Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62 results about "Oil production plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil production plant is a facility which processes production fluids from oil wells in order to separate out key components and prepare them for export. This is distinct from an oil depot, which does not have processing facilities.

Gas and oil production

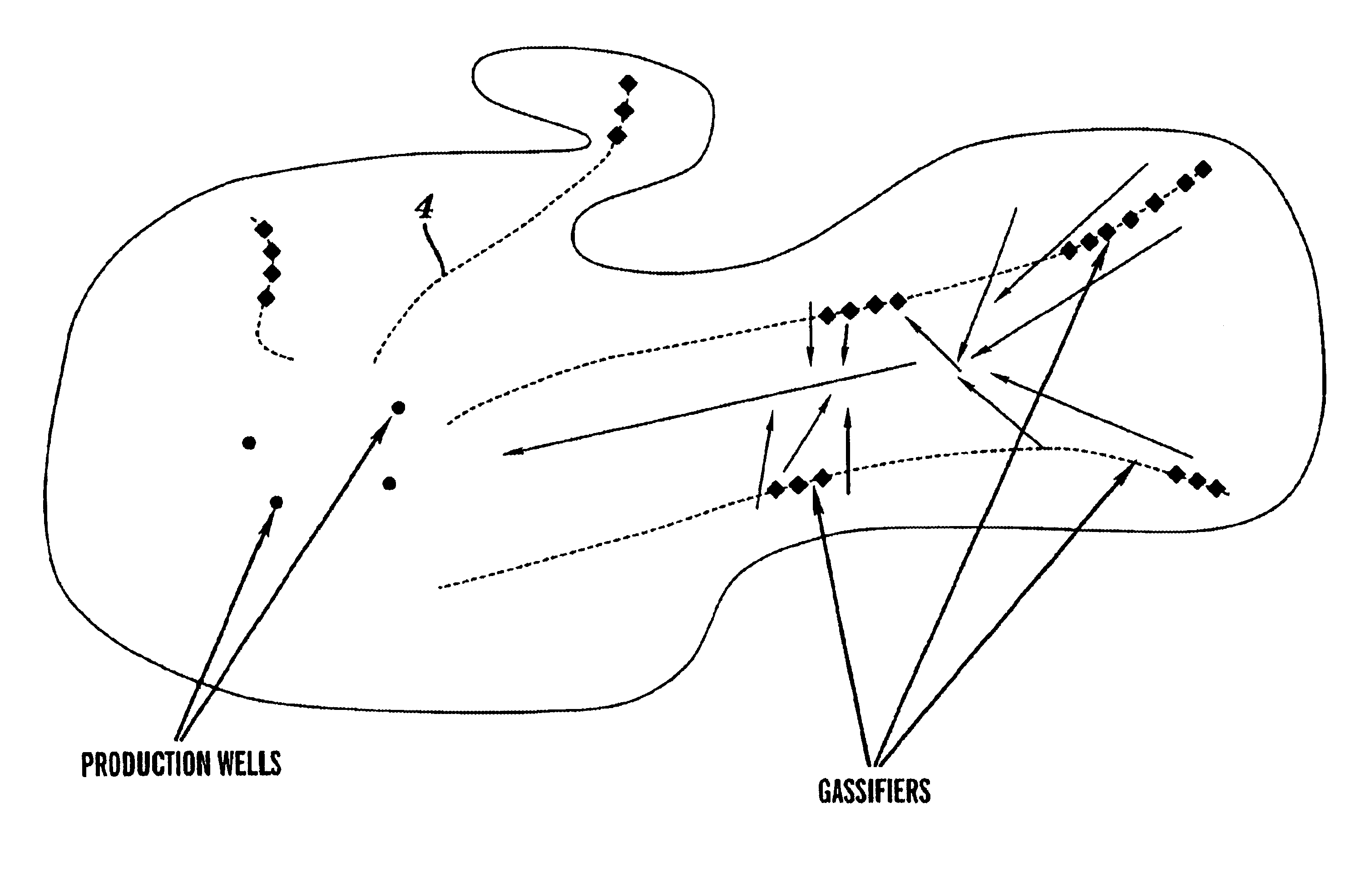

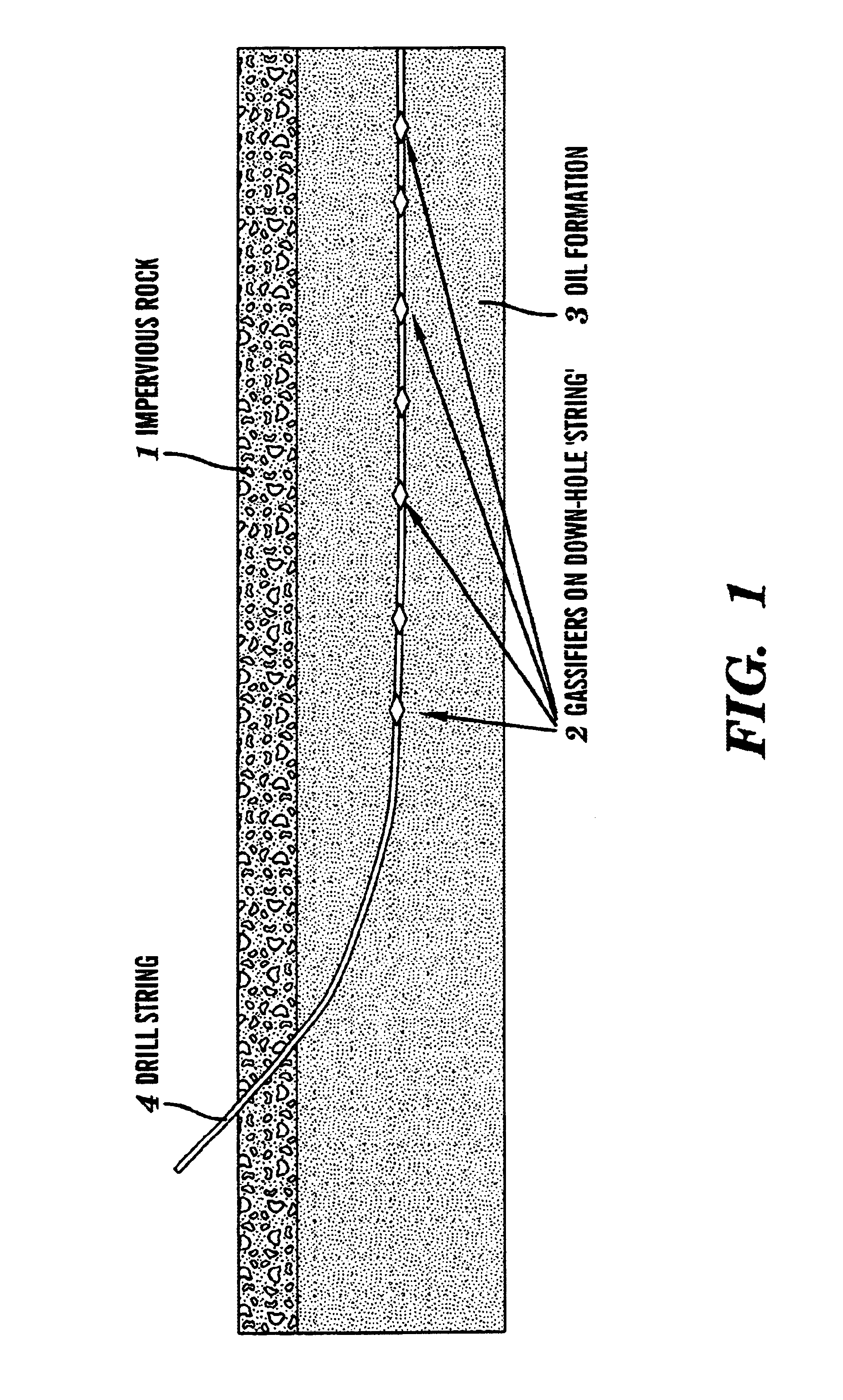

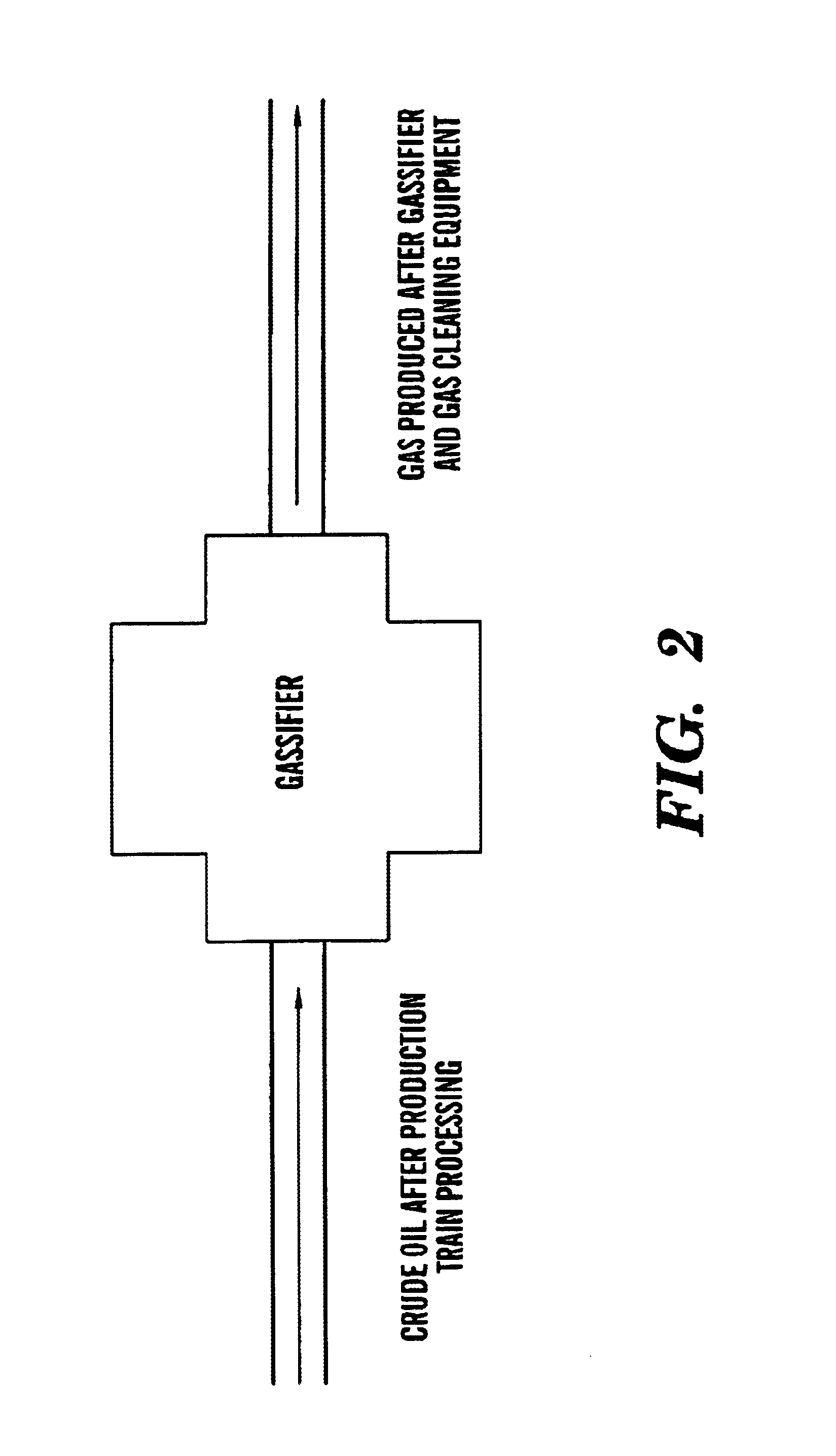

A process for in situ gasification of mineral oil in a subterranean formation comprises running a tool having a controllable thermal device therein from a surface production facility down to the subterranean formation, bringing said tool into operational proximity with the mineral oil in said subterranean formation, and activating the tool to operate the thermal device within a predetermined temperature range to generate gases or oily vapours from said mineral oil, which permits either an enhanced oil recovery (EOR) method with reduced water contamination, or a gas production process (GPP) which is useful in reducing environmental risks normally associated with transport of crude oil.

Owner:SCOTOIL SERVICES

Method for constituting a model representative of multiphase flows in oil production pipes

InactiveUS6028992ASurveyComputation using non-denominational number representationMomentumEngineering

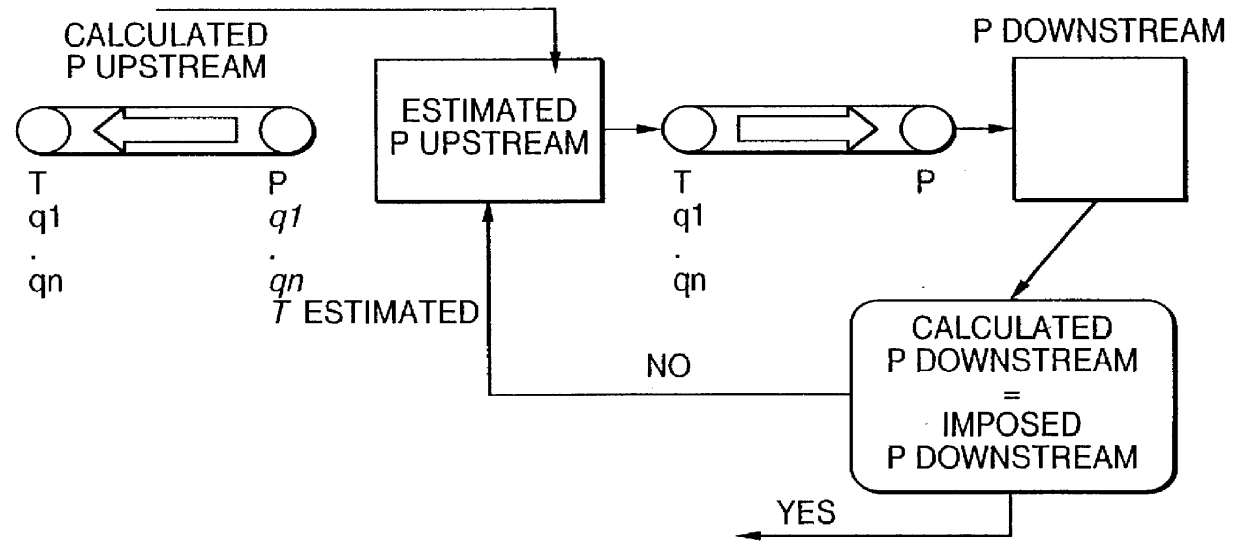

The invention provides a model representative of steady and transient flows, in a pipe, of a mixture of multiphase fluids, which takes account a set of variables defining the properties of the fluids and of the flow modes having separate phases which are dispersed and intermittent, and the dimensions and slope of the pipes. The modeled quantities characterizing the flow are determined by solving a set of transport equations, an equation of mass conservation per constituent and an equation of momentum of the mixture, and by using a hydrodynamic model and a hydrodynamic model of the fluids. The models are formed by considering the mixture to be substantially at equilibrium at all times and that the constituents of the multiphase mixture are variable all along the pipe. The method can be applied to hydrocarbon transportation network study and to determination of characteristics of flow of the multiphase mixture in the pipe.

