Biological treatment method for oil extraction waste water with high polymer concentration

A technology for oil extraction wastewater and biological treatment, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Inhibition effect, low maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Construction of mixed flora

[0023] Pseudomonas sp.J1, the preservation unit is China Center for Type Culture Collection, the preservation number is CCTCC NO: M 2011473, and the preservation date is December 17, 2011; Bacillus sp.DQ5, the preservation unit is China Typical Culture Collection Center, the preservation number is CCTCC NO: M2010078, and the preservation date is April 15, 2010; Enterobacter sp.DQ11, the preservation unit is China Typical Culture Collection Center, the preservation number is CCTCC NO: M 2010084, and the preservation date is On April 15, 2010 and Bacillus sp.DQ85, the preservation unit is the China Center for Type Culture Collection, the preservation number is CCTCC NO: M 2010083, and the preservation date is April 15, 2010. The following operations are performed:

[0024] (1) Slant culture: inoculate the above-mentioned strains on LB solid slant medium, and culture the bacteria at 30±1°C for 18 to 24 hours;

[0025] (2) First-lev...

Embodiment 2

[0034] Example 2: Treatment of incoming water from an oil production plant in Daqing Oilfield

[0035] Table 1 shows the water quality analysis of an oil production plant in Daqing Oilfield:

[0036] Table 1

[0037] index unit value water temperature ℃ 29-35 pH 7.5-7.8 COD mg / L 950-1700 NH4-N mg / L 3-8 viscosity mPa·S 6.2-6.5 polyacrylamide mg / L 800 suspended matter mg / L 120 oil content mg / L 380

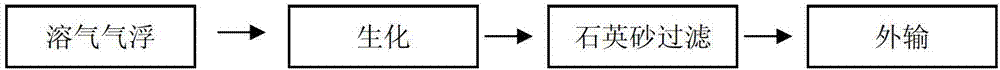

[0038] Process device parameters:

[0039] The dissolved air flotation unit is a dissolved air flotation device and an air pump air flotation device. The model of the dissolved air flotation is DB-HC100 (0.75kW), the parameters are: 2.5×1×2.5m, and the effective volume is 3m 3 , the reflux ratio is 20% (reflux ratio = reflux water volume per unit time ÷ the total water output per unit time), and the hydraulic retention time is 3 hours. The air flotation parameters of the air pump a...

Embodiment 3

[0049] Example 3: Treatment of incoming water from an oil production plant in Xinjiang

[0050] Table 2 shows the water quality analysis of an oil production plant in Xinjiang:

[0051] Table 2

[0052] project unit result oil content mg / L 952.6

[0053] Turbidity NTU 58.31 COD mg / L 1375.6 Ammonia nitrogen mg / L 6.02 Total Phosphorus mg / L 0.175 polyacrylamide mg / L 674 Salinity mg / L 13162.1 Total alkali (HCO 3 - ) mg / L 2625 pH 7.84

[0054] Process device parameters:

[0055] With embodiment 2.

[0056] Process flow:

[0057] With embodiment 2.

