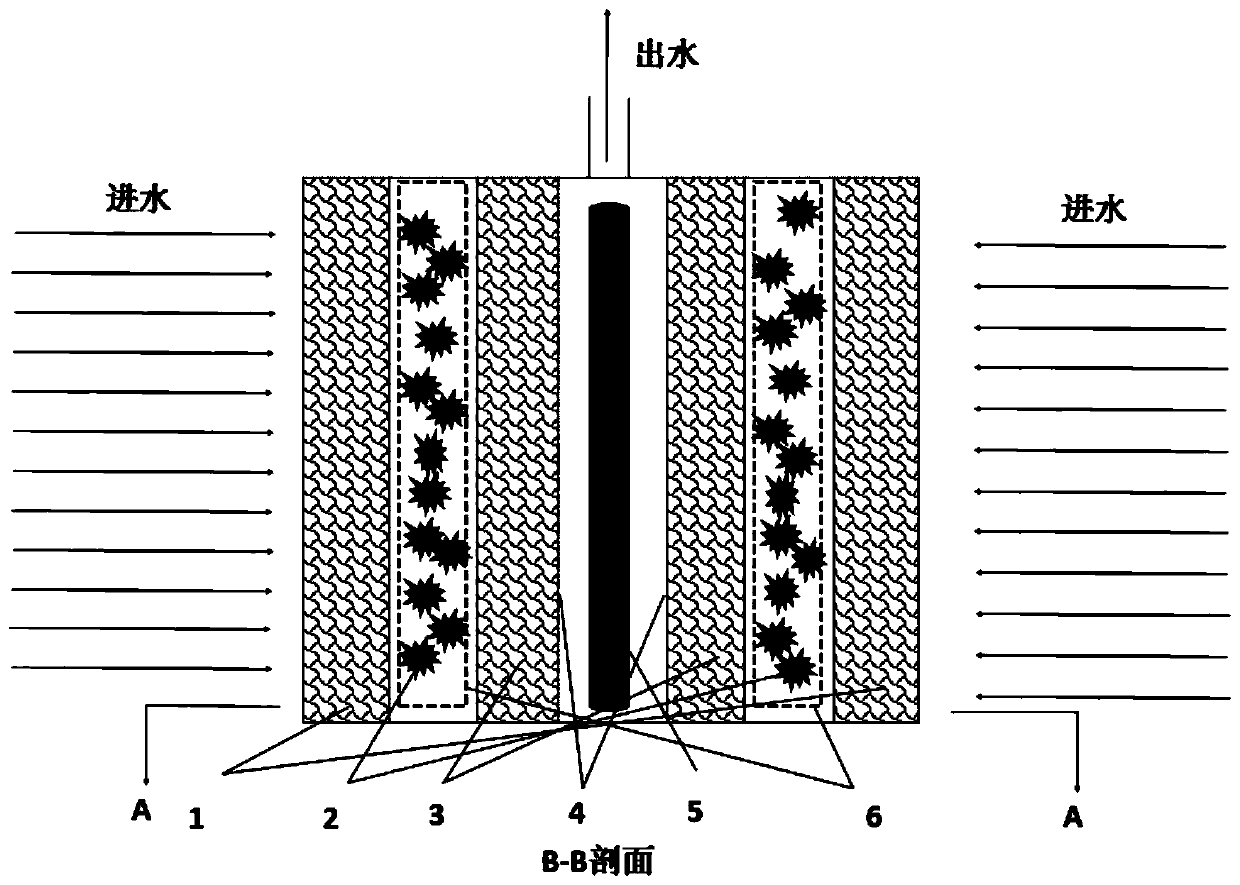

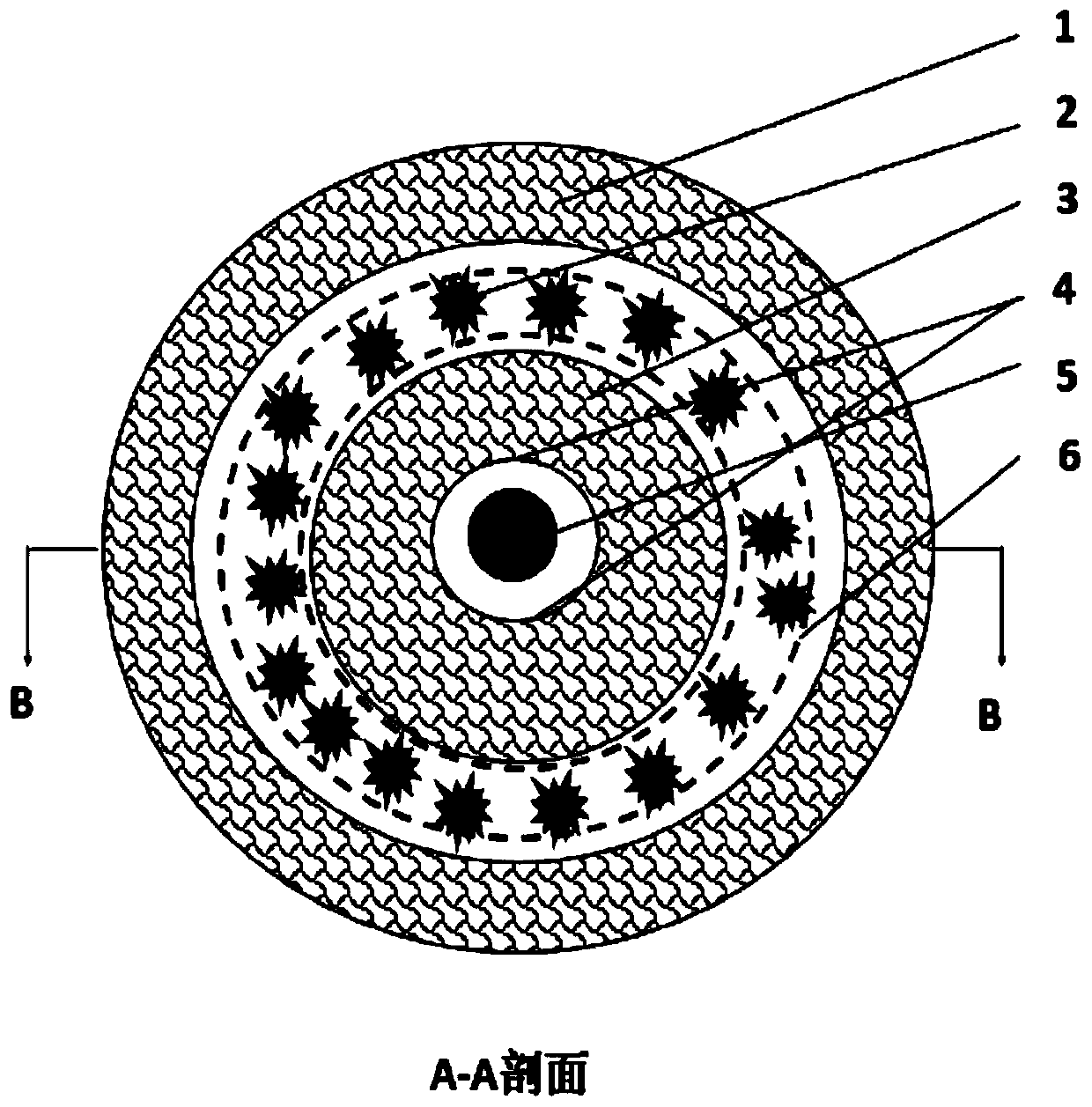

Black and odorous water body treating device and use method thereof

PendingCN107935258ASimple processSimple equipmentSpecific water treatment objectivesWater contaminantsElectrolysisTotal nitrogen

The invention discloses a black and odorous water body treating device and a use method thereof. The treating device is formed by the following parts: (1) a coagulating sedimentation or gas floating system; (2) an electrolysis system; (3) a sludge treating system. A black and odorous water body is divided into water bodies one section by one section by rubber dams, then a lifting pump is utilizedto take water from downstream of the black and odorous water body, a water outlet of the lifting pump is connected with a water inlet of the coagulating sedimentation system or the gas floating system, a water outlet of the coagulating sedimentation system or the gas floating system is connected with a water inlet of the electrolysis system, and a water outlet of the electrolysis system is drainedinto upstream of the black and the odorous water body to be circulated; a sludge discharging opening of the coagulating sedimentation system or the gas floating system is connected with an inlet of the sludge treating system to enter a sludge dewatering machine, and the sludge is dewatered by a dewatering machine of the sludge treating system into mud blocks and press filtrate. SS, COD, BOD, ammonia nitrogen, total nitrogen, total phosphorus and chromaticity are removed by coagulation and electrolysis, so that dissolved oxygen depth is improved, and the black and odorous water body can be treated.