Owner:INST FR DU PETROLE

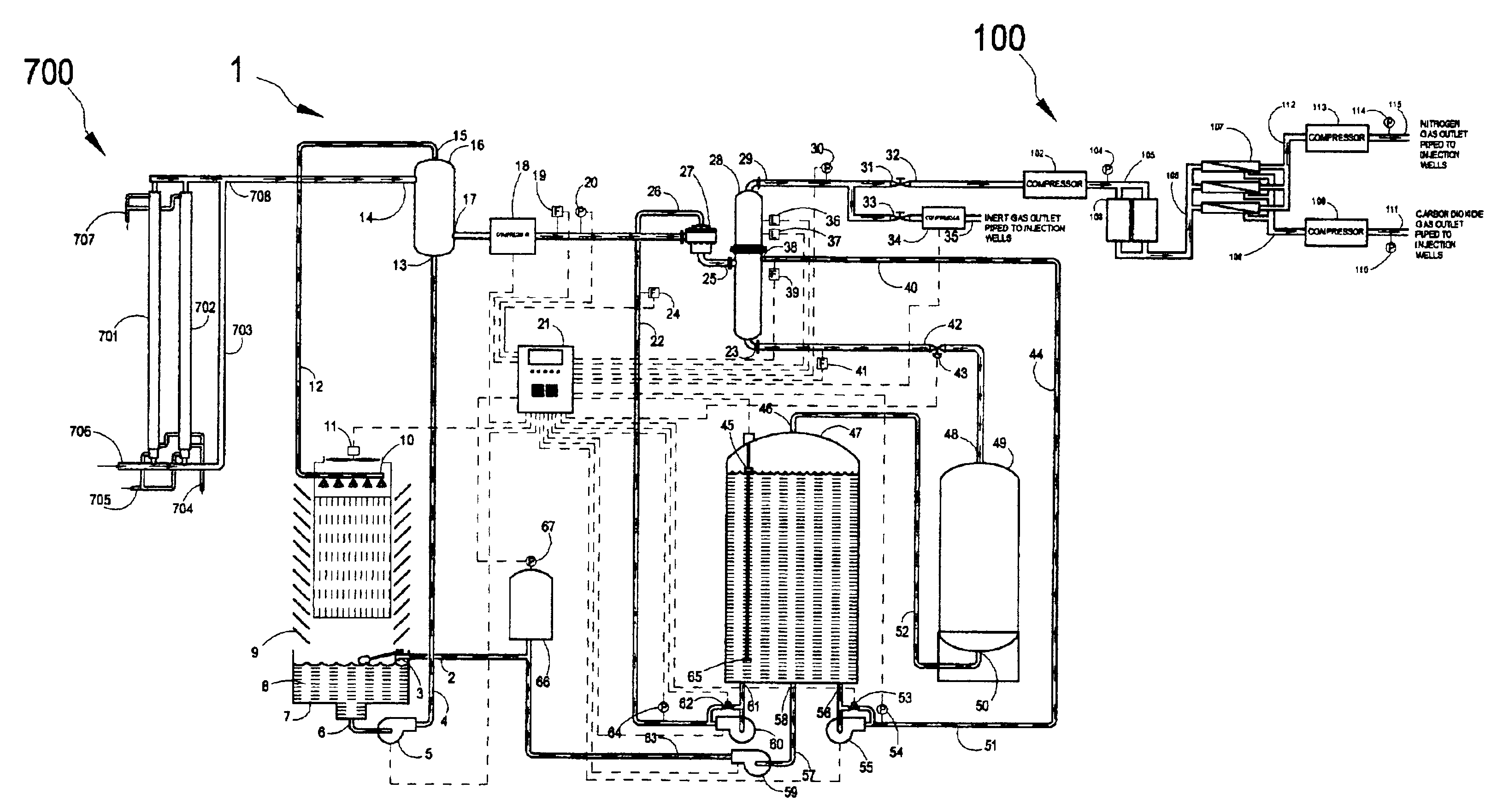

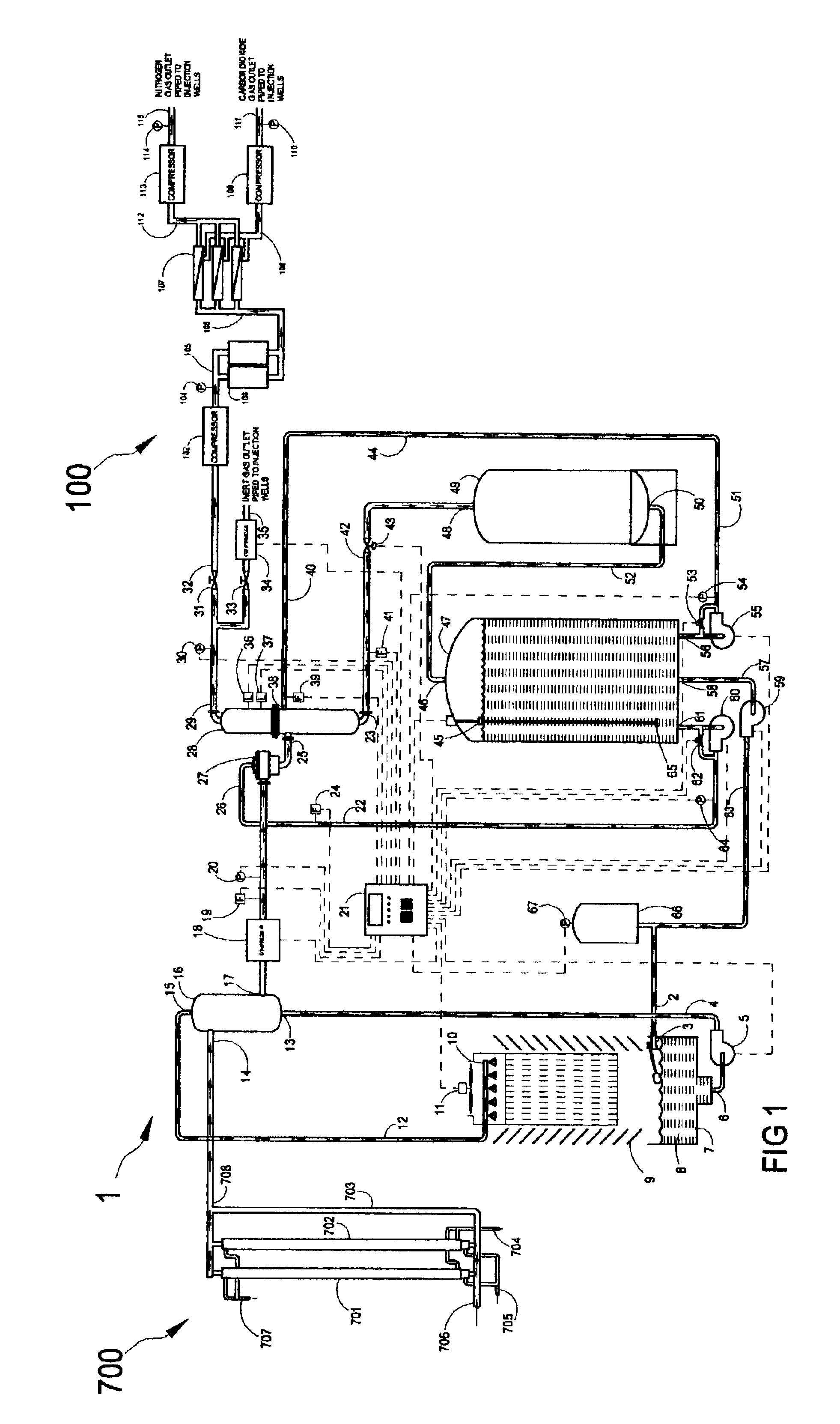

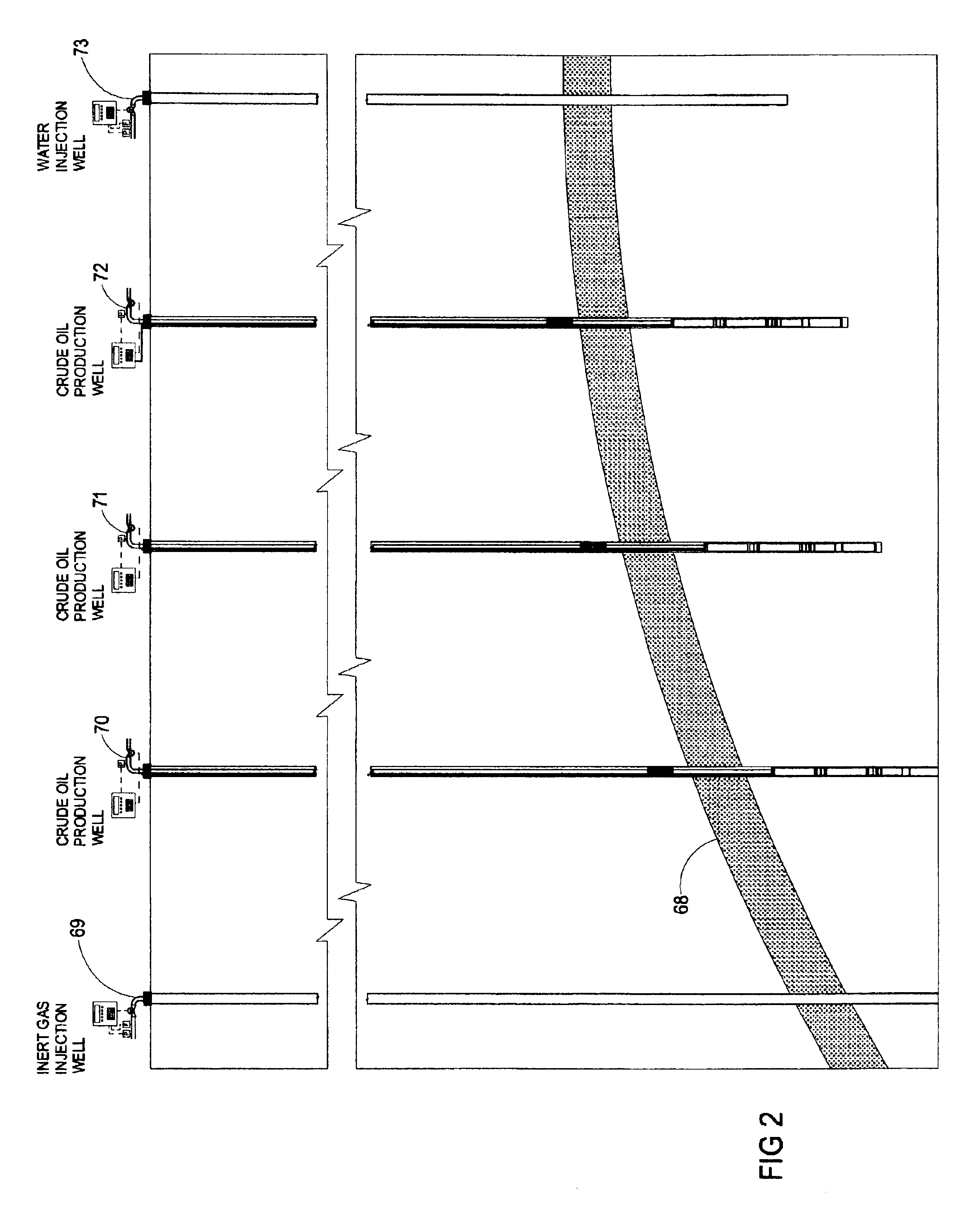

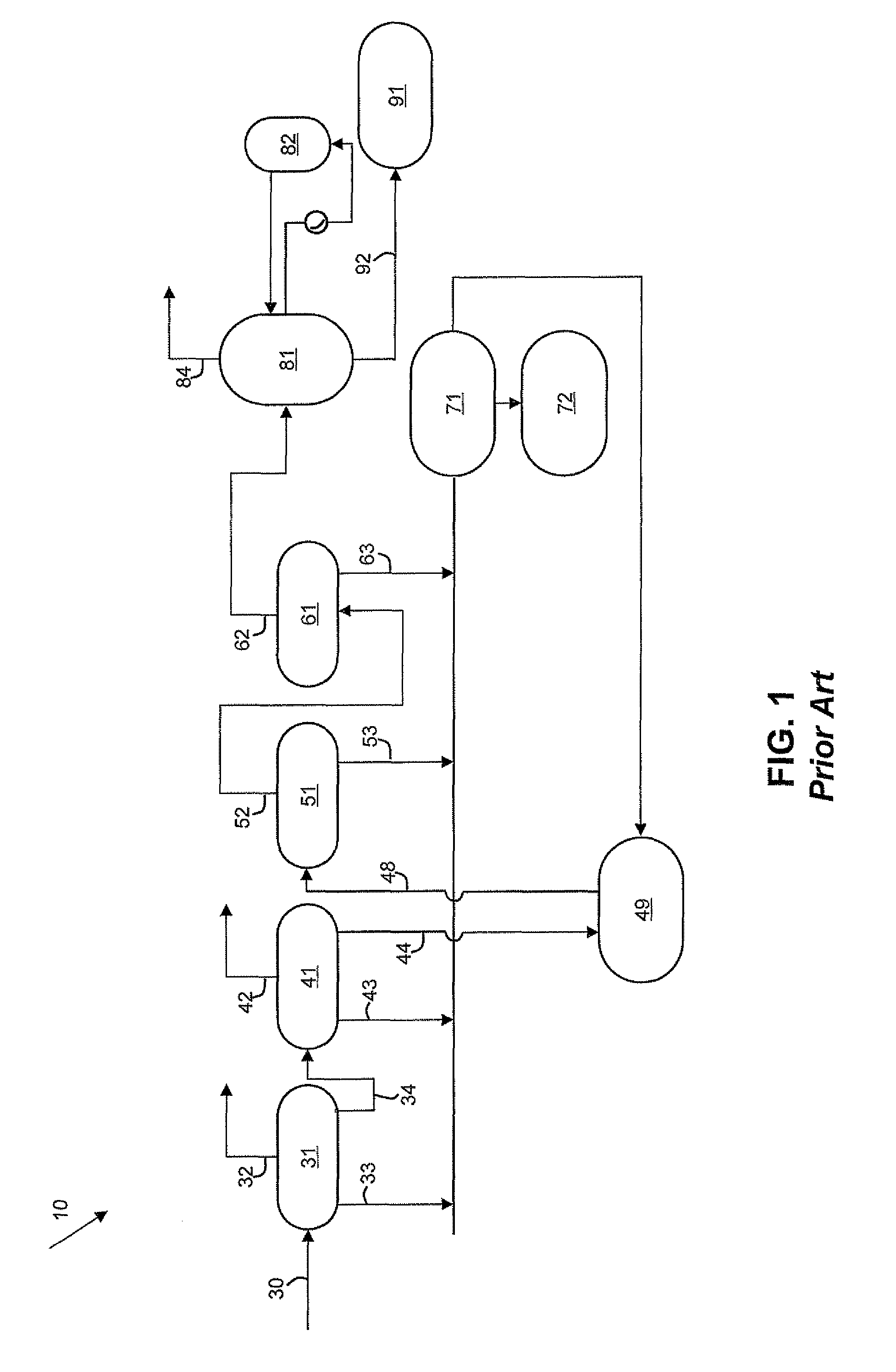

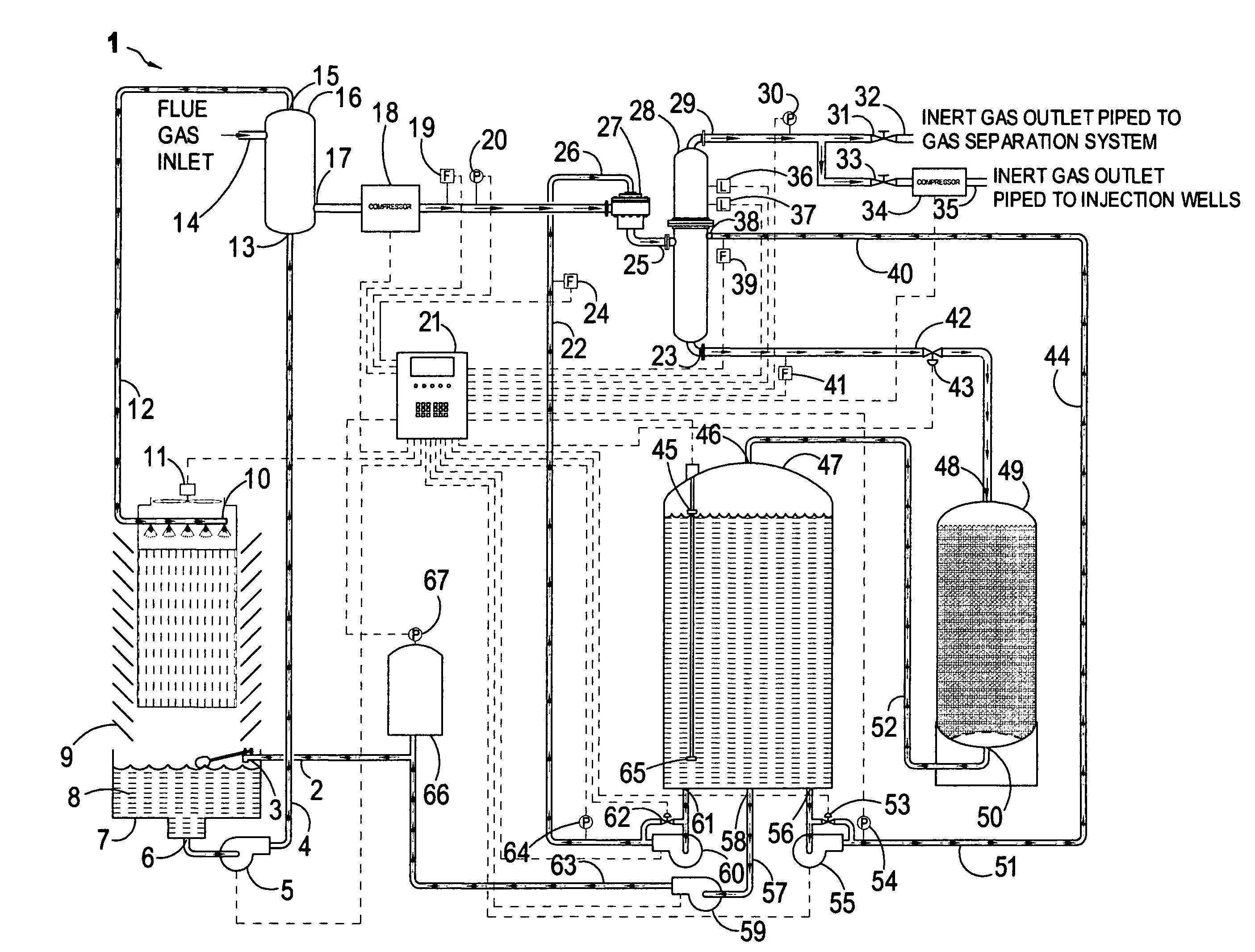

Methods and apparatus for increasing and extending oil production from underground formations nearly depleted of natural gas drive

InactiveUS6808693B2Low viscosityHigh viscosityCombination devicesLiquid separation auxillary apparatusEngineeringProduct gas

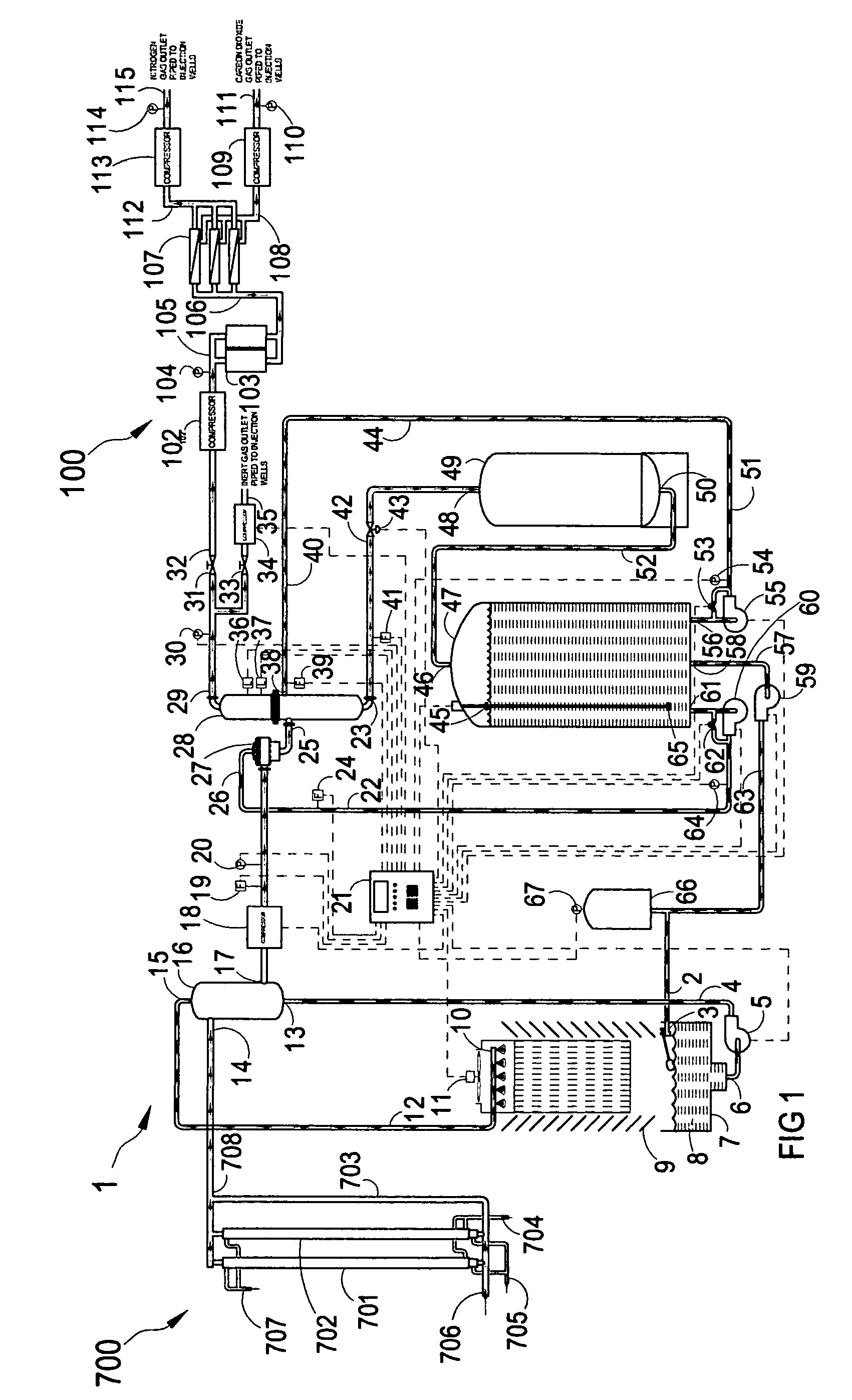

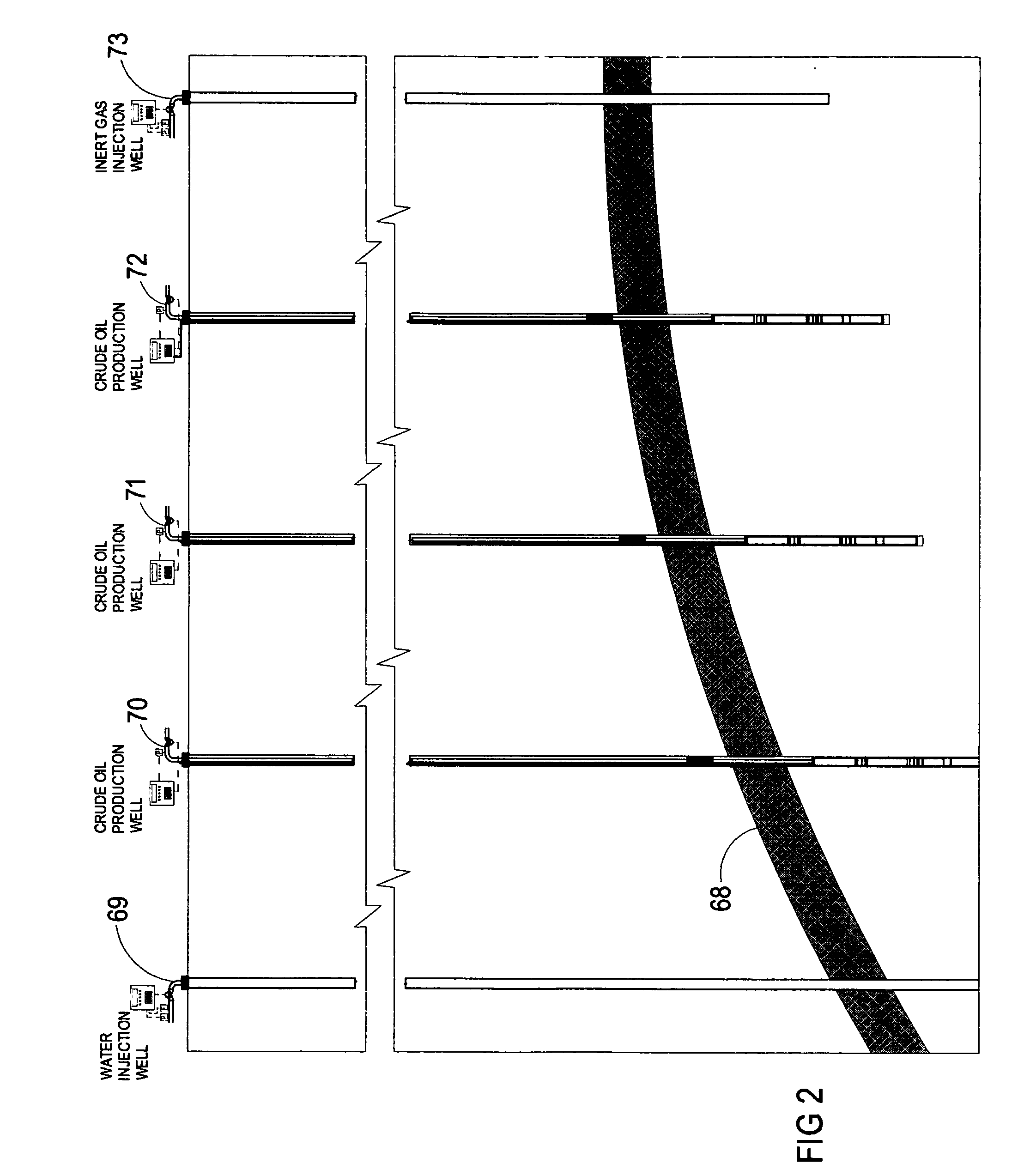

Methods and apparatus employing inert gases injected into the lower level of sloping underground oil-bearing formations as a driving mechanism and water injected into the upper level of the formations as a gas blocking mechanism for increasing and extending the production of oil from underground formations is described. Also described is an inert gas oil production system comprising an exhaust gas processing system, a well inert gas and water injection system, an oil production well system, and a fuel gas generator. A hydraulically operated crude oil pump is also described.

