Catalytic oxidation method for low-concentration non-biodegradable industrial organic wastewater treatment

A technology of organic wastewater treatment and catalytic oxidation, which is applied in the direction of special compound water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem that the treatment process is difficult to meet the corresponding requirements, and achieve wide applicability and universal application Wide range of properties and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

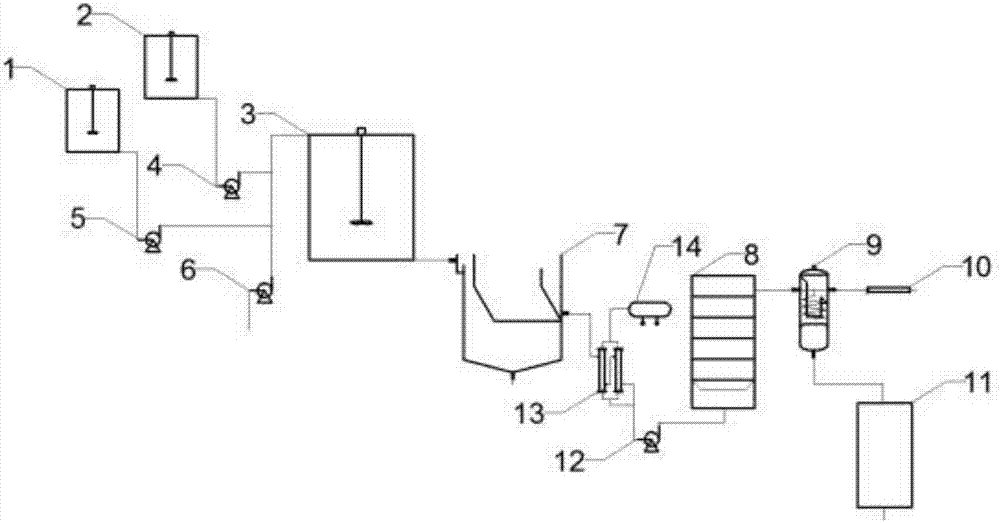

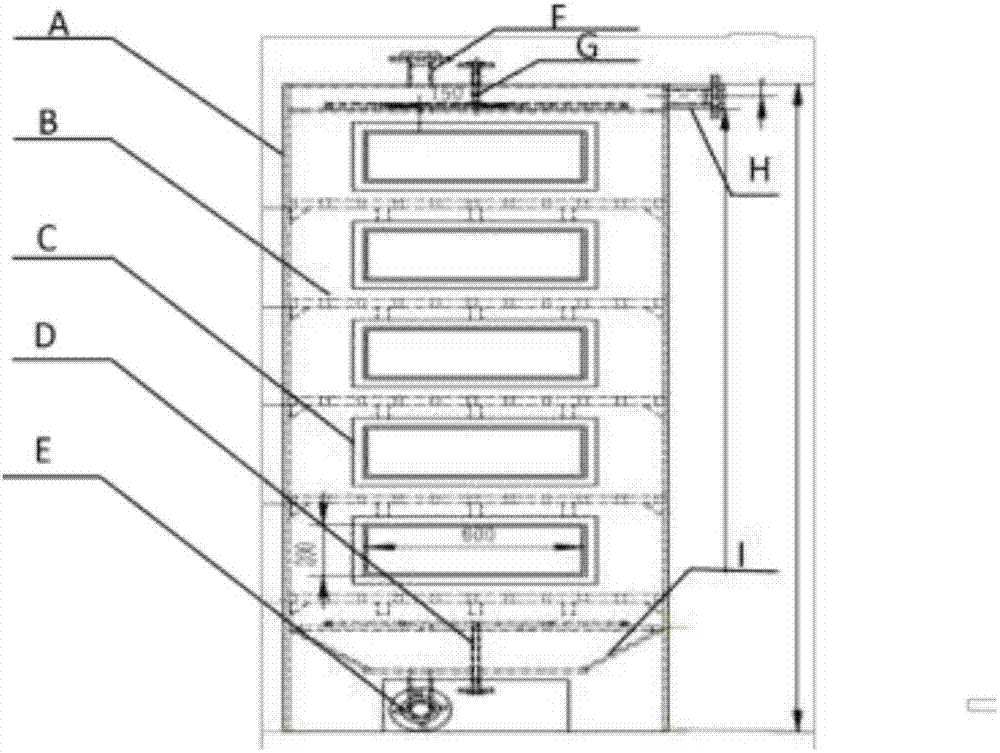

Method used

Image

Examples

example 1

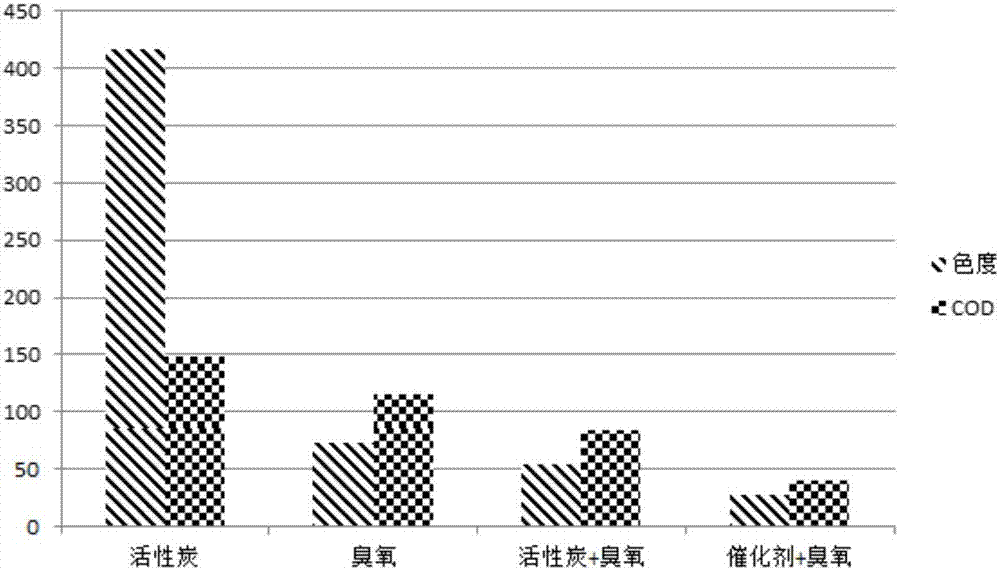

[0031] Example 1: Taking the concentrated solution of a tobacco leaf company in Yunnan as the experimental object after the biochemical effluent passed through the reverse osmosis membrane, the water quality analysis of the water sample showed that the COD was 550-600 mg / L, and the chromaticity was 1200-1300. After being treated by the process of the method, the wastewater treatment residence time is 20 minutes, the effluent water quality after the catalytic oxidation is COD≤40mg / L, and the chroma is ≤20. The process has no attenuation after treating 7 tons of waste water in the laboratory, and the reliability of the service life has been verified. The experimental results are shown in Figure 4 and Table 1.

[0032] Table 1

[0033] Treated water volume / L

example 2

[0034] Example 2: The biochemical effluent of printing and dyeing wastewater from a sewage treatment plant in Xiaoshan, Hangzhou was taken as the experimental object. After water quality analysis, it was found that the COD was 100-150 mg / L and the chroma was 100-300 degrees. After being treated by the process of the method, the wastewater treatment residence time is 20 minutes, the COD of the effluent after catalytic oxidation is ≤30 mg / L, and the chromaticity is ≤10. The process has no attenuation after treating 10 tons of waste water in the laboratory, and the reliability of the service life has been verified. The experimental results are shown in Figure 5 and Table 2.

[0035] Table 2

[0036] Treated water volume / L

example 3

[0037] Example 3: Taking the wastewater from a certain drug manufacturing den cracked in Yunnan as the experimental object, the water quality analysis of the water samples revealed that the COD was 1000-1500mg / L and the chroma was 30-50. Through the process of the method, the wastewater treatment residence time is 30 minutes, the COD of the effluent water is ≤50 mg / L, and the chroma is ≤10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com