Patents

Literature

47results about How to "Good water conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

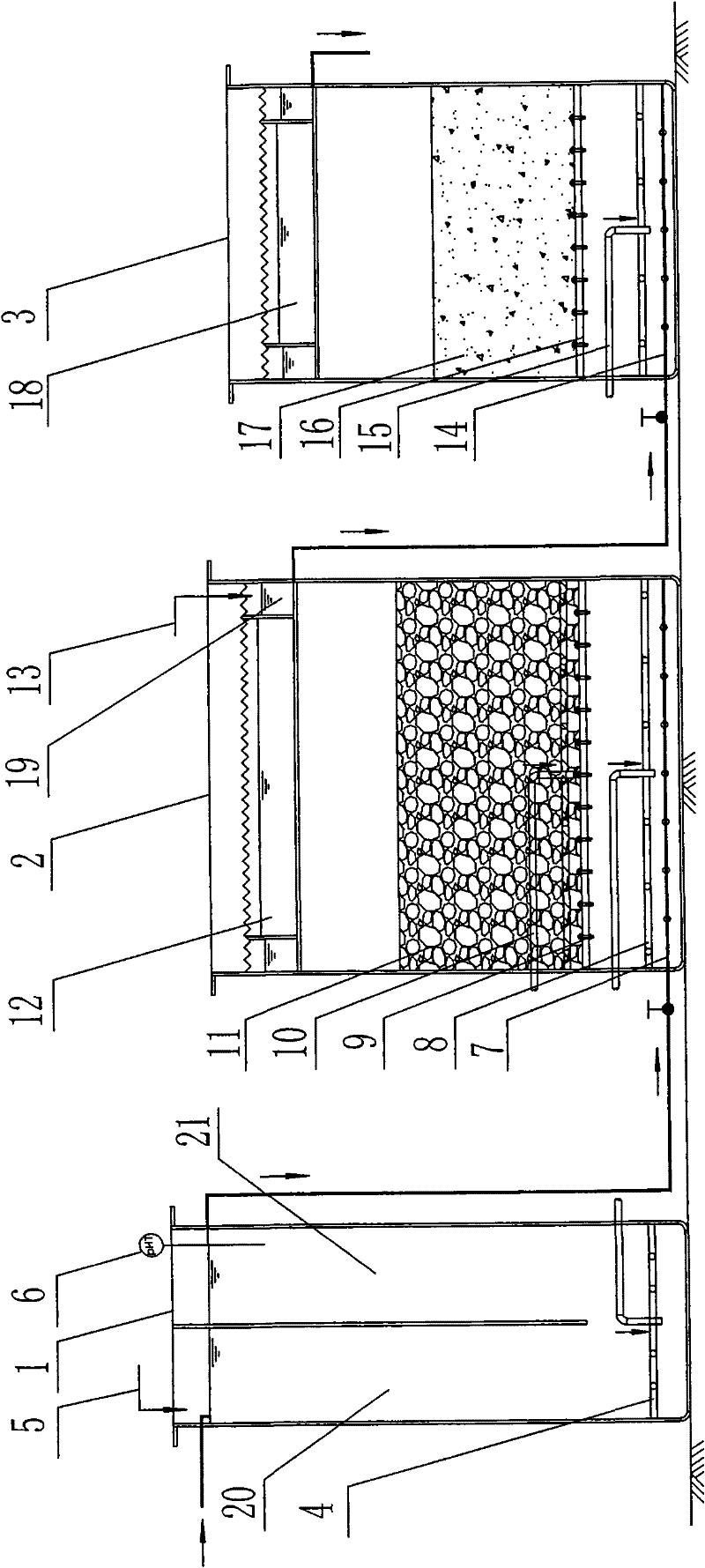

Method and device for multicomponent oxide pretreatment of organic electroplating waste water

InactiveCN101591082AImprove biodegradabilityGood water conditionsWaste water treatment from metallurgical processMultistage water/sewage treatmentPretreatment methodElectrolysis

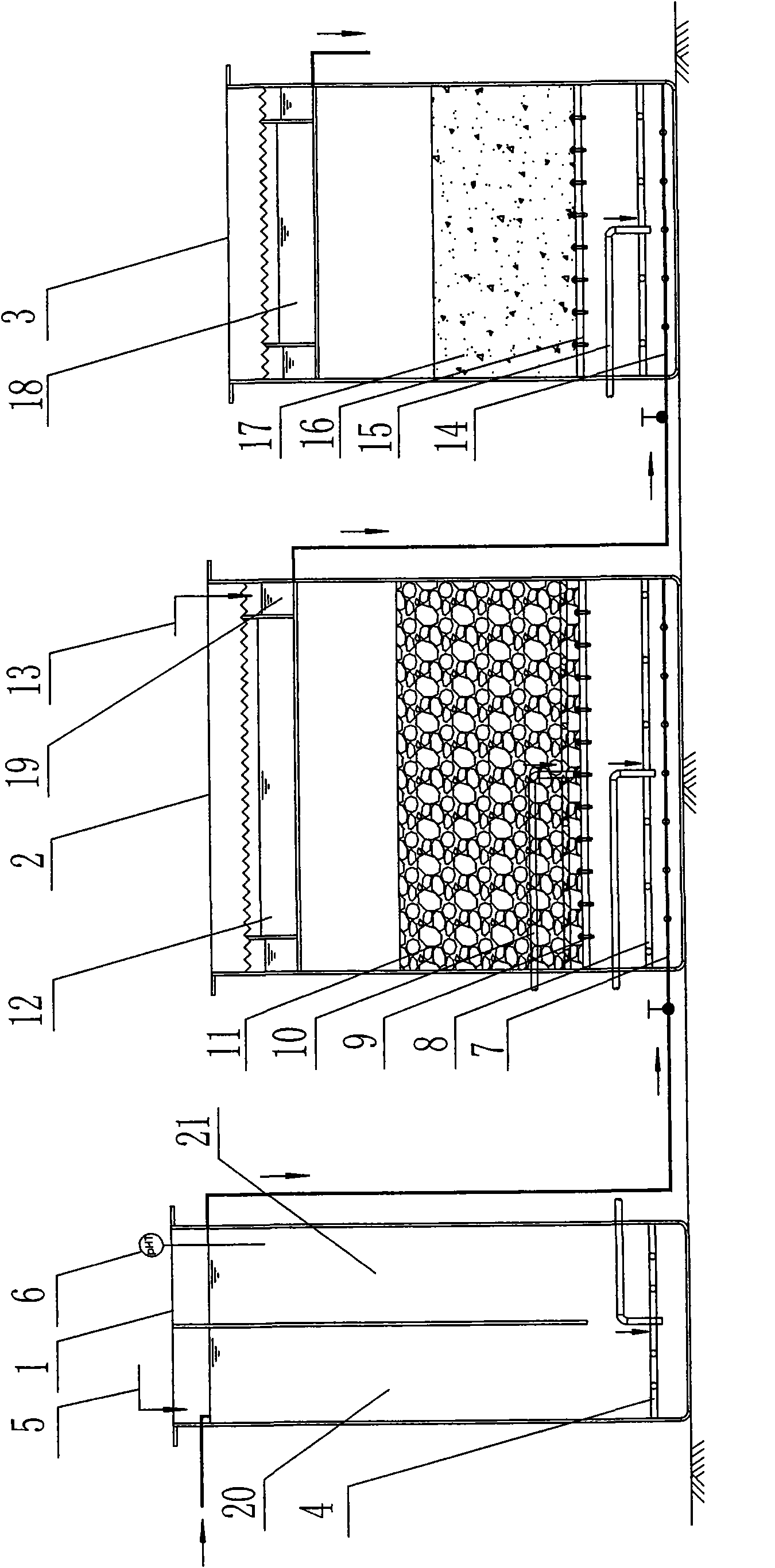

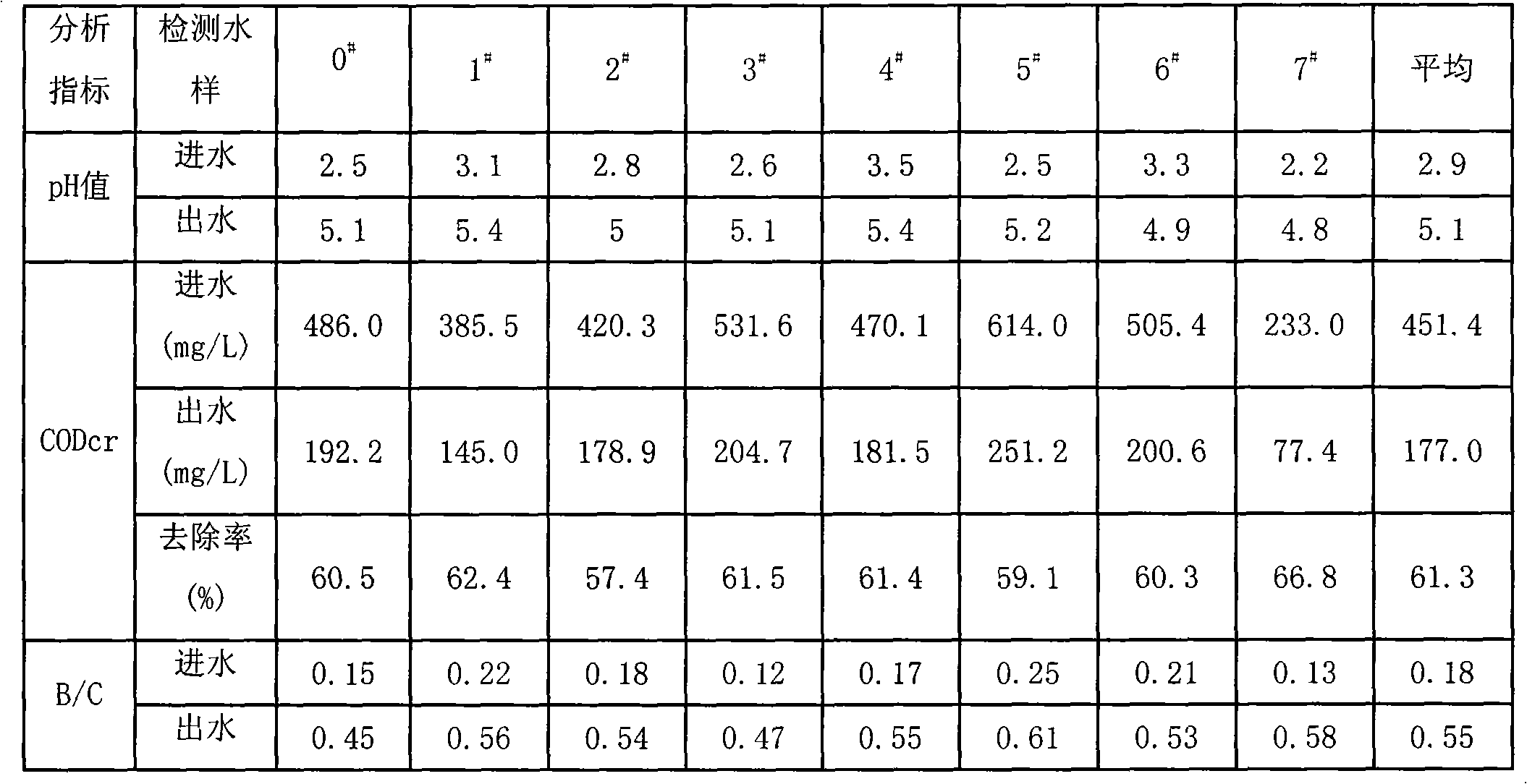

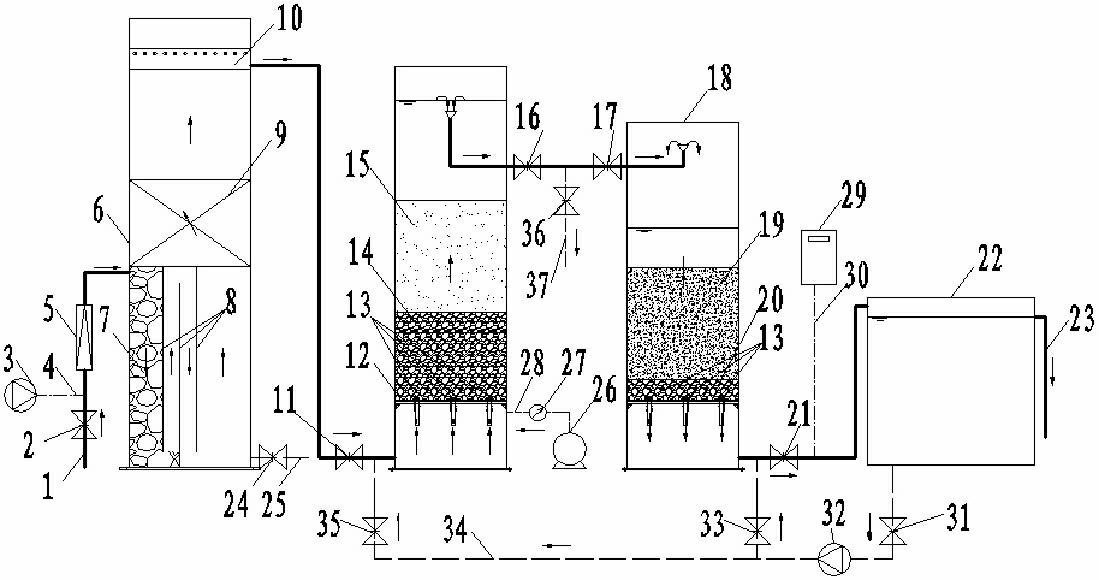

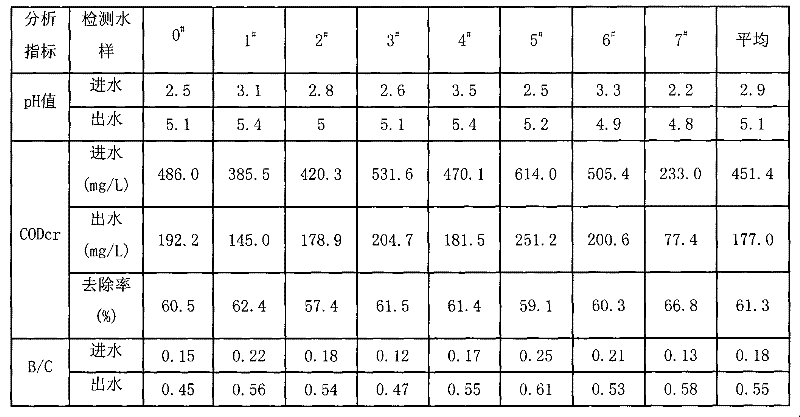

The invention relates to a method and a device for multicomponent oxide pretreatment of organic electroplating waste water, which belong to the technical filed of electroplating waste water treatment in the environment engineering. The pretreatment method is characterized in that organic electroplating waste water is sequentially subjected to acidity adjustment, ferrum-carbon micro-electrolysis reaction and Fenton oxidation reaction. The corresponding device comprises a pH adjusting tank, a ferrum-carbon micro-electrolysis bath and a Fenton oxidation pond; an acid-alkali feeding device and a pH controller which are in link control are arranged above the pH adjusting tank; the middle low part of the ferrum-carbon micro-electrolysis bath is paved with a ferrum-carbon filler layer, while the bottom is provided with a micro-electrolysis bath perforation water distribution pipe; a hydrogen peroxide feeding device is arranged above the ferrum-carbon micro-electrolysis bath; the bottom of the Fenton oxidation pond is provided with a Fenton oxidation pond perforation water distribution pipe; and the middle lower part of the Fenton oxidation pond is provided with a granular active carbon catalytic carrier layer. The method and the device obviously improve the capability of biochemistry, simultaneously perform oxidation reaction to remove mostly organic pollutants and create favorable water inlet condition for subsequent coagulating sedimentation, air flotation and biochemical treatment.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

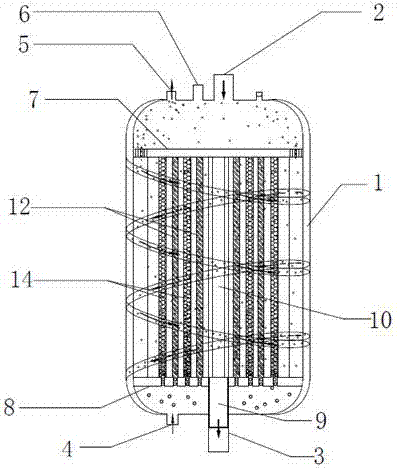

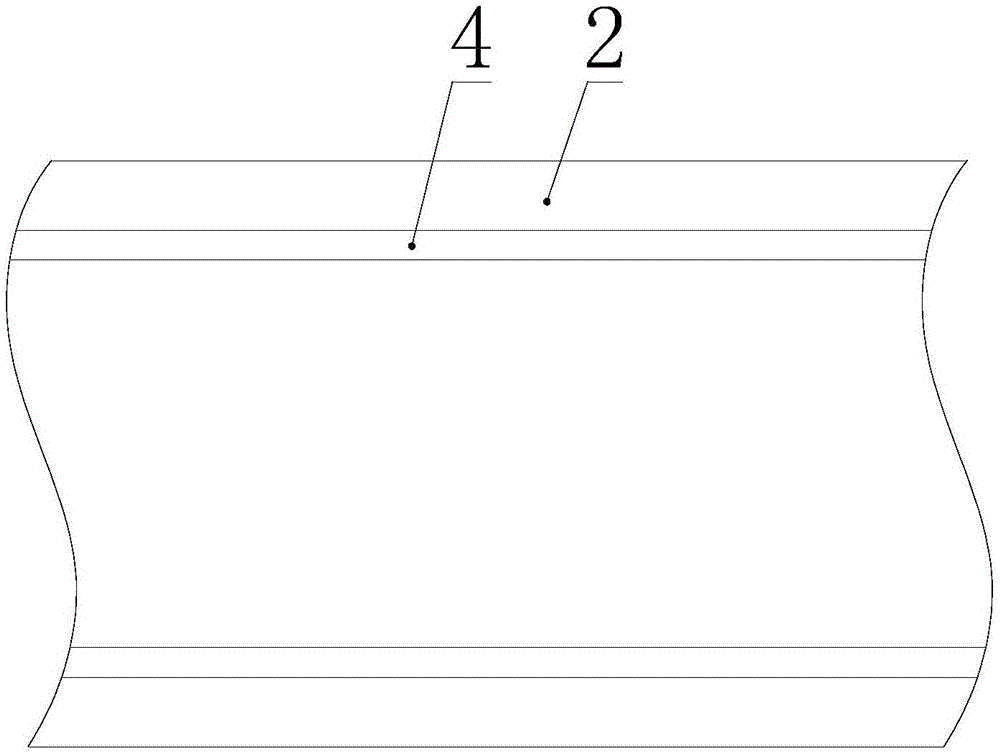

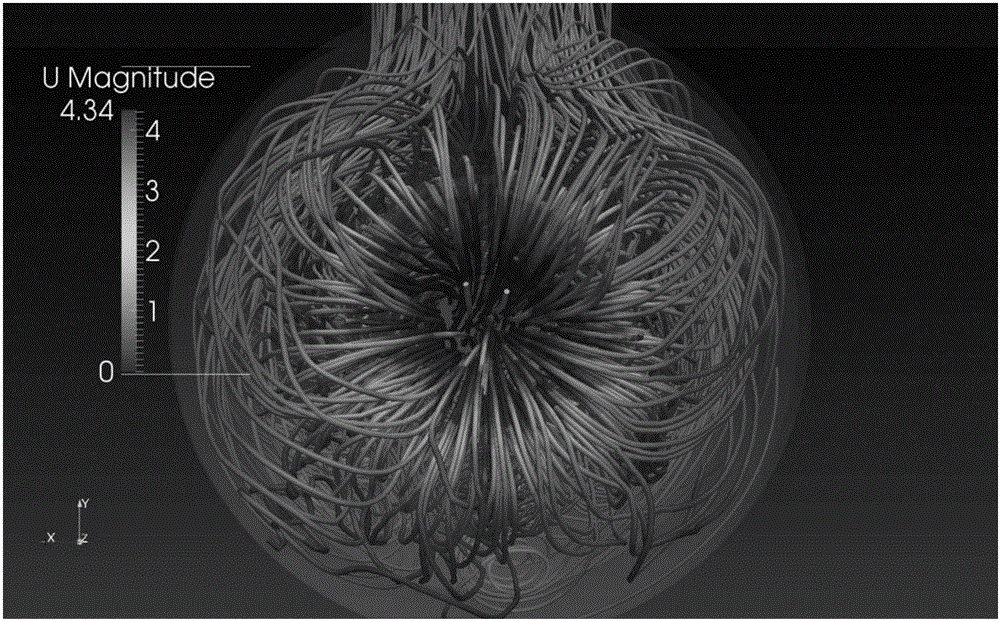

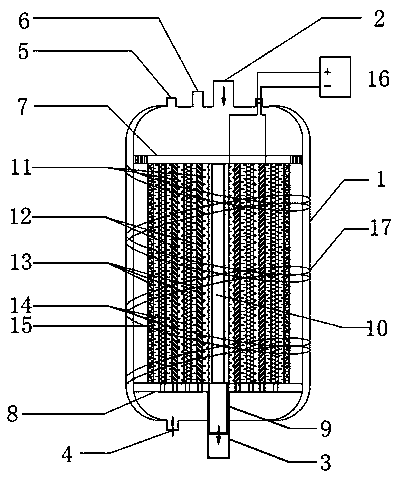

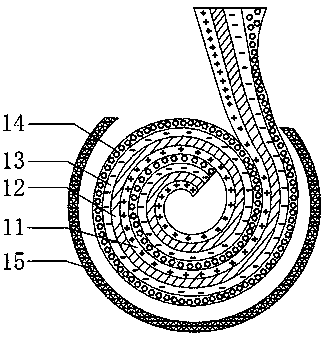

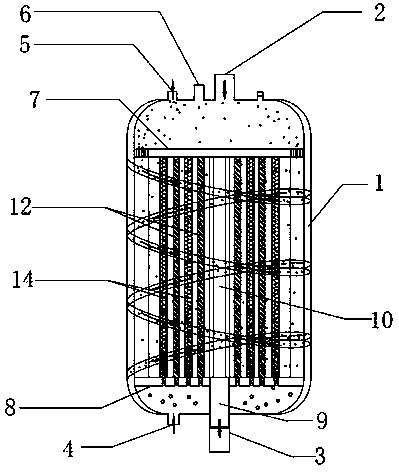

Spirally wound electrochemical water treatment reactor

ActiveCN107098442AFacilitated DiffusionEnhanced mass transferDispersed particle separationWater/sewage treatment by oxidationElectricityBarrel Shaped