Owner:BOYING XIAMEN SCI & TECH

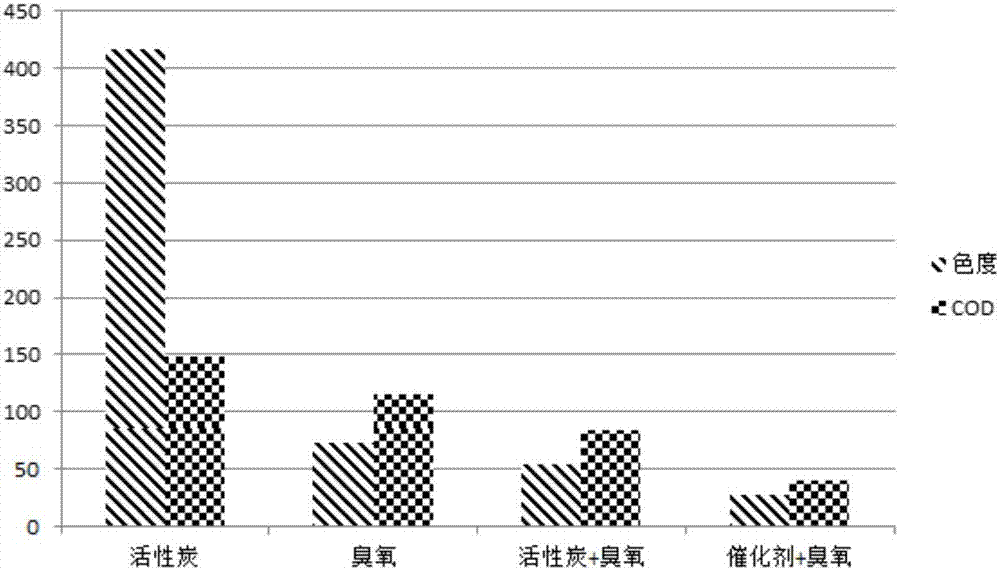

Catalytic oxidation method for low-concentration non-biodegradable industrial organic wastewater treatment

ActiveCN107473435AImprove cohesionDestabilizingWater treatment compoundsTreatment involving filtrationChemical oxygen demandCatalytic oxidation

The invention discloses a catalytic oxidation method for low-concentration non-biodegradable industrial organic wastewater treatment. A core process of the method comprises a front-end enhanced flocculation technology, a catalytic oxidation technology under conditions of normal temperature and normal pressure and a tail-end purification technology. Under the conditions of normal temperature and normal pressure, after enhanced flocculation is performed with calcium hypochlorite and a flocculating agent (polyacrylamide) firstly, ozone with certain concentration and a small amount of H2O2 are supplemented under the conditions of normal temperature and normal pressure, catalytic oxidation is executed by a honeycomb support catalyst supported with noble metal elements such as Pt, Pd, Ru and the like as well as transition metal elements such as Cu, Mn, Zn, Fe, Co and the like, and low-concentration non-biodegradable industrial organic wastewater with COD (chemical oxygen demand) lower than 1000 is efficiently treated. According to the method, the removal rate of the COD is higher than or equal to 95%, the efficiency is increased by 40% than that of independent ozonation for organic pollutants, and the ozone consumption is reduced by 60%.

Owner:云南省贵金属新材料控股集团有限公司

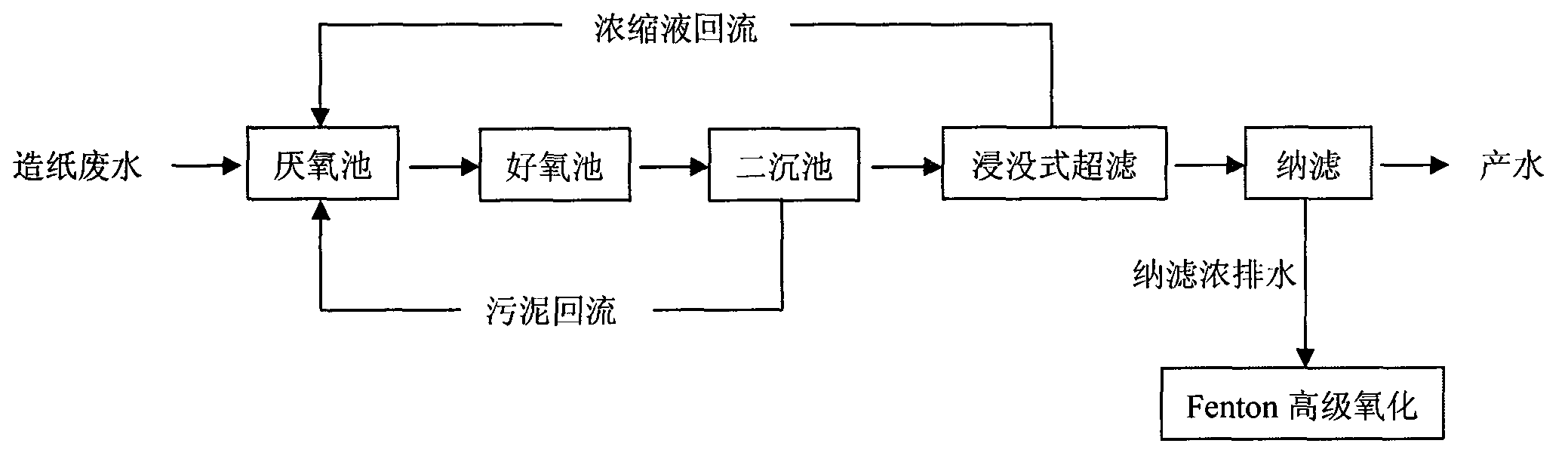

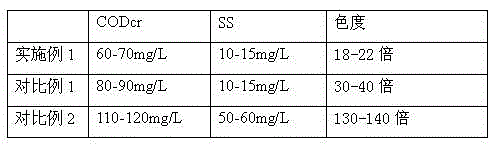

Method for treating papermaking wastewater based on combined process including integrated membrane technology and advanced oxidation technology

InactiveCN103663849AReduce operating pressureHigh recovery rateMultistage water/sewage treatmentWaste water treatment from plant processingChemical oxygen demandUltrafiltration

The invention discloses a method for treating papermaking wastewater based on a combined process including an integrated membrane technology and an advanced oxidation technology. The method comprises the steps of treating the papermaking wastewater through a previous period anoxic / aerobic biochemical process, then putting the wastewater into a submerged ultrafiltration unit and a nano-filtration treatment unit in sequence, and treating nano-filtration concentrated discharged water through a Fenton advanced oxidation technology to realize up-to-standard release. The method disclosed by the invention is a novel treatment technology of papermaking wastewater, the papermaking wastewater is formed by mixing pulping production wastewater, papermaking production wastewater and other wastewater on production as well as domestic sewage and abnormal rainwater, the CODcr (chemical oxygen demand) and pH value are adjusted, most of suspended objects and colloidal substances are removed through a rotary-drum filtration process and flocculating sedimentation, then the papermaking wastewater is subjected to anoxic / aerobic biochemical treatment and then enters the submerged ultrafiltration treatment unit, penetrating fluid enters a nano-filtration treatment system, the penetrating fluid subjected to nano-filtration can meet requirements for papermaking production water through detection, and the nano-filtration concentrated discharged water is treated in a Fenton advanced oxidation treatment unit to realize up-to-standard release. The method is particularly suitable for treating papermaking wastewater which is very difficult to recycle through a conventional sewage treatment method.