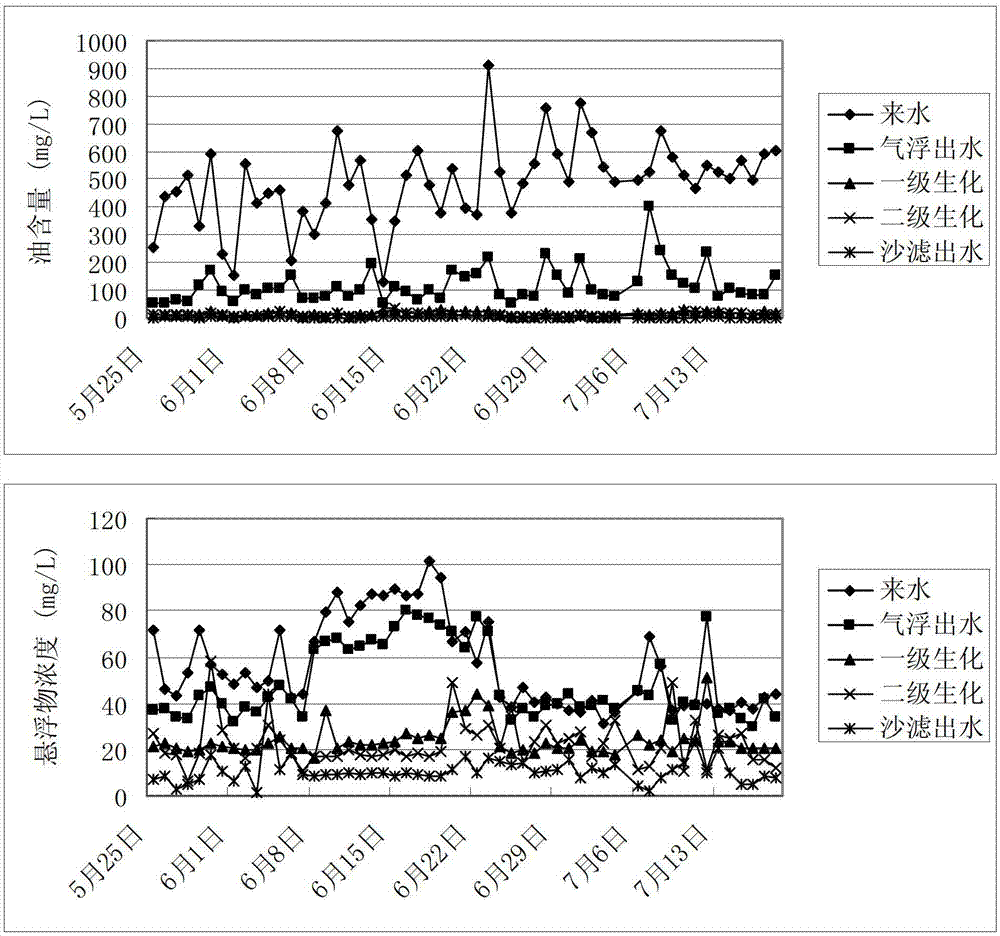

[0058] result:

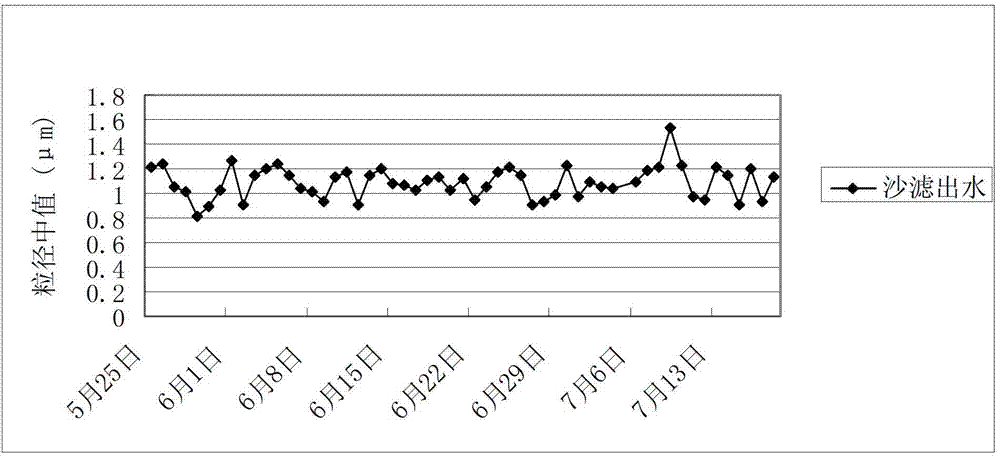

[0059] The test shows that the average oil content of incoming water is 582.7mg / L, the average oil content after air flotation treatment is 159.2mg / L, and the removal rate is 72.6%. After treatment, the average oil content is 13.7mg / L, and the average oil content of sand filtered water is 3.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com