LED lamp bead preparation method

A technology of LED lamp beads and LED chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven light spots of LED lamp beads, achieve uniform light spots, increase brightness, and improve the uniformity of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to more clearly illustrate the implementation cases of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

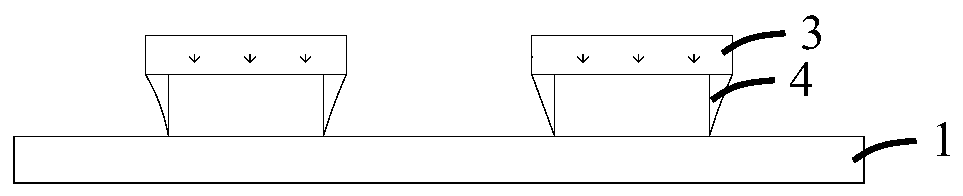

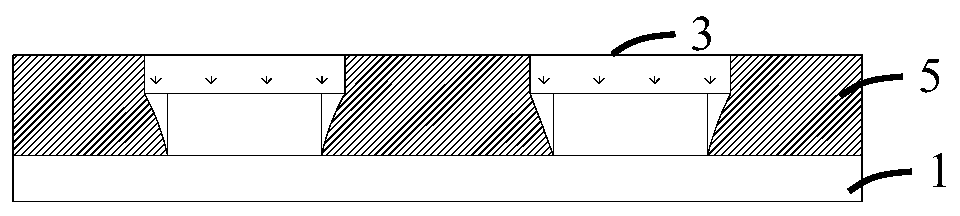

[0021] like Figure 1~4 Shown is a schematic flow chart of an embodiment of the LED lamp bead preparation method provided by the present invention. As shown in the figure, the preparation method includes:

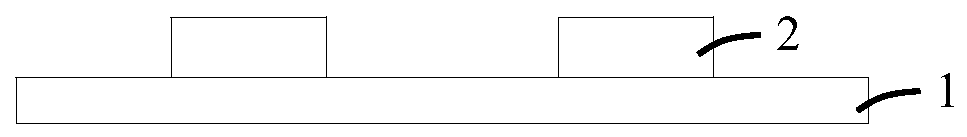

[0022] S10 Arrange the LED chips 2 on the surface of the substrate 1 according to rules, with the light-emitting side surface of the LED chips 2 facing upward, as figure 1 shown. Specifically, the shape and pitch of the arrangement of the LED chips 22 are adjusted ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com