Owner:天津森诺过滤技术有限公司

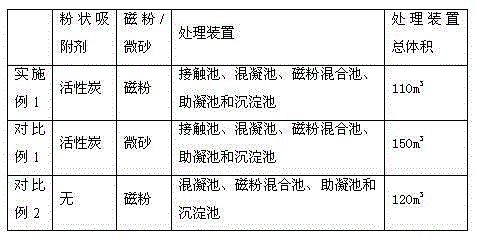

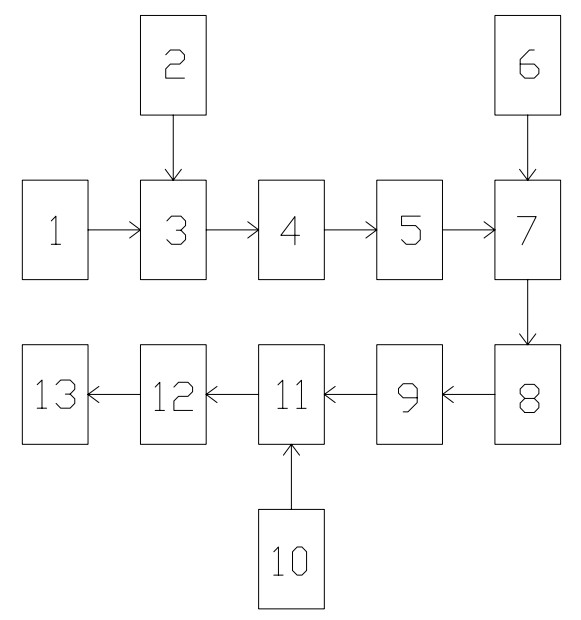

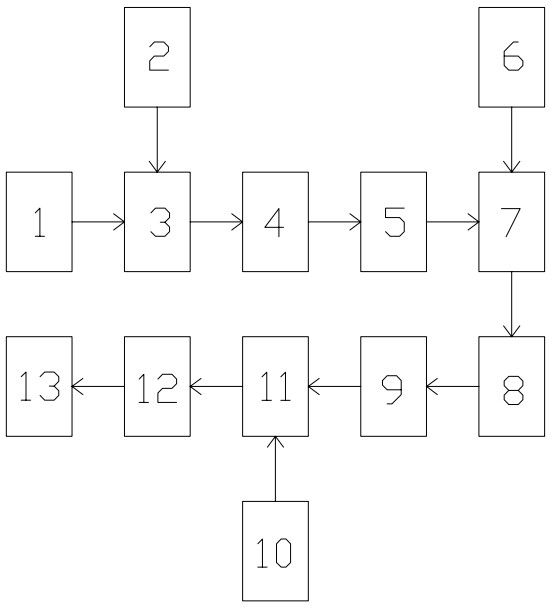

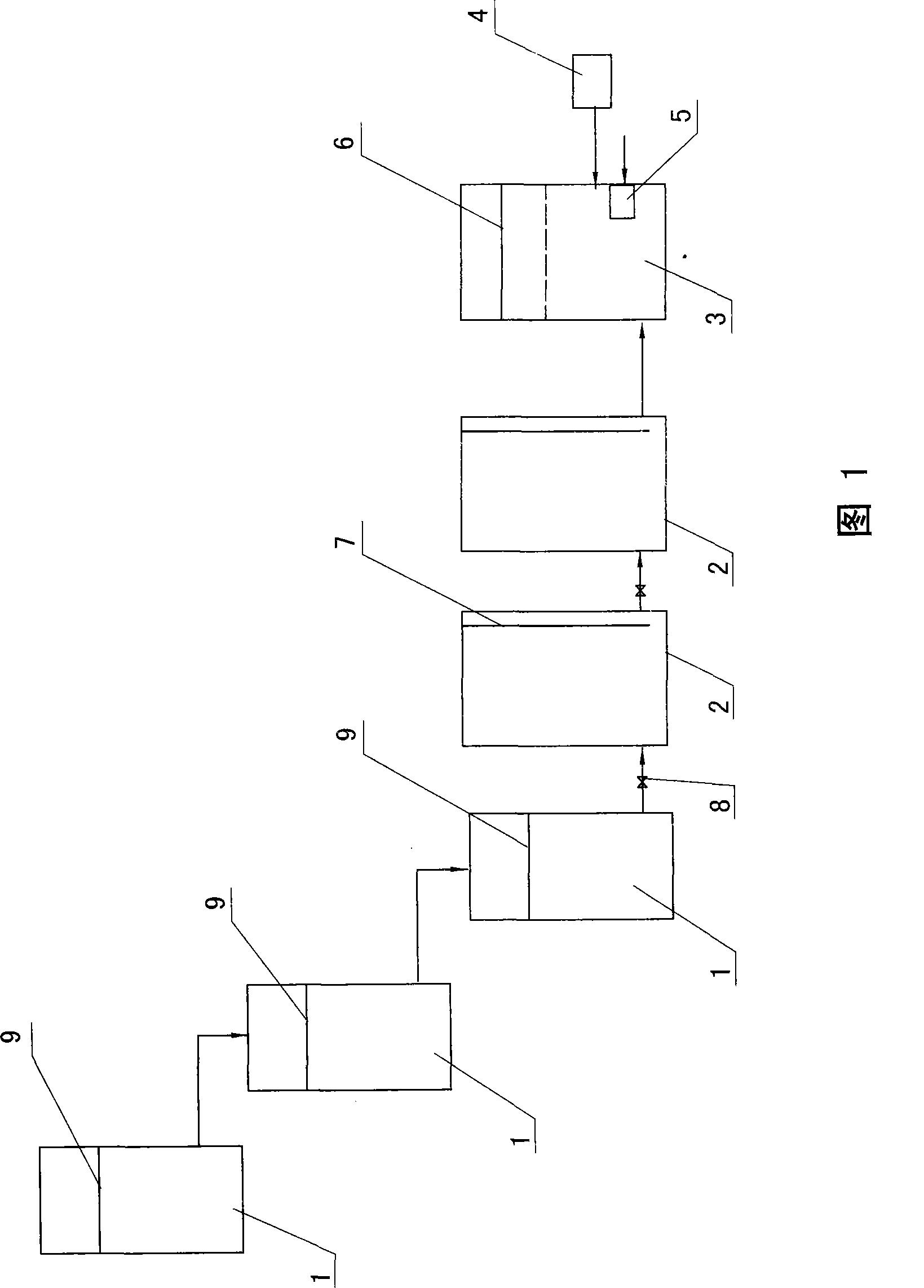

Water deep purification method

InactiveCN105540987APromote absorptionImprove purification effectWater contaminantsWater/sewage treatment bu osmosis/dialysisFlocculationActivated carbon

The invention belongs to the field of waste water treatment, and in particular relates to a water deep purification method. The water deep purification method comprises the following steps: step I, an adsorption step: adding powdered adsorbent into sewage, and mixing the powdered adsorbent and the sewage to enable the powered adsorbent to be in contact with the sewage; step II, a flocculation step: adding magnetic powder, and forming floc in the sewage; step III, a precipitation step: precipitating the floc, and separating the sewage into pure water and precipitated sludge; and step IV, a refluxing step. By virtue of flocculation and precipitation by adding carbon and magnetic powder, the unsaturated loss problem and low settlement speed problem of powder activated carbon can be simultaneously solved. The water deep purification method has the characteristics of simple structure, small size and wide application range.

Owner:QINGDAO PACIFIC CHEM EQUIP CO LTD

Waste alkali solution recovery method

InactiveCN102616968AGuaranteed continuityAlleviate Difficult Filtration ProblemsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSpinningWastewater

The invention discloses a waste alkali solution recovery method, which is mainly applicable to recovery of waste alkali solution generated during dipping and pressing of pulp in viscose fiber production, and is also applicable to recovery of alkali solution generated during papermaking, pulping, dying, spinning and the like in textile industries. Through procedures of two-stage coagulation, two-stage precipitation and filtration, oxidization, adsorption and the like, the waste alkali solution recovery method ensures continuity of production, reduces filtration difficulties, reduces energy consumption, and enables the production to be more stable. After the alkali solution is treated by the method, the content of impurities in the alkali solution is less, and the chromaticity of the alkali solution is low, thereby realizing the aim of recycling waste alkali. According to the method, equipment investment and energy consumption are low, and operation expense is low; and the method has the characteristics of environmental friendliness, safety and high production efficiency, has remarkable benefits, and can reduce the pollution of the waste alkali on environment.

Owner:YIBIN GRACE +2

Method for soda recovery and color removal after mercerization in dyeing and printing field and apparatus thereof

InactiveCN101367592AImprove cleanlinessGuaranteed continuityMultistage water/sewage treatmentWater/sewage treatment by heatingFluid levelImpurity

The invention provides a mercerization alkali recovery and color removing method and the device in dyeing field. The invention is characterized in that the method comprises the following steps: (1) filtering, (2) evaporating, (3) color removing and (4) filtering. In the color removing step, hydrogen peroxide is sprayed into a container with alkali liquid through a jet pump, and at the same time, an aeration pipe is equipped to accelerate the reaction until the alkali liquid becomes clear without any color. The device comprises a plurality of filters, a plurality of evaporators, a container for accommodating the filtered and condensed alkali liquid, a jet pump for spraying the hydrogen peroxide into the container, an aeration pipe for accelerating the reaction and a filter for removing the impurity in the liquid. Each of the evaporator is provided with a fluid level gauge and a proportional valve controlled by the evaporator. After the mercerization alkali liquid is filtered by the filters and condensed by the evaporator, the alkali liquid is stored in the container. The outlet of the jet pump is communicated with the container. The aeration pipe is emerged into the alkali liquid. The outlet of the container is provided with the filter. After the alkali is transferred into the colorless and clear alkali liquid, the alkali can be directly reused, and therefore the source can be saved.

