Carbon-iron microbattery slow-release carbon source filler and preparation method thereof

A carbon-iron microbattery and slow-release carbon source technology, applied in anaerobic digestion treatment and other directions, can solve the problems of blocked carbon source release, low core strength, high pH in the effluent area, etc., so as to improve biodegradability and avoid effluent pH. Too high, the effect of improving effluent quality and carbon source utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

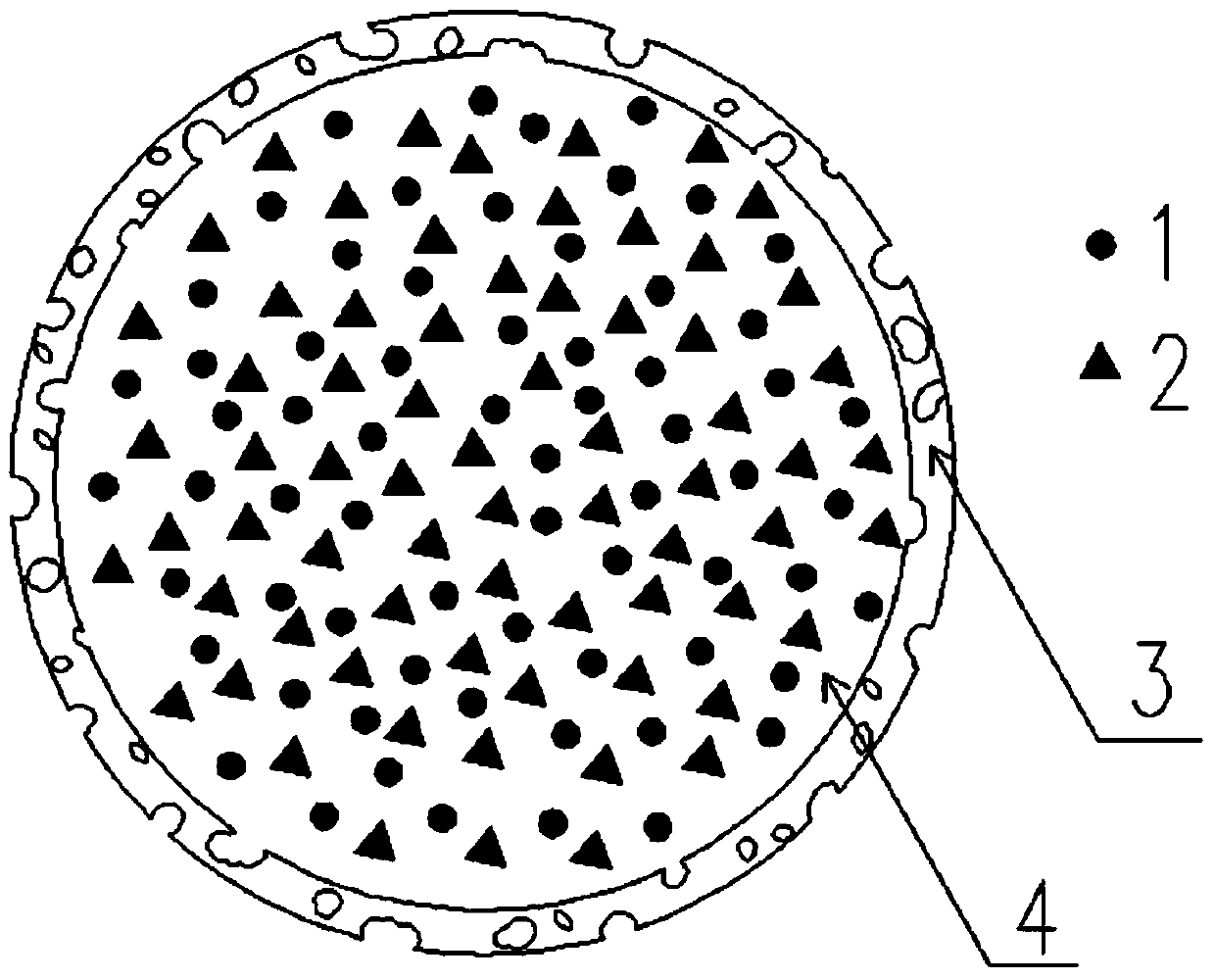

Image

Examples

Embodiment 1

[0035] In the present embodiment, the carbon-iron micro-battery slow-release carbon source filler used for groundwater pollution restoration, its preparation process is:

[0036] (1) Aerate the mixture of corn cob and corn stalk, which is the core 4 material, in ozone for 30 minutes, wash it twice with clean water, dry it for 5 days, and set aside;

[0037] (2) Crushing the natural carbon source material 1 obtained in step (1) to 60 mesh for later use;

[0038] (3) Sponge iron 2 is crushed to 80 mesh for later use;

[0039] (4) Diatomaceous earth and quartz sand are crushed to 60 mesh for later use;

