Method for treating papermaking wastewater based on combined process including integrated membrane technology and advanced oxidation technology

A process method and technical treatment technology, which is applied in the field of wastewater treatment to achieve the effects of high membrane flux, standard discharge, and reduction of total discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

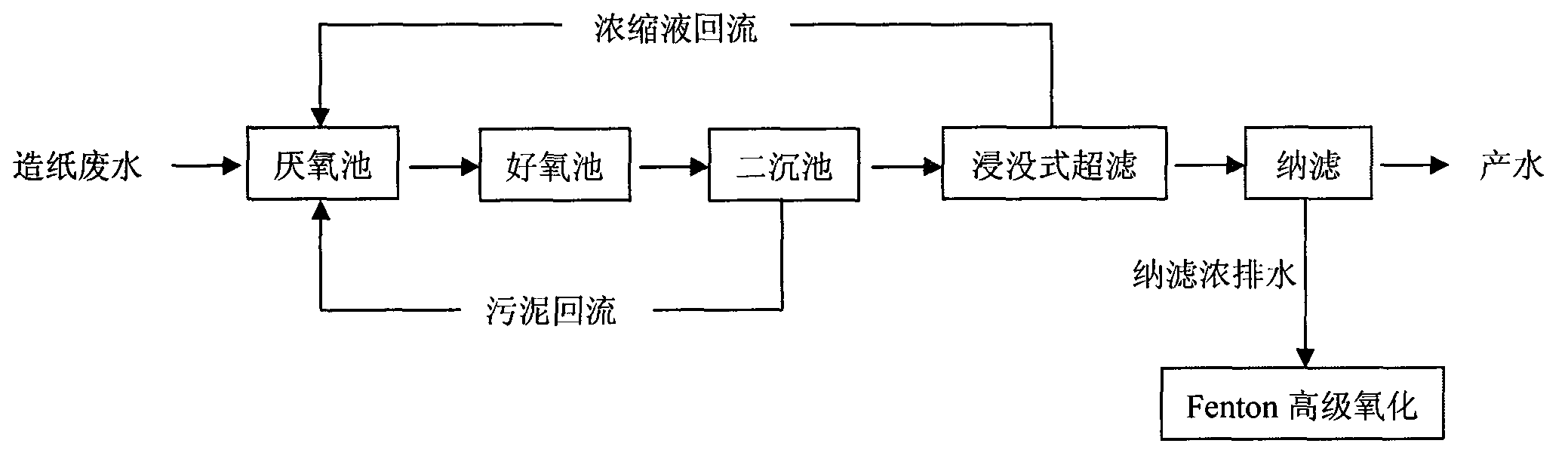

[0043] A paper mill in the north uses cotton stalks and recycled waste paper as raw materials to produce various papers. The wastewater generated from papermaking is pretreated in the early stage and the primary sedimentation tank, and then enters the biochemical system, secondary sedimentation tank, submerged ultrafiltration system, and nanofiltration system. system. The nanofiltration concentrated wastewater is discharged up to standard after passing through the Fenton advanced oxidation treatment unit.

[0044] The SMF influent is the effluent from the secondary sedimentation tank of the original sewage treatment system. The SMF outlet water enters the SMF product water tank, and the concentrated water returns to the SMF water inlet tank. SMF is constant flow 3.6m 3 / h operation, the backwash operation of the SMF system can be realized by the outlet water through the backwash pump, and the forward flush operation of the system can be realized by the inlet water through th...

Embodiment 2

[0054] A paper mill in the south uses wood as raw material and mainly produces coated paper of various specifications and styles. After passing through the mixing tank, cooling tower and primary sedimentation, the papermaking wastewater enters the biochemical treatment system, secondary sedimentation tank, submerged ultrafiltration system, nano Filtration system, nanofiltration concentrated wastewater is discharged up to the standard after passing through the Fenton advanced oxidation treatment unit, and the produced water is reused in the process section for paper production.

[0055] The SMF outlet water is used as the inlet water of the NF system. It is pumped into the NF membrane module through the suction pump, security filter and booster pump. The NF concentrated water can be completely discharged into the Fenton advanced oxidation treatment unit through the control of the valve, and can also be partially returned to the The SMF water production tank achieves a large reco...

Embodiment 3

[0064] The submerged ultrafiltration membrane module used is a curtain-type hydrophilic polyvinylidene fluoride hollow fiber membrane module. The filtration accuracy of the membrane is 0.1 micron. There are a total of 8 membrane modules, and the area of a single membrane module is 20m 2 , the processing capacity is 4.8T / h.

[0065] The nanofiltration membrane module is a 4-inch pollution-resistant roll-type nanofiltration membrane module, multi-stage treatment, a total of 6 membrane modules, the water production rate is 3.6T / h, and the recovery rate is over 75%.

[0066] Submerged ultrafiltration operation process: one operation cycle is 40 minutes, the backwash time is 30 seconds, the backwash water is ultrafiltration product water, the backwash water volume is 2.1 times the product water volume, and the online chemical cleaning is performed once a week.

[0067] Advanced oxidation process: collect the concentrated wastewater discharged from the nanofiltration membrane trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com