Owner:LUTAI TEXTILE

Method and device for processing high-concentration undegradable waste water by using jet flow membrane bioreactor (MBR)

InactiveCN101962249AStop lossFine grainTreatment with anaerobic digestion processesWater/sewage treatment bu osmosis/dialysisHigh concentrationChemical oxygen demand

The invention discloses a method and a device for processing high-concentration undegradable waste water by using a jet flow membrane bioreactor (MBR). The main process is performed in a hybrid anaerobic reactor, an intermittent tank, the jet flow MBR, a small-aperture ultrafiltration membrane system and a multiple-effect oxidation system. The device comprises a regulating tank, the hybrid anaerobic reactor, the intermittent tank, the jet flow MBR, the small-aperture ultrafiltration membrane system and the multiple-effect oxidation system in turn. The method and the device have the advantages that: the oxidation effects of the hybrid anaerobic reactor and the intermittent tank fully improve the biochemical property of the waste water; organics are effectively removed from the jet flow MBR and the membrane pollution is effectively controlled; operation energy consumption is low and noises are low; the cut-off molecular weight of a small-aperture ultrafiltration membrane in the small-aperture ultrafiltration membrane system is 1,000 to 30,000 dalton, so that the chemical oxygen demand (COD) and the chroma of the micromolecular organics can be further removed; and the effluent of the whole system has a high quality and reaches the first-grade A discharge standards of the industry, and the COD of the effluent is less than or equal to 50mg / L, so that the high-concentration undegredable waste water is treated effectively and discharged after meeting standards.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

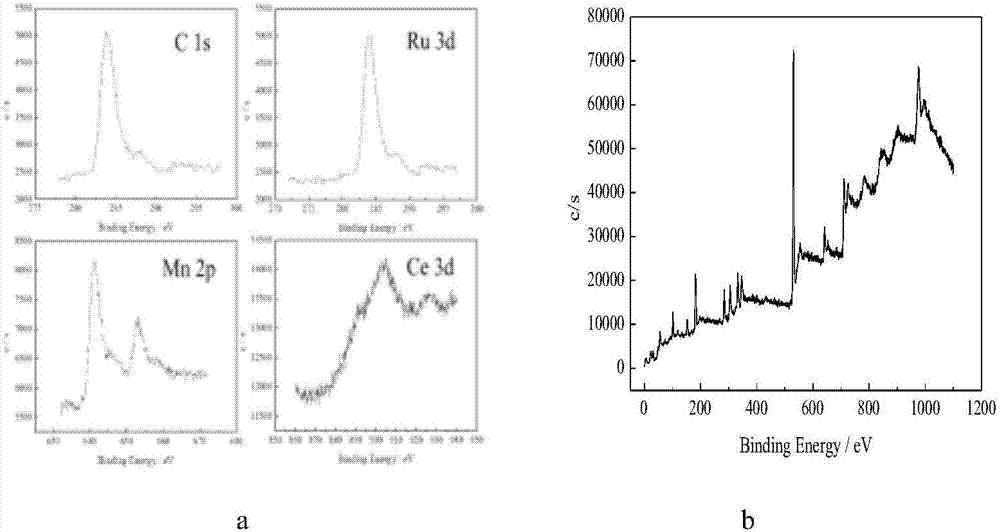

Preparation method of catalyst for treatment of biorefractory industrial organic wastewater

InactiveCN107537459AEasy to handleEliminate ChromaCatalyst carriersWater contaminantsIndustrial wastewater treatmentActivated carbon

The invention discloses a preparation method of a catalyst for treatment of biorefractory industrial organic wastewater. Treatment can be achieved at normal temperature and normal pressure by an air catalytic oxidation method. The catalyst is for a catalytic oxidation method for treatment of low-concentration (COD being less than or equal to 1000 mg / L) biorefractory industrial organic wastewater;and defects of a wet catalytic oxidation technology, such as high energy consumption, poor safety and short life of a catalyst in industrial wastewater treatment are mainly solved. A monolithic activecarbon carrier is modified by adding a rare earth compound, precious metal elements (Ru, Pt, Pd) and transition metal elements (Fe, Mn, V) at a certain ratio are loaded in an impregnation mode onto gamma-Al2O3 to prepare a coating material; and the coating material is uniformly applied onto the rare earth modified honeycomb monolithic carrier in a mode of vacuum negative pressure; and through processes such as drying, roasting, activation, etc., a monolithic catalyst with high activity, high stability and long life and for catalytic oxidation technical treatment of wastewater is prepared.

Owner:云南省贵金属新材料控股集团有限公司

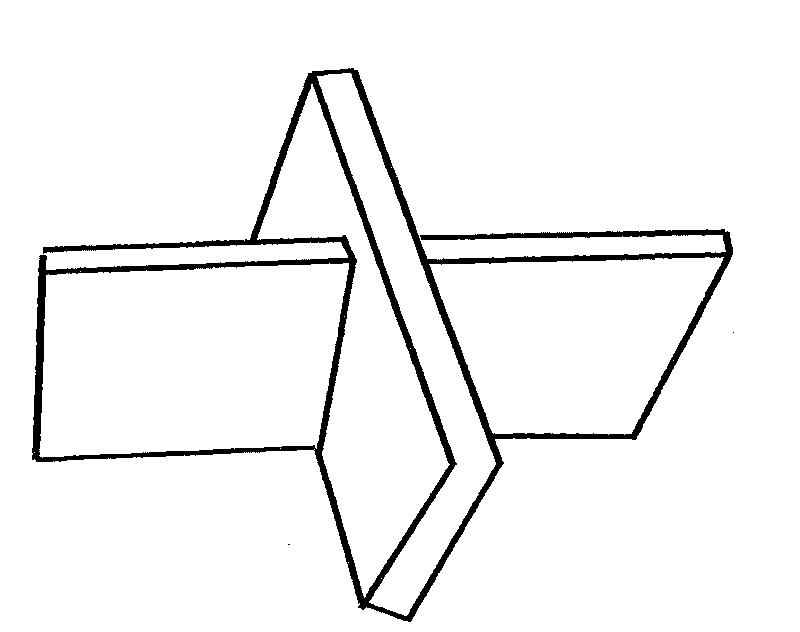

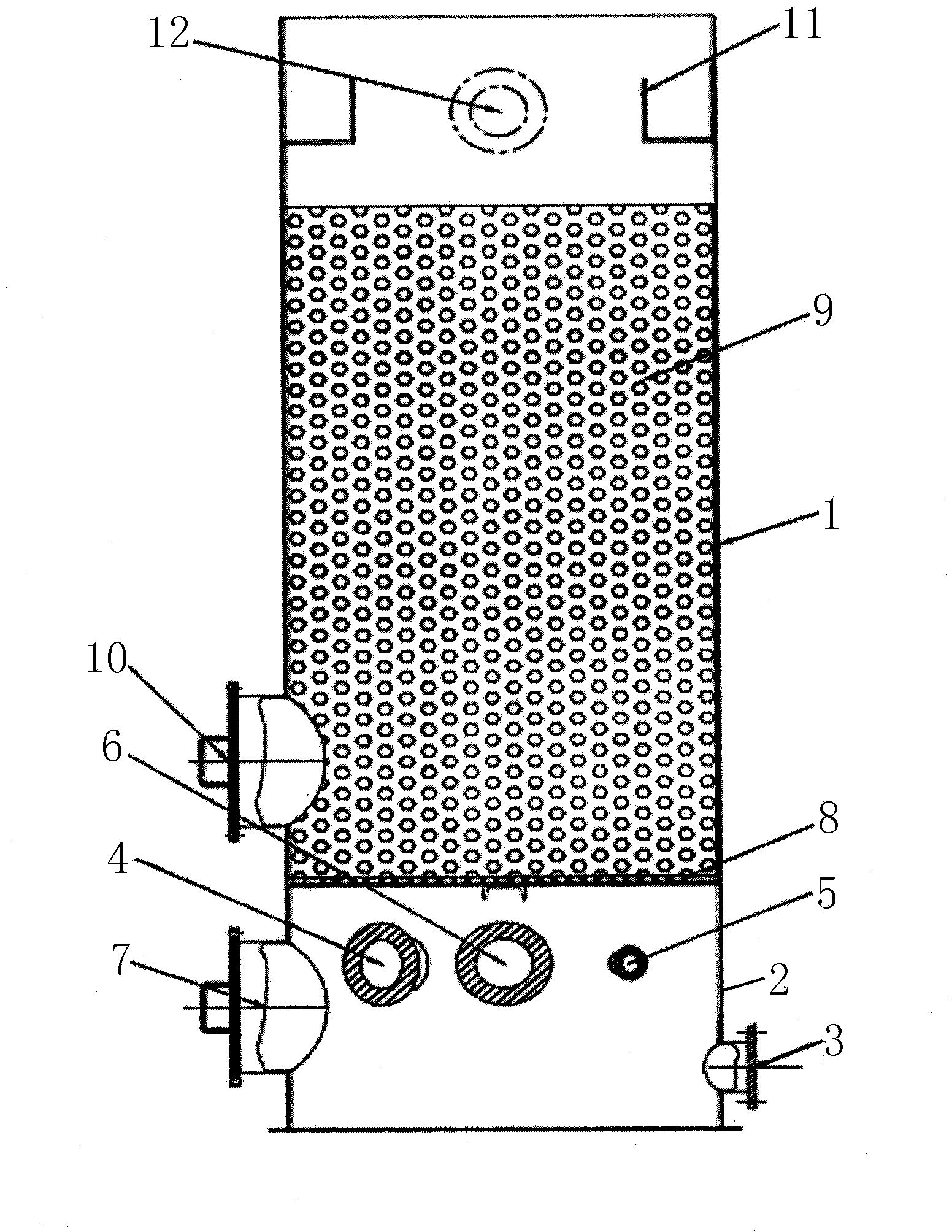

Micro-electrolysis double-Fenton reaction tower

InactiveCN104229948AImprove biodegradabilityRemoval of organic matterWater/sewage treatment by oxidationFenton reactionElectrolysis