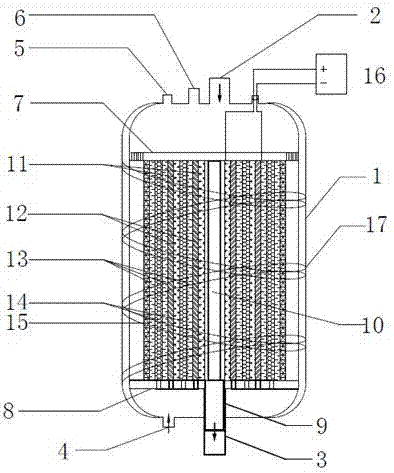

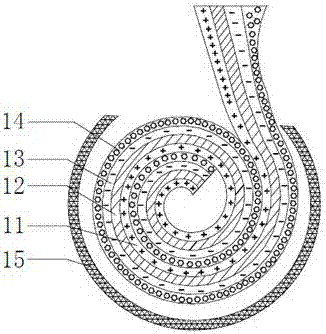

The invention discloses a spirally wound electrochemical water treatment reactor. The spirally wound electrochemical water treatment reactor comprises a vertically-arranged long-barrel-shaped shell; the interior of the shell is reaction space; the shell is provided with a water inlet and a water outlet connected with the reaction space; an electrocatalytic oxidation assembly is arranged in the reaction space in the shell and divides the reaction space located between the water inlet and the water outlet; the electrocatalytic oxidation assembly is formed by compounding and spiral winding of a positive electrode layer, a positive / negative electrode insulating layer, a negative electrode layer and a supporting layer; the positive electrode layer and the negative electrode layer are both of a net structure; and the distance between the negative electrode layer and the positive electrode layer is in a range of effective distances allowing an electrocatalysis reaction to occur between the negative electrode layer and the positive electrode layer. The structure of the reactor provided by the invention is beneficial for saving space, enlarging a reaction area, increasing gas-liquid polyphase mass transfer efficiency and realizing high-efficiency, long-acting and low-consumption treatment of pollutants in water.

Owner:CHONGQING XINHE QIYUE TECH CO LTD

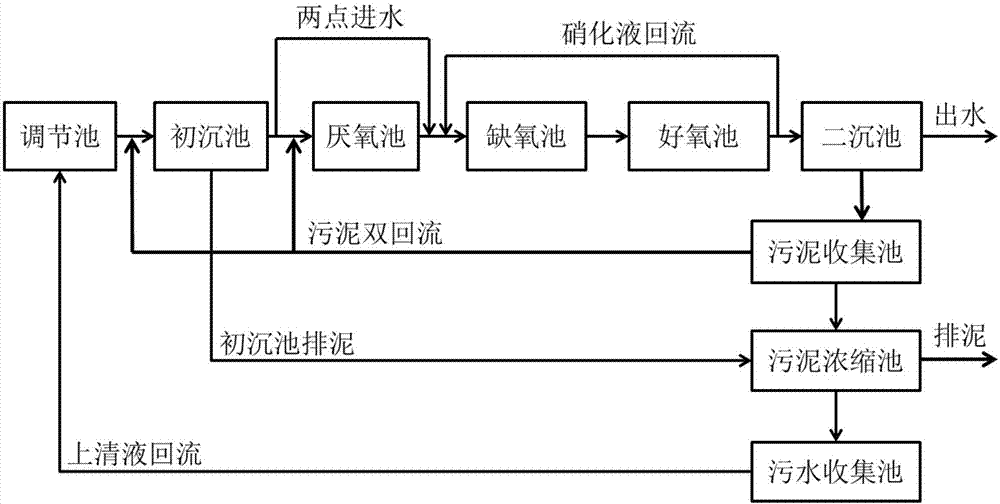

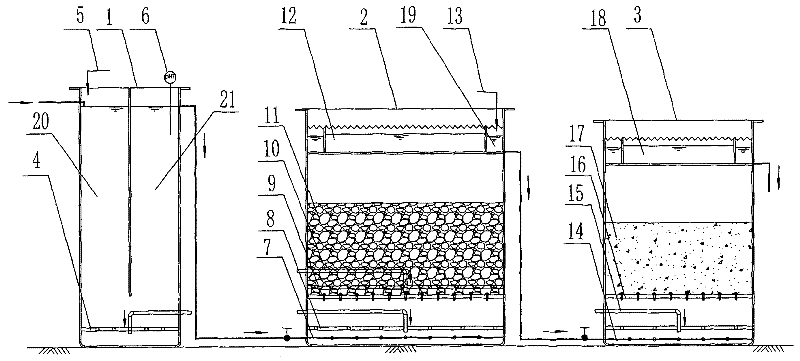

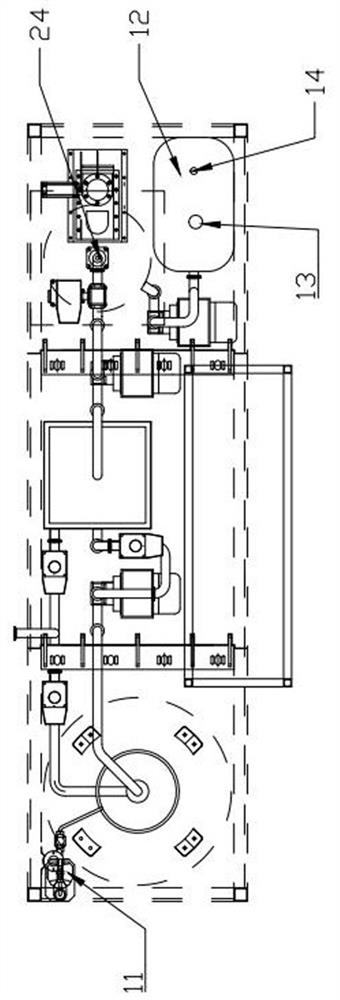

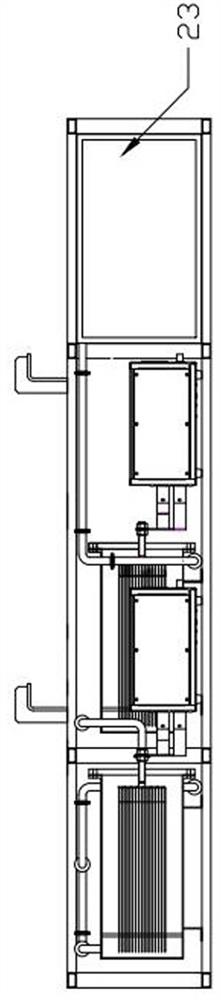

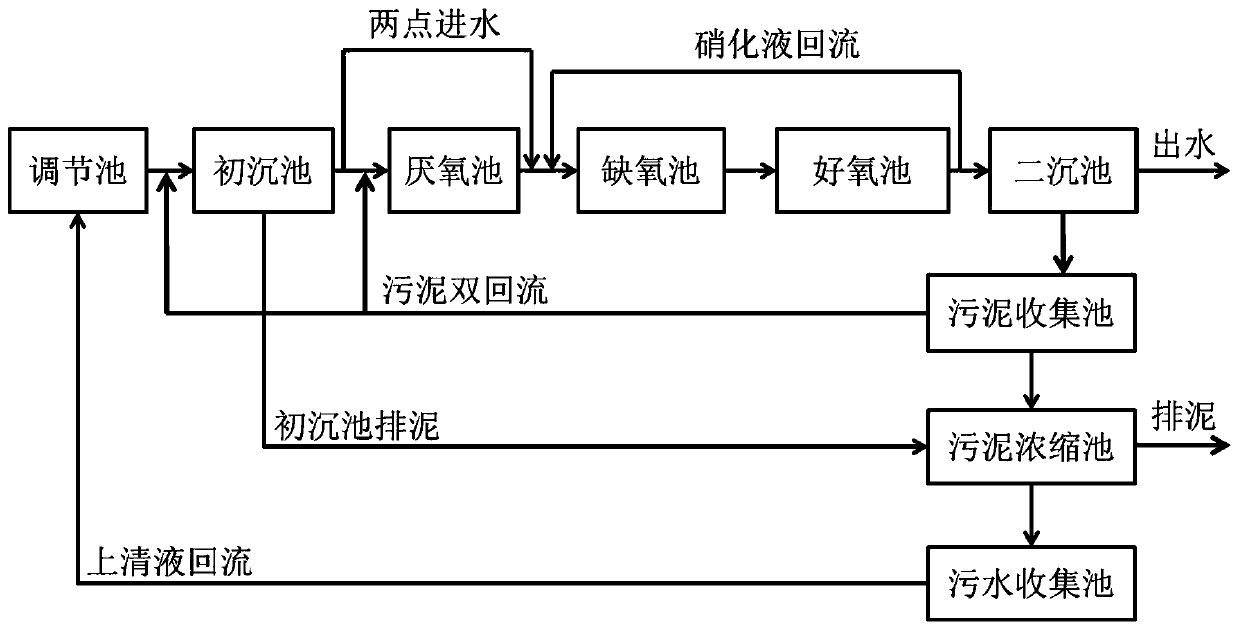

Dispersion-type sewage treatment system and treatment method using the same

ActiveCN107381961AShort stayReduce pollutionWater treatment parameter controlTreatment with anaerobic digestion processesRural areaReflux

The invention relates to a dispersion-type sewage treatment system. The system comprises a conditioning tank, a primary settling tank, an anaerobic tank, an anoxic tank, an aerobic tank, a secondary settling tank, a sludge collection tank, a sludge concentration tank and a sewage collection tank. The system is a mobile small integrated sewage treatment device based on an A2 / O technology and combination with two-point water inlet, sludge double reflux, a bubble-free aeration membrane and an aerobic cell special sub-grid form, can be used for treatment on urban domestic sewage in the urban fringe and the novel district difficult to cover with an urban drainage pipe network and economic development relatively backward vast rural areas and small towns, treatment on a part of industrial wastewater with similar characteristics to those of urban domestic sewage and treatment on urban special wastewater in hospitals and foreign guesthouses.

Owner:天津诚信环球节能环保科技有限公司

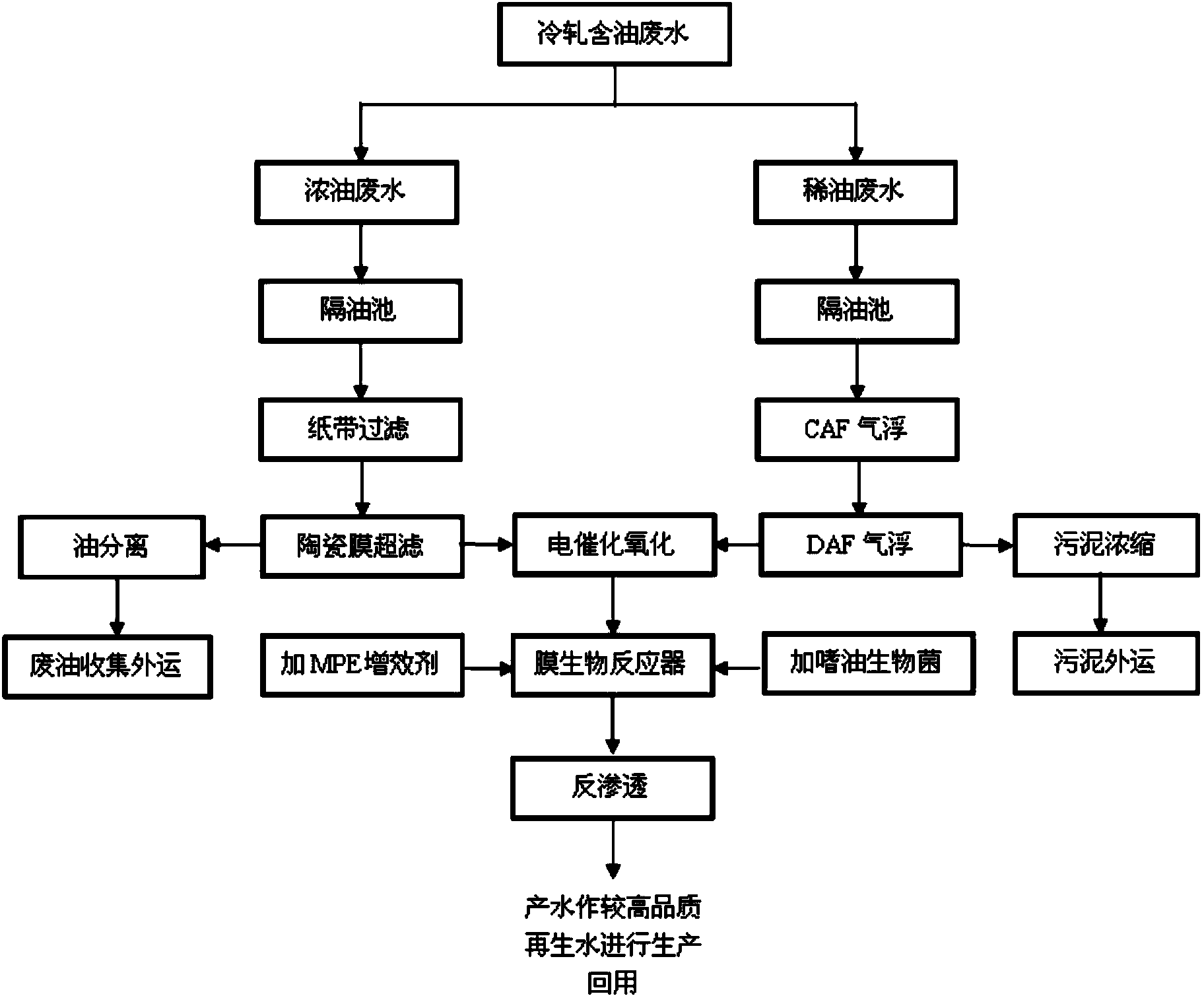

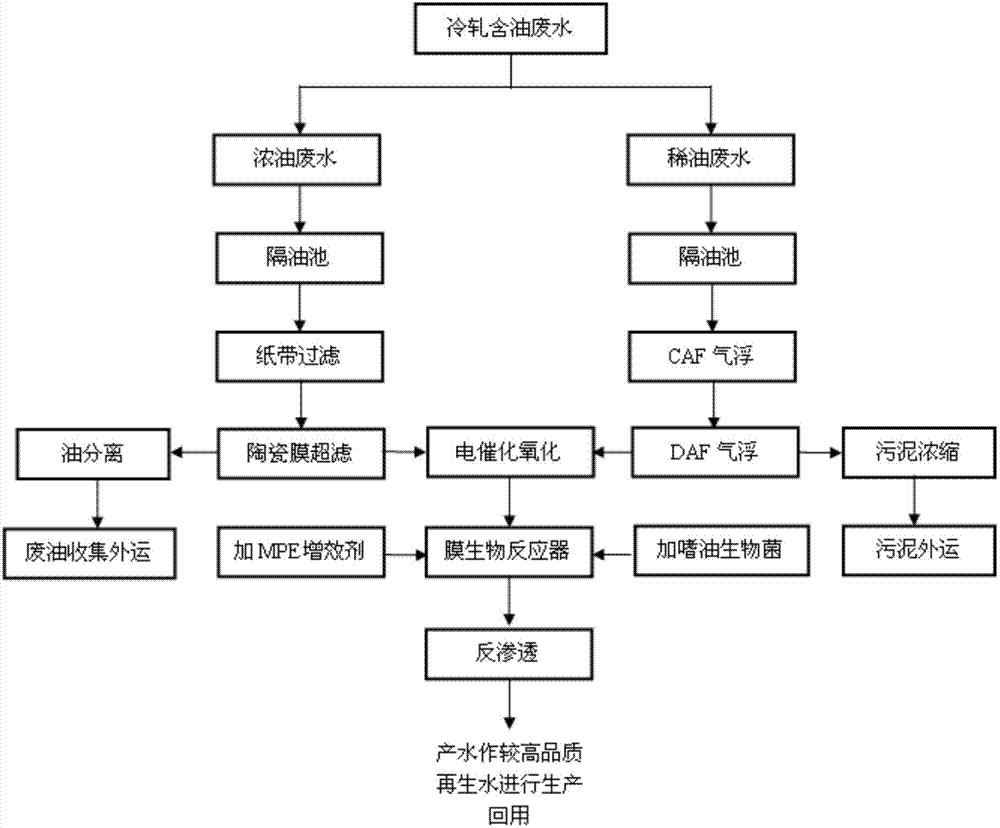

Cold rolling oily wastewater treatment process

InactiveCN103408200AThe treatment effect is stableWide range of adaptationGeneral water supply conservationWaste water treatment from metallurgical processInlet temperatureSystematic process

The invention discloses a cold rolling oily wastewater treatment process, which comprises the following steps of: (1), pretreating thick-oil wastewater sequentially by filtering of an oil separation tank and a paper tape and ultra-filtration process of a ceramic membrane, and pre-treating thin-oil wastewater sequentially by adopting the oil separation tank, a CAF (Cavitation Air Flotation) process and a DAF (Dissolved Air Flotation) process; (2), mixing pre-treated thick-oil wastewater with the pre-treated thin-oil wastewater, carrying out biochemical treatment by adopting an electrochemical catalytic oxidation process and an MBR (Membrane Biological Reactor) process in sequence, controlling the water inlet temperature of the MBR process to be 20-35 DEG C, controlling the water inlet pH value to be 7-9, and adding oil-munching high-efficiency micro-organism complex microbial inoculants and MPE (Metallocene Polyethylene) into an MBR membrane tank; and (3), filtering outlet water (treated through the MBR process) by using a reverse osmosis membrane, and carrying out deep desalination treatment so that outlet water reaches emission or industrial production reuse water standard. The invention provides a set of systematic process specially aiming at treatment and reuse of cold rolling oily wastewater in steel mills; the COD (Chemical Oxygen Demand) of treated outlet water is less than 10mg / L; the electrical conductivity of treated outlet water is less than 50mu s / cm; and oil and suspended solids are nearly eliminated completely.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

