Process and device for treating tetracycline antibiotic wastewater

A technology of antibiotic wastewater and tetracyclines, applied in natural water treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of easy oxidation of iron powder, waste of iron powder, and reduction of iron-carbon micro-electrolysis capacity, etc. , to achieve the effects of enhanced adsorption, longer service life, and shorter start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

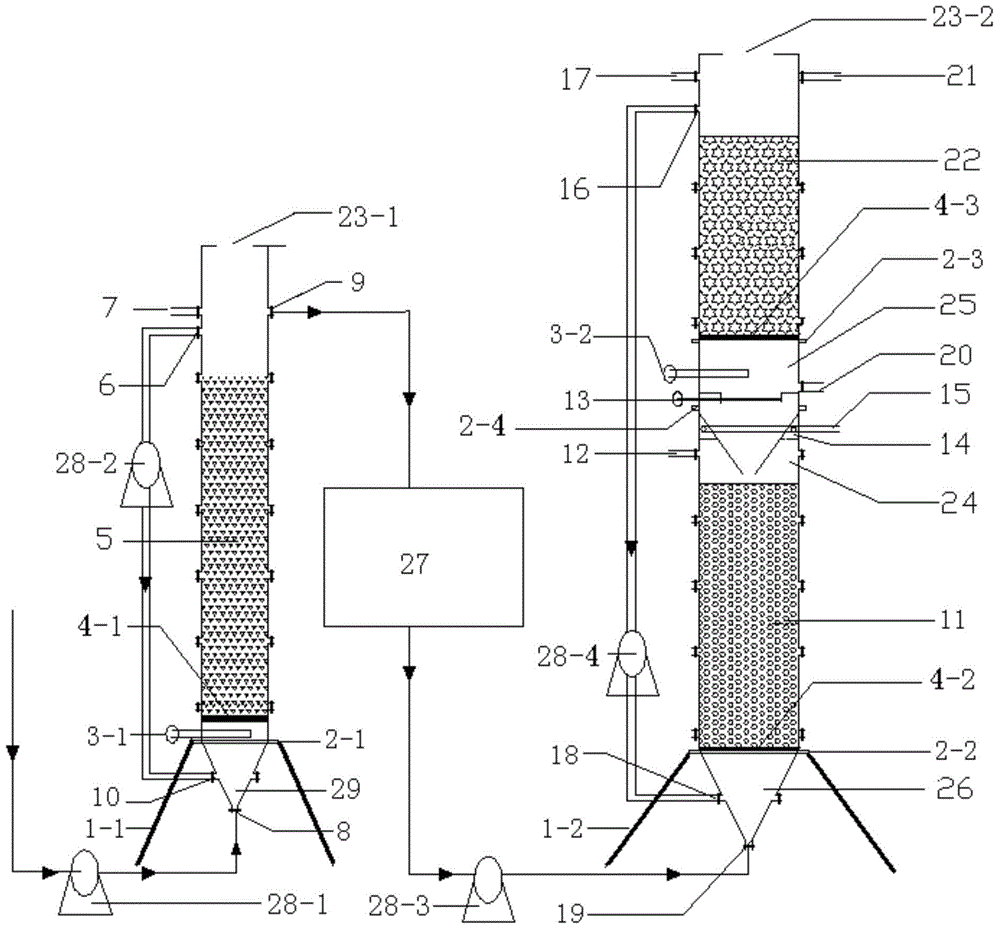

[0044] A process for treating tetracycline antibiotic wastewater, comprising a pretreatment step and an anaerobic / aerobic treatment step;

[0045] The pretreatment step uses iron-carbon micro-electrolytic ceramsite as a filler for electrolytic treatment; the particle size of the iron-carbon micro-electrolytic ceramsite is 5-7cm, and the particle density is 1200-1400kg / m 3 , bulk density 850kg / m 3 , the packing height is 100cm, the hydraulic retention time is 4h, and the gas-water volume ratio is 5:1;

[0046] The described anaerobic / aerobic treatment step is to carry out anaerobic treatment and aerobic treatment successively to the wastewater after the pretreatment step, and the anaerobic treatment uses fly ash ceramsite as filler, and the particle diameter of fly ash ceramsite is 15-20mm, particle density 850-950kg / m 3 , bulk density 400kg / m 3 , the height of the filler is 100cm; the aerobic treatment uses sludge ceramsite as the filler, the particle size is 5-10mm, and th...

Embodiment 2

[0049] A process for treating tetracycline antibiotic wastewater, comprising a pretreatment step and an anaerobic / aerobic treatment step;

[0050] The pretreatment step uses iron-carbon micro-electrolytic ceramsite as a filler for electrolytic treatment; the particle size of the iron-carbon micro-electrolytic ceramsite is 5-7cm, and the particle density is 1200-1400kg / m 3 , bulk density 950kg / m 3 , the packing height is 80cm, the hydraulic retention time is 8h, and the gas-water volume ratio is 8:1;

[0051] The described anaerobic / aerobic treatment step is to carry out anaerobic treatment and aerobic treatment successively to the wastewater after the pretreatment step, and the anaerobic treatment uses fly ash ceramsite as filler, and the particle diameter of fly ash ceramsite is 15-20mm, particle density 850-950kg / m 3 , bulk density 500kg / m 3 , the height of the filler is 60cm; the aerobic treatment uses sludge ceramsite as the filler, the particle size is 5-10mm, and the ...

Embodiment 3

[0053] The technique that is used to process tetracycline antibiotic waste water as described in embodiment 1, difference is:

[0054] In the pretreatment step, the waste water is refluxed, and the reflux ratio is 2:1; the packing is backwashed, and the backwashing cycle is 3 days;

[0055] During the process of anaerobic treatment and aerobic treatment, the waste water is refluxed, the reflux ratio is 2:1, and the packing is backwashed, and the backwashing period is 5 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com