High-speed train motor train unit vehicle-mounted toilet fecal sewage on-line direct drainage treatment method and treatment equipment

A fecal sewage and treatment equipment technology, applied in water/sewage treatment equipment, biological water/sewage treatment, sanitary equipment, etc., can solve the problems of high assessment indicators, low efficiency, and high processing equipment power, and achieve high transparency and clear water quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

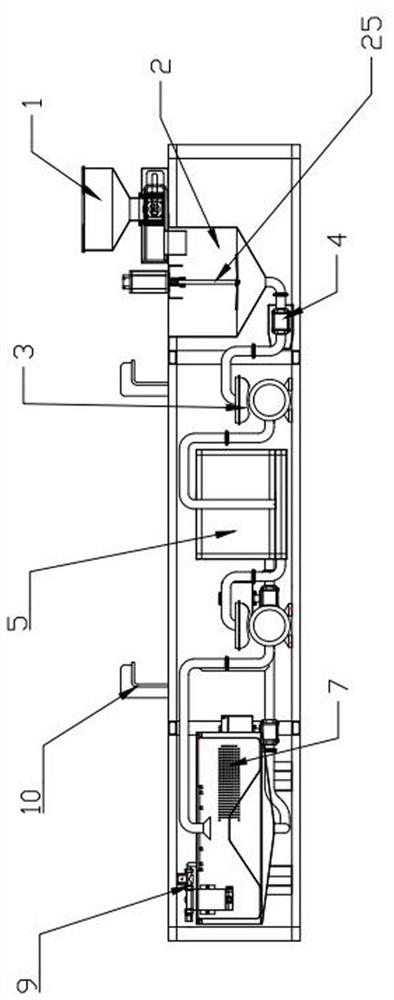

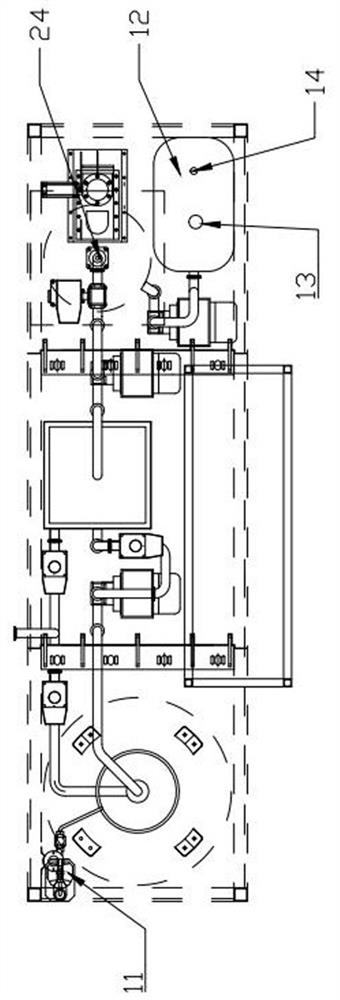

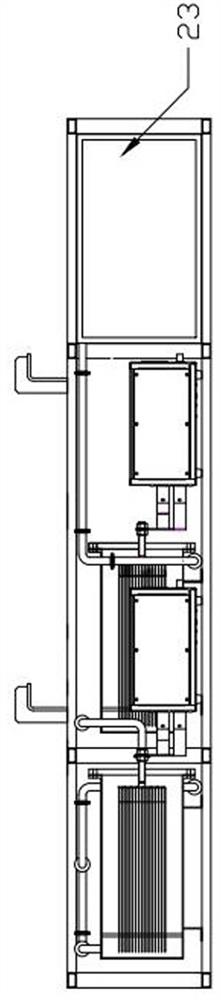

[0037] A method for on-line direct drainage of excrement and sewage in on-board toilets of high-speed trains, see Figure 1 to Figure 6 , the design includes the following steps:

[0038] (1) Crushing: The excrement water in the on-board toilet of the iron EMU is first sucked into the treatment tank through the vacuum pump, and the speed-adjusting and variable-frequency motor above the treatment tank rotates at a high speed of more than 12,000 rpm for less than 1 minute, and then passes through the shaft The alloy blade on the rod rotates and breaks the granular lumps in the feces at high speed, forming feces mixed water A in a swirling state;

[0039] (2) Flocculation: Flocculation: For the finely crushed feces mixed water A after rotary cutting, the speed of the variable frequency motor is reduced to less than 1200 rpm by frequency modulation, and the feces mixed water B is formed under the action of the stirring force of the stirring rod, and then Add volcanic rock mineral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com