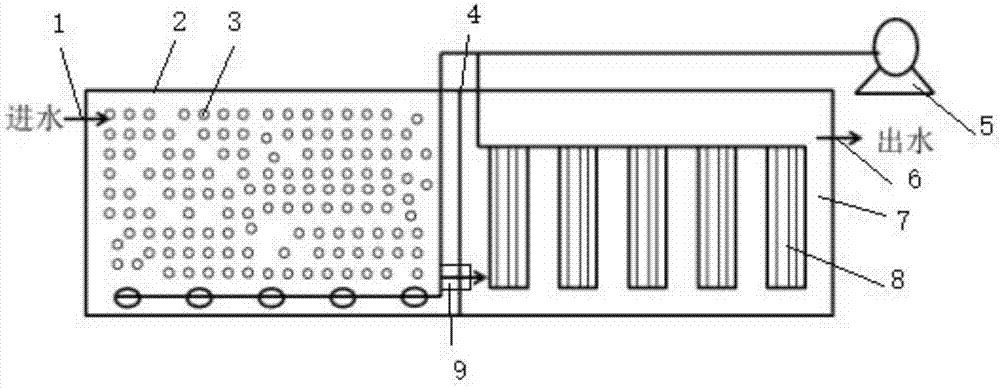

Combined set for treating micro-polluted source water in counties and towns

InactiveCN102329053AExtended backwash cycleGuaranteed water turbidityMultistage water/sewage treatmentWater sourceWater quality

The invention relates to a combined set for treating a micro-polluted source water in counties and towns, and the combined set comprises an inclined tube sedimentation tank, an aeration biozeolite filter column and an activated carbon filter column, wherein the inclined tube sedimentation tank consists of a water inlet region, a sloped tube region and a water collection region, the water inlet region is provided with turbulent stones and a baffle, the water collection region discharges water through a perforated water collection tank, the aeration biozeolite filter column consists of a water / gas inlet region, a filter material region and a water collection region, aeration is carried out in a blast aeration mode, gas is mixed in the water inlet region and enters the filter material region through a long-handle filter head, the filter material consists of coarse-grain zeolite and common-grain zeolite, the effluent water of the aeration biozeolite filter column enters the activated carbon column in a hydraulic drop mode, and the activated carbon filter column consists of a filter material region and a water outlet region. The inclined tube sedimentation tank water inlet region is provided with the turbulent stones and baffle to enhance the flocculation effect of the coagulant and the removal effect of the sedimentation tank. The activated carbon filter column connected to the aeration biozeolite filter column performs a two-stage biochemical synergistic action, and implements advantage complementation, thereby enhancing the water quality of the effluent water and lowering the treatment cost. The combined set can effectively remove ammonia nitrogen, organic substances, manganese and other pollutants in the micro-polluted source water, has the advantages of compact technical linkage, low investment and operating cost and stable quality of effluent water, and is suitable for being used in small-scale water generation occasions, such as water supply to counties and towns.

Owner:TONGJI UNIV

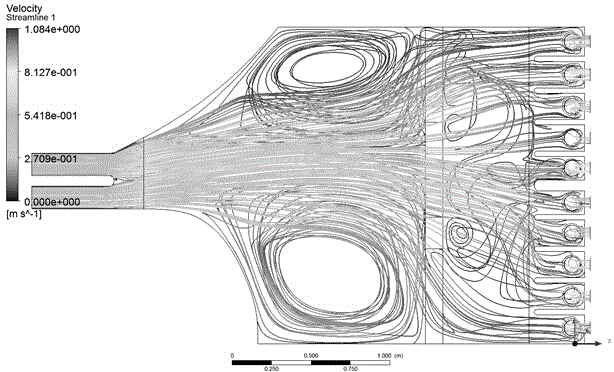

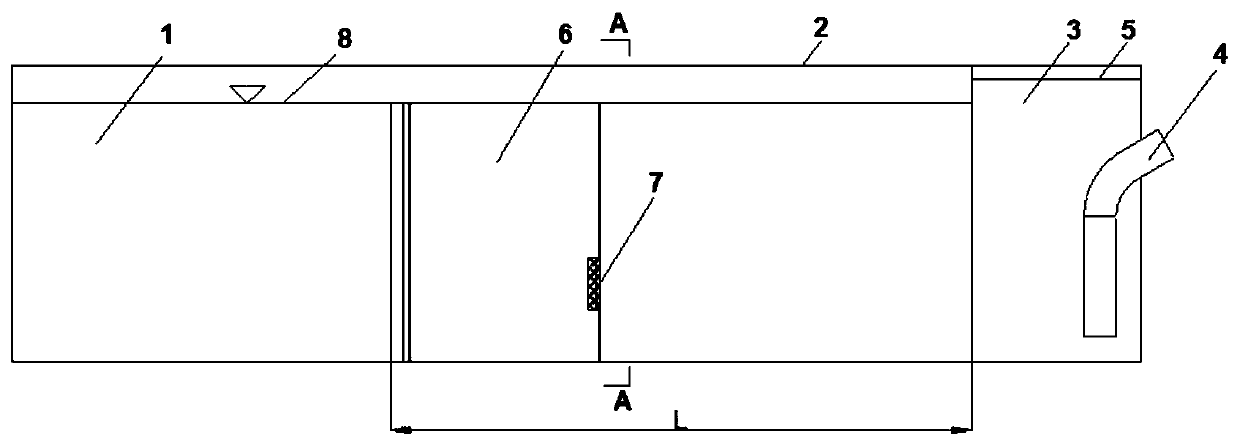

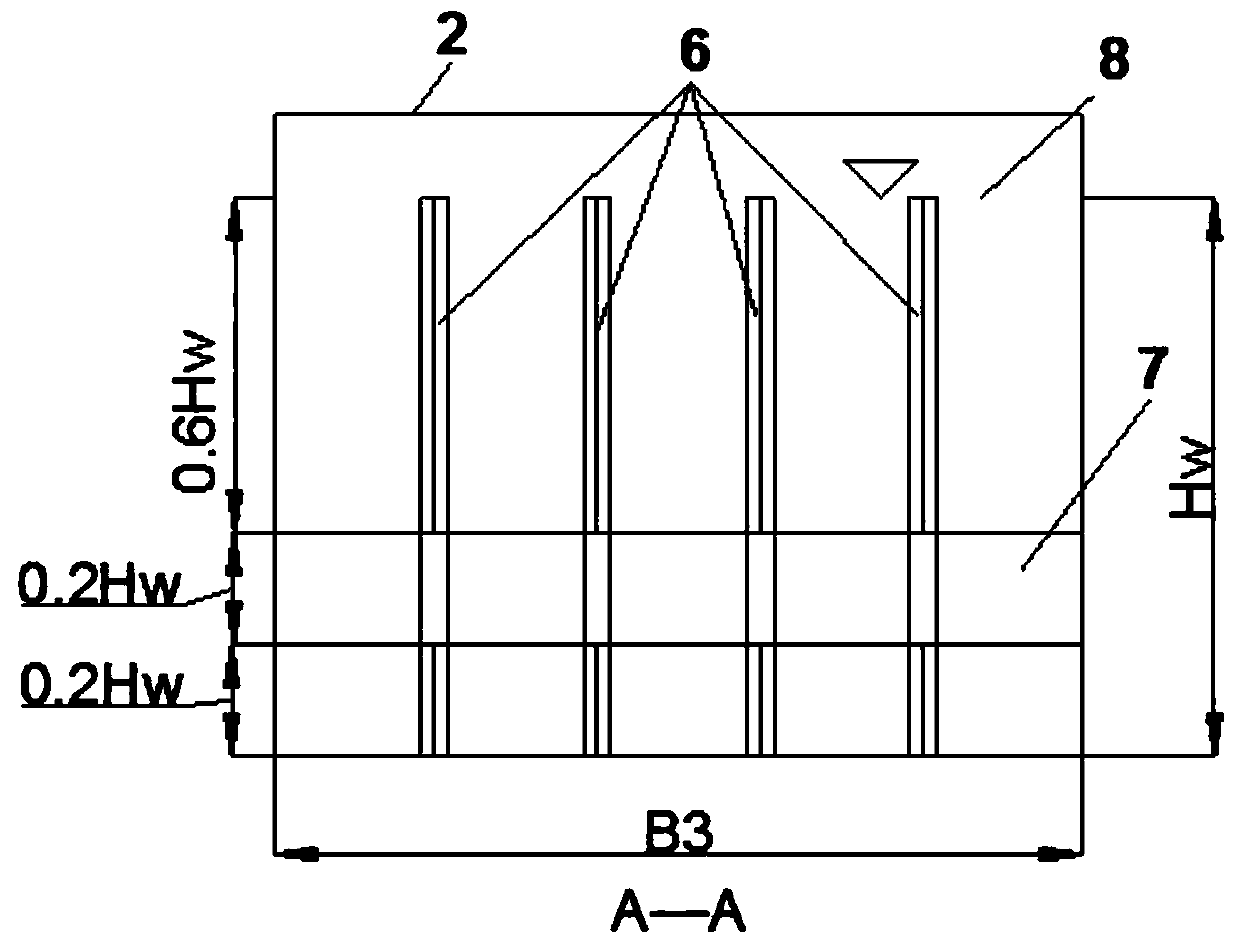

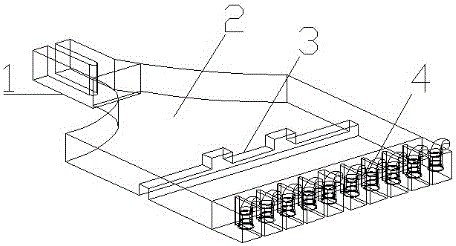

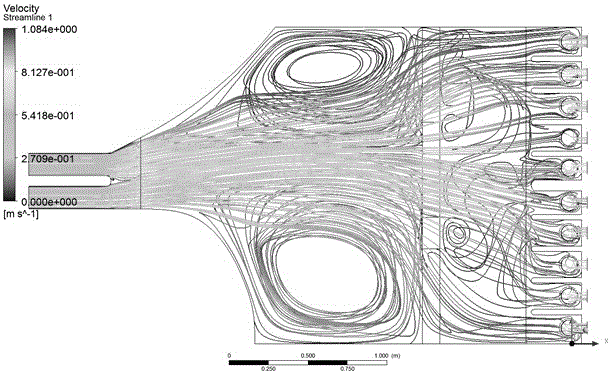

Device and method for improving flow pattern of inverted pi-shaped dam of pump station front pond

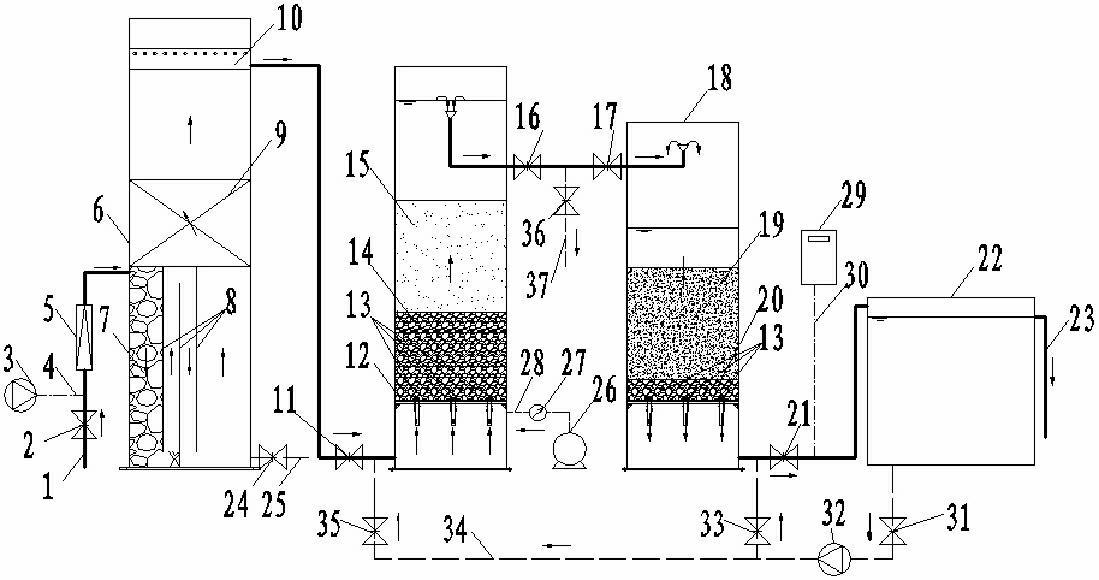

ActiveCN104805809AIncrease flow rateSimple structureBarrages/weirsStream regulationWater flowEngineering

The invention relates to a device and a method for improving the flow pattern of an inverted Pi-shaped dam of a pump station front pond. The device comprises a front pond and a flow deflector arranged on the rear part of a return flow zone in the front pond, wherein the front part of the front pond is connected with an inlet culvert; an intake pond is arranged on the rear part of the front pond. The device is characterized in that the flow deflector is the inverted pi-shaped dam; the inverted pi-shaped dam is provided with a similarly inverted letter Pi-shaped section vertical to the water flow direction; the distance between the inverted Pi-shaped dam and the intake pond is 0.2-0.4 time of the length of the front pond; the inverted Pi-shaped dam is formed by a lower dam and two upper dams symmetrically arranged on the lower dam; the lower dam of the inverted Pi-shaped dam is in a cuboid shape; the length of the lower dam is equal to the width of the front pond; the width of the lower dam is 0.5 time of the water depth in the front pond; the height of the lower dam is 0.4 time of the water depth in the front pond; each upper dam of the inverted Pi-shaped dam is in a cuboid shape; the length of each upper dam is 0.1 time of the width of the front pond; the width of each upper dam is 0.5 time of the water depth in the front pond; the height of each upper dam is 0.4 time of the water depth in the front pond. Through the device and the method for improving the flow pattern of the inverted Pi-shaped dam of the pump station front pond provided by the invention, the water intake condition of a water pump is improved, and the performance and the stability of a pump station are improved.

Owner:YANGZHOU UNIV

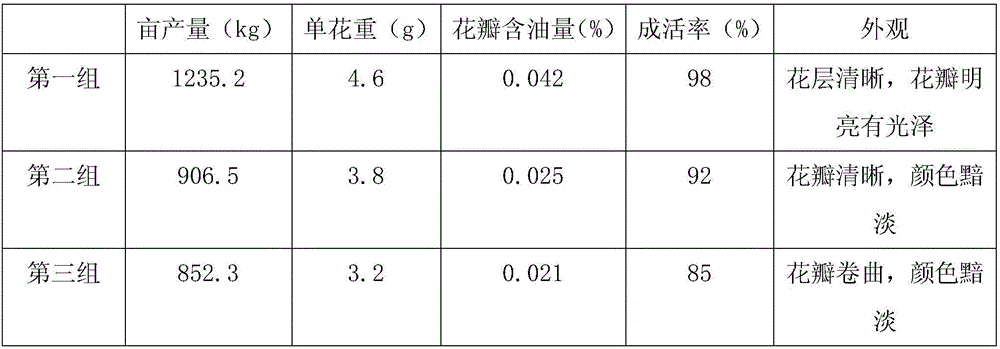

Rose planting method

InactiveCN106386035AIncrease productionEasy to useAnimal corpse fertilisersExcrement fertilisersInsect pestNutrient solution

The invention relates to a rose planting method, and belongs to the field of flower planting. The method comprises the following steps: selecting a land suitable for planting roses, building a greenhouse, applying a self-made base fertilizer which is prepared by organic fertilizer, phosphatic fertilizer and magnesium fertilizer to the land and arranging furrows, transplanting the rose plants; using a self-made composite organic fertilizer prepared from the self-made organic fertilizer, the phosphate fertilizer, a potash fertilizer and the magnesium fertilizer in winter every year; frequently applying a thin fertilizer in the daily time, spraying a nutrient solution which is prepared by the self-made organic fertilizer, the phosphate fertilizer and the potash fertilizer at a certain time interval, wherein the self-made organic fertilizer is prepared by fermenting rose rot branches, soybean meal, peanut residue, pomelo peel, fish bone, crab shell and human excrement and urine according to specific proportion; finally performing pruning and pest killing. According to the overall planting method provided by the invention, the survival rate of the rose plants is high, diseases and insect pests can be prevented, the fertilizer is saved, the production cost is reduced, the yield of crops per mu is increased, the quality of the obtained roses is good, and the method is suitable for large-scale system reproduction and strong in actual operability.

Owner:靖西县卉美花卉种植专业合作社

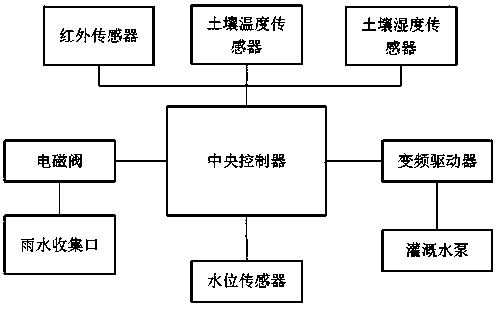

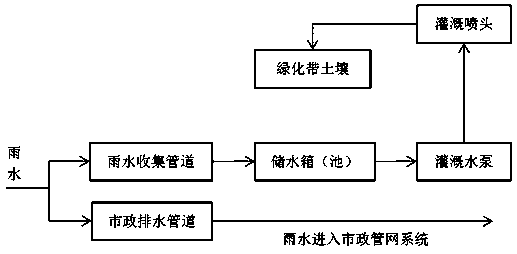

Municipal rainwater collection and irrigation system

ActiveCN111528050AControl irrigation water pressureControl irrigation timeSewerage structuresGeneral water supply conservationWater sourceWater storage tank

The invention discloses a municipal rainwater collection and irrigation system. The municipal rainwater collection and irrigation system comprises an infrared sensor, a soil temperature sensor, a soilhumidity sensor, an electromagnetic valve, a variable frequency driver and a water level sensor which are all connected with a central controller, wherein the electromagnetic valve is connected witha rainwater collection port, the variable frequency driver is connected with an irrigation water pump, and the rainwater collection port, a water storage tank and an irrigation spray head are connected through pipelines. Compared with the prior art, the municipal rainwater collection and irrigation system has the advantages that traditional manual irrigation is improved into an intelligent irrigation system, water resources are saved, a large amount of manpower and material resources are saved, the working efficiency is improved, and various operating costs are reduced. Meanwhile, under the condition that the water resources are saved to the maximum extent, the best water source condition is provided for plants, and healthy growth of the plants is guaranteed.

Owner:江苏溧阳建设集团有限公司

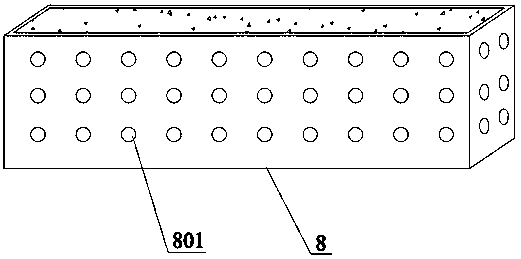

Ecological treatment system and ecological treatment method for gravel yard

InactiveCN109821868AImproves fertility and porosityFacilitate ecological governanceSpadesSoil lifting machinesIrrigationEcosystem

Disclosed are an ecological treatment system and an ecological treatment method for a gravel yard. The ecological treatment system comprises a soil treatment module and a planting restoration module.The soil treatment module comprises a crushing cavity, an improved matrix cavity and a mixing cavity. The planting restoration module comprises an irrigating and seeding device, a soil turning and impurity removing device and a plurality of planting troughs. The irrigating and seeding device comprises a rotating cavity, and the rotating cavity is divided into a seed storage cavity and an irrigation cavity by a partition plate. A plurality of rows of sowing devices are arranged on the outer side the seed storage cavity, and a plurality of rows of spraying heads are arranged on the outer side ofthe irrigation cavity. The soil turning and impurity removing device disposed below the irrigating and seeding device comprises a long rotating shaft and a plurality of rows of hook teeth disposed onthe long rotating shaft. Through holes are uniformly formed in the periphery of each planting trough, and gravel soil improved by the soil treatment module is paved in the troughs. The method combining physical improvement with biological improvement is adopted to fundamentally solve the problems of excessive gravel, hardening, poor water storage capacity and low nutrition of the soil of the gravel yard, and accordingly, the original ecosystem of the gravel yard is restored.