The invention discloses a micro-electrolysis double-Fenton reaction tower which is characterized in that an aerator pipe, a water inlet pipe, a hydrogen peroxide feed pipe, a backwash water inlet pipe and a manhole are formed in the periphery of a base of a cylinder; a mounting and supporting layer is tiled between the base and the cylinder; iron-carbon packing is filled inside the cylinder through a filling hole formed in one side of the cylinder; an annular overflow weir is arranged on an inner edge on the top of the cylinder; and a water outlet pipe is arranged on a cylindrical wall of the cylinder which corresponds to the annular overflow weir. According to the arrangement, the micro-electrolysis double-Fenton reaction tower disclosed by the invention has the advantages that synchronous electrolysis and oxidation of sewage are realized, most of organic matters and chroma in wastewater can be removed, and the biodegradability of the sewage is improved.

Owner:SHANDONG YUANBAO ENVIRONMENTAL PROTECTION EQUIP

Oil-bearing car-washing wastewater treatment method and equipment

InactiveCN106946377AFast precipitationGood clarificationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFiltrationWater quality

The invention provides a car-washing wastewater treatment method and equipment which are applied to small-sized car-washing stations. The car-washing wastewater treatment method comprises the following steps of: clarifying in a coagulating sedimentation tank with sloping plates by using a coagulant; carrying out turbidity removal and oil absorption by using fiber bundle media; carrying out air-water backwashing after the fiber bundle media become invalid; carrying out oil removal treatment on oil stain accumulated in the fiber bundle media by adding a cleaning agent at a certain water temperature; for residual organic matters of the fiber bundle media, firstly soaking the fiber bundle media by using an agent, and then cleaning; and adsorbing the organic matters and a surface active agent by using diatomite and activated carbon. The equipment adopting the method comprises the coagulating sedimentation tank designed by modular combination, a fiber filtration tank and an adsorption tank; and matched wastewater collection tanks and clear water tanks can be buried in the ground. The equipment is small in volume, low in manufacturing cost and operation cost, simple to operate and convenient to maintain and has a good effluent effect. The quality of water treated by the method and equipment can reach Water Quality Standard for Domestic Miscellaneous Water (CJ / T48-1999). The method and equipment have wide application prospect.