Owner:HYDROTREAT

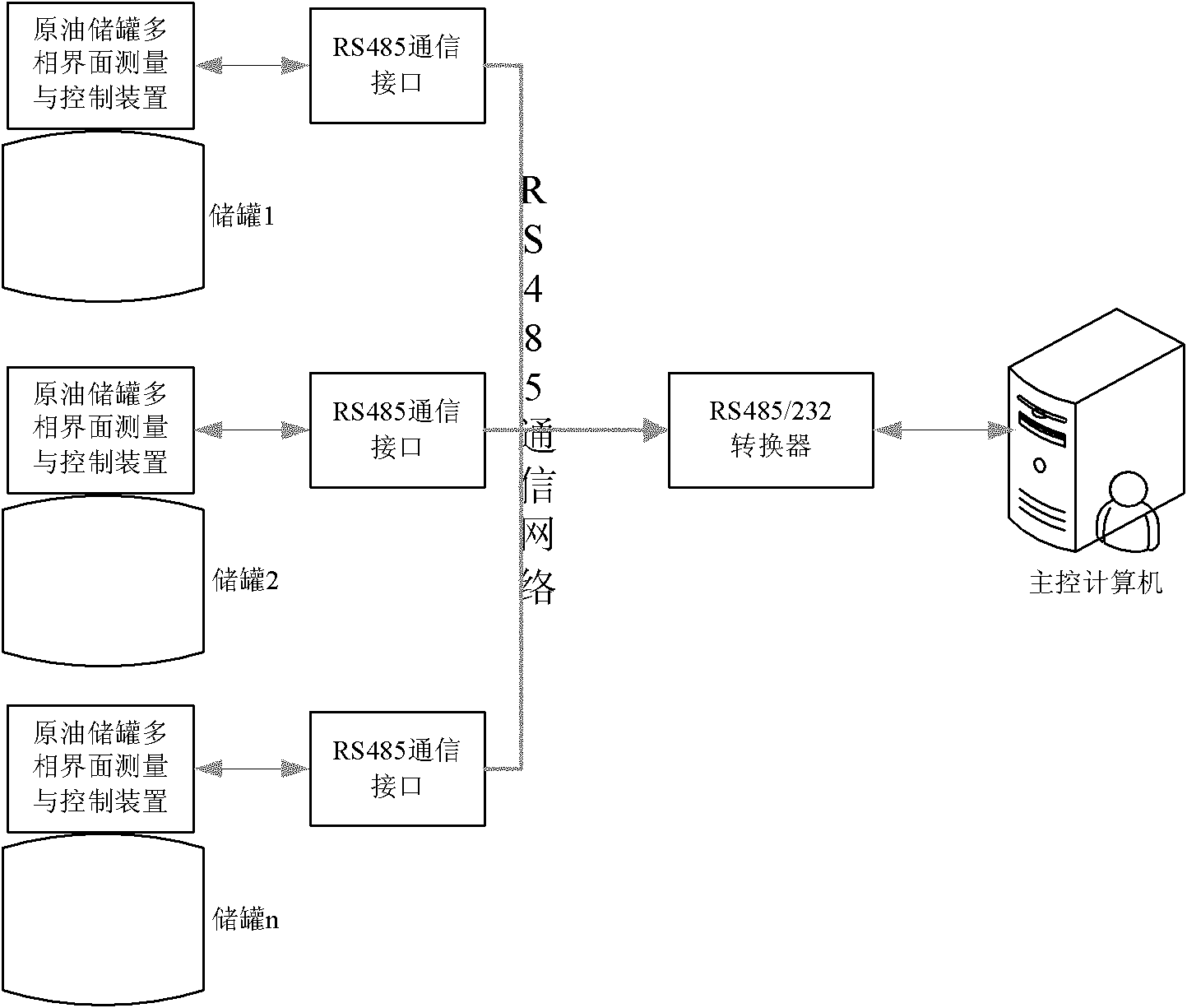

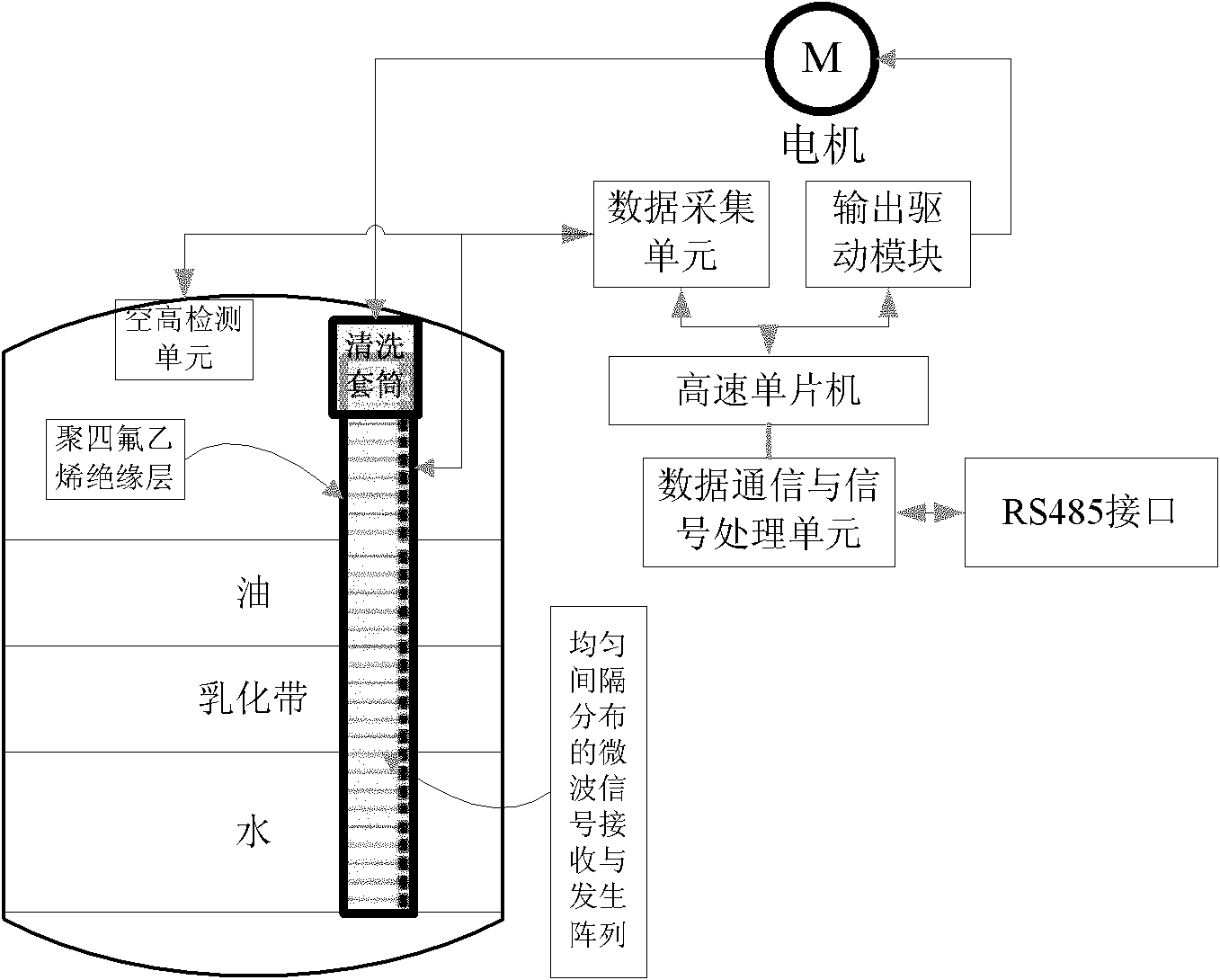

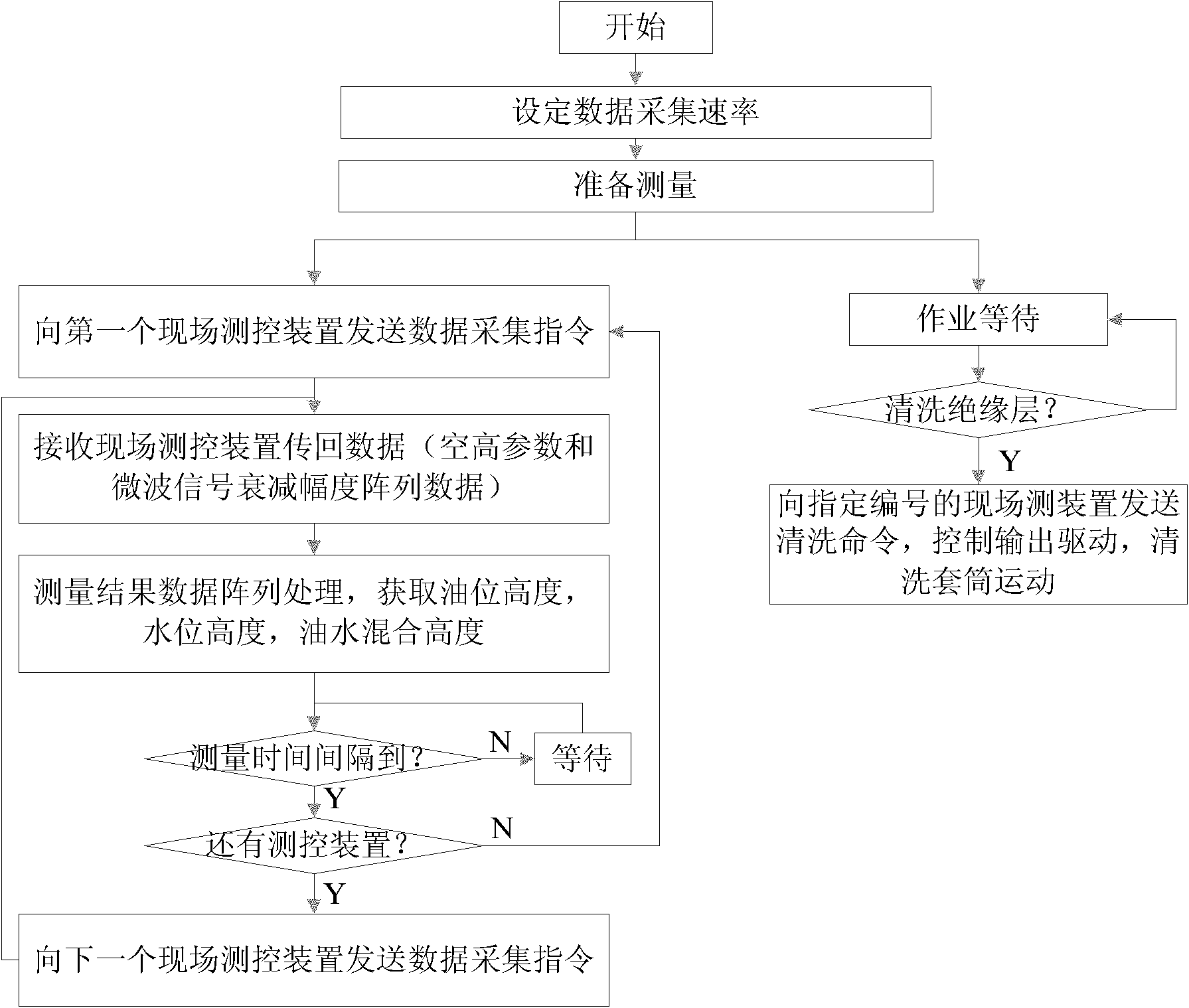

Oil-water interface measuring device of crude oil storage tank and measuring method thereof

InactiveCN102052952AFully automatedImprove modernizationMachines/enginesLevel indicatorsMicrocontrollerMeasurement device

The invention discloses an oil-water interface measuring device of a crude oil storage tank and a measuring method thereof. The oil-water interface measuring device comprises a main control computer, an RS485 (Recommended Standard 485) communication network and field measurement and control devices, wherein the main control computer is connected onto the RS485 communication network which is connected with the plurality of field measurement and control devices by RS485 communication interfaces; and each field measurement and control device comprises a data communication and signal processing unit, a single chip microcomputer, a data acquisition unit, an output driving module of the single chip microcomputer, a measuring array probe sheathed cleaning unit, a space height detection unit and a matrix type multi-phase interface tomoscan unit. The invention integrates the advanced sensor technology, data acquisition, modern communication and the computer control technology so as to realize comprehensive automation of measurement of the storage tank, greatly improves the accuracy of measurement, liberates workers from heavy work, leads workers to be capable of browsing and inquiring measured data and curves on the internet, and can improve modernization and informationization level of control and management of the production process of oil production plants in an oil field.

Owner:SHAANXI UNIV OF SCI & TECH

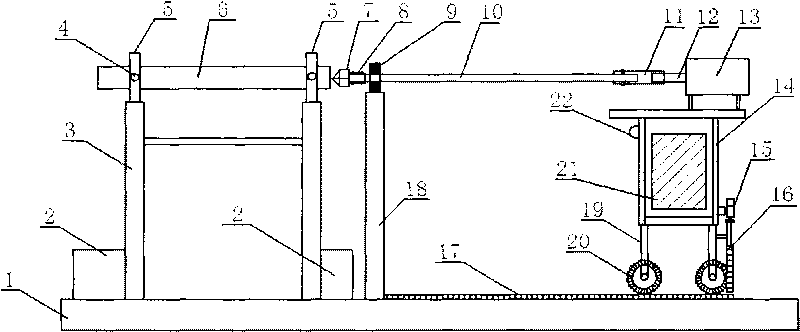

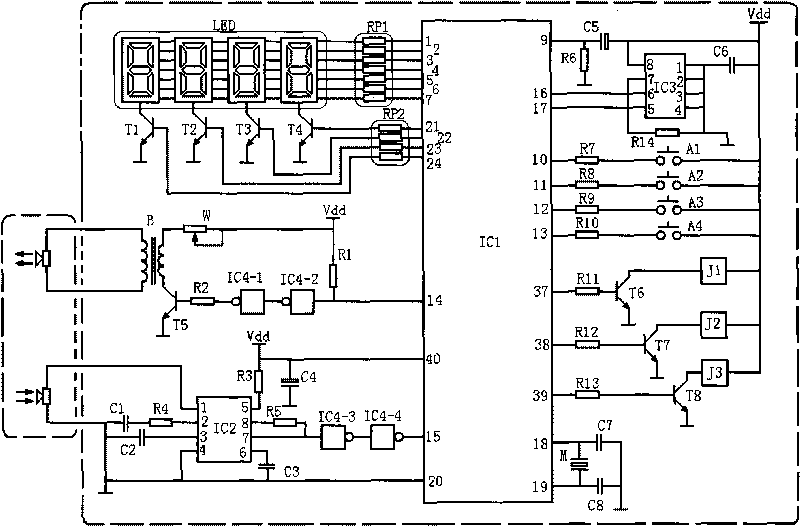

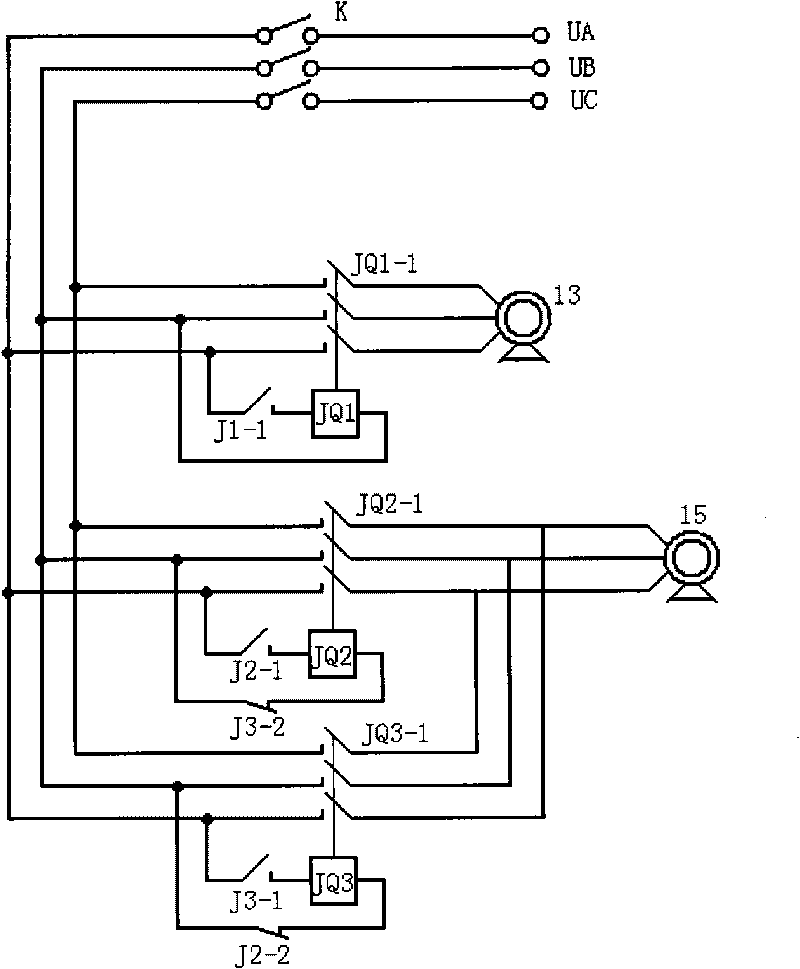

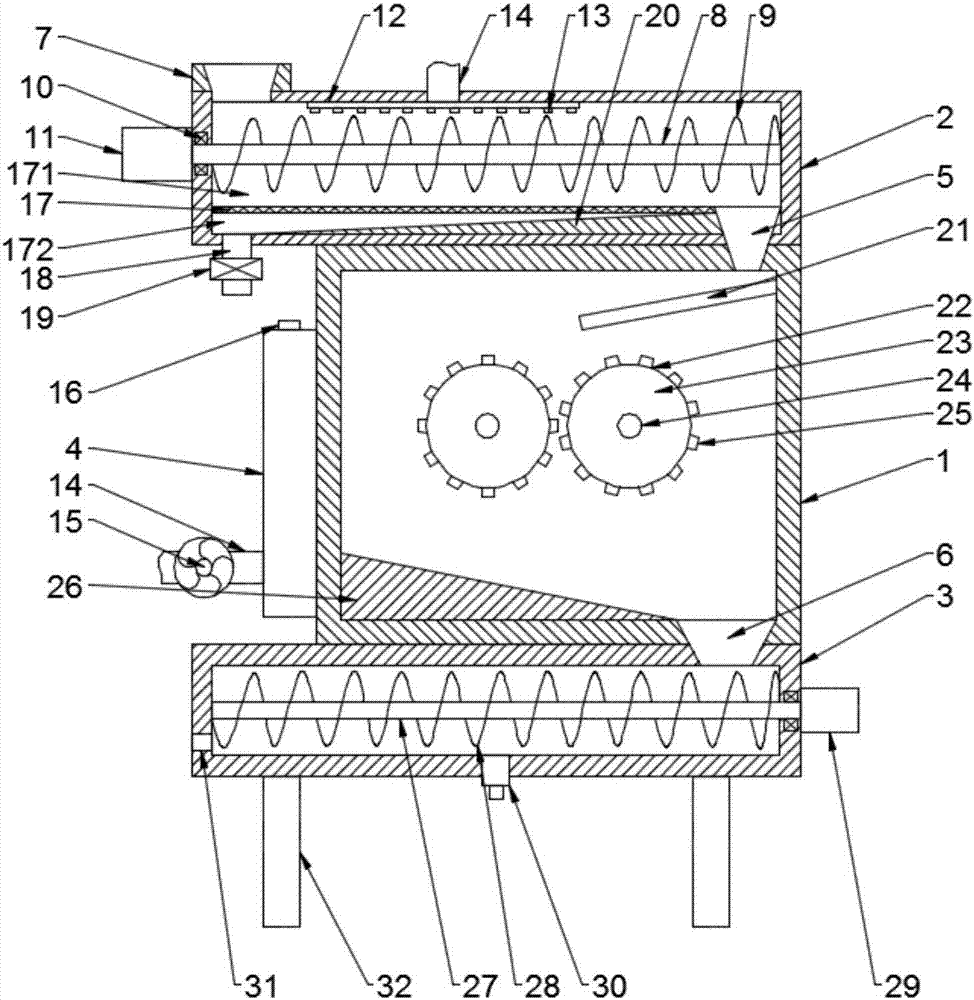

Automatic-control oil pipe dry-type paraffin removal unit

InactiveCN101722163AImprove wax removal effectRapid wax removalComputer controlSimulator controlAutomatic controlDrive motor

The invention relates to an automatic-control oil pipe dry-type paraffin removal unit which comprises a base, an oil pipe fixing support, a bracing frame, a drill bit, a drill stem, a propulsion motor, a drive motor, a rack slide rail, a worktable, a worm, gears, an oil storage box and an automatic controller. Compared with the prior art, the invention has the following advantages: 1. high paraffin removal efficiency and wide application range: the paraffin removal unit is driven by the motors and uses the special paraffin bit and doctor blades, and thus having obvious paraffin removal effect and high speed; due to the simple mechanism of the paraffin removal unit, the paraffin removal effect is obvious and is suitable for small operating zones of oil production plants and self application of mine groups; 2. environmental protection and energy saving: the paraffin removal unit saves substantive water resources and reduces the environmental pollution of dirty oil and paraffin; 3. automatic control: the paraffin removal unit is controlled by an automatic electronic circuit, thereby simplifying the operation and greatly reducing the labor intensity for workers.

