Combined set for treating micro-polluted source water in counties and towns

A combined device and micro-pollution technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high price, ensure the turbidity of the effluent, reduce costs and save money effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

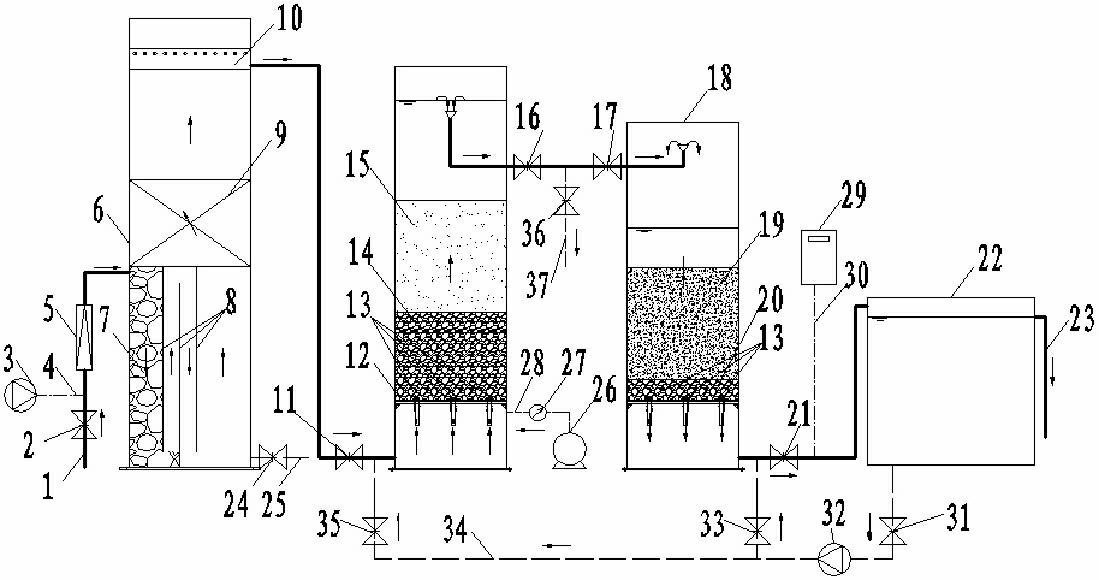

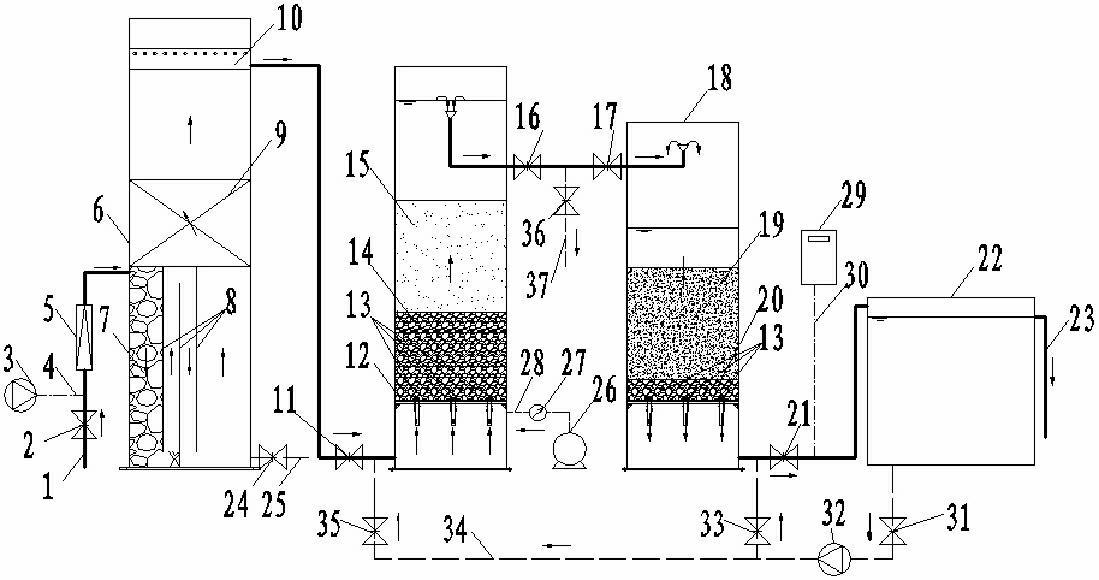

[0030] like figure 1 As shown in the figure, the inlet water enters the inclined tube sedimentation tank 6 after adding coagulant, passes through the spoiler stone 7, the water inlet baffle 8, and the inclined tube 9, and after sedimentation, the water is discharged from the perforated sump 10, and enters the aerated biological zeolite filter column countercurrently. 12 The water inlet area of the lower layer, after mixing with the gas, enters the coarse zeolite support layer 14 and the granular zeolite layer 15 successively from the long handle filter head 13, and the effluent freely falls to the activated carbon filter column 18, and flows downward through the granular activated carbon 19, quartz The sand supporting layer 20 and the long handle filter head 13 are discharged to the water tank 22. The front end of the water inlet area of the inclined tube sedimentation tank 6 is provided with a 200-300mm spoiler stone 7 and a water inlet baffle 8 . The filler of the aerat...

Embodiment 2

[0033] When backwashing the aerated biological zeolite filter column, close the first valve 2, the second valve 11, the fourth valve 17, and the eighth valve 33; open the third valve 16, the seventh valve 31, and the tenth valve 36; close the dosing Metering pump 3 and integrated ClO 2 Generator 29; run the backwash water pump 32, adjust the aeration rate of the blower 26, control the air-water ratio of backwash, and the backwash waste water is discharged from the backwash waste liquid pipe 37. After the recoil is finished, close the backwash water pump 32, the seventh valve 31, the backwash water inlet pipe 35, and the tenth valve 36, and open the first valve 2, the second valve 11, the fourth valve 17, the dosing metering pump 3 and the integrated Formula ClO 2 The generator 29 restores the water production process.

Embodiment 3

[0035] When backwashing the activated carbon filter column, close the sixth valve 24, the water tank 22, and the ninth valve 34; open the fourth valve 17, the fifth valve 21, the seventh valve 31, the eighth valve 33, and the tenth valve 36; close the integrated ClO 2 Generator 29; run the backwash water pump 32, and the backwash waste water is discharged from the backwash waste liquid pipe 37. After the recoil finishes, close the backwash water pump 32 and the seventh valve 31, the eighth valve 33, the tenth valve 36, open the water tank 22 and the integrated ClO 2 The generator 29 restores the water production process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com