Owner:BEIHUA UNIV

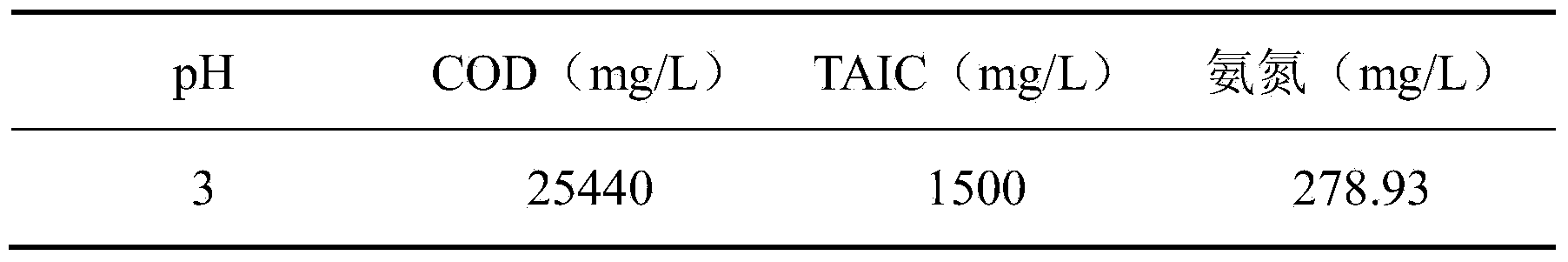

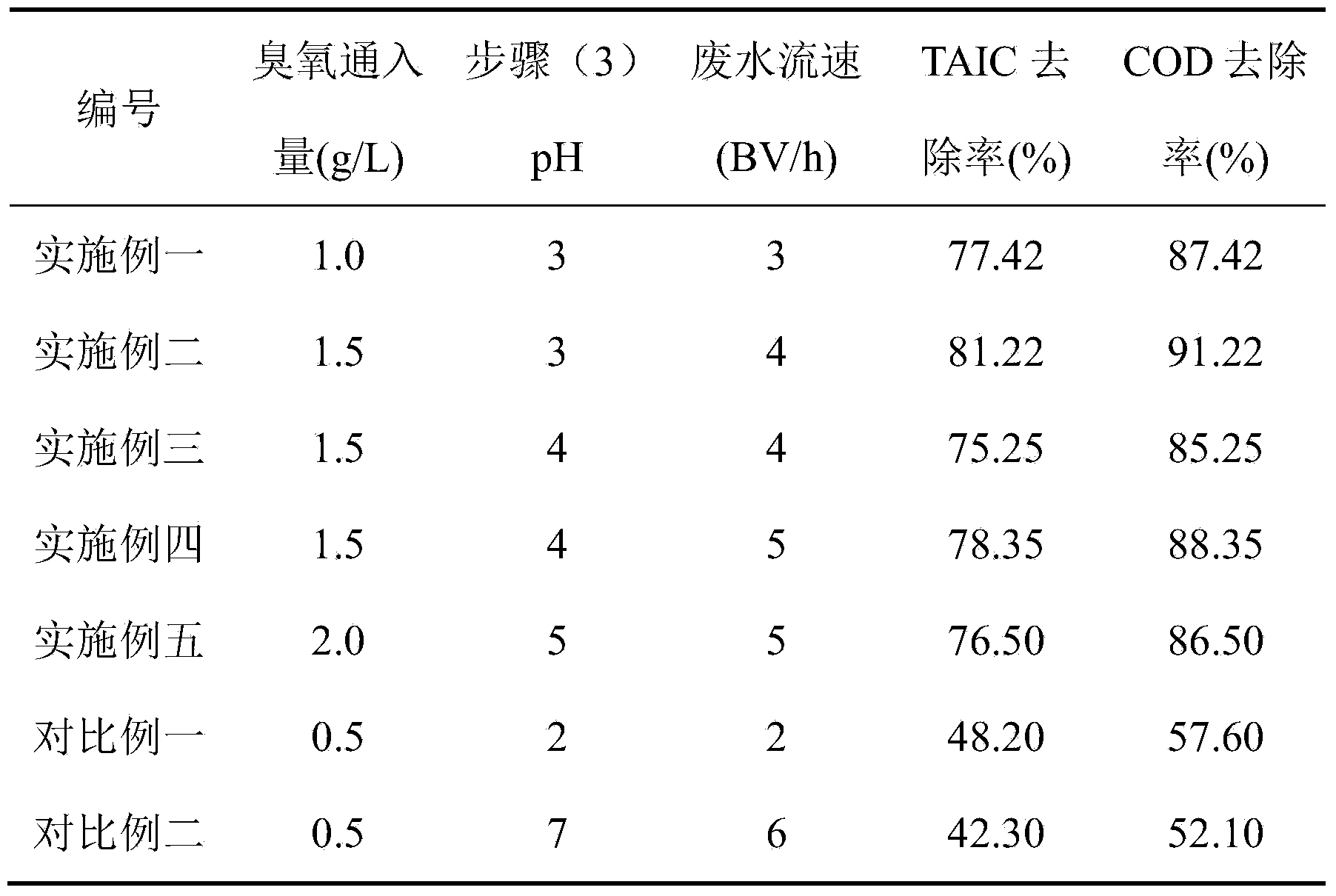

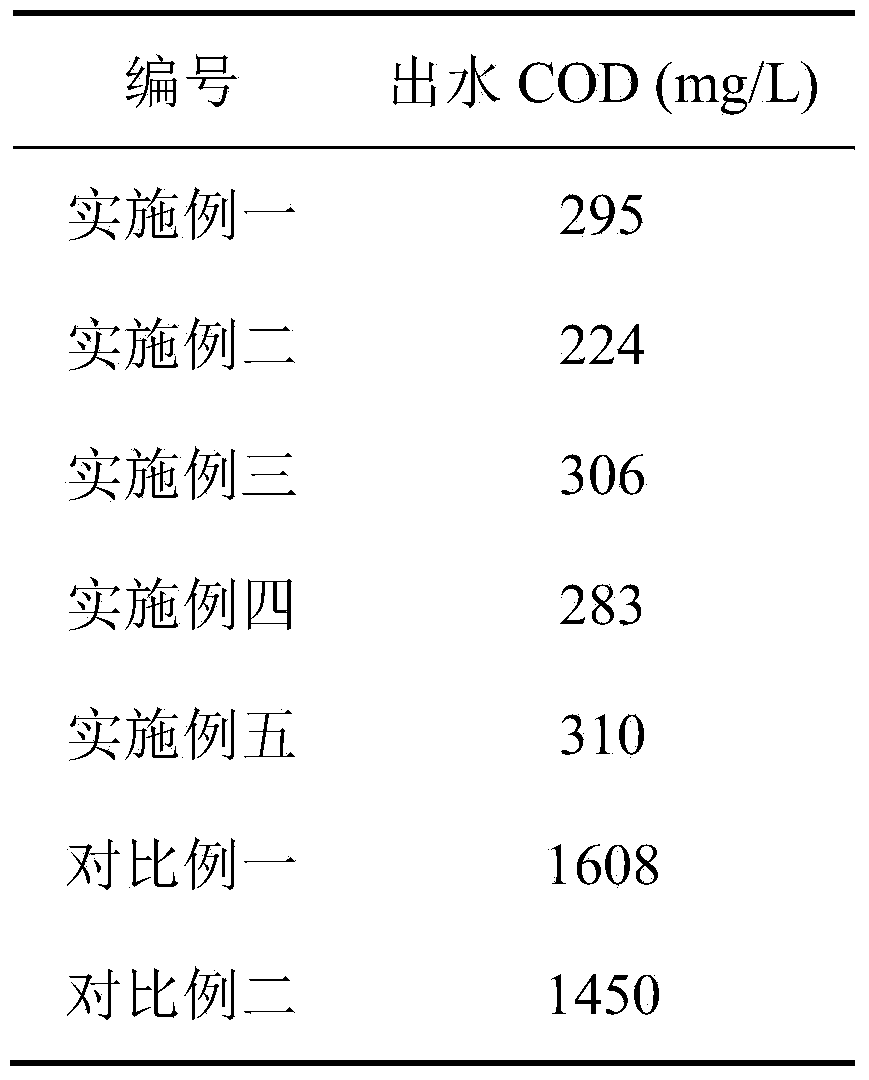

Method for processing triallyl isocyanurate production wastewater

InactiveCN104071950AEfficient degradationImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentOzone generatorWater quality

The invention provides a method for processing triallyl isocyanurate production wastewater. The method is characterized by comprising the following steps: homogenizing, namely mixing wastewater with domestic sewage for primarily adjusting the quality of the wastewater; ozone oxidation treatment, namely feeding the homogenized wastewater to an ozone reaction pool, generating ozone by adopting an ozone generator, and filling the ozone reaction pool with ozone by adopting a microporous aerator, wherein the ventilation quantity of ozone is 1.0-2.0g / L; resin adsorption, namely adding an acid to the wastewater after ozone oxidation treatment for adjusting the pH to 3-5, and then controlling the flow velocity of the wastewater after the pH is adjusted to 3-5BV / h, so that the wastewater after the pH is adjusted passes through a resin adsorption bed; biochemical treatment, namely adding an alkali to the wastewater passing through the resin absorption bed for adjusting the pH to 6-8, and then sequentially feeding to an anaerobic tower and a biochemical reaction basin to carry out biochemical treatment; finally, sequentially processing by a coagulation reaction pool and a sand filter chamber, thereby achieving the discharge standard.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

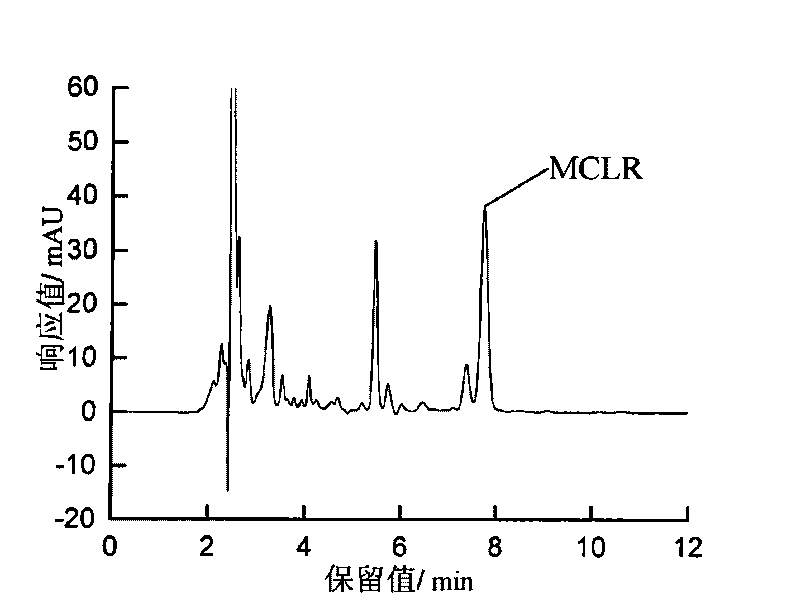

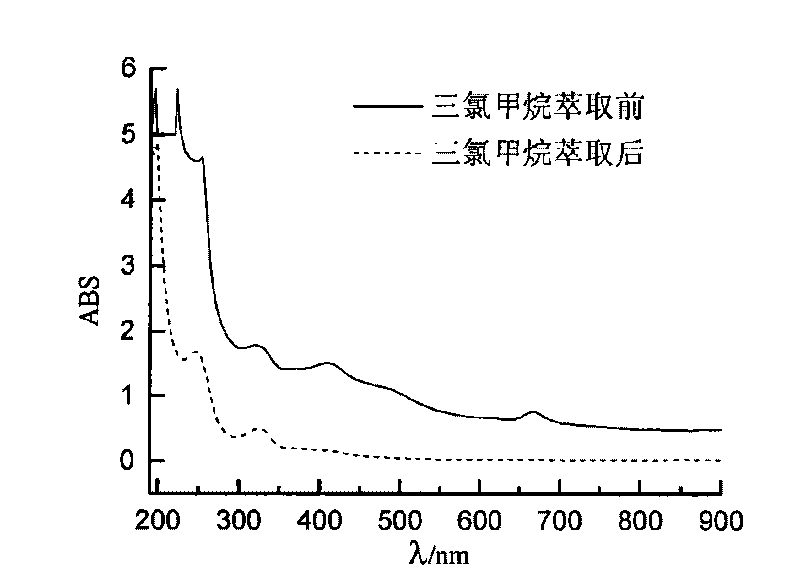

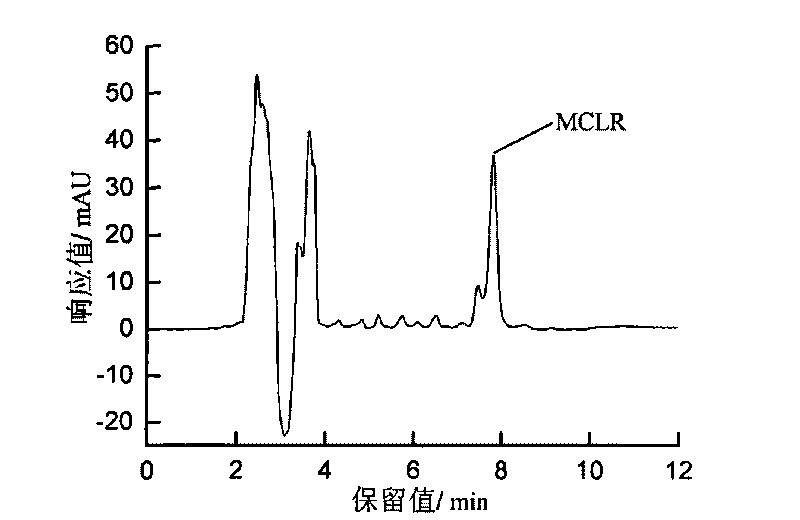

Method for purifying microcystins MCLR through extraction and normal-pressure column chromatography

The invention relates to the field of analytical chemistry, in particular to a method for purifying microcystins MCLR through extraction and normal-pressure column chromatography. The method comprises the following steps: 1) crushing algae cells; 2) performing crude extraction with methanol; 3) performing liquid-liquid extraction; 4) performing C18 solid-phase extraction; 5) performing Sephadex LH-20 gel chromatography and collecting MCLR activity peaks; and 6) performing DEAE ion-exchange chromatography, collecting MCLR activity peaks and obtaining pure MCLR. The method provided by the invention has the advantages of simplicity, effectiveness, economical efficiency, implementation capability under common experimental conditions and relative stability, and can prepare milligram-grade pure MCLR of which the purity is proved to be up to over 85 percent by HPLC analysis.