Owner:张少波

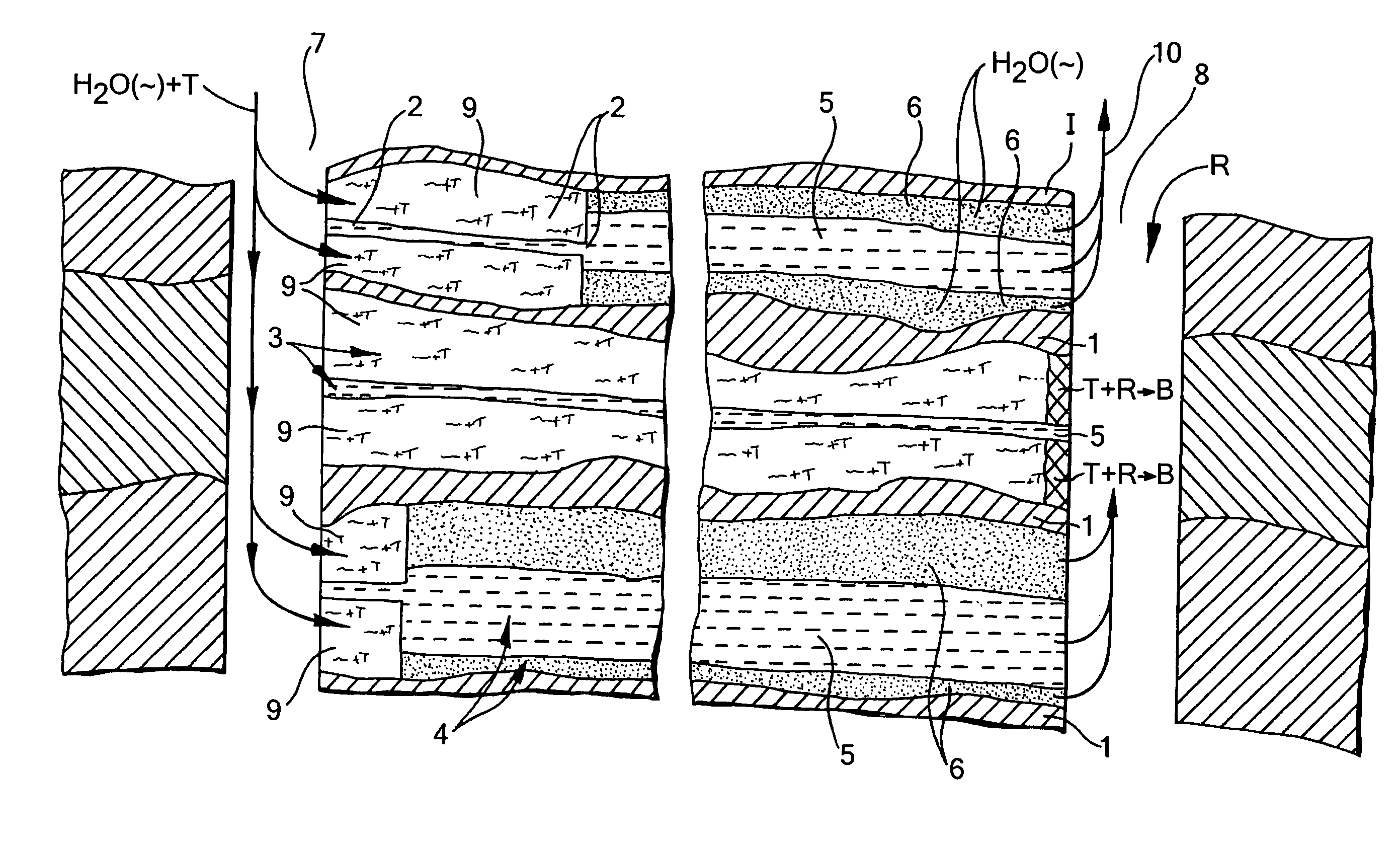

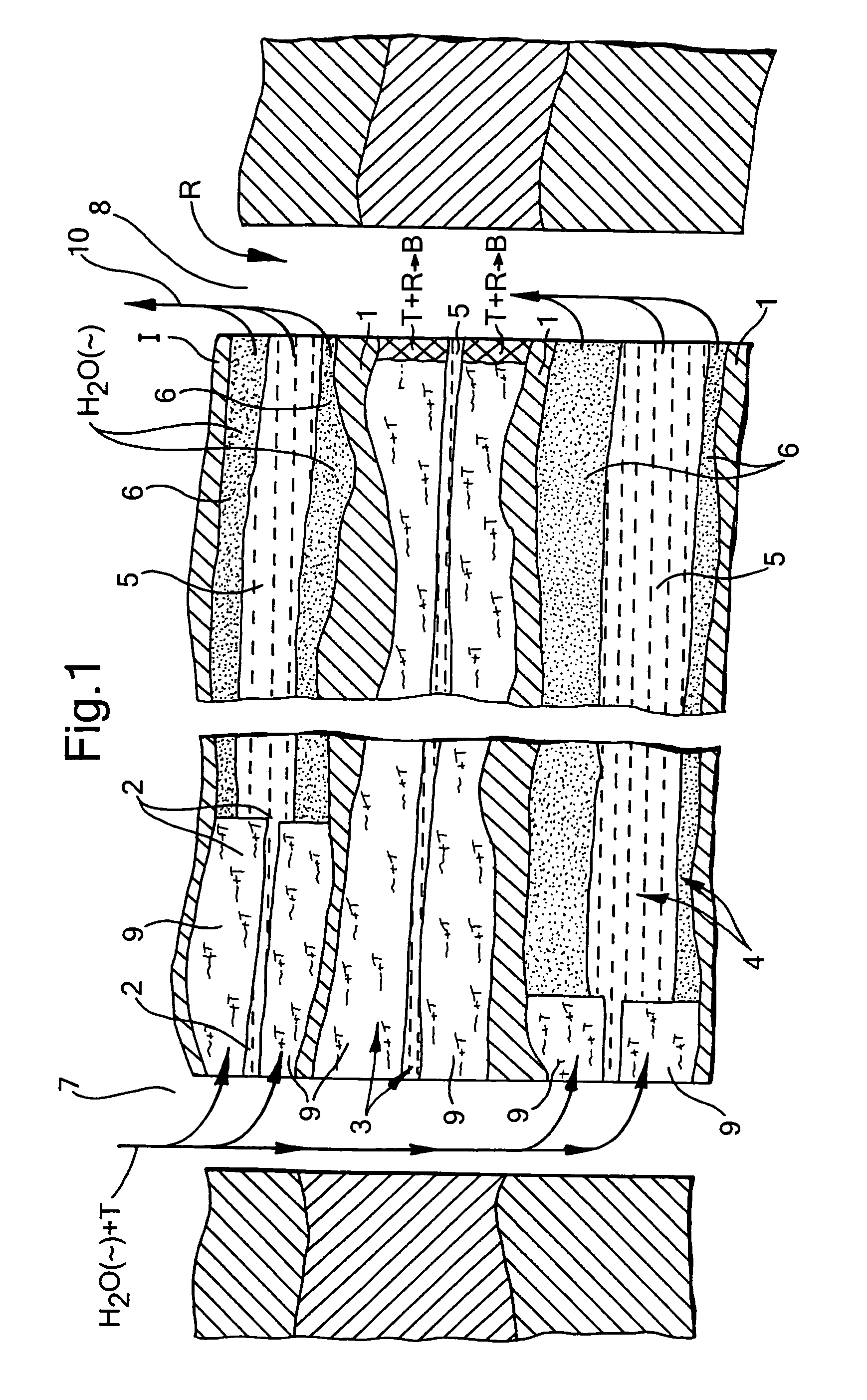

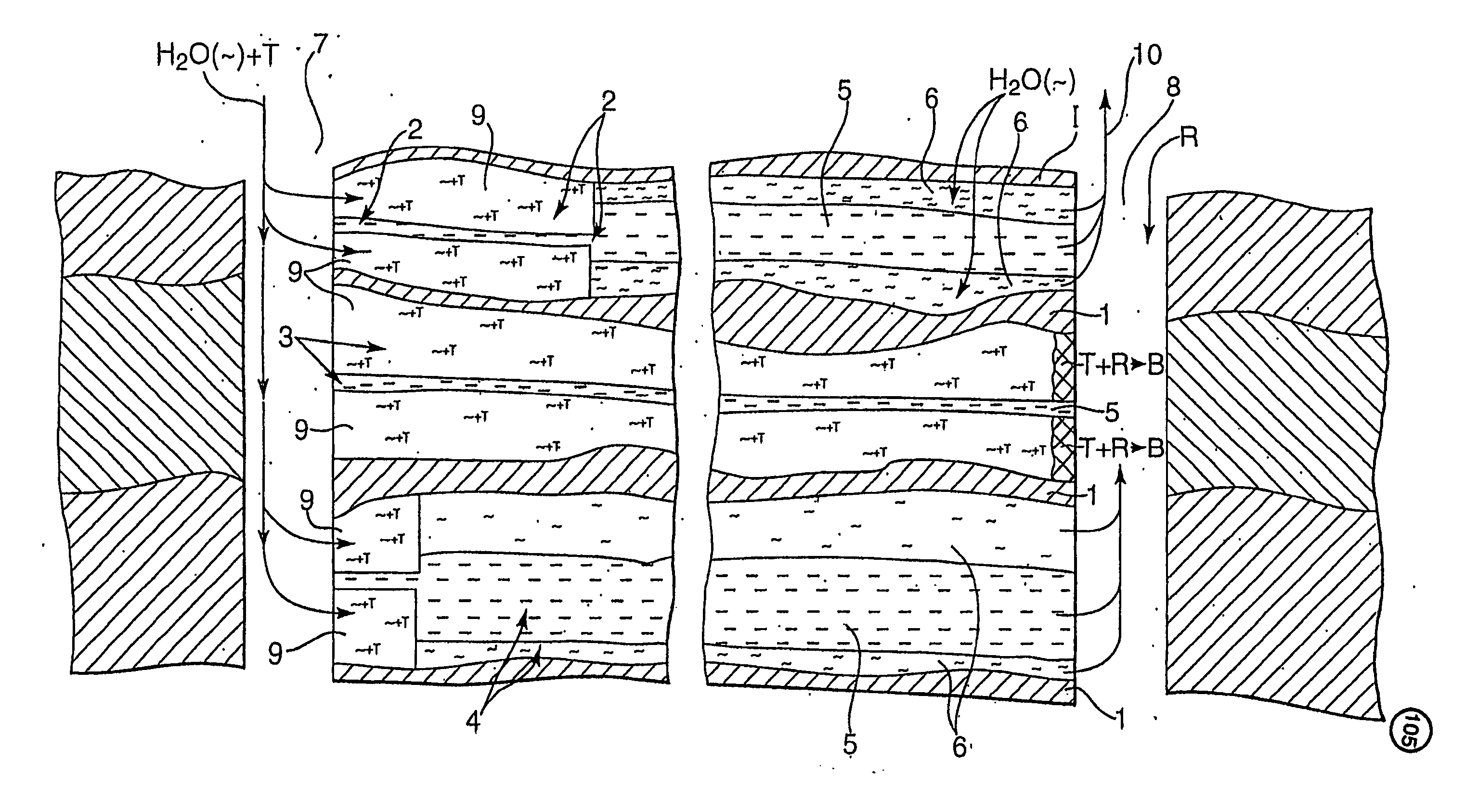

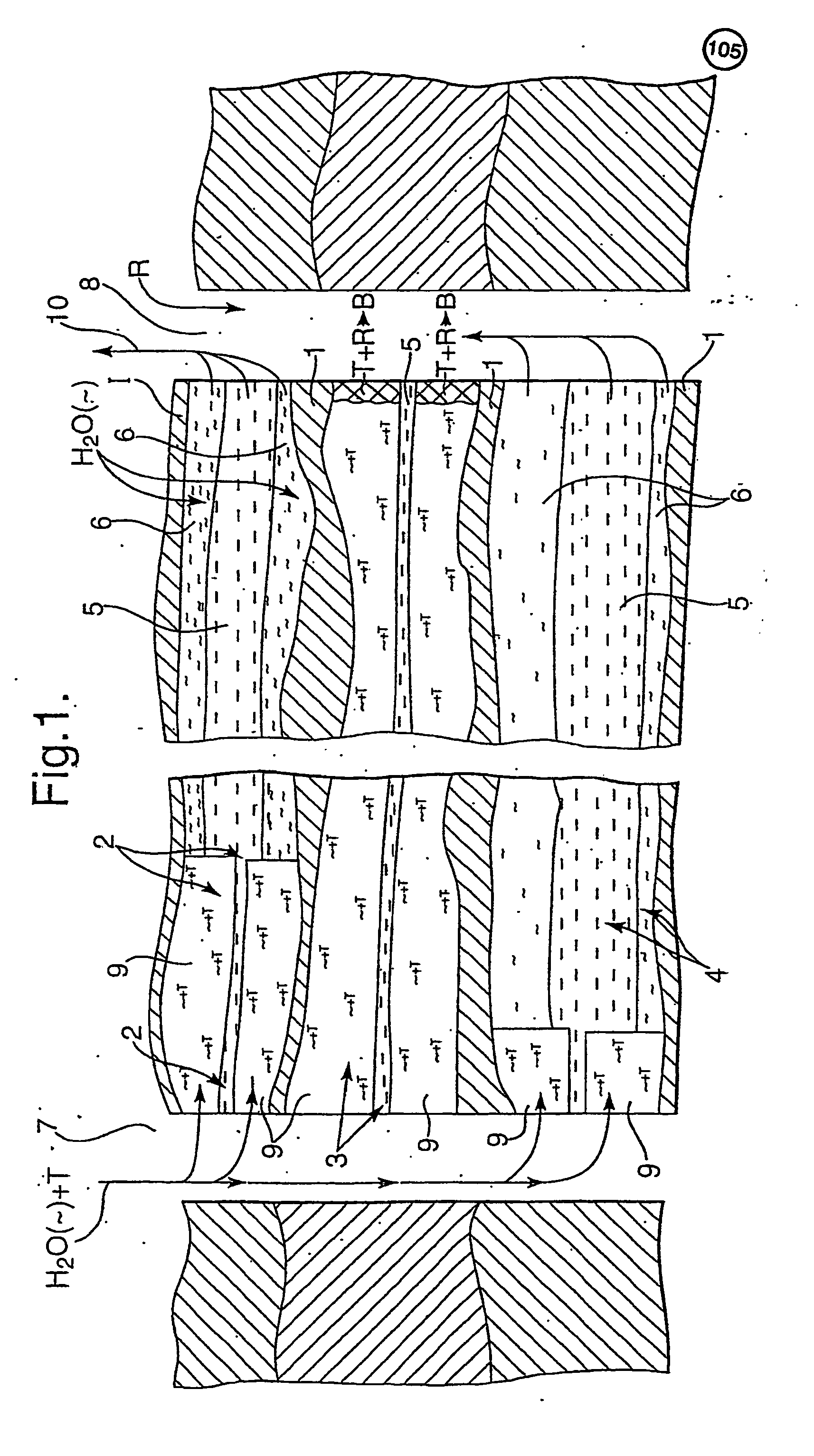

Inhibiting breakthrough of driving fluid via a permeable geological layer into an oil production well

A method for selectively reducing the permeability of one or more relatively permeable geological layers of an oil-bearing formation, to inhibit breakthrough of driving fluid from a driving fluid injection well via at least one of said layers into an oil production well, which method comprises the steps of injecting a driving fluid comprising a first compound into the formation via the injection well; detecting the first compound in well fluid of the oil production well; upon detection, injecting a second compound into the formation via the oil production well, to react with the first compound in order to provide a flow restriction generated by a third compound which comprises a reaction product of the first and second compounds in at least one relatively permeable geological layer through which breakthrough of the driving fluid into the oil production well has occurred.