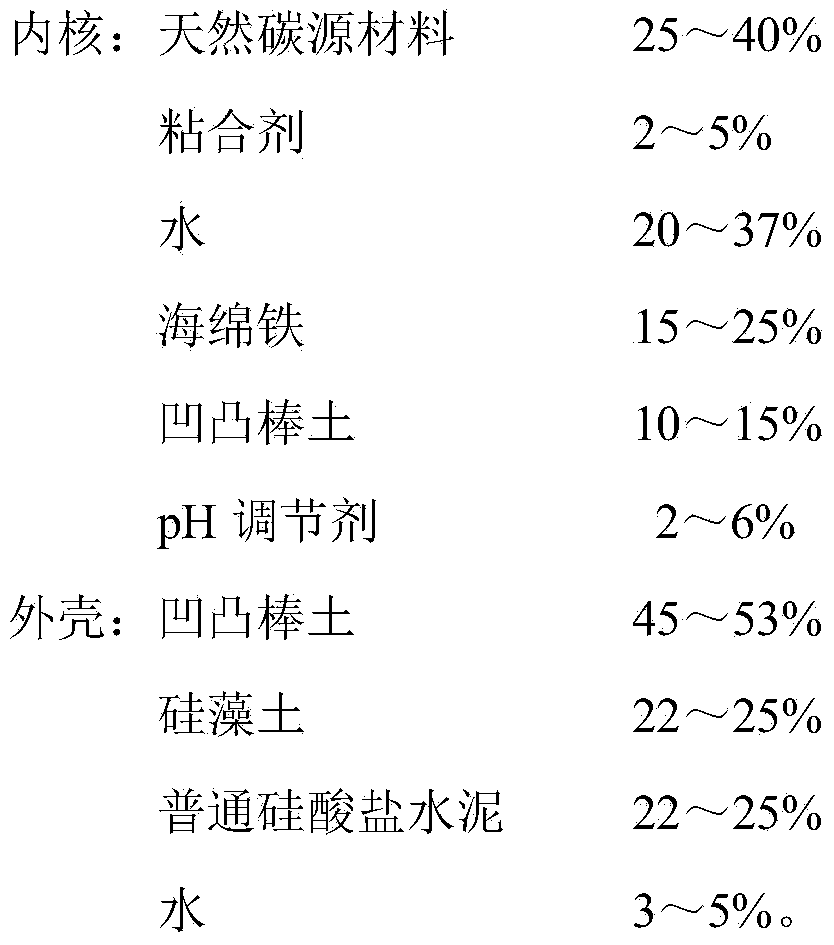

[0040] (5) Mix corn cob and corn stalk powder, sodium alginate, water, sponge iron 2, attapulgite and citric acid evenly, and gradually put them into the granulator, start the granulator, spray water gradually, and roll to the ball type. The composition and mass percentage of the core material are as follows: corn cob and corn stalk mixture 30%, sodium alginate 2%, water 37%, sp...

Embodiment 2

[0046] In this example, the preparation process of the slow-release carbon source filler used for the in-situ repair of the carbon-iron micro-battery in polluted groundwater is:

[0047] (1) Soak the kernel 4 material peanut shell in a hydrogen peroxide solution accounting for 5% (mass percentage) of hydrogen peroxide for 10 hours, take it out, rinse it with clean water 3 times, and dry it for 7 days for later use;

[0048] (2) Crush the natural carbon source material 1 obtained in step (1) to 50 mesh for later use;

[0049] (3) Crush the sponge iron to 90 mesh for later use;

[0050] (4) Diatomaceous earth and quartz sand are crushed to 40 mesh for later use;

[0051] (5) Mix peanut shell powder, gum arabic, iron sponge, attapulgite and sodium bicarbonate evenly, and the composition and mass percentage of core 4 are as follows: peanut shell 35%, gum arabic 4%, attapulgite 10%, sponge Iron 16%, sodium bicarbonate 5% and water 30%;

[0052] Add water to the granulator and ro...

Embodiment 3

[0058] In this example, the preparation process of the slow-release carbon source filler used for the in-situ repair of the carbon-iron micro-battery in polluted groundwater is:

[0059] (1) Soak the core material walnut shell in a hydrogen peroxide solution accounting for 5% (mass percentage) of hydrogen peroxide for 12 hours, take it out, rinse it with clean water 3 times, and dry it for 6 days for later use.

[0060] (2) Crush the natural carbon source material 1 obtained in step (1) to 40 mesh and set aside.

[0061] (3) Sponge iron 2 is crushed to 100 mesh and set aside.

[0062] (4) Diatomaceous earth and quartz sand are crushed to 50 mesh for later use;

[0063] (5) Put 10g of PVA with an alcoholysis degree of 89% in 90mL of water, dissolve in water at 60-70°C and stir for 20-30min, and use 10% PVA (polyvinyl alcohol) solution for later use;

[0064] The components of the inner core and the mass percentages of each component are: walnut shell 25%, 10% PVA solution 30%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com