Owner:洛阳智昊工程科技有限公司

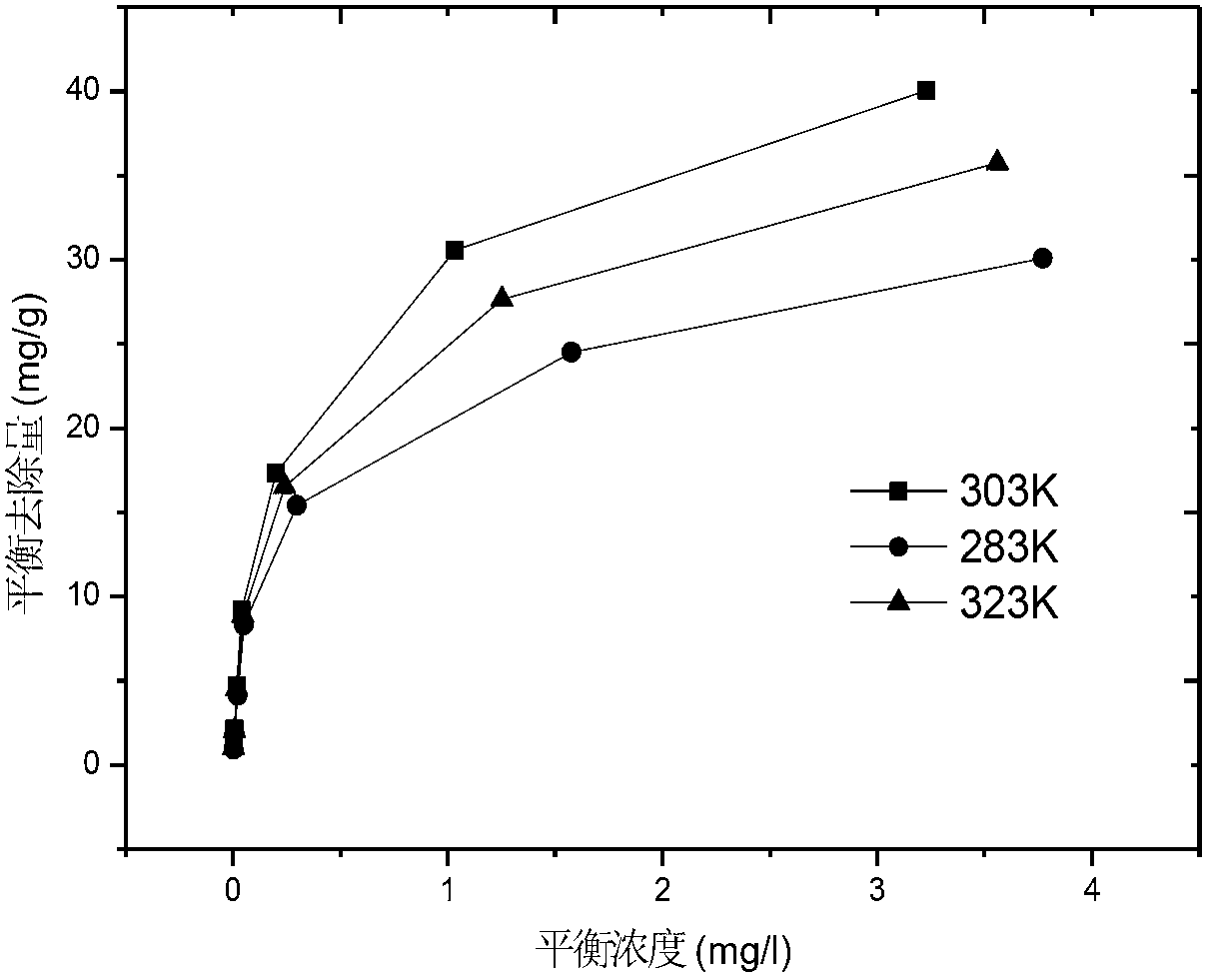

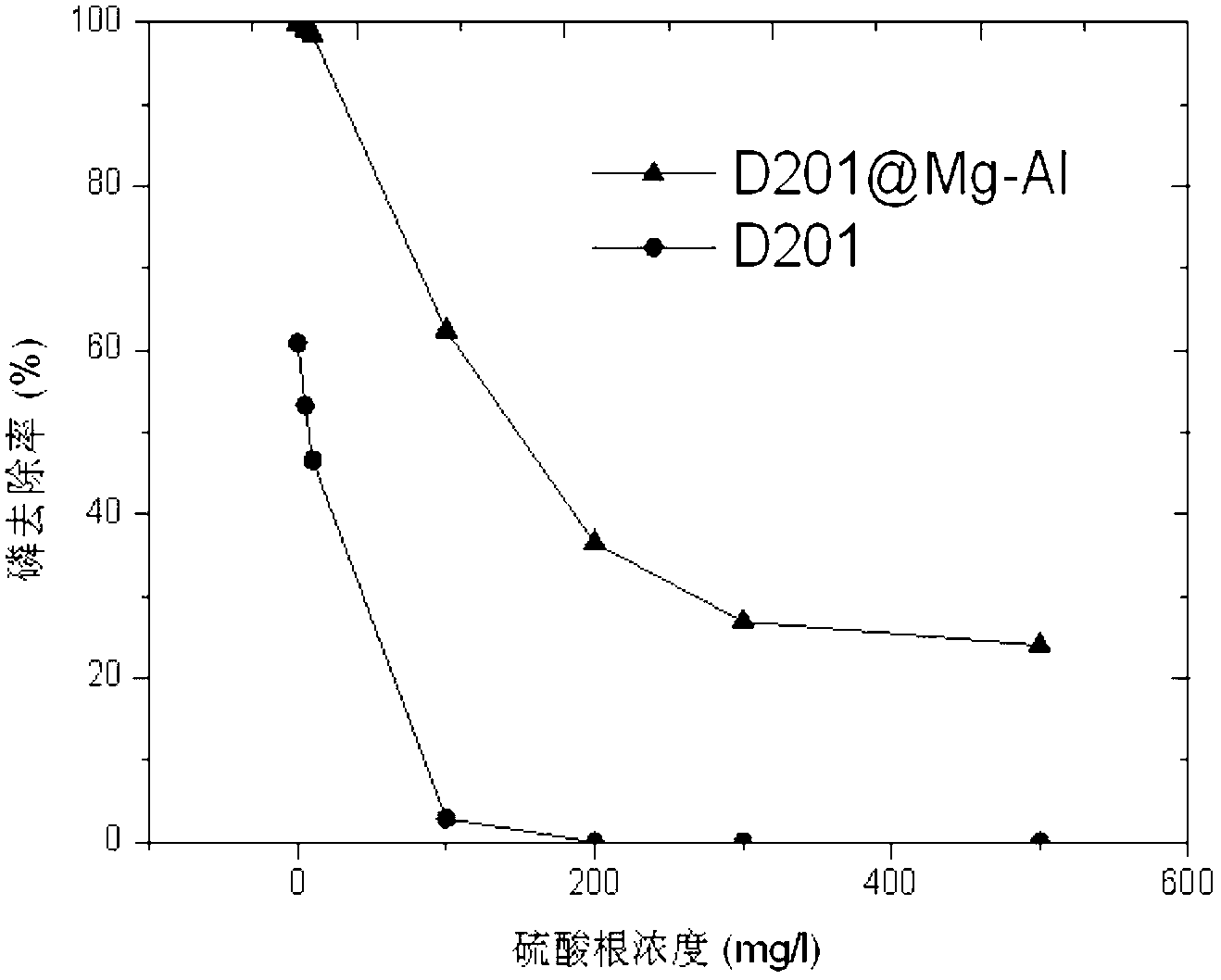

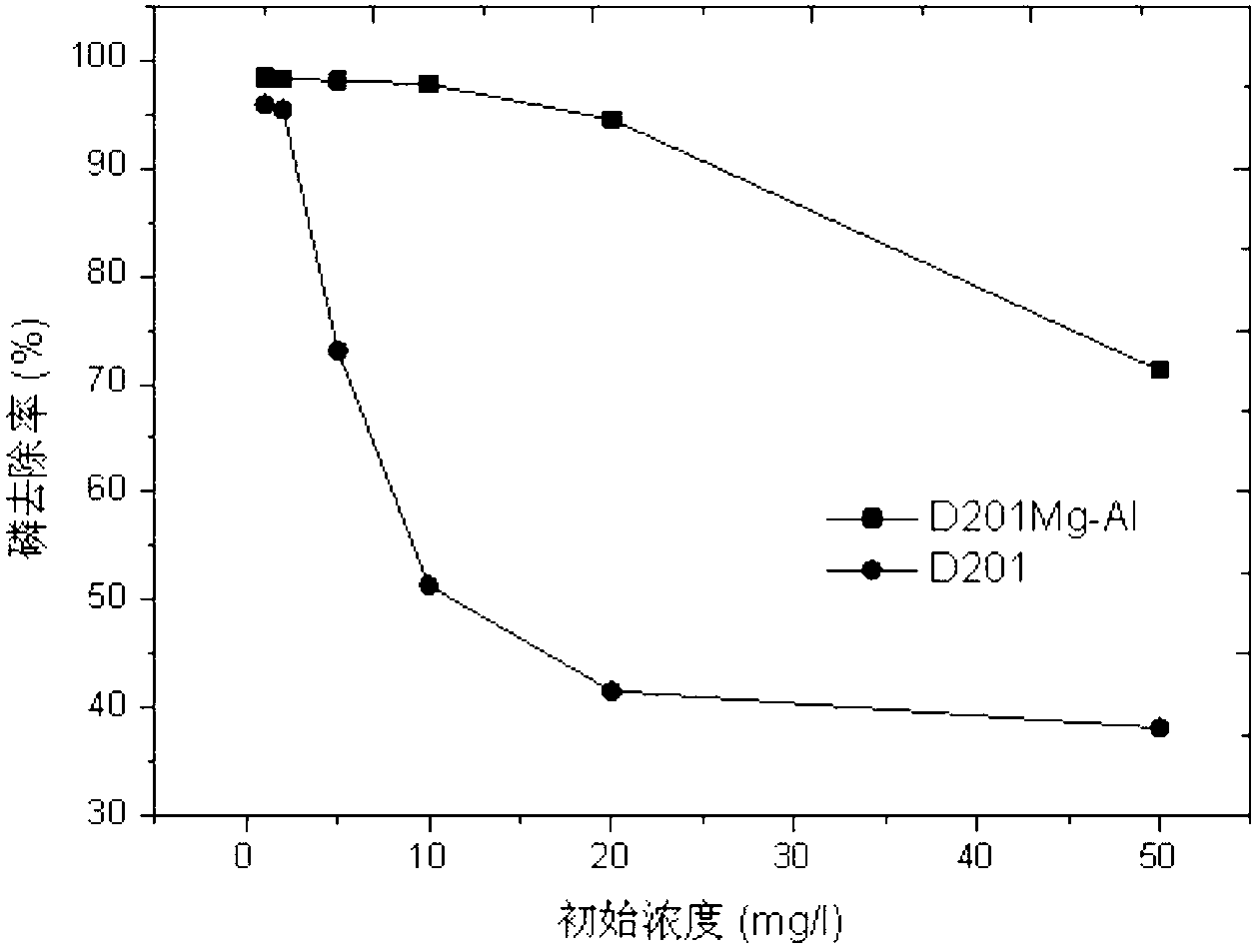

Resin base phosphorus removal absorbent and preparation method thereof

InactiveCN102921386AStrong complexation and coordination abilityHigh selectivityOther chemical processesWater/sewage treatment by sorptionAbsorption capacityHigh absorption

The present invention discloses a resin base phosphorus removal absorbent and a preparation method thereof. According to the resin base phosphorus removal absorbent, a solution containing AlCl3, HCl and MgCl2 flows through a strongly alkaline anion resin placed in an absorption column until Al<3+> completely penetrates, then the obtained strongly alkaline anion resin is subjected to centrifugation dehydration, the free water removed strongly alkaline anion resin is rapidly added to a solution containing MgCl2 and NaHCO3 to carry out a reaction, and drying is performed after completing the reaction to obtain the phosphorus removal absorbent, wherein the total magnesium-aluminum load amount is 20-140 mg / g. According to the present invention, the magnesium-aluminum binary hydrous oxide is loaded on the resin, such that the obtained new absorbent provides higher absorption capacity and absorption selectivity than the resin with no load, wherein the absorption capacity is increased by 40-200%, and the absorption selectivity is increased by about 150 times.

Owner:SOUTHEAST UNIV

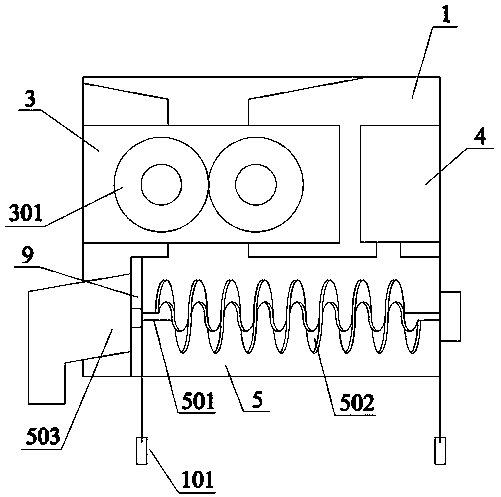

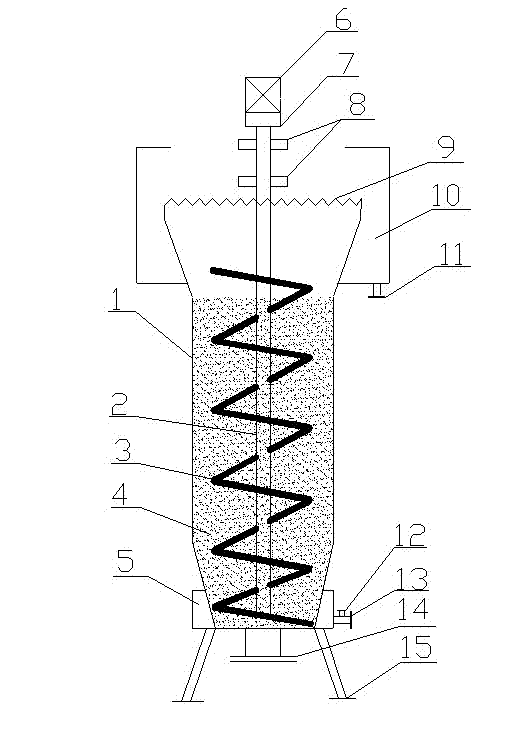

Screw-type internal electrolysis processor

The invention relates to a screw-type internal electrolysis processor for an industrial wastewater treatment process. A cylinder is fixed on a bench device and provided with a screw fixed on a driving device and capable of rotating; the screw comprises a screw shaft and screw chips surrounding the screw shaft; and a gap distance between the screw and the cylinder enables the packing to pass through. The invention has advantages of energy saving, low investment, small land occupation and high efficiency, and can enable the whole packing to collide and rub, timely remove generated products on the packing surface, and maintain the packing in a non-caking and activated state.

Owner:GUANGDONG LVYUAN ENVIRONMENTAL TECH CO LTD

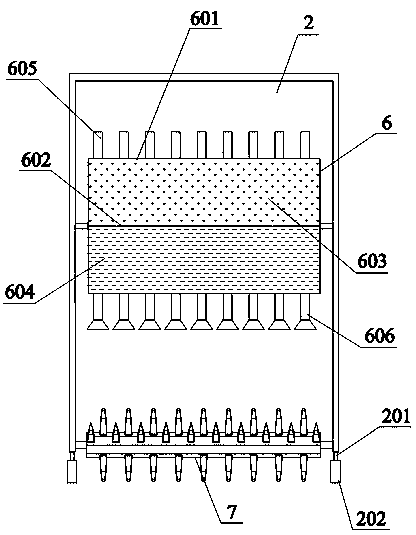

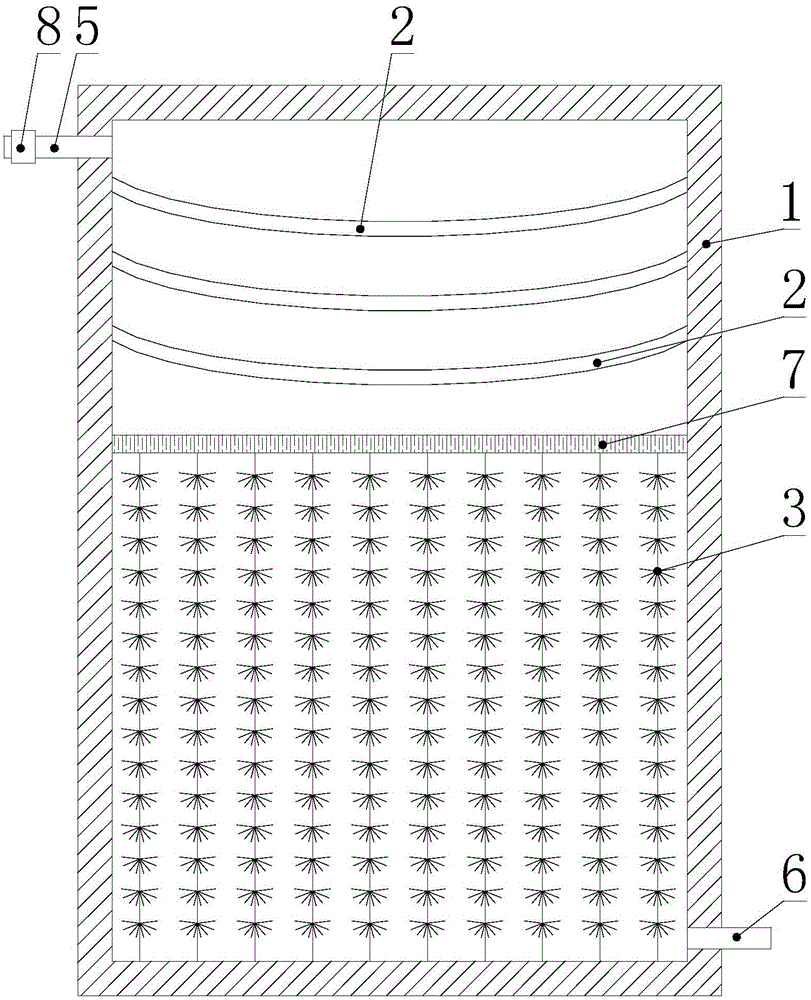

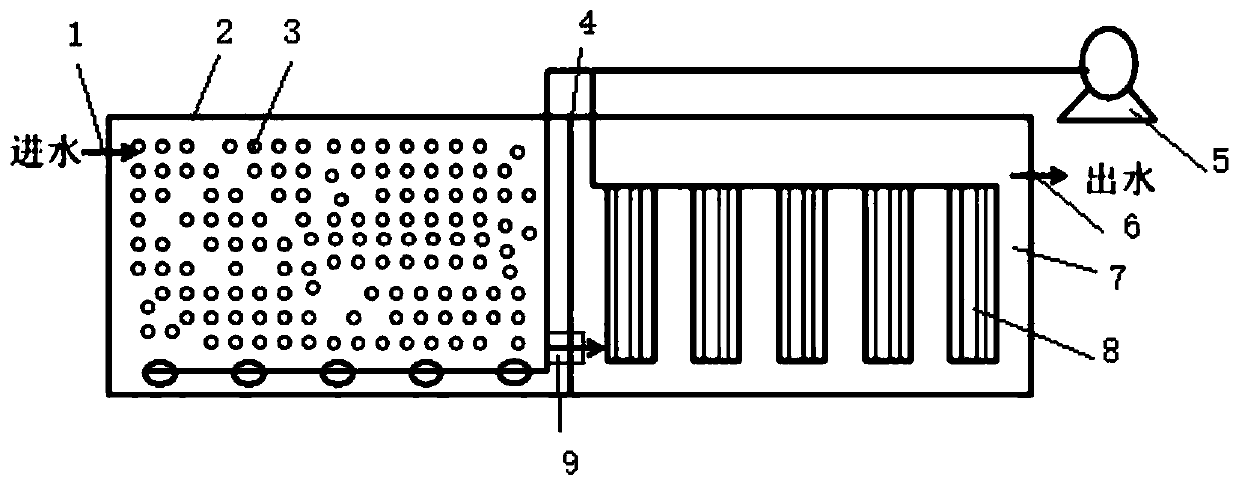

Photo-catalytic/biochemical integrated reactor

InactiveCN105130098AImprove the efficiency and effect of water biochemical treatmentImprove the efficiency and effect of water biochemical treatment in anoxic zoneWater/sewage treatment by irradiationTreatment with anaerobic digestion processesToxic materialHydroxyl radical

The invention discloses a photo-catalytic / biochemical integrated reactor, which includes a reactor body. An upper part of the reactor body is a photo-catalytic zone and a lower part of the reactor body is an anoxic zone. At least one high-pressure mercury lamp tube is arranged in the photo-catalytic zone, wherein a photo-catalyst layer is formed on inner wall of each high-pressure mercury lamp tube. A filling material is arranged in the anoxic zone. The photo-catalytic / biochemical integrated reactor has the following significant effect: in the photo-catalytic zone, hydrogen peroxide and high-active hydroxyl free radicals are generated and are used for degrading organic substances, dyes and a part of toxic substances, which are difficult to degrade biologically and is slow in biological degradation, in waste water, thereby providing an excellent input condition to the anoxic zone at the lower part and further improving water bio-chemical treatment efficiency and water bio-chemical treatment effect in the anoxic zone.