Owner:BEIJING FORESTRY UNIVERSITY

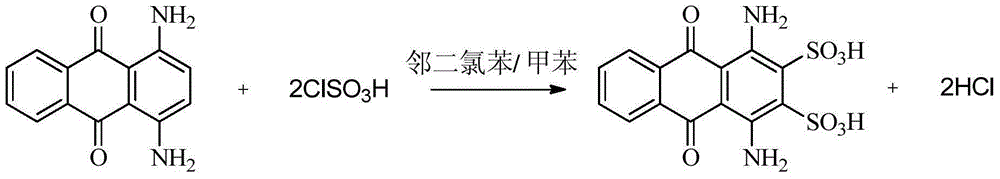

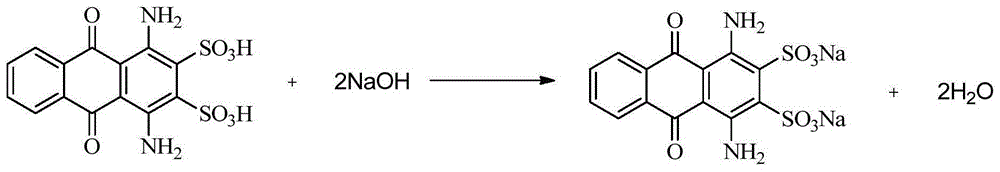

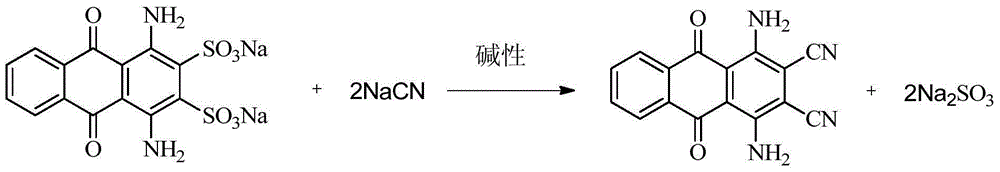

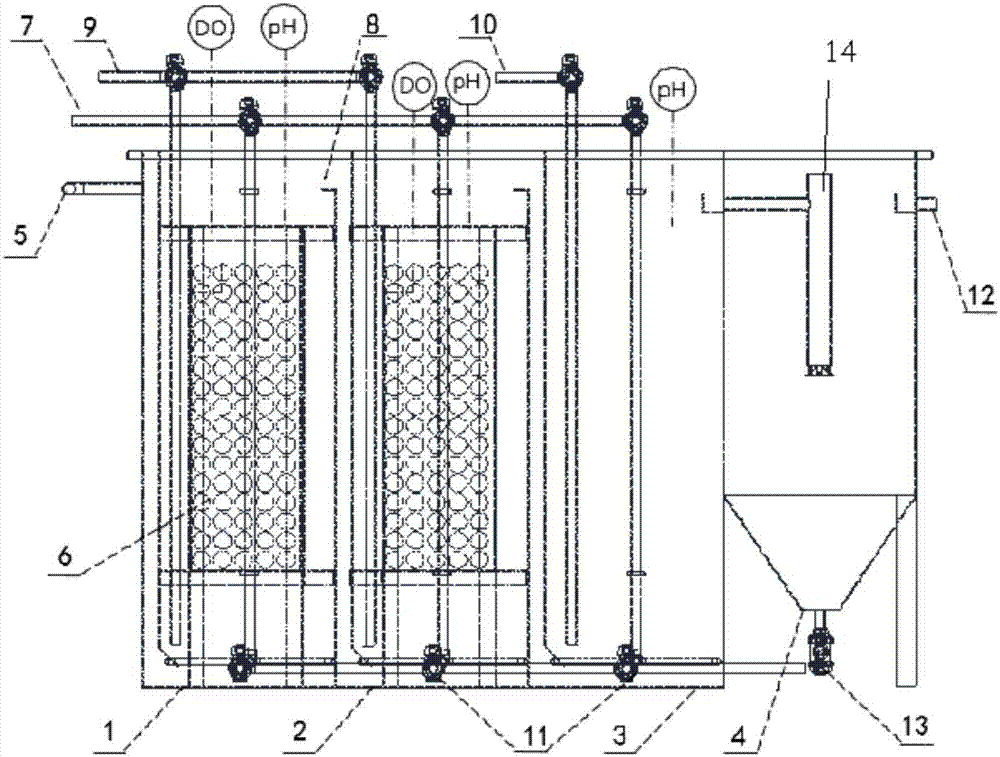

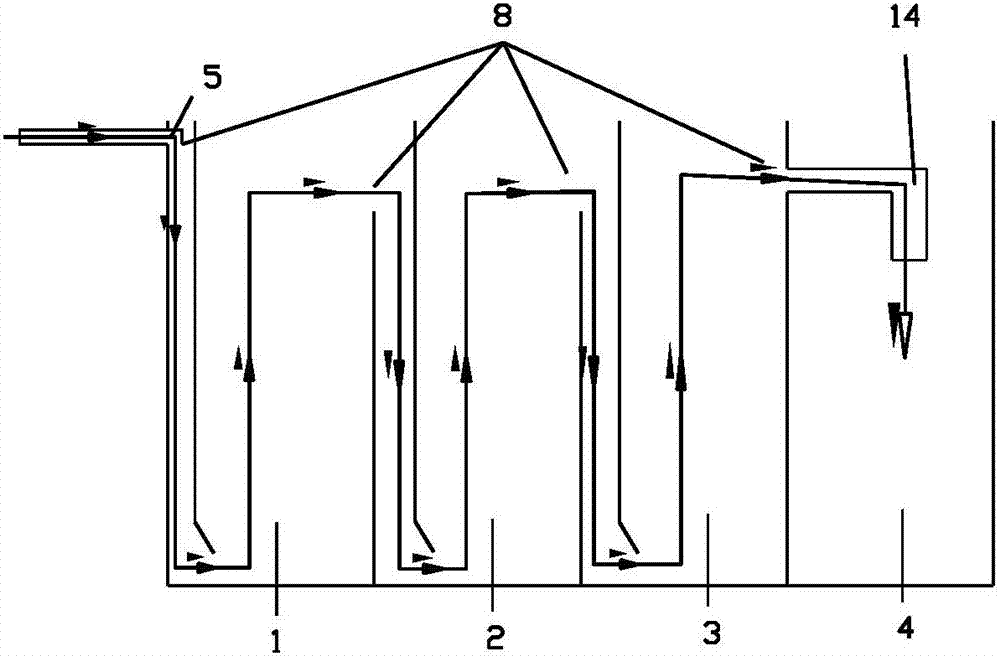

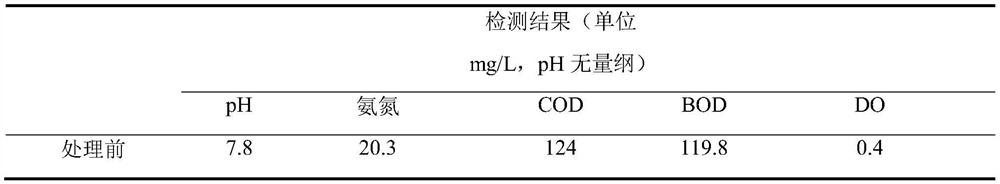

Treatment process of dicyanogen wastewater generated during production of disperse blue 60

ActiveCN105110545ARemove CODEliminate ChromaWater contaminantsMultistage water/sewage treatmentChemical oxygen demandCyanide

The invention discloses a treatment process of dicyanogen wastewater generated during production of disperse blue 60. The process includes the steps of at 220-300 DEG C and under a pressure of 2-10Mpa, subjecting the dicyanogen wastewater occurring during the production of the disperse blue 60 is subjected to wet oxidation and filtering to obtain filtrate I; removing ammonia nitrogen by means of a blow-off method or a magnesium ammonium phosphate precipitation method so as to obtain filtrate II; under alkaline condition, performing ozonation discoloration and / or adsorption decoloring as well as filtering to obtain filtrate III; adjusting pH of the filtrate III to 4-9, performing concentrating, collecting condensate and concentrate, directly discharging the condensate, and subjecting the concentrate to crystallization separation to obtain a salt. The dicyanogen wastewater is treated, by means of wet oxidation, ammonia nitrogen removal, oxidization discoloring and concentration crystallization, residual cyanide and DMF (dimethylformamide) in the wastewater are effectively decomposed, and COD (chemical oxygen demand) and chromaticity of the wastewater are decreased.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Micro-electrolysis pretreatment device of printing and dyeing wastewater, and device thereof