Owner:SHELL OIL CO

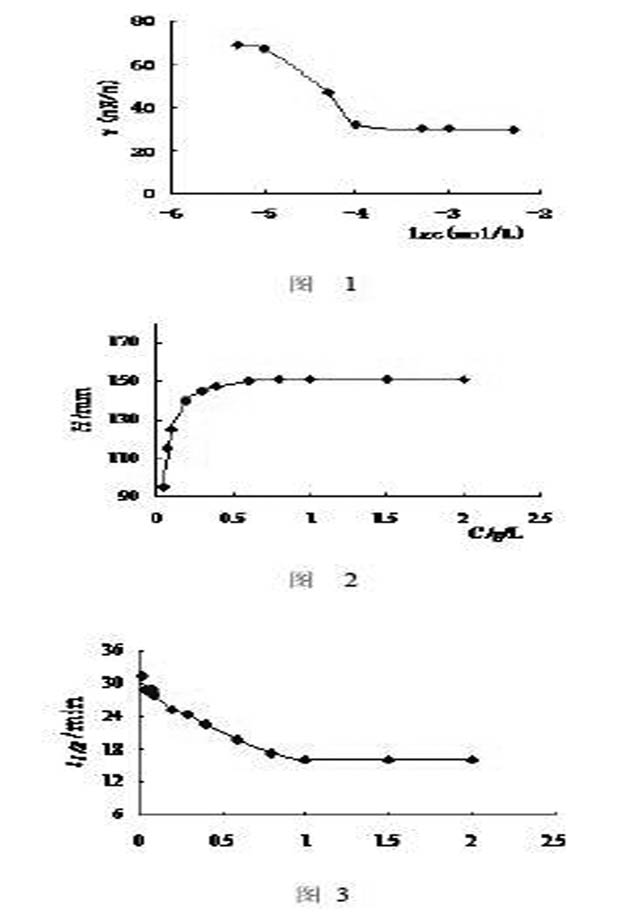

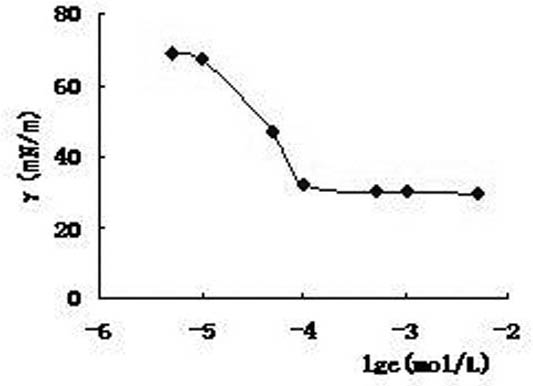

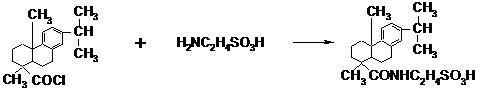

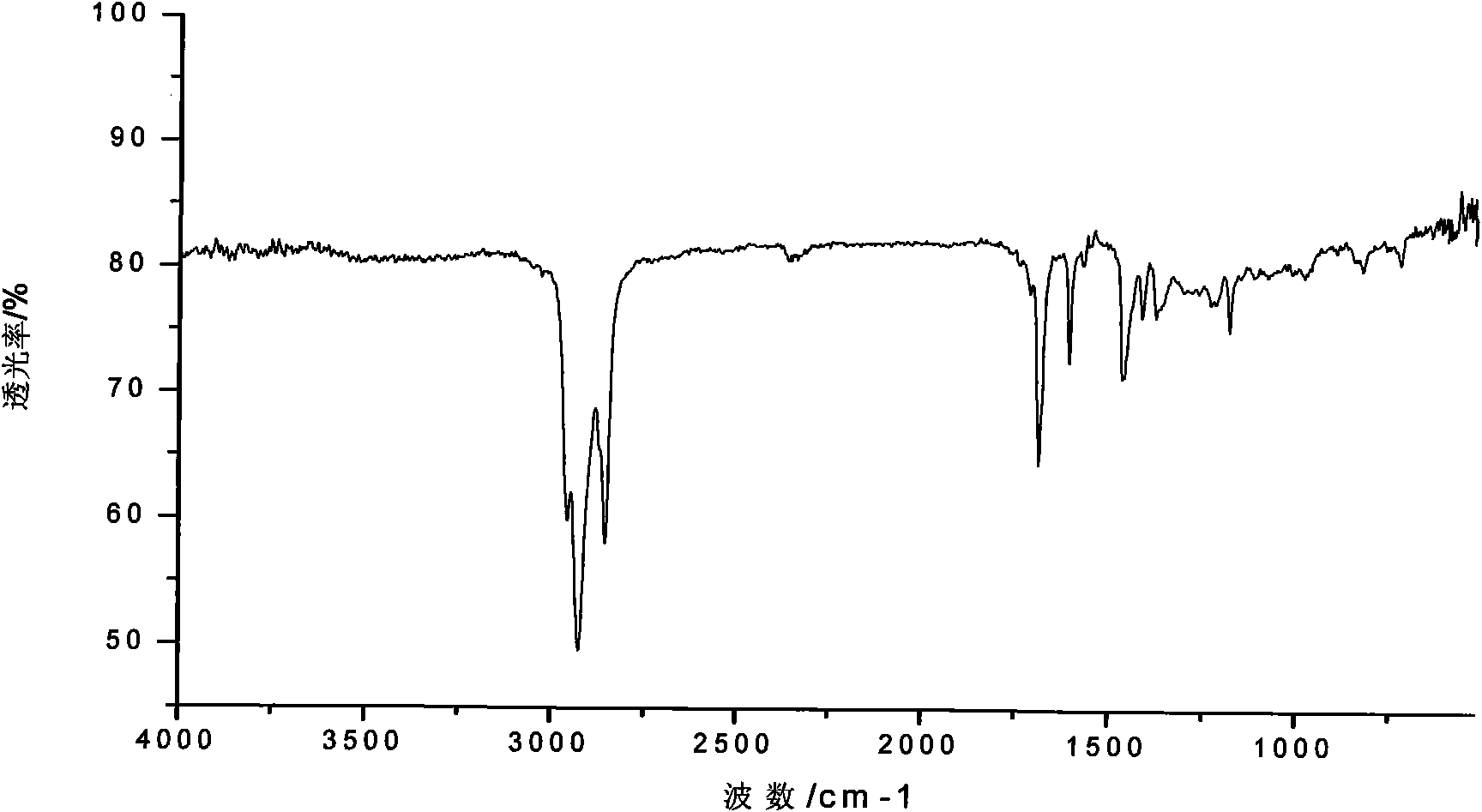

Dehydroabietylamide ethyl sulfonate surfactant, synthesis method and application of surfactant in tertiary oil recovery

InactiveCN101972614AReduce interfacial tensionTransportation and packagingSulfonic acids salts preparationSulfonateAlkali free

The invention discloses a dehydroabietylamide ethyl sulfonate surfactant, a preparation method and application of the surfactant in tertiary oil recovery. In the method, dehydroabietic acid is taken as a raw material and reacts with base after acylation and sulfonation in sequence to form salt. Therefore, a new variety-dehydroabietylamide ethyl sulfonate surfactant is added in the big family of the surfactant; and the surfactant can be used in tertiary oil recovery, wherein, interfacial tension of crude oil in Daqing No. 2 Oil Production Plant can be lowered to 10-2-10-4mN / m orders of magnitude in an alkali-free binary system formula.

Owner:NORTHEAST GASOLINEEUM UNIV

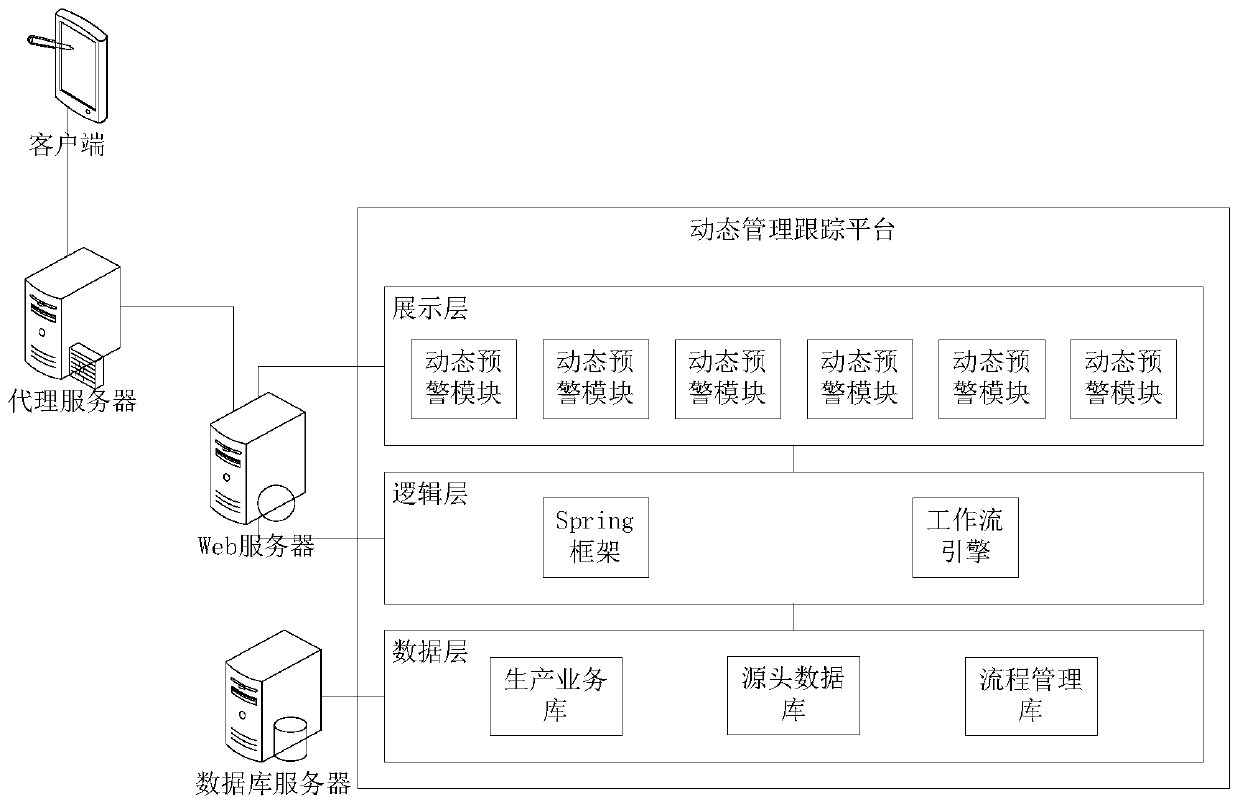

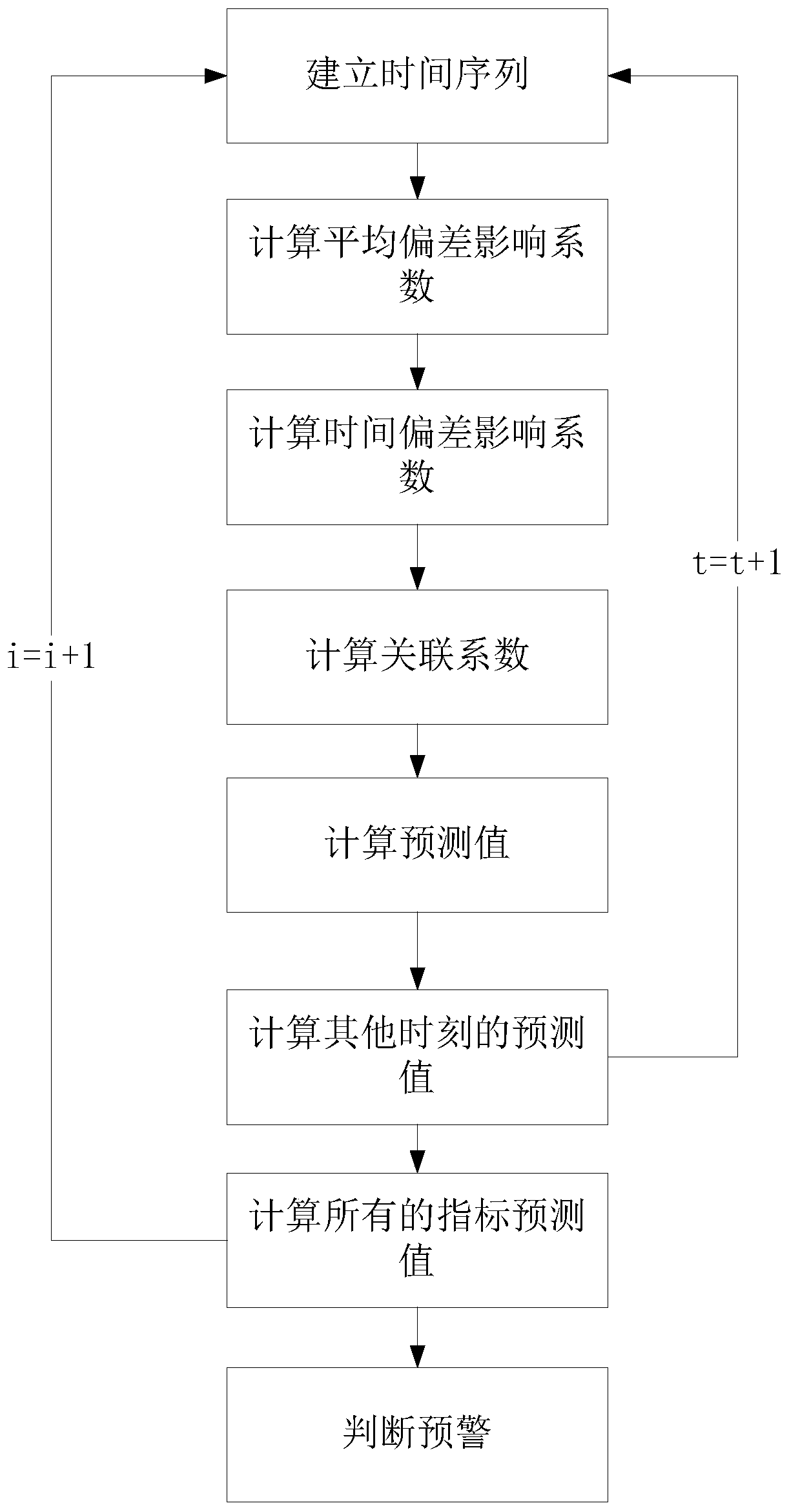

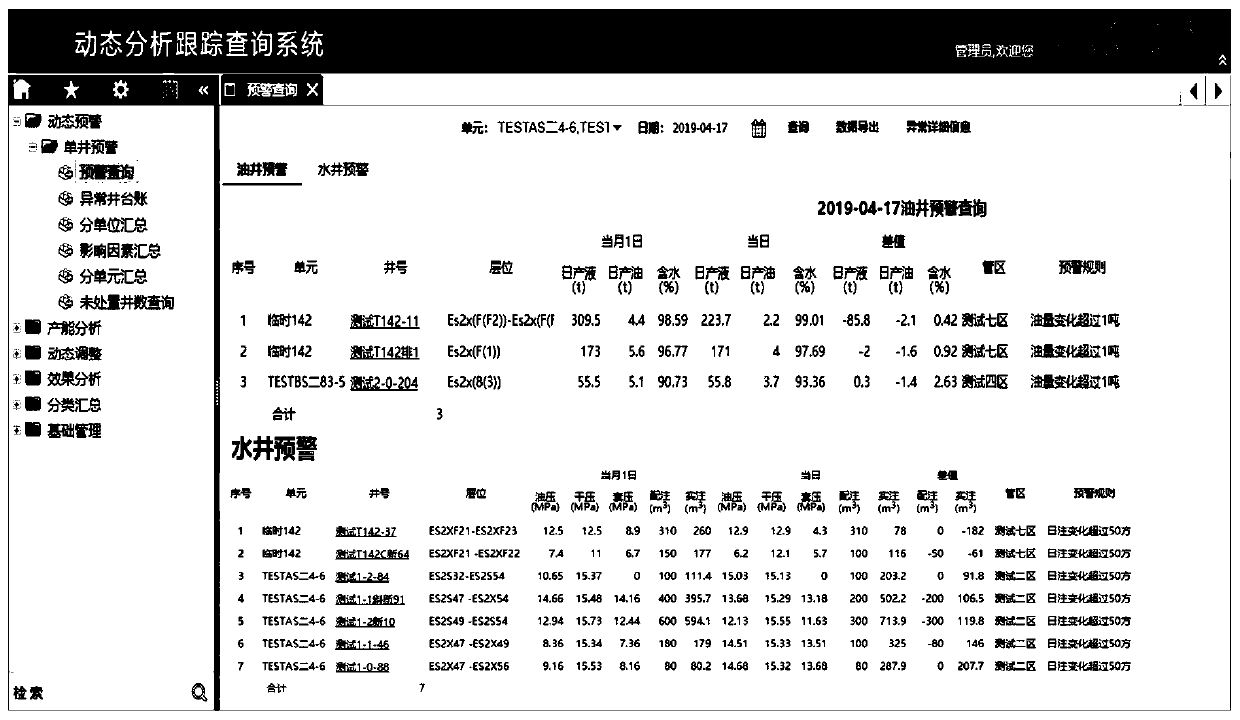

Oil production plant dynamic management tracking system and early warning method thereof