Owner:CHONGQING TAIKE ENVIRONMENTAL PROTECTION TECH CO LTD

Method and device for multicomponent oxide pretreatment of organic electroplating waste water

InactiveCN101591082BImprove biodegradabilityGood water conditionsWaste water treatment from metallurgical processMultistage water/sewage treatmentElectrolysisPretreatment method

The invention relates to a method and a device for multicomponent oxide pretreatment of organic electroplating waste water, which belong to the technical filed of electroplating waste water treatment in the environment engineering. The pretreatment method is characterized in that organic electroplating waste water is sequentially subjected to acidity adjustment, ferrum-carbon micro-electrolysis reaction and Fenton oxidation reaction. The corresponding device comprises a pH adjusting tank, a ferrum-carbon micro-electrolysis bath and a Fenton oxidation pond; an acid-alkali feeding device and a pH controller which are in link control are arranged above the pH adjusting tank; the middle low part of the ferrum-carbon micro-electrolysis bath is paved with a ferrum-carbon filler layer, while thebottom is provided with a micro-electrolysis bath perforation water distribution pipe; a hydrogen peroxide feeding device is arranged above the ferrum-carbon micro-electrolysis bath; the bottom of the Fenton oxidation pond is provided with a Fenton oxidation pond perforation water distribution pipe; and the middle lower part of the Fenton oxidation pond is provided with a granular active carbon catalytic carrier layer. The method and the device obviously improve the capability of biochemistry, simultaneously perform oxidation reaction to remove mostly organic pollutants and create favorable water inlet condition for subsequent coagulating sedimentation, air flotation and biochemical treatment.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

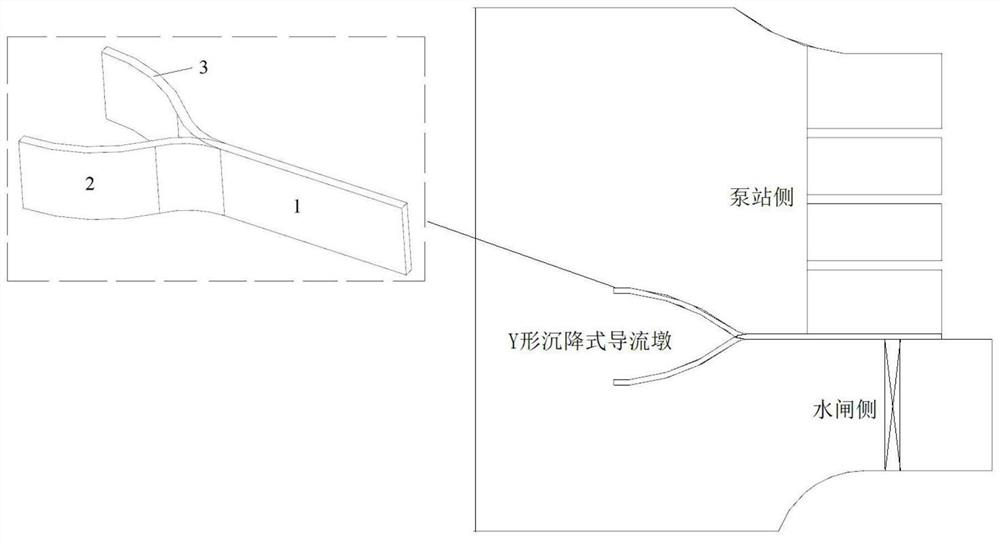

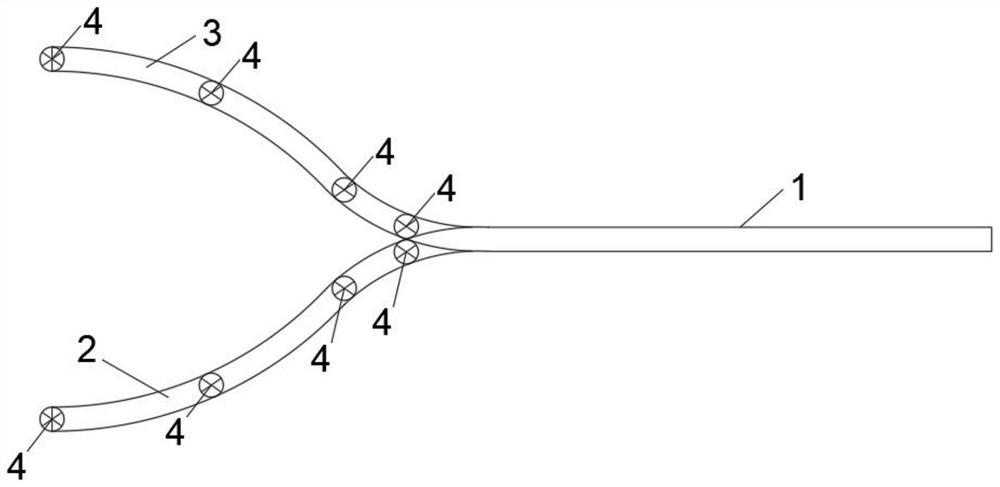

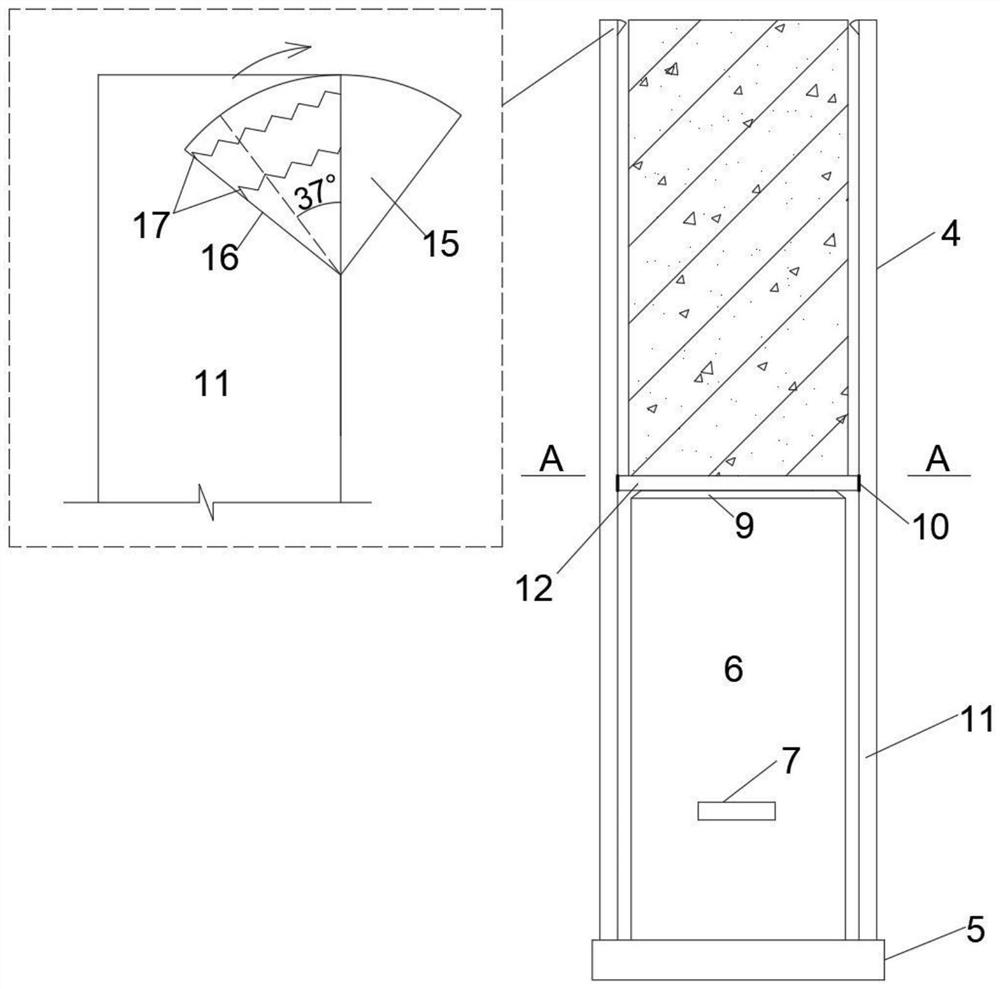

Y-shaped sedimentation type flow guide pier suitable for combination of gate station

ActiveCN114293518AReasonable structureSimple and scientific structureBarrages/weirsHydro energy generationEngineeringMechanical engineering

The Y-shaped sedimentation type flow guide pier comprises a long straight body section, a first arc body section and a second arc body section, and the first arc body section and the second arc body section are oppositely arranged and spliced with the long straight body section to form a Y-shaped structure; the Y-shaped sedimentation type flow guide mop is arranged at the joint of a water gate and a pump station in gate-station combination, the long straight body section is connected with a gate pier at the joint of the water gate and the pump station, the first arc body section is located on the side of the water gate, and the second arc body section is located on the side of the pump station. The first arc body section and the second arc body section are respectively supported by a hydraulic lifting platform at the bottom, the pump station independently operates by controlling the hydraulic lifting platform to enable the second arc body section to sink below the water gate and the pump station foundation, and when the water gate independently operates, the hydraulic lifting platform is controlled to enable the first arc body section to sink below the water gate and the pump station foundation. According to the Y-shaped sedimentation type flow guide pier, by isolating backflow, the water inlet condition of the side wall is optimized, and then the water inlet condition of a gate station combination project is improved.

Owner:YANGZHOU UNIV

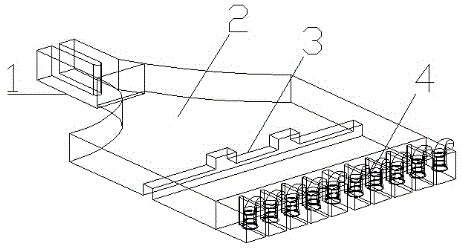

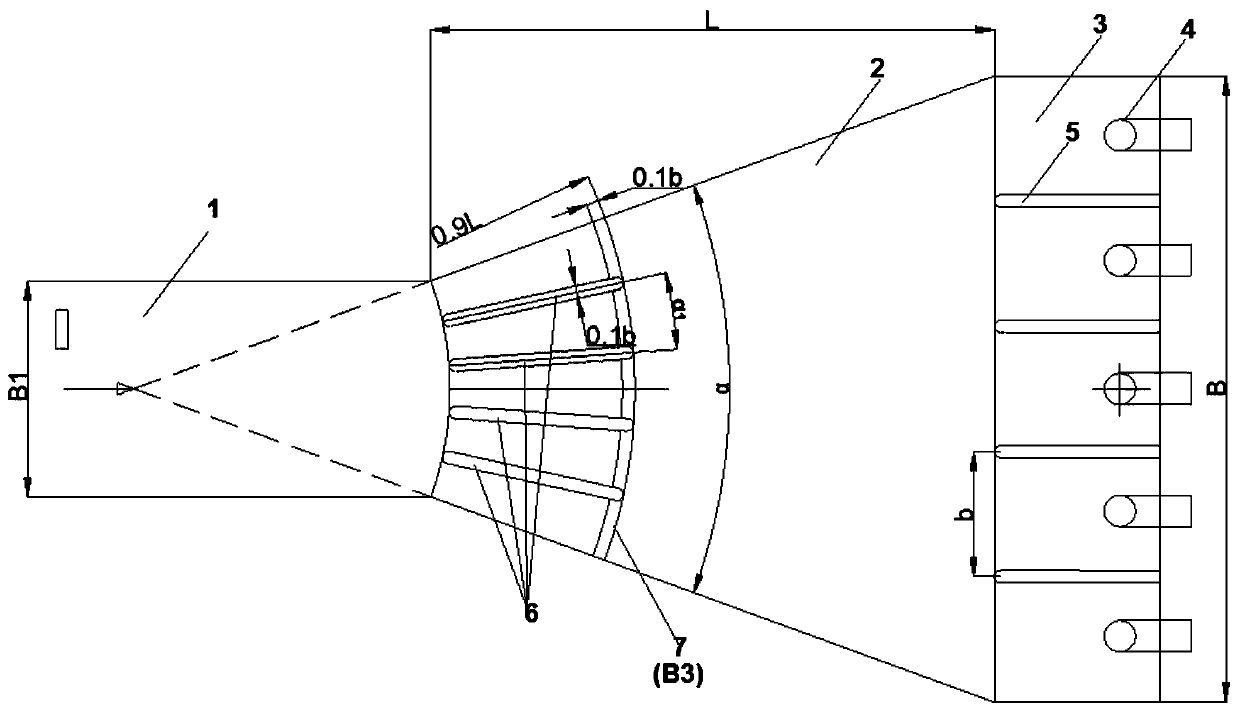

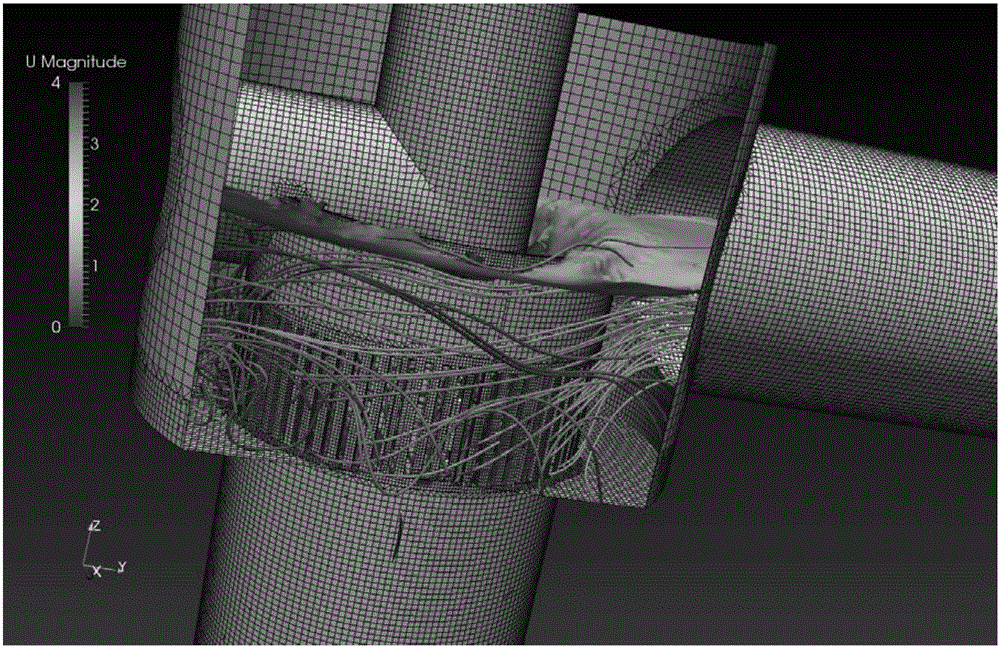

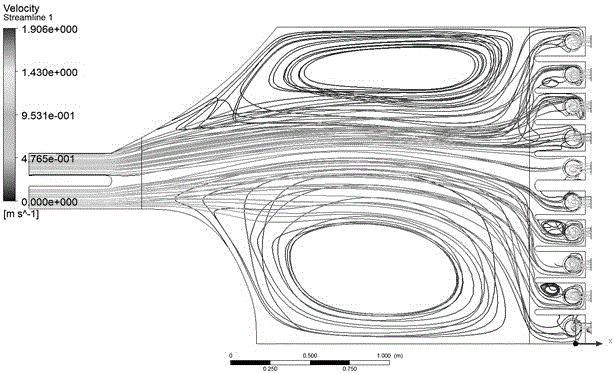

Structure and method for regulating diffusion flowing of pump station forebay

InactiveCN110952648AConducive to safe and economical operationImprove fluiditySewerage structuresPumping plantsWater trapWater flow

The invention discloses a structure and method for regulating diffusion flowing of a pump station forebay, and belongs to the technical field of water conservancy projects. The structure comprises anapproach channel, the forebay, water inlet ponds, separating piers between the water inlet ponds and water pump water sucking pipes in the water inlet ponds and is characterized in that the forebay isprovided with a plurality of flow separating plates and an arc strip plate, the flow separating plates are fixed to the forebay, and are in one-to-one corresponding to the separating piers, the arc strip plate is fixed to the rear ends of the flow separating plates, and the flow separating plates are connected into a comb-shaped combination plate. The structure is suitable for forward water inletforebays of various pump stations. The forebay flowing state can be effectively improved, the vortex and the backflow of the forebay can be removed, the water flow in the forebay and the water inletpond can be more smooth, the good water inlet condition is provided for water inlet of a water pump, the safe and economic operation of a pump station is facilitated, and the structure is simple, technically reliable, easy to implement, small in engineering amount, and large in economic benefit. The structure is technically reliable, easy to implement, obvious in benefit and wide in application prospect.

