Light-Fenton catalytic oxidation coal chemical industry wastewater deep treatment system and coal chemical industry wastewater treatment method thereof

A Fenton catalytic oxidation technology for coal and coal chemical wastewater, which is applied in the fields of oxidized water/sewage treatment, energy wastewater treatment, light water/sewage treatment, etc., can solve the problems of sludge accumulation treatment effect, low efficiency and high cost, and achieve The effect of improving removal effect, increasing concentration and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

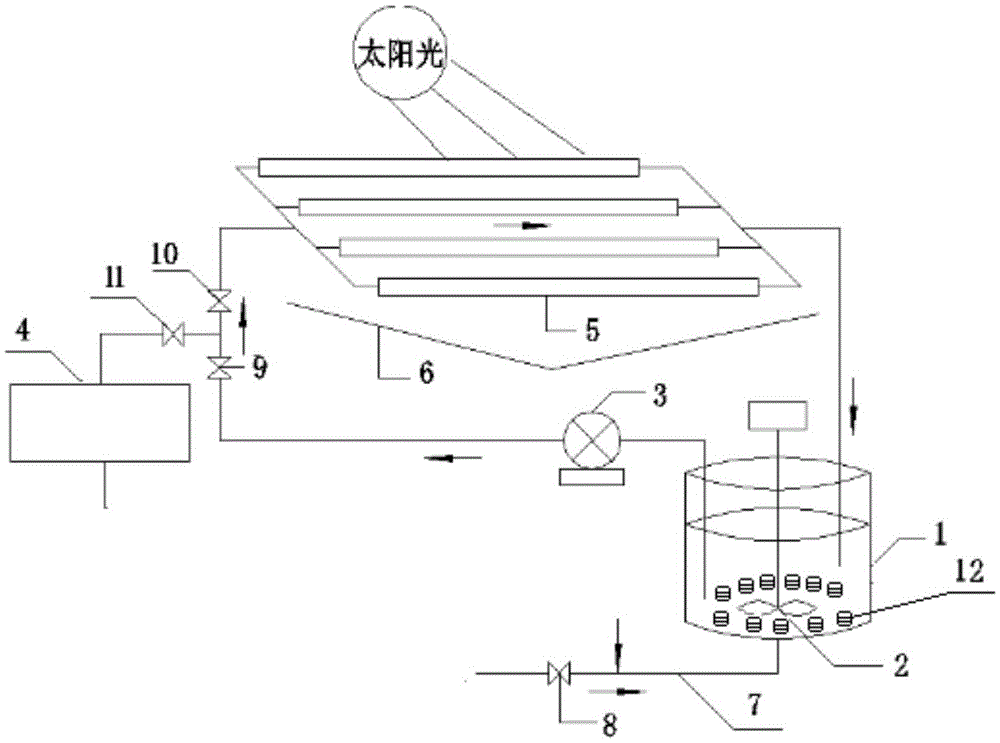

[0028] Specific implementation mode one: combine figure 1 Describe this embodiment, a light-Fenton catalytic oxidation coal chemical industry wastewater advanced treatment system in this embodiment, which includes a stirring tank 1, an agitator 2, a lift pump 3, a liquid storage tank 4, a plurality of light reaction tubes 5, light Reflector 6, water inlet pipe 7, gate valve one 8, gate valve two 9, gate valve three 10, gate valve four 11 and water flow distributor 12;

[0029] As described, one end of the water inlet pipe 7 is communicated with the gate valve-8, and the other end is communicated with the water inlet at the bottom of the mixing tank 1;

[0030] The water flow distributor 12 is arranged at the bottom of the mixing tank 1;

[0031] The plurality of photoreaction tubes 5 are arranged side by side, and one end of the plurality of photoreaction tubes 5 is connected with the liquid outlet of the liquid storage tank 4, and the other end is connected with the inlet of...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the material of the photoreaction tube 5 is colored glass attached with transition metal ions, and the transition metals are Co, Cr and Cu, wherein, Co accounts for 0.1%-2% of the total mole percentage of transition metals, Cr accounts for 0.1%-2% of the total mole percentage of transition metals, Cu accounts for 0.1%-0.3% of the total mole percentage of transition metals, and the rest is glass. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0035] Specific implementation mode three: combination figure 1 This embodiment will be described. The difference between this embodiment and the first embodiment is that a stirrer 2 is provided in the stirring tank 1 . Other compositions and connection methods are the same as those in Embodiment 1.

[0036] Specific implementation mode four: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the length of the photoreaction tube 5 is 50 cm, the inner diameter is 2 cm, the thickness is 1 cm, and the material is PE tube. Other compositions and connection methods are the same as those in Embodiment 1.

[0037] Specific implementation mode five: combination figure 1This embodiment is described. The difference between this embodiment and the first embodiment is that the diameter of the water inlet pipe 7 is 6 cm, and the material is PE pipe. Other compositions and connection methods are the same as those in Embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com