Method for processing triallyl isocyanurate production wastewater

A technology of triallyl isocyanurate and production wastewater, applied in natural water treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems such as difficulty in meeting discharge standards, and achieve stable and effective operation , the effect of improving biodegradability and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

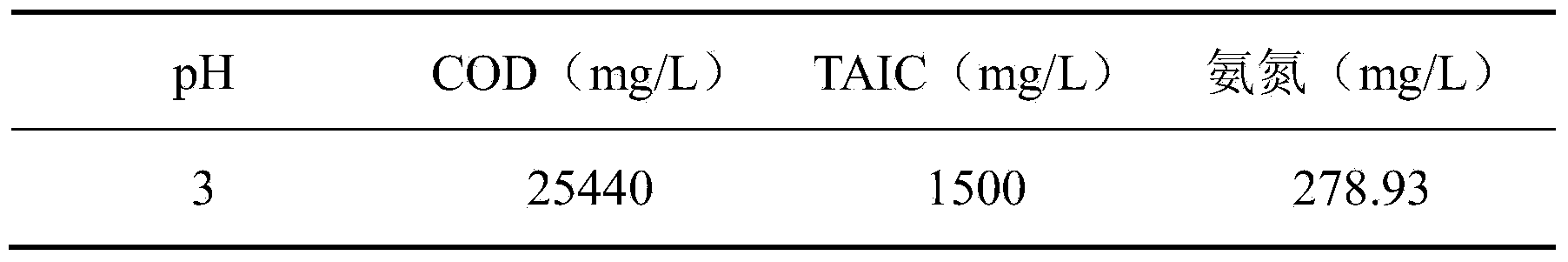

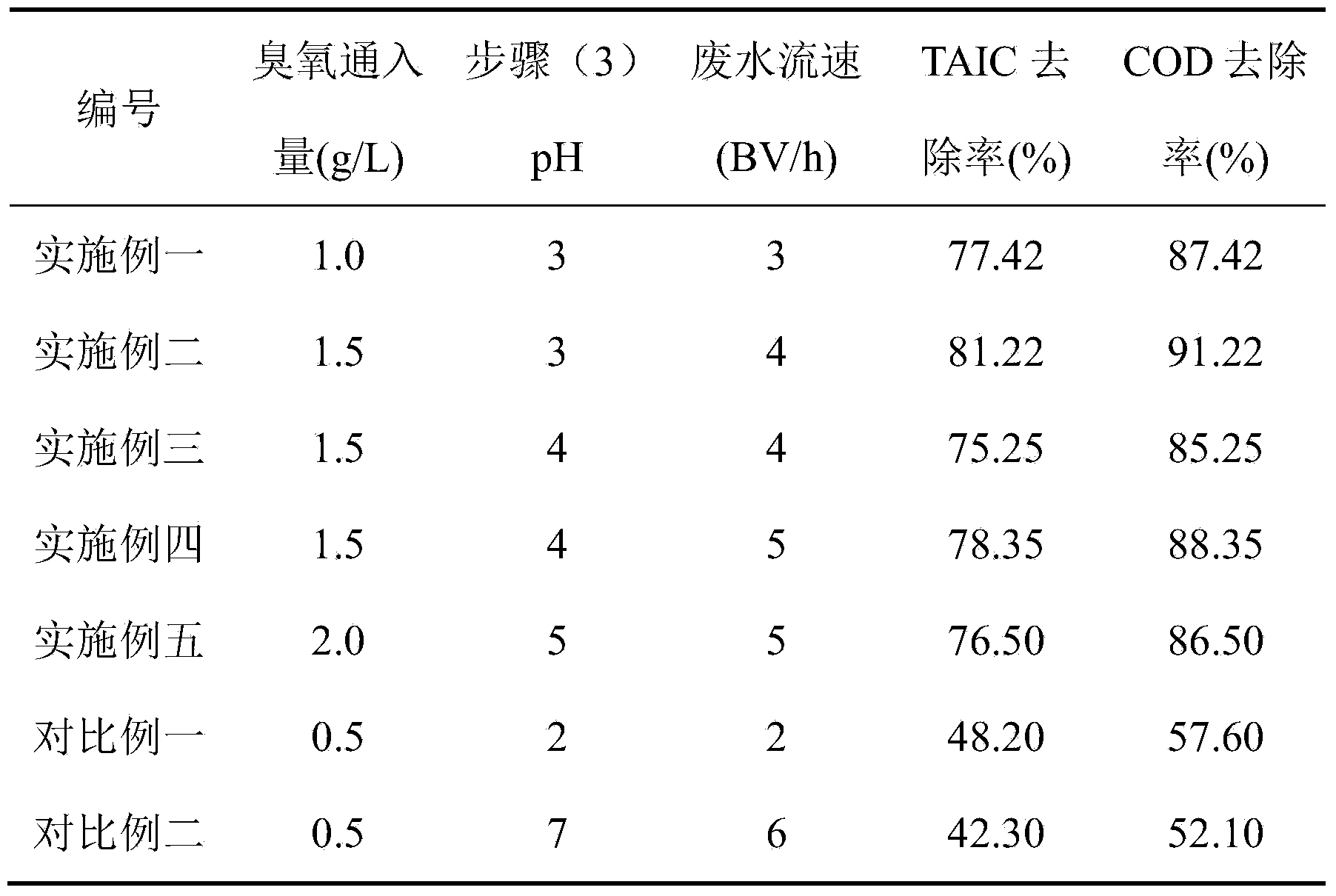

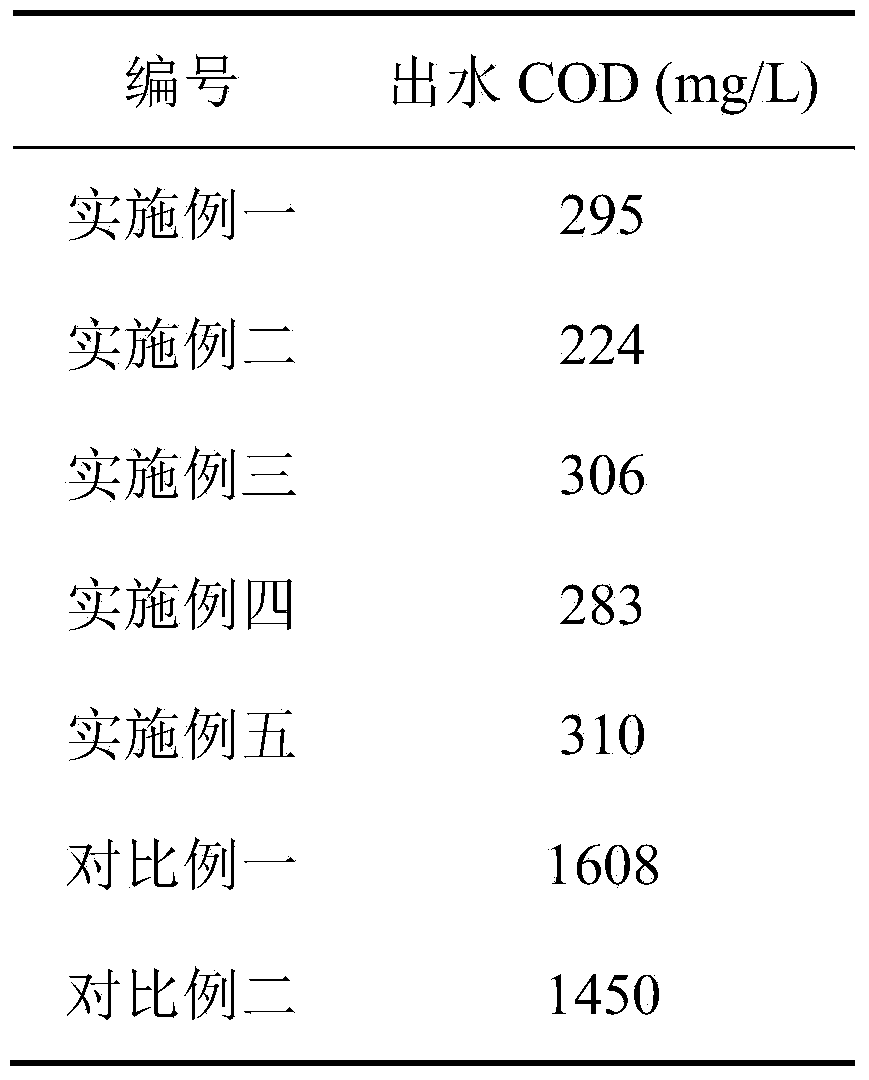

[0021] The method for processing TAIC production waste water, comprises the following steps:

[0022] (1) In the step of uniform water quality, the TAIC production wastewater is sent to the adjustment tank, and the wastewater quality is initially adjusted by mixing the domestic sewage and the TAIC production wastewater.

[0023] (2) Ozone oxidation step, the wastewater after adjusting the water quality is sent to the ozone reaction tank, so that the ozone can oxidize and degrade the organic matter in the wastewater, and the required ozone is generated by the ozone generator and sent to Into the ozone reaction tank, the ozone feed rate is 1.0g / L.

[0024] (3) Resin adsorption step, adding sulfuric acid to the wastewater after ozone oxidation treatment, adjusting the pH of the wastewater to 3, controlling the flow rate of the wastewater to 3BV / h through the speed-regulating water pump, so that the wastewater passes through the resin adsorption bed, and through the adsorption Th...

Embodiment 2

[0027] The method for processing TAIC production waste water, comprises the following steps:

[0028] (1) In the step of uniform water quality, the TAIC production wastewater is sent to the adjustment tank, and the wastewater quality is initially adjusted by mixing the domestic sewage and the TAIC production wastewater.

