Method for soda recovery and color removal after mercerization in dyeing and printing field and apparatus thereof

A color alkali and mercerizing technology, applied in the fields of printing and dyeing, textile printing and dyeing, can solve the problems of waste of resources, pollution of the environment, consumption of large sulfuric acid, etc., and achieve the effects of energy saving, low energy consumption, and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

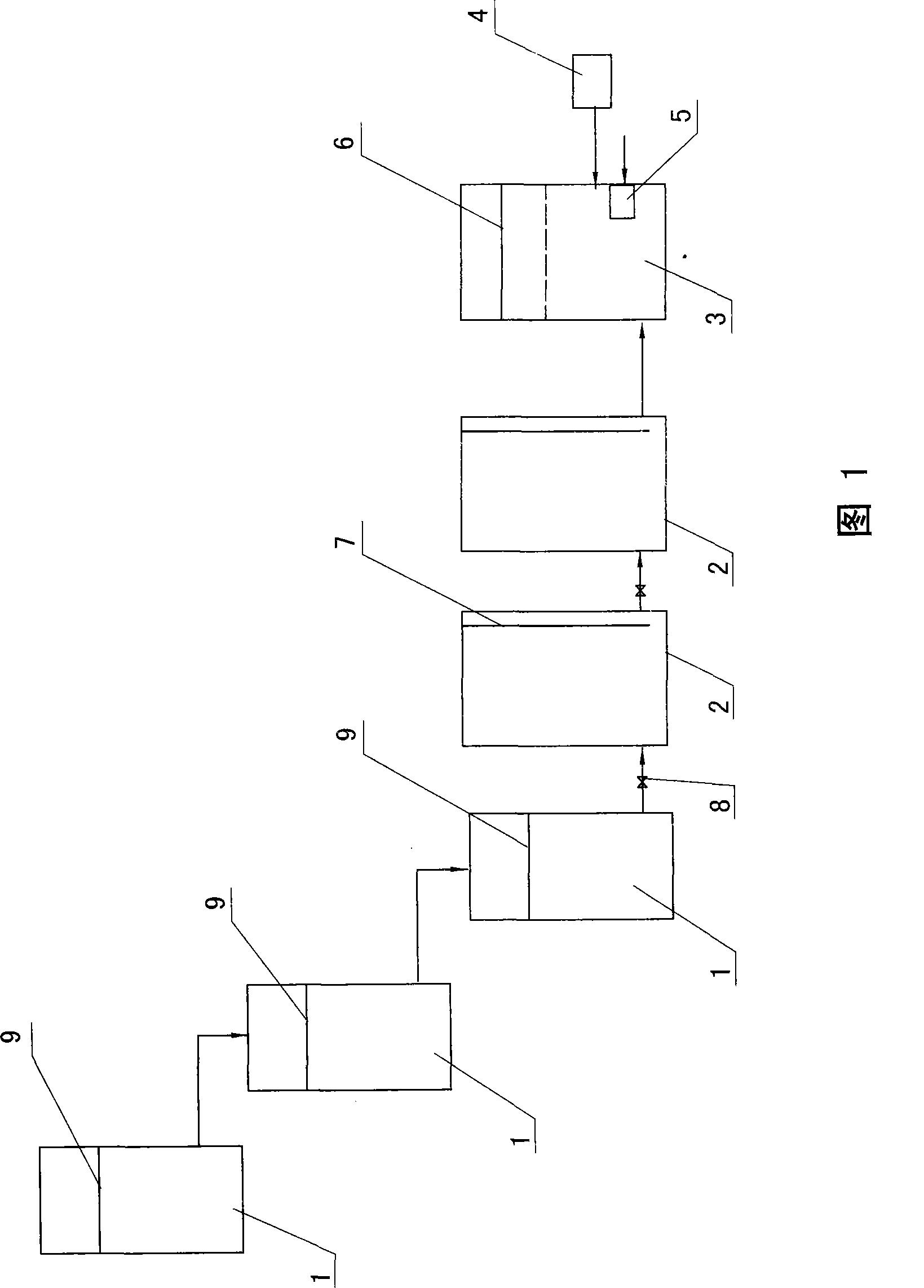

[0016] In the embodiment shown in Figure 1: the device contains 3 filters 1 and 2 evaporators. The three filters 1 are arranged in a straight line according to the order of filtration accuracy from low to high. The adjacent filters 1 are connected end to end, and the outlet of the filter 1 at the end is connected to the first evaporator 2, and the outlet of the evaporator 2 is connected to the first evaporator 2. The second evaporator 2, and above-mentioned two evaporators 2 are all equipped with a liquid level gauge 7 and a proportional valve 8 controlled by it, the outlet of the second evaporator 2 is connected to the container 3, and the outlet of the jet pump 4 is communicated with the container 3, The aeration pipe 5 is immersed in the color alkali solution, and the outlet of the container 3 is connected with a filter 6 .

[0017] When working: the color alkali solution after mercerizing is filtered by three filters 1 and evaporated and concentrated by two evaporators 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com