Owner:YANGZHOU UNIV

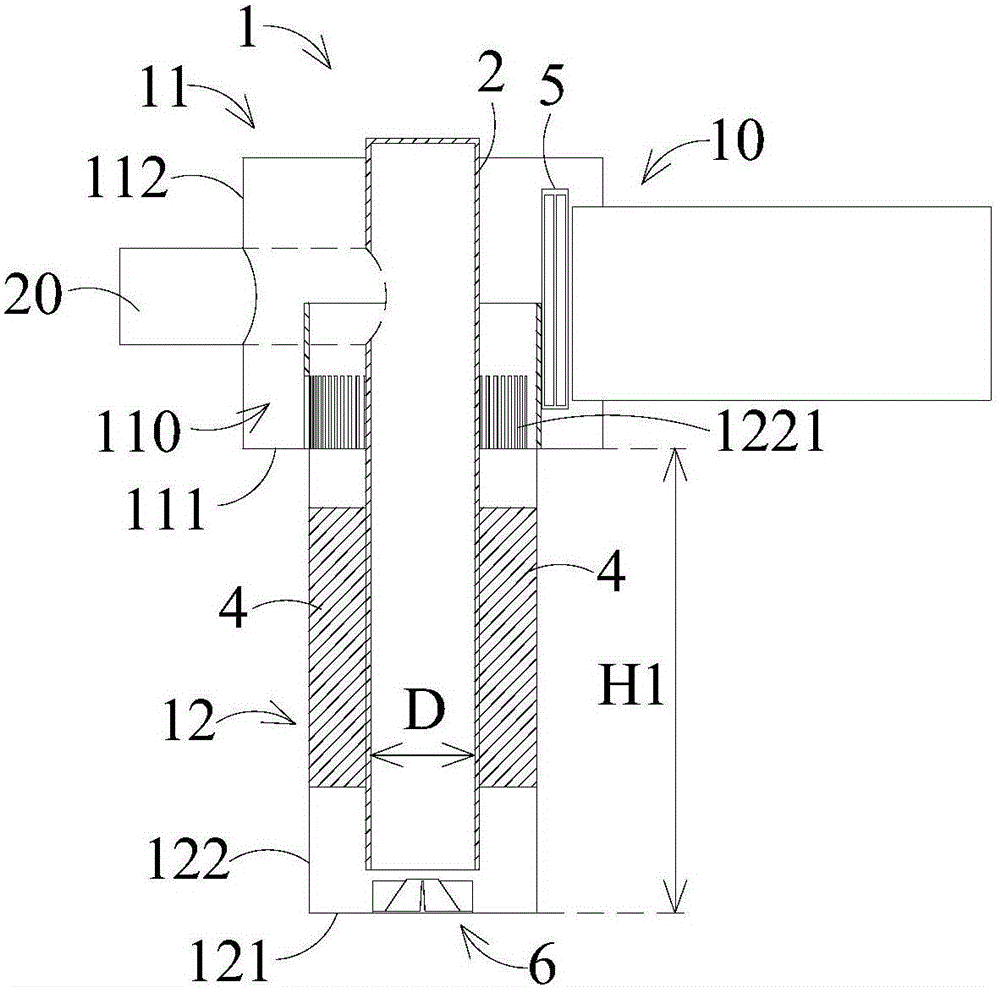

Prefabricated pump station unit and water distribution unit

ActiveCN107435371AAvoid or reduce the impactGood water conditionsSewerage structuresEngineeringWellbore

The invention provides a prefabricated pump station unit and a water distribution unit. The prefabricated pump station unit comprises a prefabricated pump station body and a wellbore installed inside the pump station body. The pump station body comprises an outer cylinder and an inner cylinder; the outer cylinder comprises an outer cylinder bottom and an outer peripheral wall installed on the outer cylinder bottom, wherein a submerged pump is installed on the outer peripheral wall; the inner cylinder comprises an inner peripheral wall; a top end of the inner cylinder is provided with an opening; an upper end of the inner cylinder is installed on the outer cylinder bottom of the outer cylinder in a penetrating mode and is positioned inside the outer cylinder; the rest part of the inner cylinder is positioned outside the outer cylinder; a circulation space is formed by a partial inner peripheral wall, a partial outer peripheral wall and the outer cylinder bottom. The fabricated pump station unit has good current stabilization and guiding performance so that the state of flow entering suction opening of the submerged pump is uniform, therefore good condition for water inlet is provided for the submerged pump and operation stability of the submerged pump is improved.

Owner:GRUNDFOS HLDG +1

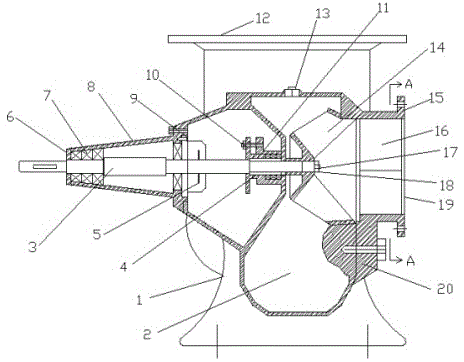

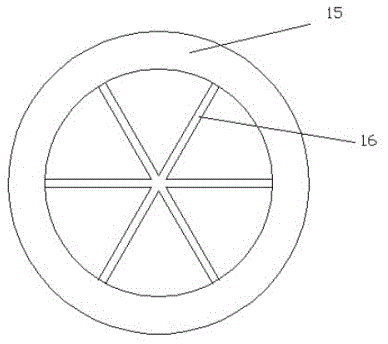

Novel mixed-flow pump

InactiveCN103603807ARelieve pressureReduce noisePump componentsRotary non-positive displacement pumpsImpellerCavitation

The invention discloses a novel mixed-flow pump which comprises a pump body, a pump shaft, an impeller and rotating resistance blades. The pump shaft is mounted and supported in the pump body through a bearing body, a bearing, a front cover, a rear cover and a shaft sleeve. The impeller is fixed at one end of the pump shaft, the rotating resistance blades are arranged at the front end of a pump cover, and the rotating resistance blades and the pump cover are cast to be of an integral structure. The impeller is arranged in a mixed-flow chamber, a water outlet is formed in the upper portion of the pump body, and a sucking opening, the mixed-flow chamber and the water outlet are communicated. According to the novel mixed-flow pump, the rotating resistance blades are evenly arranged on the pump cover of an existing mixed-flow pump, the pressure fluctuation and the cavitation noise of water flow are lowered, the water inlet condition of a water pump is improved, and the safety and the stability of operation of the water pump are improved.

Owner:谭国华

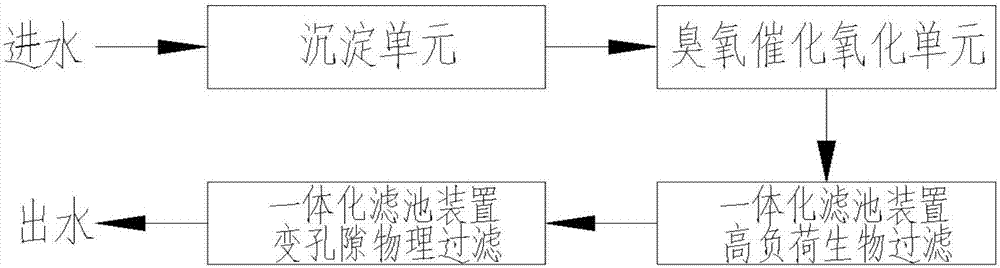

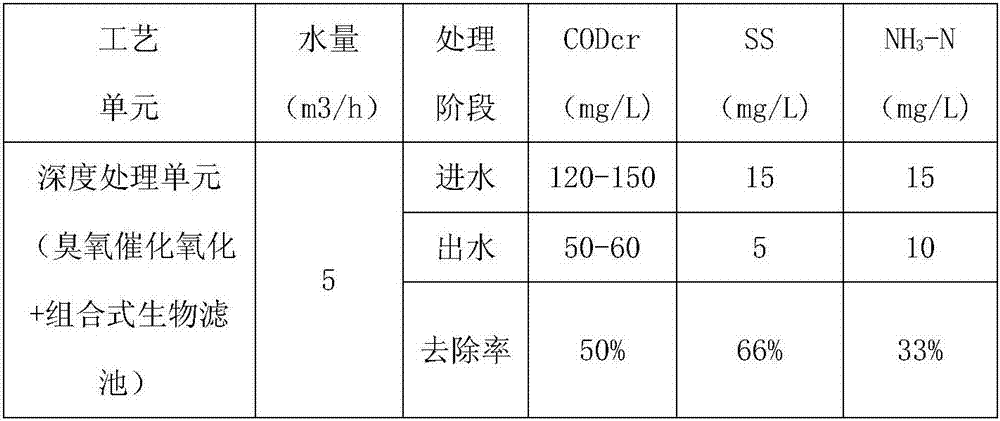

Deep treatment method of petrochemical engineering organic wastewater difficult to biodegrade

InactiveCN107235603AAchieve decolorizationAchieve degradabilityWater contaminantsMultistage water/sewage treatmentDecompositionFixed bed

The invention discloses a deep treatment method of petrochemical engineering organic wastewater difficult to biodegrade. Secondary treatment effluent of a petrochemical engineering sewage treatment device is treated with a catalytic ozonation and integrated biological filter combination technology, and the method specifically comprises the steps as follows: a coagulant and a coagulant aid are added to secondary treatment effluent for a precipitation reaction; then the sewage enters an ozonation reactor and is subjected to an oxidation reaction with ozone under the action of fixed bed catalytic filler, and the purposes of decolorizaiton and organic matter decomposition are achieved; finally, a high-load biological filter procedure and a variable-pore filter procedure are performed through an integrated biological filter, and after the sewage is treated by biological membranes attached to and growing on the surface of biological filter filler and is filtered by variable-pore filler, biodegradable organic matter in ozone decomposed water can be removed. The method is simple in process and convenient to operate, emission of pollutants in the petrochemical engineering sewage can be effectively reduced, the effluent quality requirement of existing secondary treatment process upgrading and reconstruction is met, and the economic benefit is increased.

Owner:CEEP CO LTD

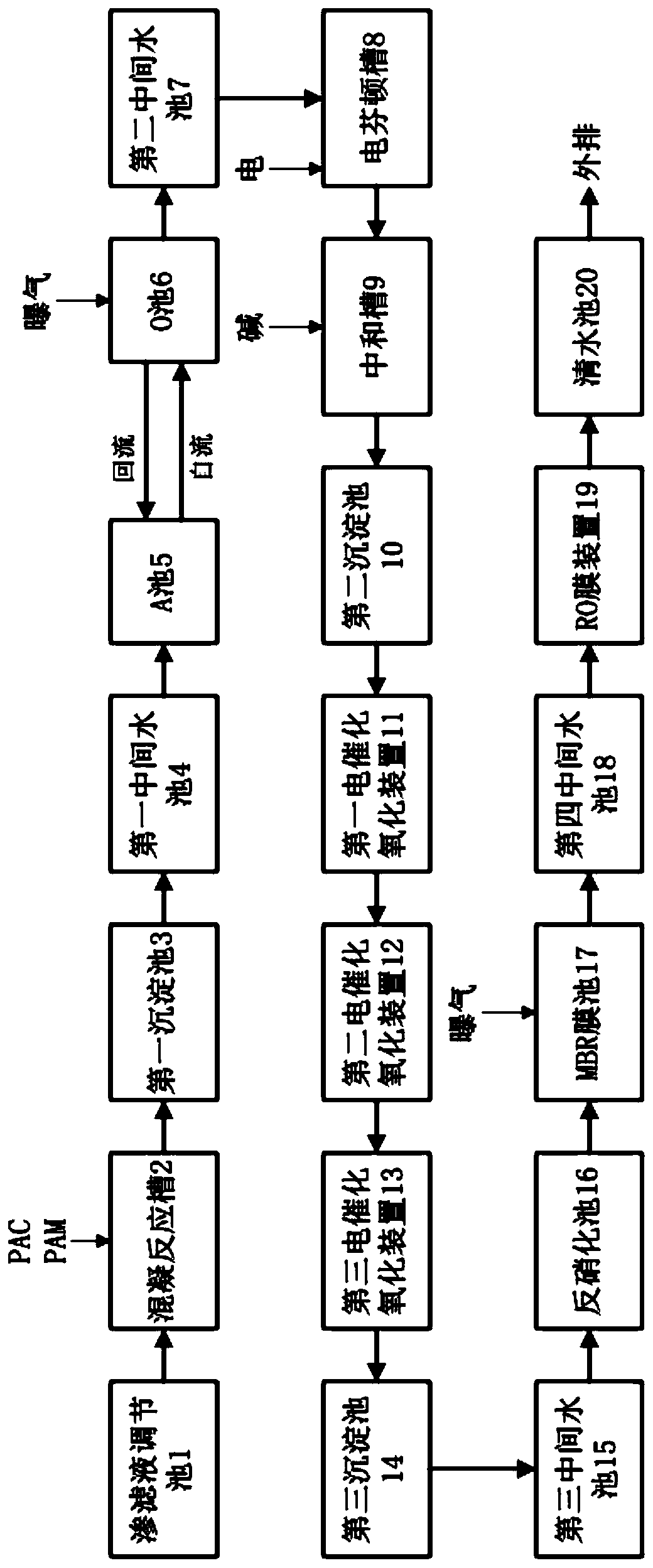

Leachate treatment system for rural household refuse landfill

PendingCN110950508AEfficient removalImprove removal efficiencyWater treatment compoundsWater contaminantsCatalytic oxidationEnvironmental engineering

The invention discloses a leachate treatment system for a rural household refuse landfill, and relates to the technical field of environmental protection and treatment. The leachate treatment system comprises a leachate regulating tank, and further comprises a coagulation reaction tank, a first sedimentation tank, a first intermediate water tank, an AO biochemical device, a second intermediate water tank, an electro-Fenton tank, a neutralizing tank, a second sedimentation tank, a multi-stage electro-catalytic oxidation device, a third sedimentation tank, a third intermediate water tank, a denitrification tank, an MBR membrane tank, a fourth intermediate water tank, a RO membrane device and a clean water tank which are connected in sequence. According to the method, the landfill leachate can be treated with low cost and high efficiency, so that the defects in the existing landfill leachate treatment method are overcome.

Owner:湖北山鼎环境科技股份有限公司

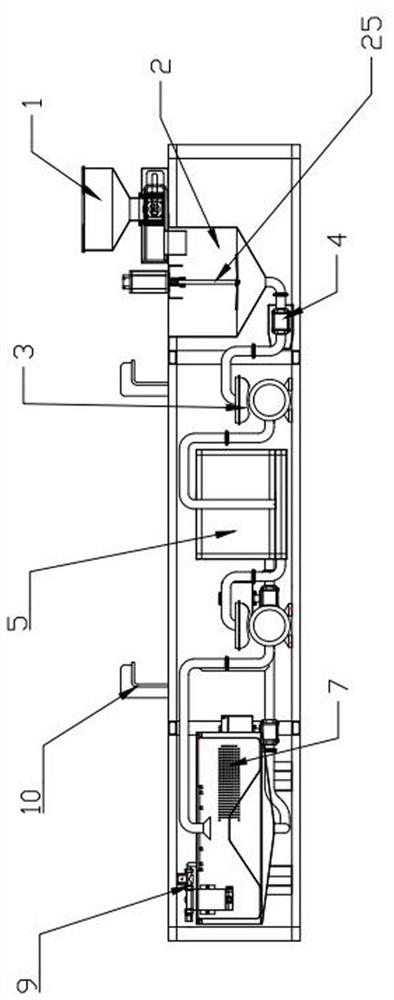

High-speed train motor train unit vehicle-mounted toilet fecal sewage on-line direct drainage treatment method and treatment equipment

PendingCN114455784AImprove clarity and transparencyRealize processing cycleBiological treatment apparatusTreatment involving filtrationFlocculationIn vehicle

The invention relates to the field of high-speed rail equipment vehicle-mounted toilet water treatment equipment, in particular to a high-speed rail motor train unit vehicle-mounted toilet fecal sewage on-line direct drainage treatment method and treatment equipment. The invention aims to solve the problems of short required treatment time, limited space and high treatment standard of vehicle-mounted toilet excrement water online treatment equipment in a high-speed rail motor train unit. The method comprises the technological processes of crushing, flocculation, solid-liquid separation, electro-catalysis, biological deodorization and the like. The method has the most prominent advantages that the flocculation effect is achieved by utilizing micropores in volcanic rock to achieve ion replacement with organic matter in sewage, the organic matter in excrement is flocculated out through ion replacement, no new solid waste is generated, treatment is efficient, and the organic matter degradation pretreatment rate is high.

Owner:洛阳博鑫生物工程科技有限公司

Distributed sewage treatment system and treatment method using the treatment system

ActiveCN107381961BShort stayReduce pollutionWater treatment parameter controlTreatment with anaerobic digestion processesRural areaIndustrial waste water

The invention relates to a dispersion-type sewage treatment system. The system comprises a conditioning tank, a primary settling tank, an anaerobic tank, an anoxic tank, an aerobic tank, a secondary settling tank, a sludge collection tank, a sludge concentration tank and a sewage collection tank. The system is a mobile small integrated sewage treatment device based on an A2 / O technology and combination with two-point water inlet, sludge double reflux, a bubble-free aeration membrane and an aerobic cell special sub-grid form, can be used for treatment on urban domestic sewage in the urban fringe and the novel district difficult to cover with an urban drainage pipe network and economic development relatively backward vast rural areas and small towns, treatment on a part of industrial wastewater with similar characteristics to those of urban domestic sewage and treatment on urban special wastewater in hospitals and foreign guesthouses.

Owner:天津诚信环球节能环保科技有限公司

A new method for manufacturing ecological blanket matrix for mine restoration

The invention relates to a method for manufacturing a new type of mine restoration ecological blanket matrix. The porous water-storage clay is crushed into particles with a particle size of ≤5mm, and mixed with dried sludge at a volume ratio of 1.5-2.8:7.2-8.5. Uniform, adding grass seeds therein to make a new type of mine restoration ecological blanket matrix; the dried sludge is processed into a pH range of 7.5-9, a moisture content range of 45-50%, and a carbon-nitrogen ratio range of 15- 20:1, the organic matter content ranges from 10% to 30% in the dried sludge of urban domestic sewage treatment plants. The new ecological blanket matrix for mine restoration made by the invention can store water and purify rainwater at the same time, improve soil pores, create good water source conditions for the initial growth and germination of plant grass seeds and adapt to the environment, and improve the survival rate of herbal plants in mine restoration ecological blankets, especially suitable for It is suitable for mines and rock slopes with poor water retention and storage conditions.