[0029] (2) In the ozone oxidation step, the wastewater after adjusting the water quality is sent to the ozone reaction tank, and the ozone is generated by the ozone generator and sent into the ozone reaction tank after passing through the membrane microporous aerator, so that the ozone can reduce the organic matter in the wastewater. Carry out oxidative degradation, the feed rate of ozone is 1.5g / L.

[0030] (3) Resin adsorption step, adding sulfuric acid to the wastewater after ozone oxidation treatment, adjusting the pH of the wastewater to 3, controlling the flow rate of the wastewater to 4BV / h through the speed-regulating water pump, so that the wastewate...

Embodiment 3

[0033] The method for processing TAIC production waste water, comprises the following steps:

[0034] (1) In the step of uniform water quality, the TAIC production wastewater is sent to the adjustment tank, and the wastewater quality is initially adjusted by mixing the domestic sewage and the TAIC production wastewater.

[0035] (2) Ozone oxidation step, the wastewater after adjusting the water quality is sent to the ozone reaction tank, so that the ozone can oxidize and degrade the organic matter in the wastewater, and the required ozone is generated by the ozone generator and sent to Into the ozone reaction tank, the ozone feed rate is 1.5g / L.

[0036] (3) Resin adsorption step, adding sulfuric acid to the wastewater after ozone oxidation treatment, adjusting the pH of the wastewater to 4, controlling the flow rate of the wastewater to 4BV / h through the speed-regulating water pump, so that the wastewater passes through the resin adsorption bed, and through the adsorption Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com