Waterborne metallic paint and preparation thereof

A water-based metal coating and coating technology, applied in the direction of coating, etc., to achieve the effect of simple production process, full coating film and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 55 parts by weight of n-butanol into the reactor and heat up to 115°C, add dropwise 50 parts by weight of acrylic acid containing 8wt%, methacrylic acid of 7wt%, ethyl acrylate of 5wt%, butyl acrylate of 42wt%, 10wt% % of butyl methacrylate, 3wt% of methyl methacrylate, 8wt% of hydroxyethyl acrylate, 2wt% of hydroxypropyl acrylate, 3wt% of glycidyl methacrylate, 5wt% of styrene and 7wt% % n-octyl acrylate acrylic mixed monomer, 0.3 parts by weight of cumene peroxide and 0.1 parts by weight of n-butyl mercaptan, the mixed solution is controlled to be added dropwise in 5 hours, kept warm for 2 hours, and then added 0.1 parts by weight of cumene peroxide, continue to keep warm for 5 hours and then vacuumize to remove n-butanol, then lower the temperature of the reaction system to below 60°C, then neutralize the pH value to 6.5 with ammonia water or organic amine neutralizer, and finally Add appropriate amount of water to adjust the solid content to 45wt%.

Embodiment 2

[0022] Add 60 parts by weight of n-butanol into the reactor and heat up to 120°C, add dropwise 40 parts by weight of acrylic acid containing 10wt%, methacrylic acid of 3wt%, ethyl acrylate of 8wt%, butyl acrylate of 37wt%, 2wt% % of butyl methacrylate, 5wt% of methyl methacrylate, 10wt% of hydroxyethyl acrylate, 2wt% of hydroxypropyl acrylate, 5wt% of glycidyl methacrylate, 15wt% of styrene and 3wt% % n-octyl acrylate acrylic mixed monomer, 0.4 parts by weight of cumene peroxide and 0.3 parts by weight of n-butyl mercaptan, the mixed solution is controlled to be added dropwise in 6 hours, kept warm for 2 hours, and then added 0.1 parts by weight of cumene peroxide, continue to keep warm for 3 hours and then vacuumize to remove n-butanol, then lower the temperature of the reaction system to below 60°C, then neutralize the pH value to 6.5 with ammonia water or organic amine neutralizer, and finally Add appropriate amount of water to adjust the solid content to 50wt%.

Embodiment 3

[0024]Take by weight according to the following proportions: water-soluble resin prepared in Example 1: 30%, hexamethoxymethylmelamine resin: 4%, triethylamine: 0.1%, propylene glycol ether: 0.5%, water: 30%, Polyacrylate block copolymer dispersion: 1.5%, non-silicone defoamer 0.5%, acrylate leveling agent 0.4%, pigment red: 1%, titanium dioxide: 29.0%, barium sulfate: 3%. Disperse and stir the weighed self-made water-soluble resin, water, polyacrylate block copolymer dispersant and acrylate leveling agent evenly, add pigment red, titanium dioxide and barium sulfate, disperse and stir for 20min, grind with a sand mill for 3- 4 times until the fineness is below 10 μm, add hexamethoxymethylmelamine resin, triethylamine, propylene glycol ether and defoamer to disperse and stir for 30 minutes, and adjust the viscosity of the dispersed product with water to obtain the water-based environmentally friendly metal coating of the present invention.

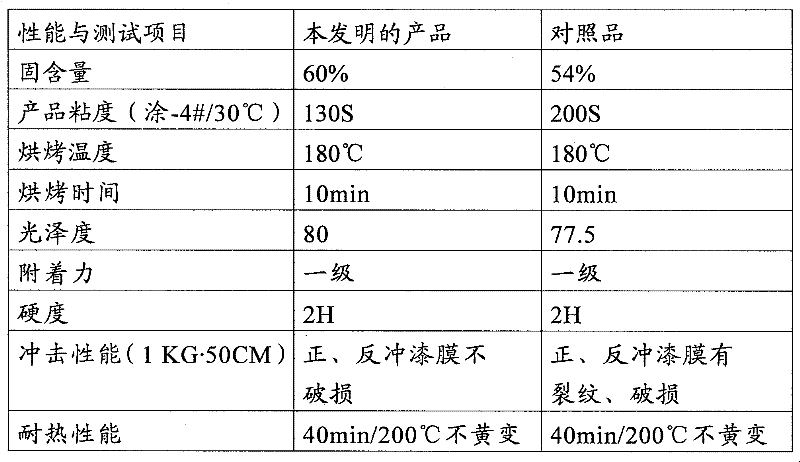

[0025] In addition, TPR-008 water-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com