Owner:WUHAN GAN SHI DAI ENVIRONMENT RESOURCE TECHCO

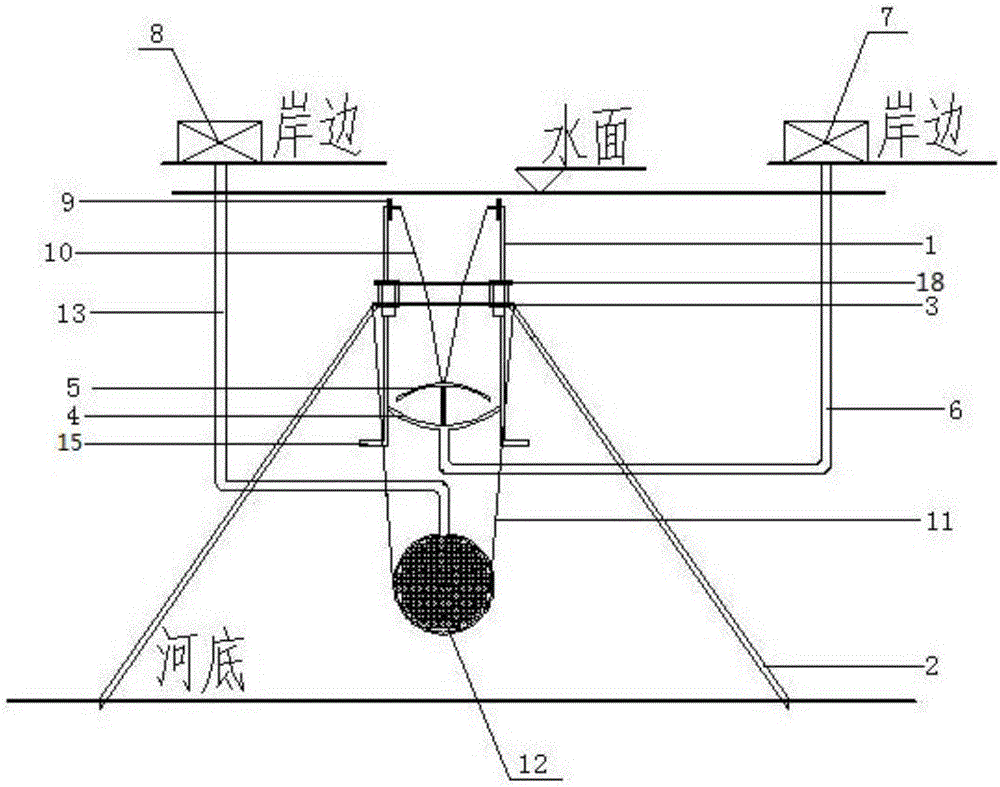

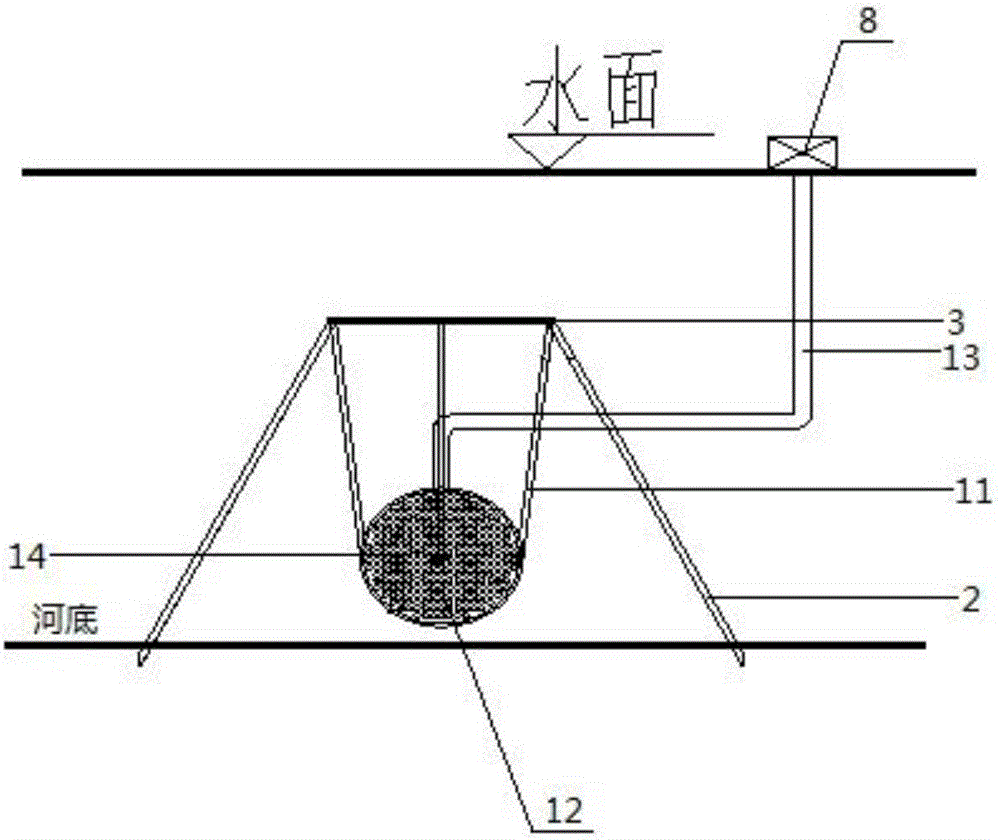

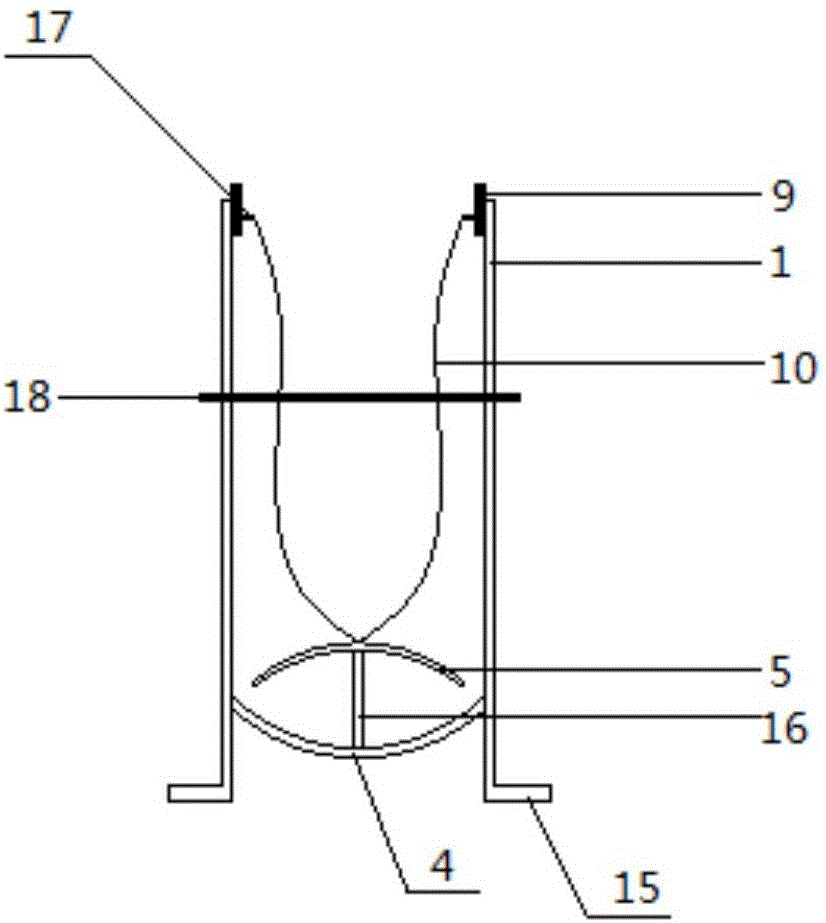

River trash collection device

ActiveCN106759189AConstant distanceConstant suction flowWater cleaningRefuse collectionArchitectural engineering

The invention discloses a river trash collection device which comprises a supporting frame and a collection barrel. The supporting frame comprises a connection plate, a support and a steel ball vertically hung under the connection plate through a steel rope. The steel ball is filled with multiple steel beads. One end of the support is fixedly connected with the connection plate through a rotating shaft. The other end of the support is inserted into a river bottom. The collection barrel is in a U shape. The outer side wall of the U-shaped collection barrel is provided with a steel plate. The middle of the connection plate is of a through hole structure. The collection barrel is sleeved with the connection plate of the through hole structure. The steel plate and the connection plate are in matched connection through a bolt and a nut. The top of the collection barrel is provided with a water inlet ring. The water inlet ring and the collection barrel are in matched connection through internal and external threads. A steel ring is welded in the water inlet ring. A trash collection net is hung to the steel ring. An arc partition plate is arranged in the collection barrel. The arc partition plate is fixedly connected with a bottom plate of the collection barrel through a steel column. The bottom plate of the collection barrel is provided with a through hole which is connected with a water sucking hose. The collection barrel is connected with a water sucking pump through the water sucking hose. The river trash collection device is good in practicability.

Owner:HOHAI UNIV

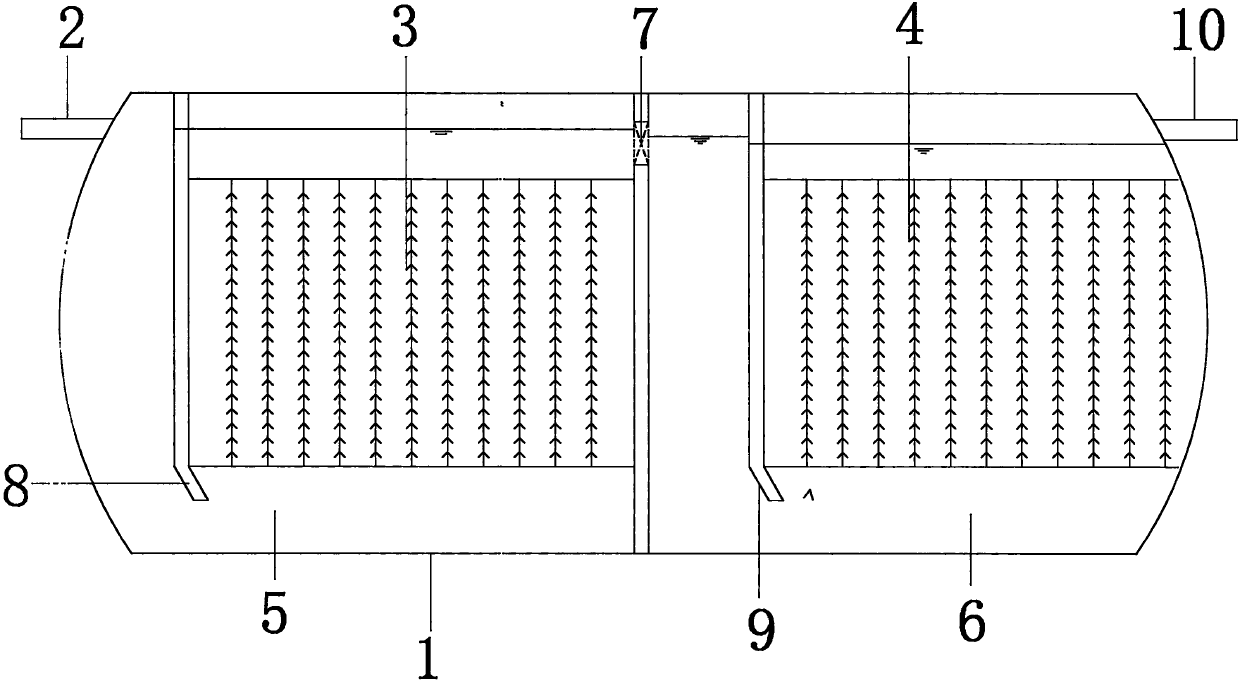

Integrated glass fiber reinforced plastic anaerobic jar

InactiveCN111056628AGood water conditionsImprove the mixing effectWater contaminantsBiological treatment apparatusGlass fiberSewage

The invention belongs to the technical field of sewage treatment, and discloses an integrated glass fiber reinforced plastic anaerobic jar. The integrated glass fiber reinforced plastic anaerobic jarcomprises a tank body; a water inlet pipe is mounted at the top of the left side of the tank body; a water outlet pipe is mounted at the top of the right side of the tank body; a first anaerobic tankand a second anaerobic tank are respectively arranged on the left side and the right side of the inner cavity of the tank body; a first anaerobic filler layer is arranged in the inner cavity of the first anaerobic tank; a second anaerobic filler layer is arranged in the inner cavity of the second anaerobic tank; a first notch is formed in the bottom of the left side of the first anaerobic tank; afirst baffle plate is arranged at the first notch; by adopting an up-and-down baffling mode, a good water conservancy condition is achieved, the mixing effect is good, organic matters in sewage can bein full contact with anaerobic microorganisms, the decomposition of organic matters is facilitated, the biodegradation degree of organic matters is improved, and the tank body is high in structural strength, excellent in acid and alkali resistance, moisture resistance and oxidation resistance, free of deformation at high and low temperatures and long in service life.

Owner:HUNAN YIJING ENVIRONMENTAL PROTECTION TECH CO LTD

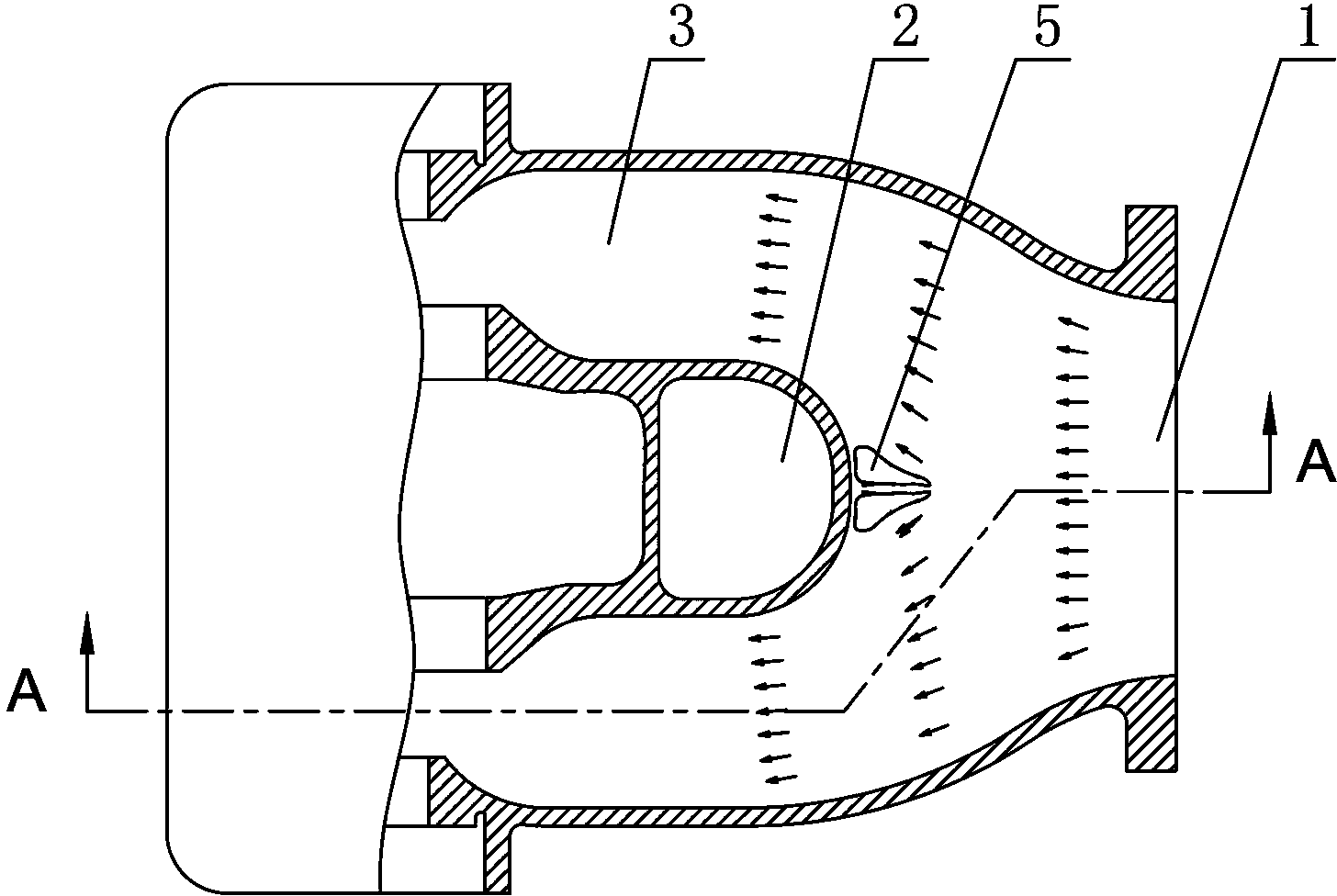

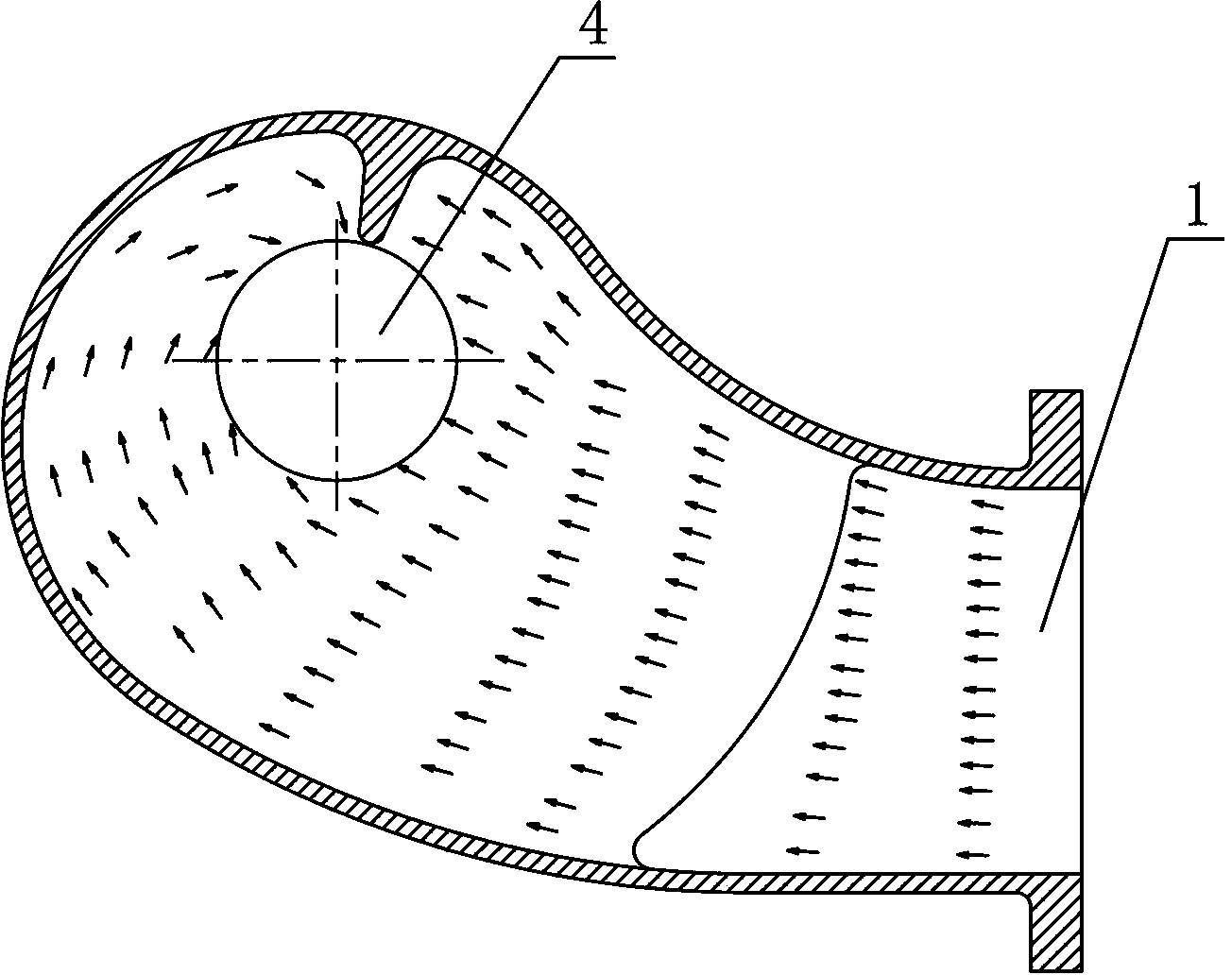

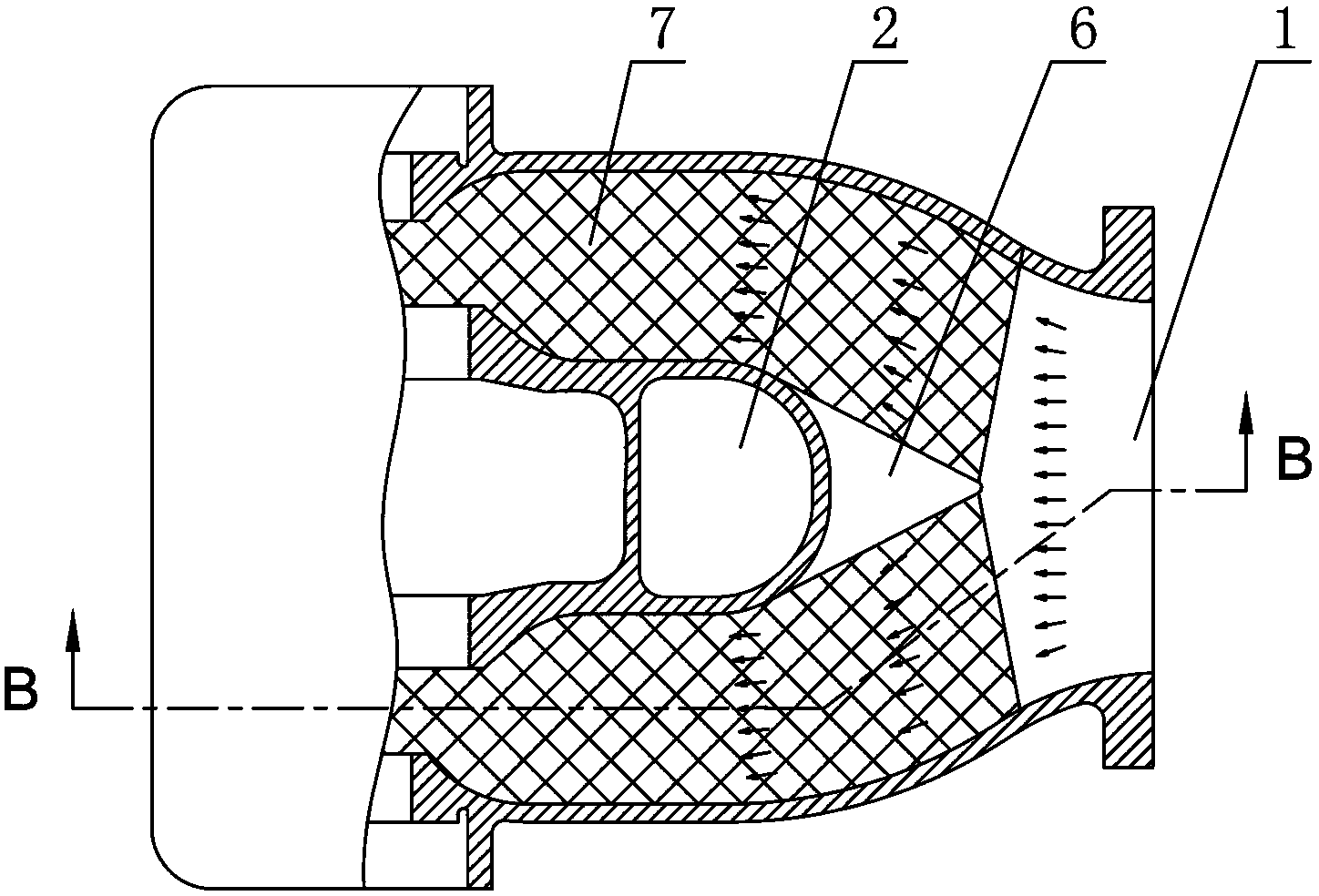

Water inlet flow channel of axially split pump

InactiveCN103758785AUniform change in cross-sectional areaImprove pressure bearing capacityPump componentsPumpsImpellerEngineering