PendingCN110599034ACollaborative workImprove timelinessDigital data protectionResourcesWeb serviceDatabase server

The invention discloses an oil production plant dynamic management tracking system. The system comprises a client, a proxy server, a Web server and a database server, the display layer is a layer which is directly contacted by a user; operation is carried out on an interface provided by the display layer; the display layer is mainly used for receiving input data of a user and displaying data processed by a system background; and a user communicates with an application program through the interface, the UI interface of the display layer is divided into a service part and a management part, theservice part comprises a dynamic early warning module, a productivity analysis module and a dynamic adjustment module, and the management part comprises an effect analysis module, a classification andsummarization module and a basic management module.

Owner:CHINA PETROLEUM & CHEM CORP

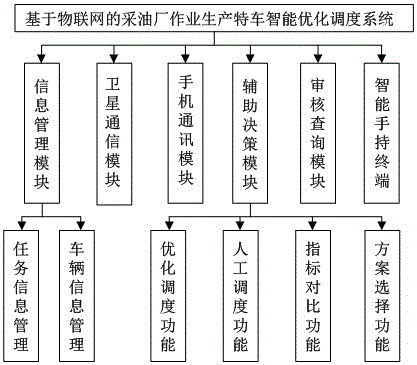

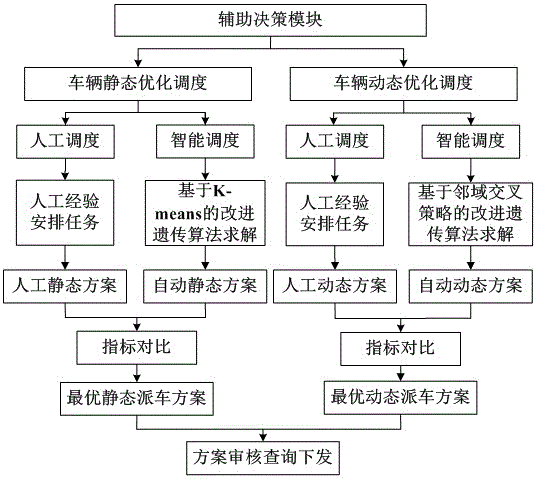

Intelligent optimization dispatching system for special vehicles for oil production plant production based on things of internet

InactiveCN106327016AImprove timelinessIncrease profitForecastingResourcesStatic optimizationComputer module

The invention discloses an intelligent optimization dispatching system for special vehicles for oil production plant production based on things of internet. The system comprises an auxiliary decision module, a mobile phone communication module and an intelligent handheld terminal; the auxiliary decision module comprises static and dynamic special vehicle optimization dispatching subsystems; the static special vehicle optimization dispatching subsystem generates static dispatching schemes by adopting artificial experience and a dispatching method based on an intelligent static optimization algorithm respectively and automatically comparing various index parameters of different static dispatching schemes to obtain an optimal static dispatching scheme; the dynamic special vehicle optimization dispatching subsystem generates dynamic dispatching schemes by adopting artificial experience and a dispatching method based on an intelligent dynamic optimization algorithm respectively and automatically comparing various index parameters of different dynamic dispatching schemes to obtain an optimal dynamic dispatching scheme; and the mobile phone communication module receives vehicle and task state updating information reported by the intelligent handheld terminal and sends the optimal static dispatching scheme and the optimal dynamic dispatching scheme to the intelligent handheld terminal. The system can improve the dispatching effect of special vehicles and ensure the timeliness of production.

Owner:SINOPEC SHENGLI OILFIELD

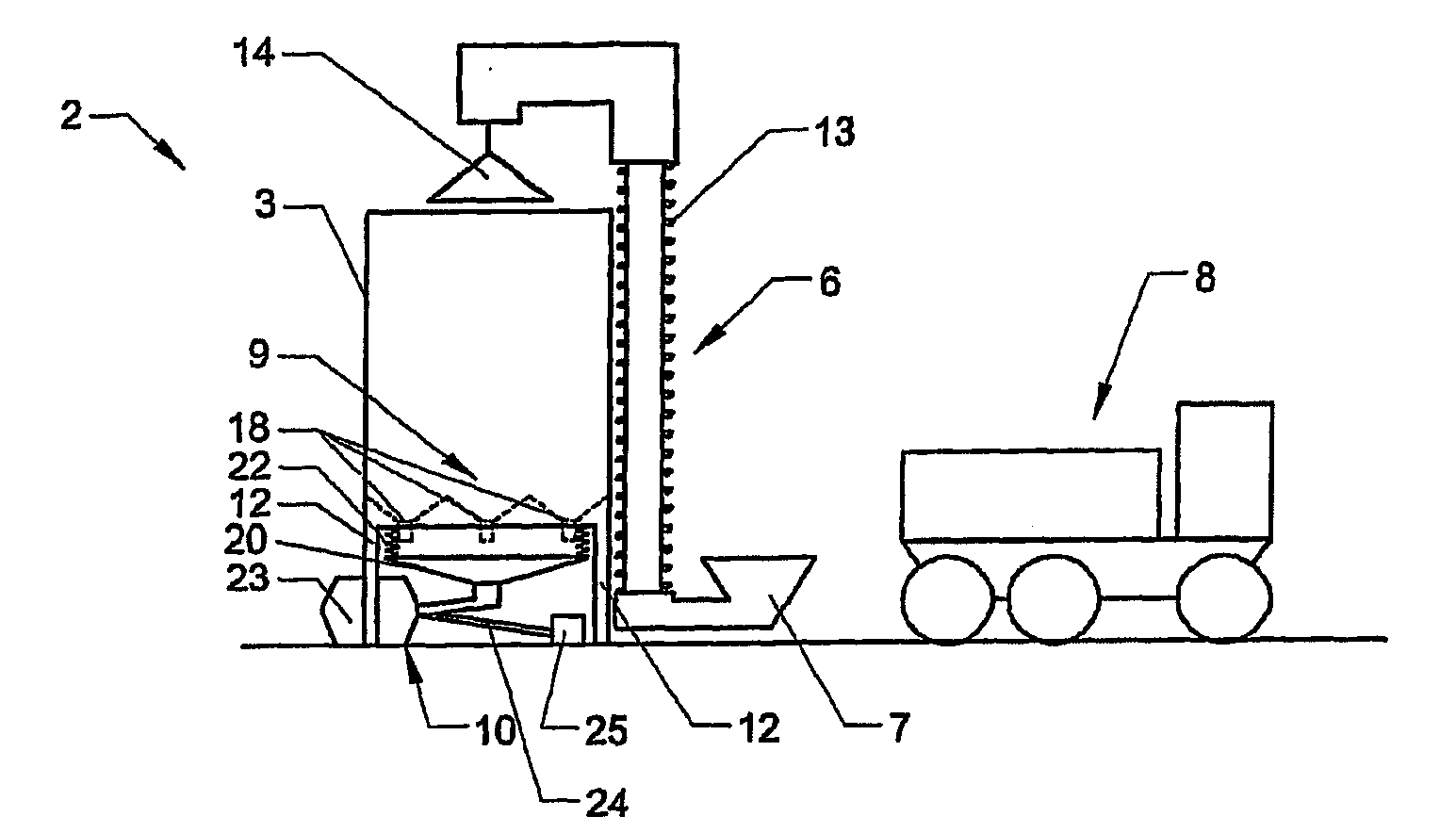

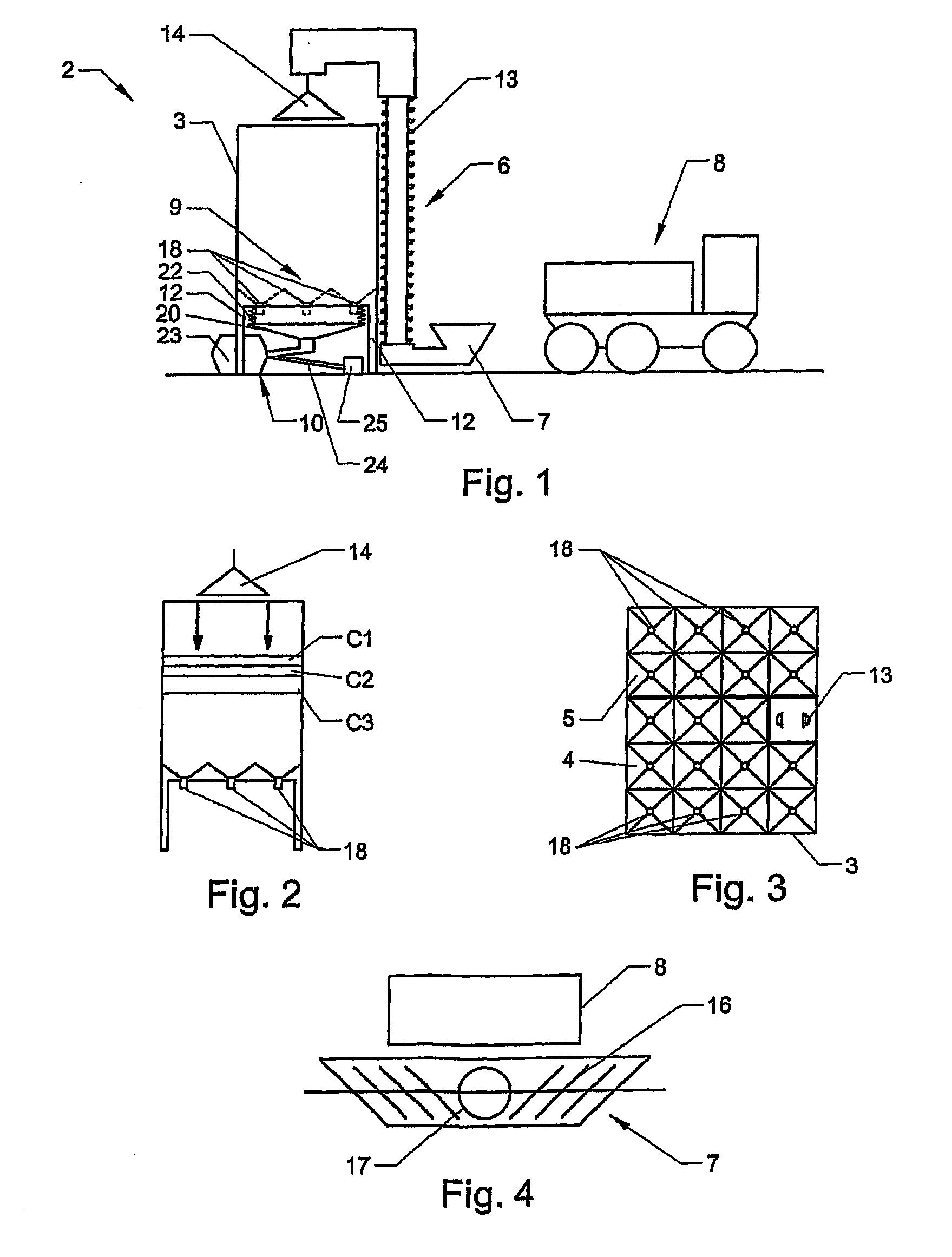

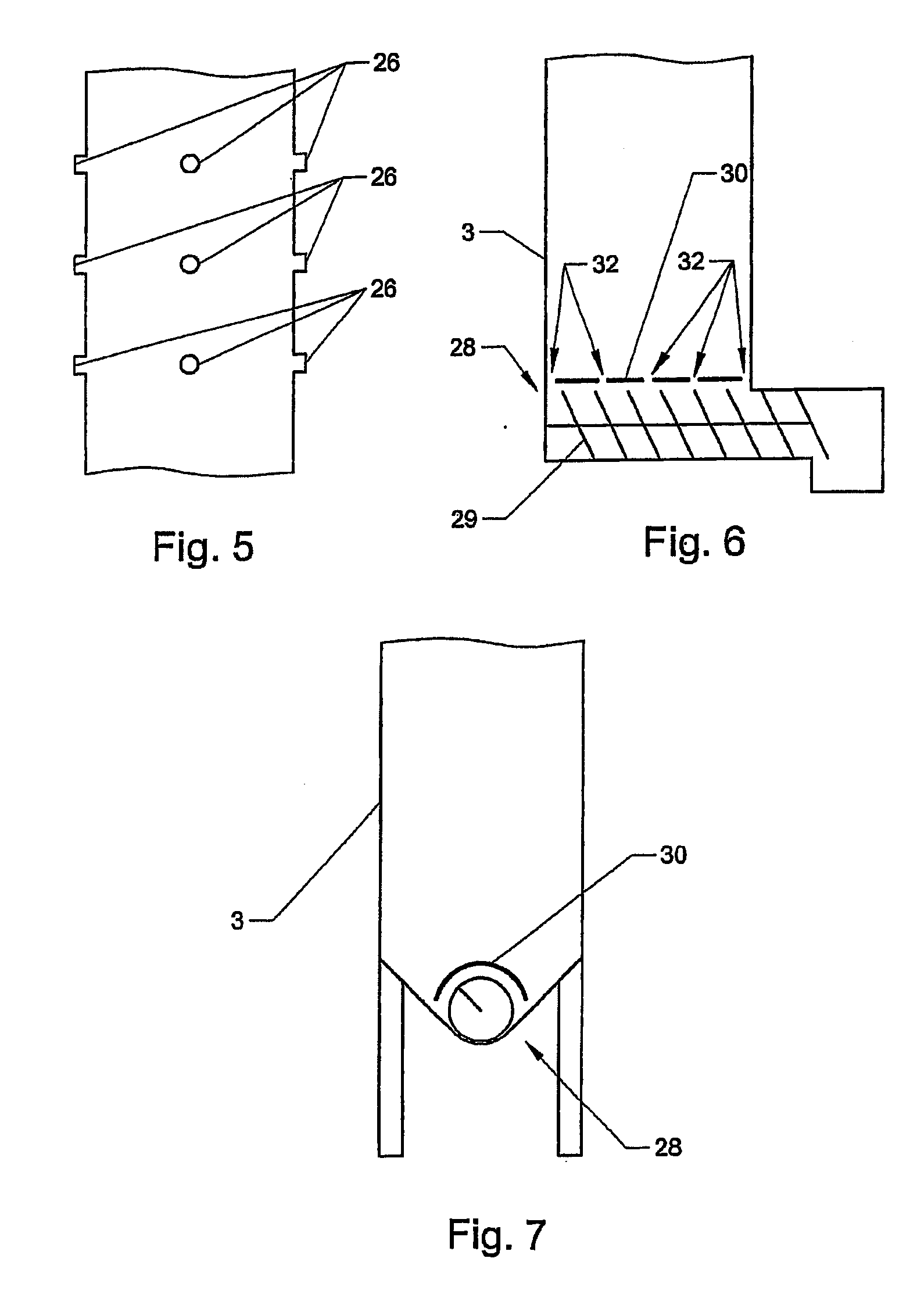

Concrete production plant

InactiveUS20090135665A1Occupy limited spaceMeet the limit requirementsMixing operation control apparatusIngredients storageOil production plantWork site

Owner:CHRISTIAN CONTAMIN

Deepwater production system

InactiveUS20160356143A1Possible to produceWaste water treatment from quariesFluid removalOcean bottomMarine engineering

A method and system for oil production in remote deep-water areas, especially in areas where weather or ice conditions may require closing and removal of surface facilities and equipment. Processing of the produced oil from subsea oil wells is partly performed subsea on a subsea oil and gas production unit (10) called Deepwater Production System (DPS), whereas the remaining processing takes part on a vessel (1) that may be disconnected from the DPS if the conditions make it necessary. The method and system take advantage of combining and integrating subsea processing with processing at atmospheric pressure onboard the vessel.