PendingCN107010699AFast removal rateFast electrochemical reactionWater treatment parameter controlWater contaminantsElectrolysisWater flow

A micro-electrolysis pretreatment device of printing and dyeing wastewater comprises a primary baffled micro-electrolysis cell, a secondary baffled micro-electrolysis cell, a neutralization tank and a sedimentation tank which are serially arranged, and wastewater enters a reaction tank from the bottom end through flow guiding channels arranged in the primary baffled micro-electrolysis cell, the secondary baffled micro-electrolysis cell, the neutralization tank and the sedimentation tank. The serially arranged primary and secondary baffled micro-electrolysis cells prolong the reaction time, increase the reaction space, and avoid the press hardening and channeling phenomena of a packing layer, caused by the gravity effect, under the action of the water flow and aeration; and the device can effectively remove the chroma and improve the biodegradability of printing and dyeing wastewater with high CODs, difficult degradation and poor biodegradability, greatly improves the treatment effect of the micro-electrolysis reaction, and provides good conditions for subsequent biochemical treatment.

Owner:江苏艾特克环境工程设计研究院有限公司

Ecological restoration method for black and odorous river channel

PendingCN113264633AStrong maneuverabilityThorough governanceWater resource protectionWater treatment parameter controlTreatments waterEcosystem

The invention provides an ecological restoration method for a black and odorous river channel, and belongs to the technical field of sewage treatment. According to the method, ecological restoration is carried out on the black and odorous river channel from five aspects of source control and sewage interception, bottom mud treatment, water body purification, ecological restoration and maintenance management, and the method is high in operability, thorough in treatment and high in treatment efficiency; through reconstruction of a riverway ecological system, the self-cleaning capacity of the water body is gradually restored, the peculiar smell and chroma of the black and odorous water body are gradually eliminated, finally ecological balance of the water body is achieved, the water quality is improved, the water body ecological system can be healthily and stably developed for a long time, and good environment-friendly and ecological functions are achieved.

Owner:SCI RES ACADEMY OF GUANGXI ENVIRONMENTAL PROTECTION

Photocatalytic urea treatment and recycle device

PendingCN110015792ARealize reuse flushingEliminate ChromaWater/sewage treatment by irradiationWater treatment compoundsTurbidityPotassium

The invention provides a photocatalytic urea treatment and recycle device. The treatment device comprises a water inlet system, a flexible ceramic membrane filtering system, an activated carbon adsorption system and an ultraviolet sterilization system; the water inlet system comprises a water inlet pump and a water inlet pipeline; the flexible ceramic membrane filtering system is composed of two layers of flexible ceramic membrane assemblies of outer-layer ceramic membrane 1 and inner-layer ceramic membrane 3; the activated carbon adsorption system is located between the outer-layer ceramic membrane 1 and the inner-layer ceramic membrane 3, and is composed of activated carbon and plant ash 2; and the ultraviolet sterilization system comprises an ultraviolet lamp 5. By means of the photocatalytic urea treatment and recycle device, colloid and suspended solids in urea can be filtered out, the chromaticity and the turbidity of the urea are removed, bacteria and viruses are killed, nitrogen, phosphorus and potassium in the urea are separated, recycled and reused as fertilizer, and the filtered urea is reused for washing hands, flushing bathrooms and the like.

Owner:BEIJING JIAOTONG UNIV

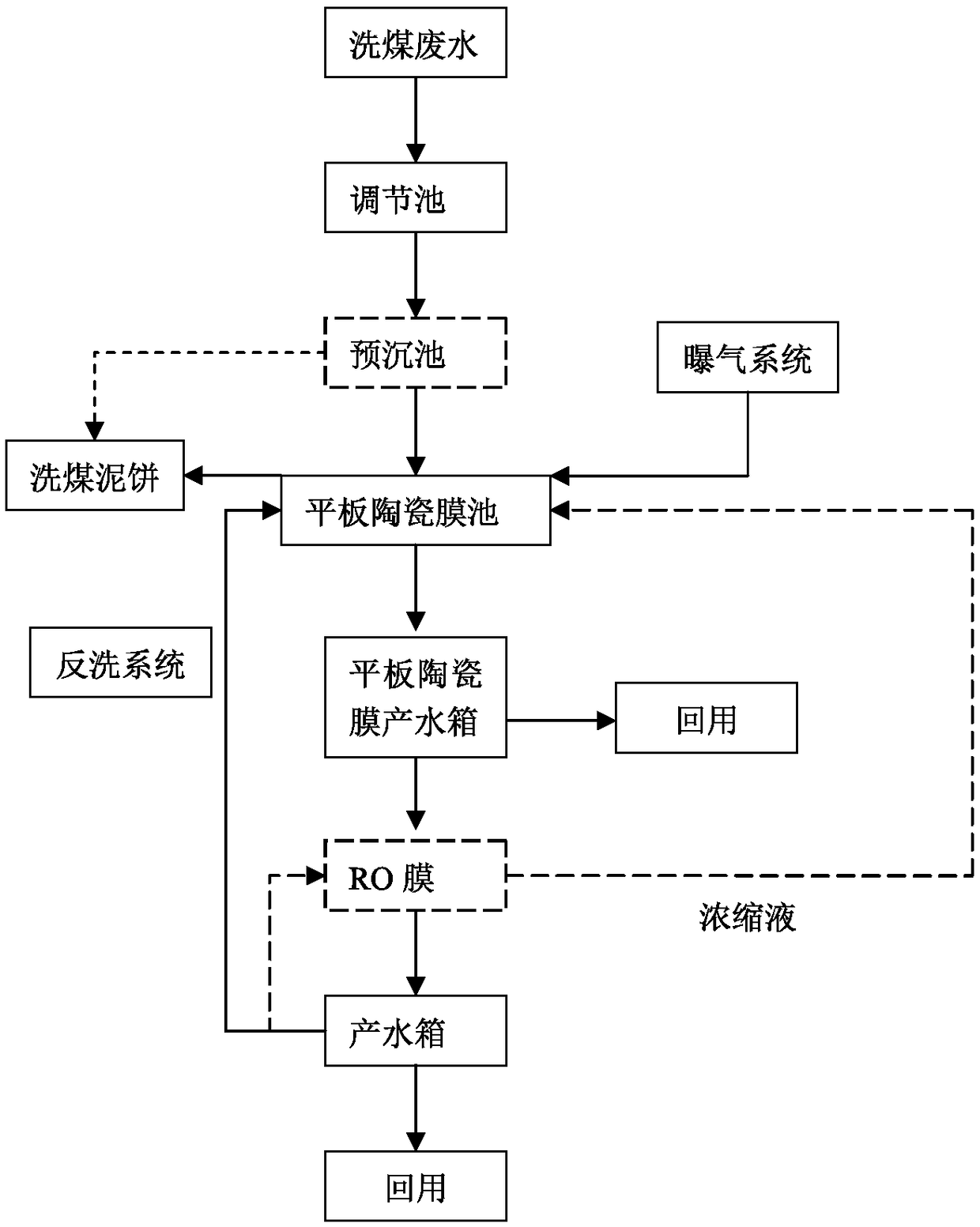

Processing method of coal mine water and/or coal washing waste water

InactiveCN109179578AEfficient removalHigh SS contentWater treatment parameter controlSpecific water treatment objectivesParticulatesResource utilization

The invention discloses a processing method of coal mine water and / or coal washing waste water. The processing method comprises following steps: 1, coal mine water and / or coal washing waste water is introduced into an adjusting pool to adjust water quality and water amount so as to obtain raw water; 2, the raw water is introduced into a flat ceramic membrane pool, a flat ceramic membrane assemblyis adopted for purification to remove small particles in the raw water and reduce the turbidity of produced water, wherein according to the operation mode of the flat ceramic membrane assembly, pumping, intermittent stopping, and backwash period are adopted alternatively; and 3, bottom sludge from the flat ceramic membrane pool is prepared into coal washing cakes which can be mixed with coal-air fuel, so that a fuel is prepared, and sludge resource utilization is realized, and produced water of the flat ceramic membrane assembly is subjected to deep treatment or is subjected to direct recycling as industrial recycled water. The processing method is capable of removing large particles, and small particles effectively; no medicine is added; the bottom sludge can be recycled as a fuel; the water quality of obtained water is stable, and recycling standards are reached.

Owner:SANDA FILM SCI & TECH XIAMEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com