The invention discloses a water inlet flow channel of an axially split pump. The water inlet flow channel mainly comprises a water inlet, a volute zone and flow channel zones. Longitudinal water distributing ribs are arranged between the water inlet and the volute zone, and transverse flow guide ribs are arranged in the flow channel zones. Prismatic protrusions are arranged at starting ends of the longitudinal water distributing ribs and extend backwardly, the widths of the prismatic protrusions are gradually increased towards the two side flow channel zones, and the longitudinal water distributing ribs are connected with the inner walls of the two side flow channel zones in a smooth transition manner. The transverse flow guide ribs are horizontally arranged on central flow lines of the two side flow channel zones and are connected with the water inlet and an inlet of a water pump impeller all along. The water inlet flow channel has the advantages that the longitudinal water distributing ribs are reasonably arranged according to the shape of the water inlet flow channel, so that various sectional areas of the inside of the flow channel can be changed uniformly, and dead water zones and vortex zones can be eliminated; the transverse flow guide ribs are arranged on the central flow lines of the flow channel zones, so that a water inlet condition can be improved, and the structural strength of the water inlet flow channel can be enhanced.

Owner:钱向阳

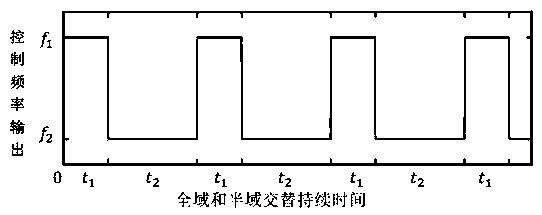

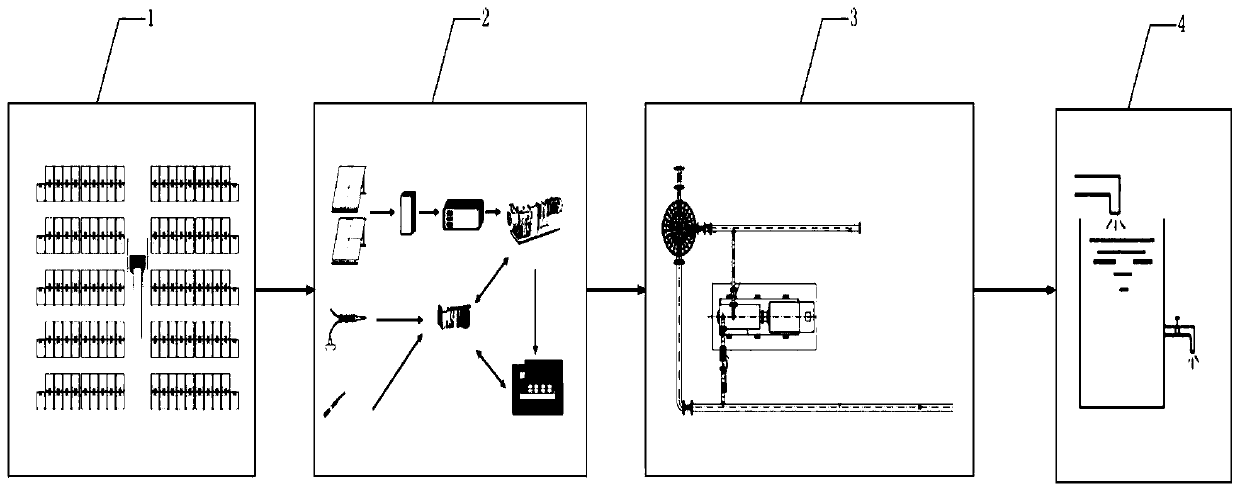

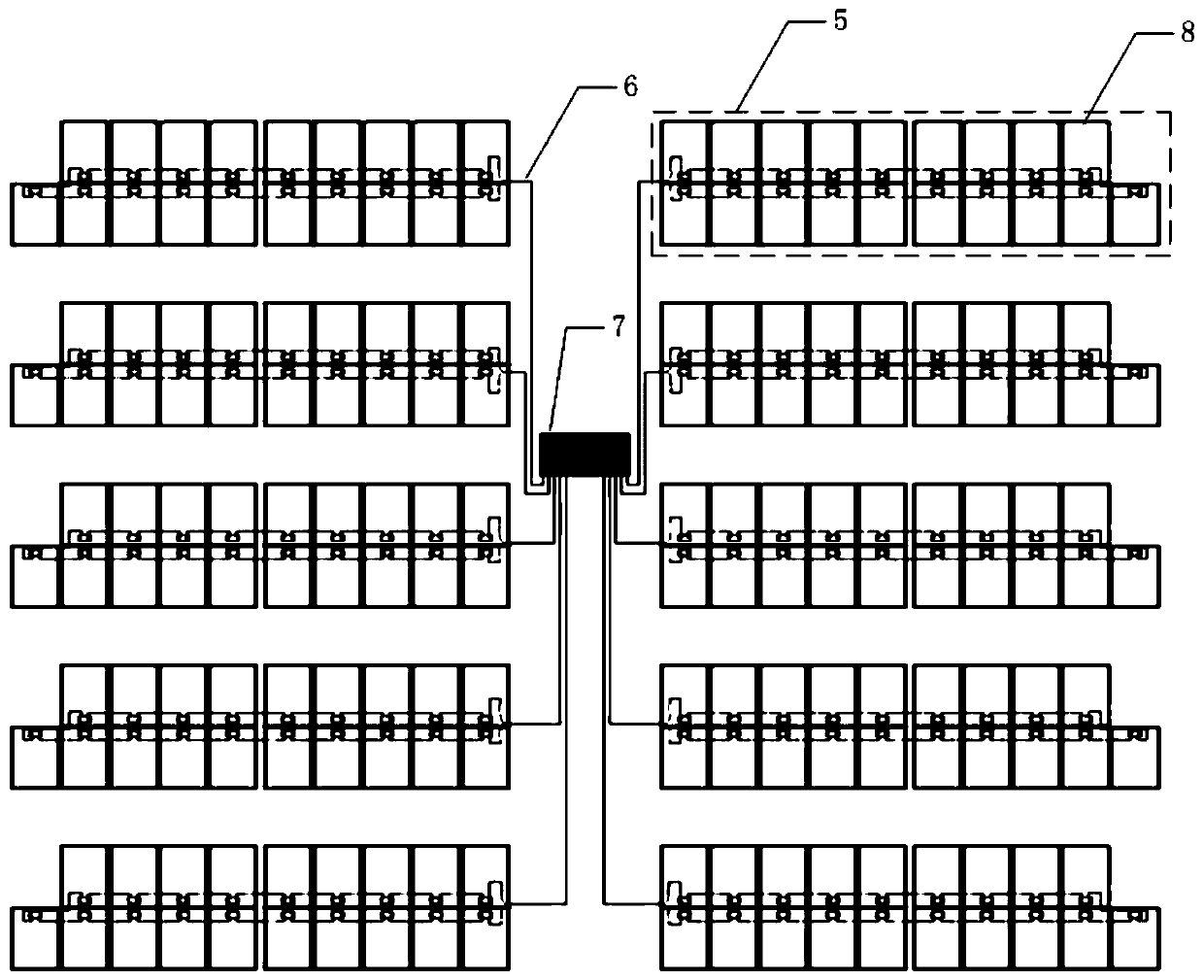

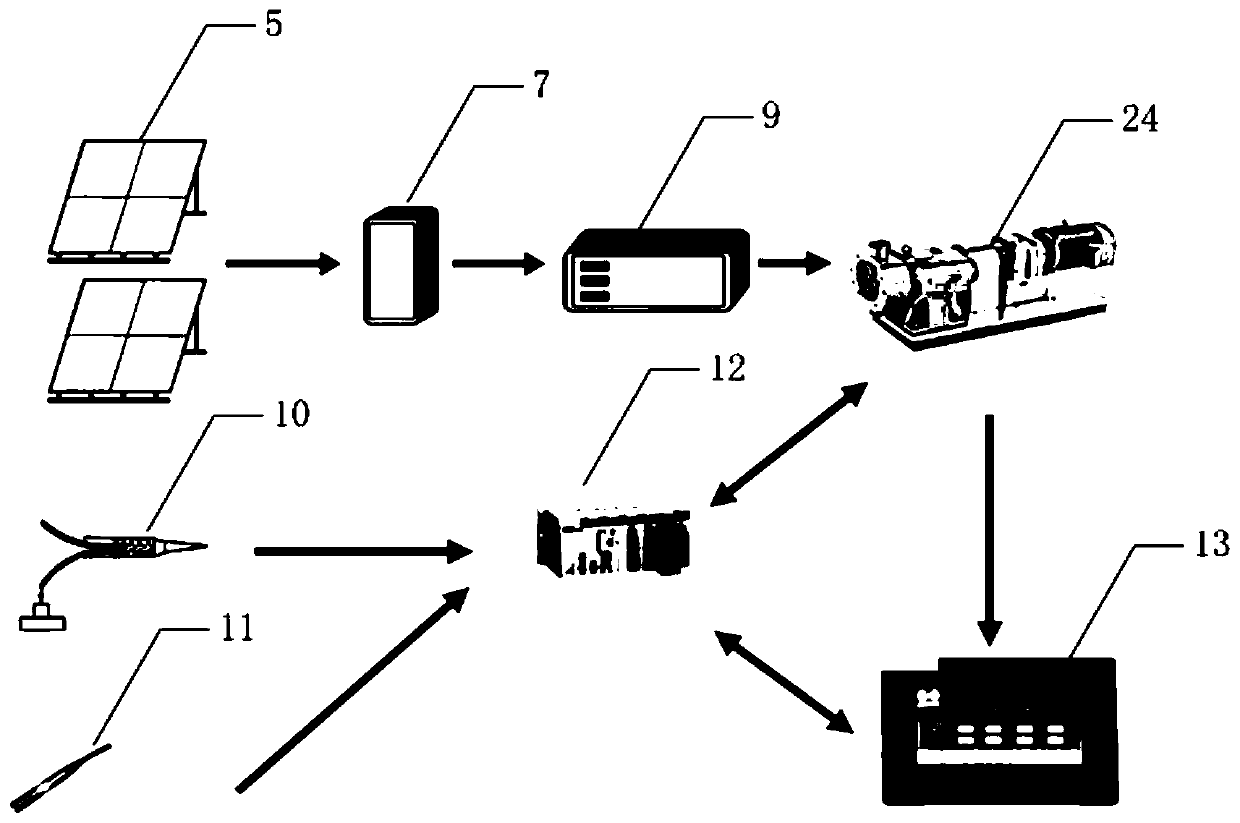

High-altitude ultrahigh-lift high-power solar photovoltaic water lifting technology and system

PendingCN111102179AGuaranteed stabilityReal-time monitoring of fluctuationsPump testingBatteries circuit arrangementsThermodynamicsEngineering

The invention discloses a high-altitude ultrahigh-lift high-power solar photovoltaic water lifting technology and system. The system comprises a photovoltaic power generation system, an intelligent control system, an ultrahigh-lift pumping system and a pipeline system, wherein the photovoltaic power generation system is electrically connected with the intelligent control system; the intelligent control system is in communication connection with the ultrahigh-lift pumping system; and the ultrahigh-lift pumping system is fixedly connected with the pipeline system. The high-altitude ultrahigh-lift high-power solar photovoltaic water lifting technology and system are suitable for high-altitude areas with thin air, and the single-stage lift of a solar photovoltaic pump station can reach 1200m or above. The single-stage power of a water pump reaches 600kW in the environment with the altitude being 2500m or above. In the working process, the fluctuation of voltage and current is monitored inreal time, the working stability of the pump station is guaranteed, and the problem that a traditional photovoltaic pump station is difficult to achieve water delivery of an ultrahigh-lift pump station in a high-altitude area is successfully solved.

Owner:四川省川机工程技术有限公司 +2

A spiral-wound electrochemical water treatment reactor

ActiveCN107098442BFacilitated DiffusionEnhanced mass transferDispersed particle separationWater/sewage treatment by oxidationCatalytic oxidationElectrochemistry

Owner:CHONGQING XINHE QIYUE TECH CO LTD

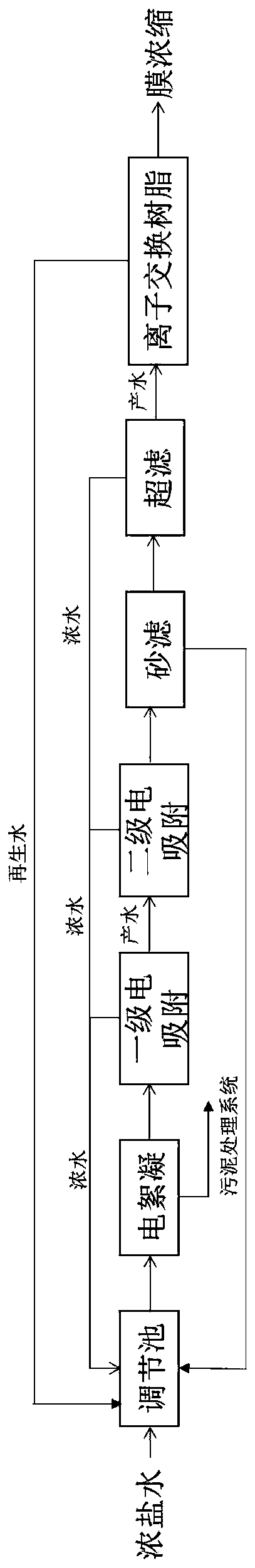

Pretreatment method for reduction of strong brine in iron and steel industry

InactiveCN111233220AReduce energy consumptionLow costTreatment involving filtrationWaste water treatment from metallurgical processSaline waterPretreatment method

The invention relates to a pretreatment method for reduction of strong brine in the iron and steel industry, which comprises the following steps of: 1) feeding strong brine in an iron and steel industry into an adjusting tank to balance water quality and water quantity, then feeding effluent of the adjusting tank into electric flocculation equipment, feeding sludge discharged by the electric flocculation equipment into a sludge treatment system to be treated, feeding effluent of electric flocculation into first-stage electro-adsorption equipment, returning second-stage electro-adsorption concentrated water to a front-end regulating tank, enabling the water produced after the secondary electro-adsorption treatment to enter a sand filtering device and an ultrafiltration device, enabling concentrated water to flow back to an adjusting tank for circular treatment, enabling the water produced after ultrafiltration to enter chelating ion exchange resin, enabling regenerated wastewater of theion exchange resin to flow back to the adjusting tank for circular treatment, and enabling effluent to enter a membrane concentration unit. The method has the advantages of low energy consumption inthe technological process, low cost, simple equipment, easiness in operation and stable treatment effect, and creates a good water inlet condition for subsequent membrane concentration.

Owner:ANGANG STEEL CO LTD

Device and method for improving flow state of inverted π-shaped dam in forebay of pumping station

ActiveCN104805809BImprove performanceImprove running stabilityBarrages/weirsStream regulationWater flowEngineering

The invention relates to a device and a method for improving the flow pattern of an inverted Pi-shaped dam of a pump station front pond. The device comprises a front pond and a flow deflector arranged on the rear part of a return flow zone in the front pond, wherein the front part of the front pond is connected with an inlet culvert; an intake pond is arranged on the rear part of the front pond. The device is characterized in that the flow deflector is the inverted pi-shaped dam; the inverted pi-shaped dam is provided with a similarly inverted letter Pi-shaped section vertical to the water flow direction; the distance between the inverted Pi-shaped dam and the intake pond is 0.2-0.4 time of the length of the front pond; the inverted Pi-shaped dam is formed by a lower dam and two upper dams symmetrically arranged on the lower dam; the lower dam of the inverted Pi-shaped dam is in a cuboid shape; the length of the lower dam is equal to the width of the front pond; the width of the lower dam is 0.5 time of the water depth in the front pond; the height of the lower dam is 0.4 time of the water depth in the front pond; each upper dam of the inverted Pi-shaped dam is in a cuboid shape; the length of each upper dam is 0.1 time of the width of the front pond; the width of each upper dam is 0.5 time of the water depth in the front pond; the height of each upper dam is 0.4 time of the water depth in the front pond. Through the device and the method for improving the flow pattern of the inverted Pi-shaped dam of the pump station front pond provided by the invention, the water intake condition of a water pump is improved, and the performance and the stability of a pump station are improved.

Owner:YANGZHOU UNIV

Cold rolling oily wastewater treatment process

InactiveCN103408200BEfficient removalGood water conditionsGeneral water supply conservationWaste water treatment from metallurgical processChemical oxygen demandCavitation

The invention discloses a cold rolling oily wastewater treatment process, which comprises the following steps of: (1), pretreating thick-oil wastewater sequentially by filtering of an oil separation tank and a paper tape and ultra-filtration process of a ceramic membrane, and pre-treating thin-oil wastewater sequentially by adopting the oil separation tank, a CAF (Cavitation Air Flotation) process and a DAF (Dissolved Air Flotation) process; (2), mixing pre-treated thick-oil wastewater with the pre-treated thin-oil wastewater, carrying out biochemical treatment by adopting an electrochemical catalytic oxidation process and an MBR (Membrane Biological Reactor) process in sequence, controlling the water inlet temperature of the MBR process to be 20-35 DEG C, controlling the water inlet pH value to be 7-9, and adding oil-munching high-efficiency micro-organism complex microbial inoculants and MPE (Metallocene Polyethylene) into an MBR membrane tank; and (3), filtering outlet water (treated through the MBR process) by using a reverse osmosis membrane, and carrying out deep desalination treatment so that outlet water reaches emission or industrial production reuse water standard. The invention provides a set of systematic process specially aiming at treatment and reuse of cold rolling oily wastewater in steel mills; the COD (Chemical Oxygen Demand) of treated outlet water is less than 10mg / L; the electrical conductivity of treated outlet water is less than 50mu s / cm; and oil and suspended solids are nearly eliminated completely.

Owner:武钢集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com