Micro-electrolysis pretreatment device of printing and dyeing wastewater, and device thereof

A pretreatment device, printing and dyeing wastewater technology, applied in water/sewage treatment, water treatment parameter control, water/sewage treatment equipment, etc., can solve problems such as difficult to achieve effects, achieve fast removal rate, inhibit passivation and oxygen competition The role of cathode electrons, the effect of fast electrochemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

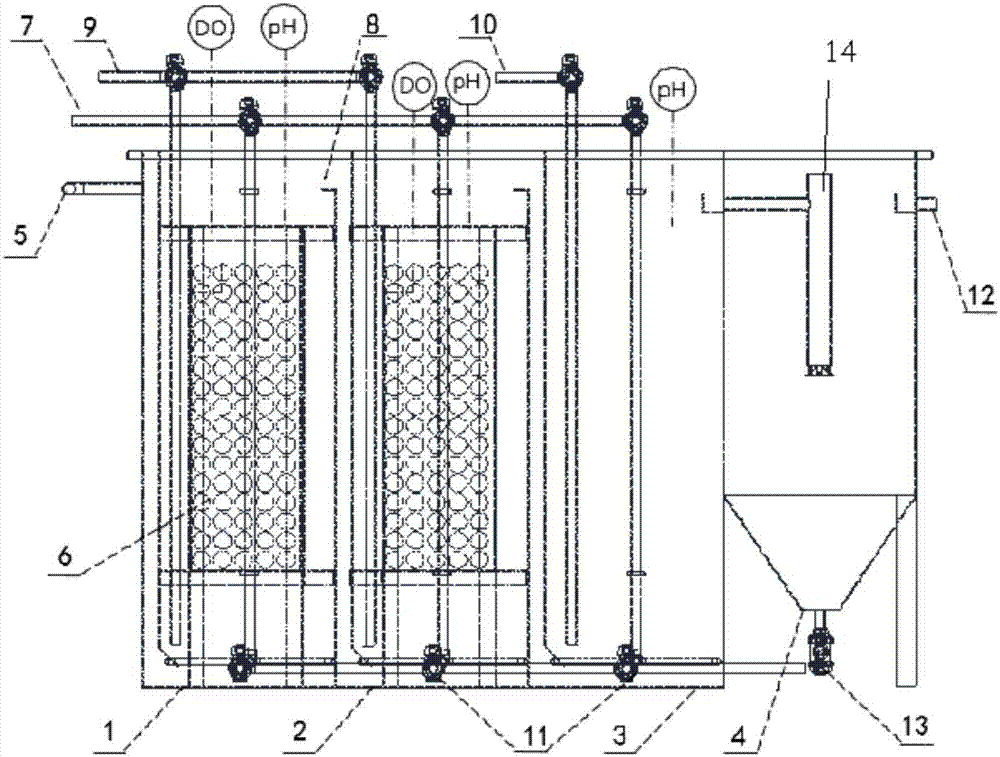

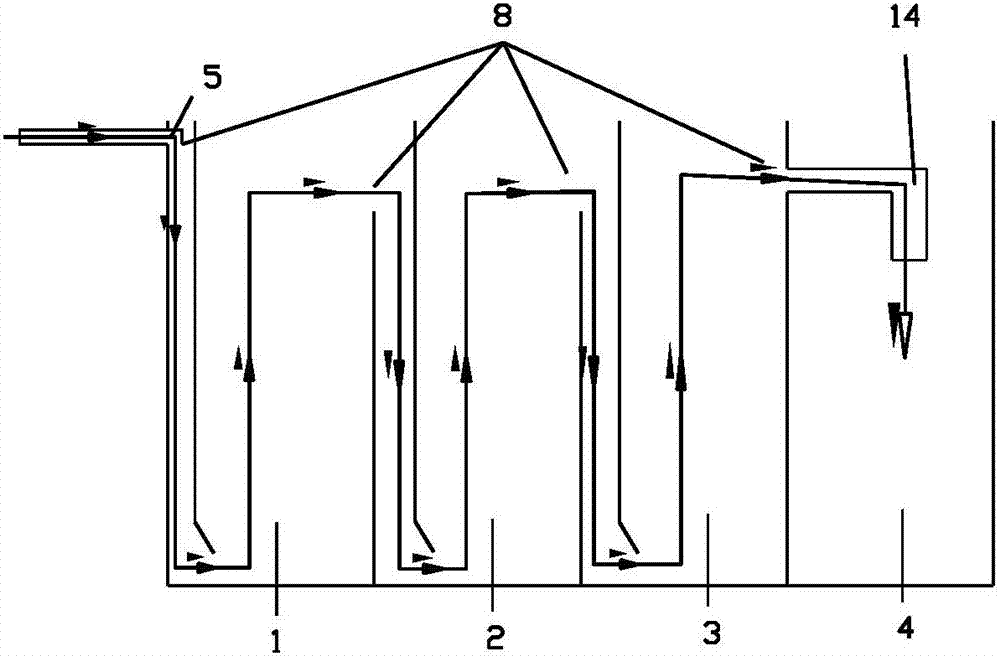

[0052] The printing and dyeing wastewater enters the primary baffled micro-electrolytic cell 1 and the secondary baffled micro-electrolytic cell 2 continuously from the water inlet 5, and the aeration is turned on to control the dissolved oxygen in the range of 0.8-1.0 mg / L, so that the printing and dyeing wastewater to be treated and The iron-carbon-aluminum particles in the baffle-type micro-electrolysis reaction cell fully contact and react, and the reaction time is 1 h.

[0053] At the same time, the pH online monitoring system monitors the pH of the solution in the baffle type micro-electrolysis reaction tank, and controls the pH range in the reaction tank to be 10-11 through an acid-base dosing device, and enters the neutralization tank 3 after reacting for 1.5 h. Use the pH online monitoring system to monitor the wastewater in the neutralization tank 3, and ensure that the pH of the effluent is 7-8 through the regulation of the acid-base dosing port, and then enter the s...

Embodiment 2

[0056] The printing and dyeing wastewater enters the primary baffled micro-electrolytic cell 1 and the secondary baffled micro-electrolytic cell 2 continuously from the water inlet 5, and the aeration is turned on to control the dissolved oxygen within the range of 0.5-0.8 mg / L, so that the printing and dyeing wastewater to be treated and The iron-carbon-aluminum particles in the baffle-type micro-electrolysis reaction cell fully contact and react, and the reaction time is 3 h.

[0057] At the same time, the pH online monitoring system monitors the pH of the solution in the baffle type micro-electrolysis reaction tank, and controls the pH range in the reaction tank to be 10-11 through an acid-base dosing device, and enters the neutralization tank 3 after reacting for 1.5 h. Use the pH online monitoring system to monitor the wastewater in the neutralization tank 3, and ensure that the pH of the effluent is 7-8 through the regulation of the acid-base dosing port 10 of the neutral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com