Owner:KVAERNER AS

Production device of abelmoschus esculentus seed crushed and pressed oil

The invention discloses a production device for crushing and pressing oil of okra seeds, which comprises a crushing box, a cleaning cylinder and a squeezing cylinder. A filter screen is arranged at the bottom of the inner chamber of the cleaning cylinder, and the filter screen separates the inner chamber of the cleaning cylinder into a cleaning chamber and a drainage chamber. chamber, the left side of the top wall of the cleaning chamber is equipped with a spray device, the top of the cleaning chamber is connected to the hopper, the left side of the crushing box is fixedly connected to the water tank, the inner cavity of the crushing box is equipped with a crushing device, and the squeezing cylinder is equipped with a crushing device. Shaft, the pressing shaft is set with a squeezing auger, the bottom of the left end of the pressing cylinder is provided with a slag discharge hole, the bottom wall of the pressing cylinder is connected to the oil nozzle, and a filter is installed in the oil nozzle, and the bottom of the squeezing cylinder is uniform There are several supporting legs; the present invention fully cleans the okra seeds by setting the cleaning cylinder, removes impurities in the okra seeds, facilitates the pressing process, and ensures the quality of the pressed oil at the same time; and the setting of the crushing device is for the okra seeds Crushed to reduce the difficulty of the pressing process and improve the oil yield.

Owner:周衡

Method for water control and oil production increasing acidification of oil well at water content increasing stage of low-pressure heterogeneous reservoir

The invention relates to a method for the water control and oil production increasing acidification of an oil well at the water content increasing stage of a low-pressure heterogeneous reservoir, which comprises the following steps of: washing a shaft by using a flushing fluid, and filling the flushing fluid into a sleeve; replacing the flushing fluid in an oil tube with acidification liquid, and introducing the acidification liquid into the middle part of an oil layer; sealing well a packer seat, sealing an annular space of an oil jacket, replacing the acidification liquid in the oil tube with high-viscosity displacing liquid, introducing the displacing liquid into the oil layer, fastening an oil tube valve and a sleeve valve up, performing reaction for 30min to 8h, and performing pumping and flow back by using an oil tube swab; when an acid flooding pressure is less than or equal to 7MPa, replacing the acidification liquid with the high-viscosity displacing liquid in a volume which is 2 / 3 of that of the oil tube of the shaft, and performing reaction for 3h; when the acid flooding pressure is more than or equal to 7MPa, replacing the acidification liquid with the high-viscosity displacing liquid in the volume which is 4 / 5 of that of the oil tube of the shaft, and performing reaction for 3h; and after the pressure is released, opening the mouth of the well, and setting an oil tube pumping drum for pumping and flow back until reaching a water oil ratio, wherein the deepest pumping position is 300 to 500m above a perforated interval of the oil layer. The method avoids the probability of high water yield of the acidified oil well, poor effects achieved by measures or scrap of the oil well.

Owner:PETROCHINA CO LTD

Improved natural gas drive oil production method

ActiveCN101555786AAvoid wastingEffective displacement of crude oilFluid removalPressure decreaseOil field

Owner:PETROCHINA CO LTD

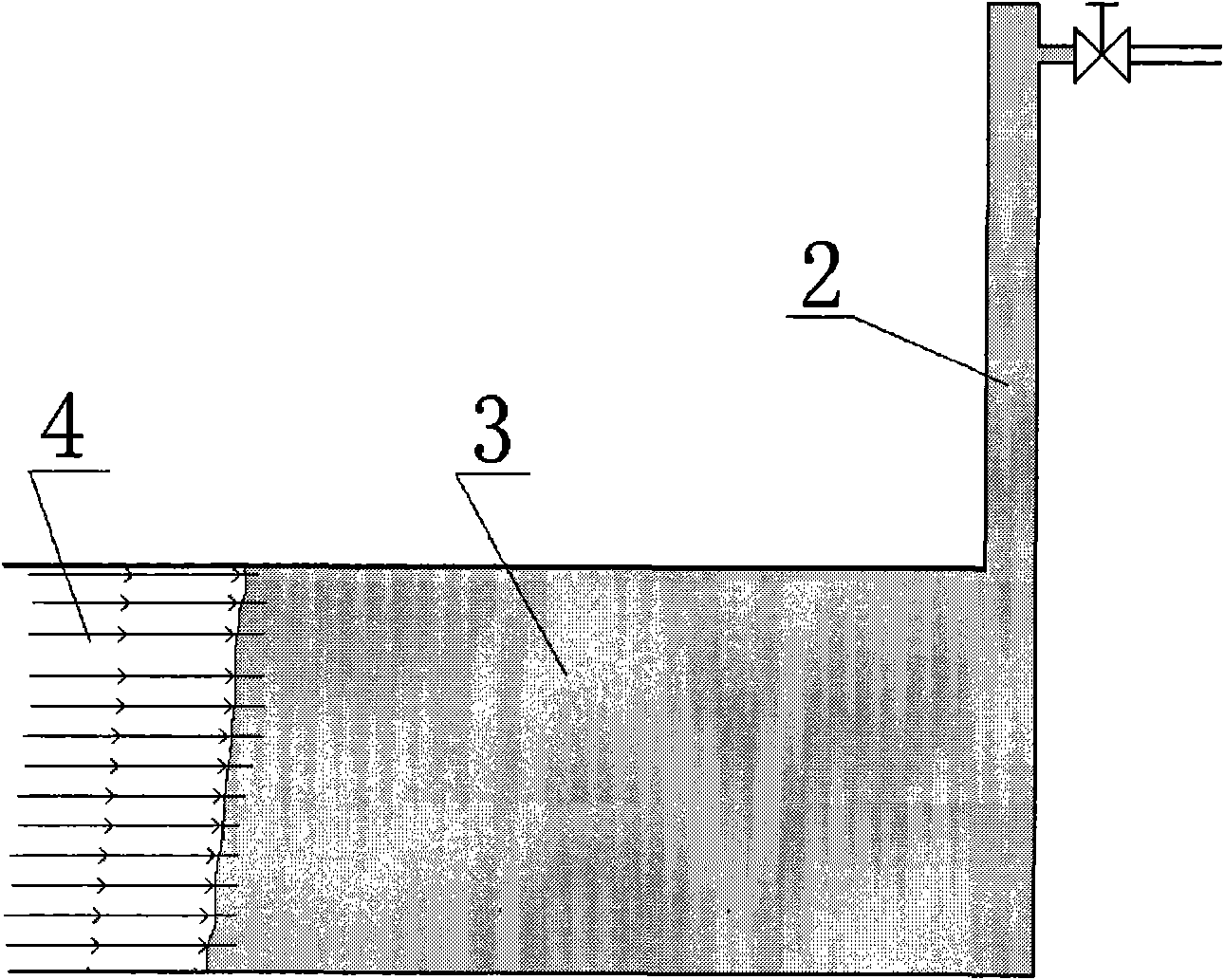

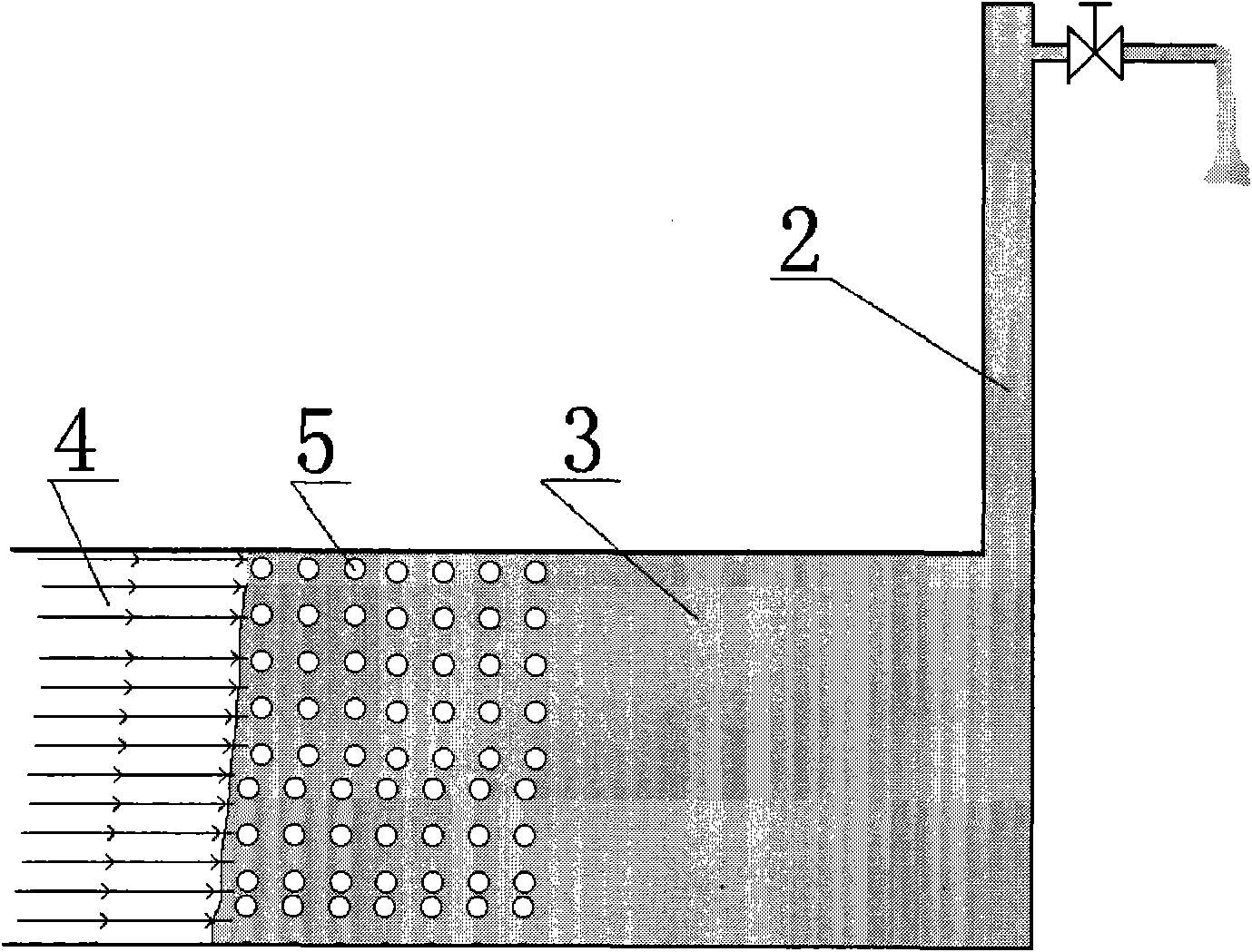

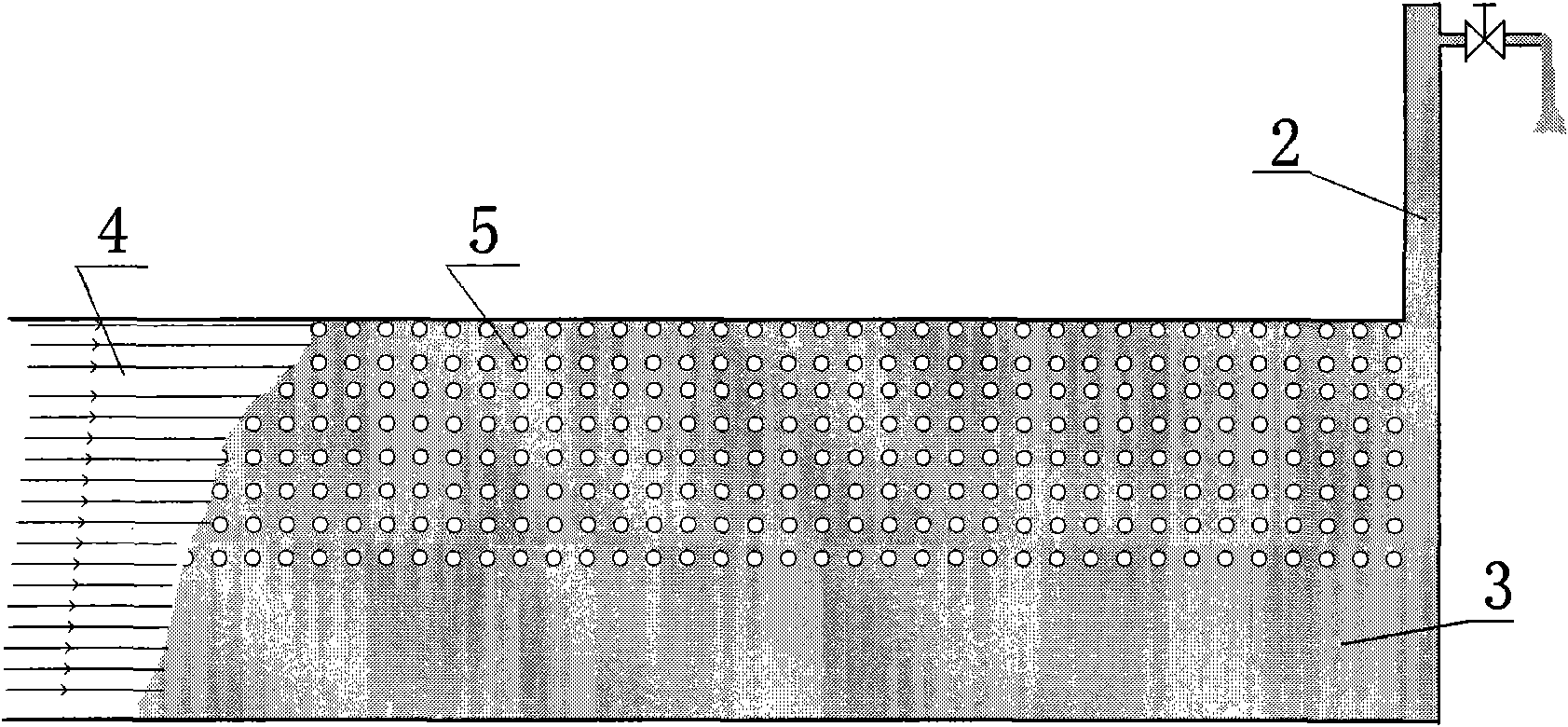

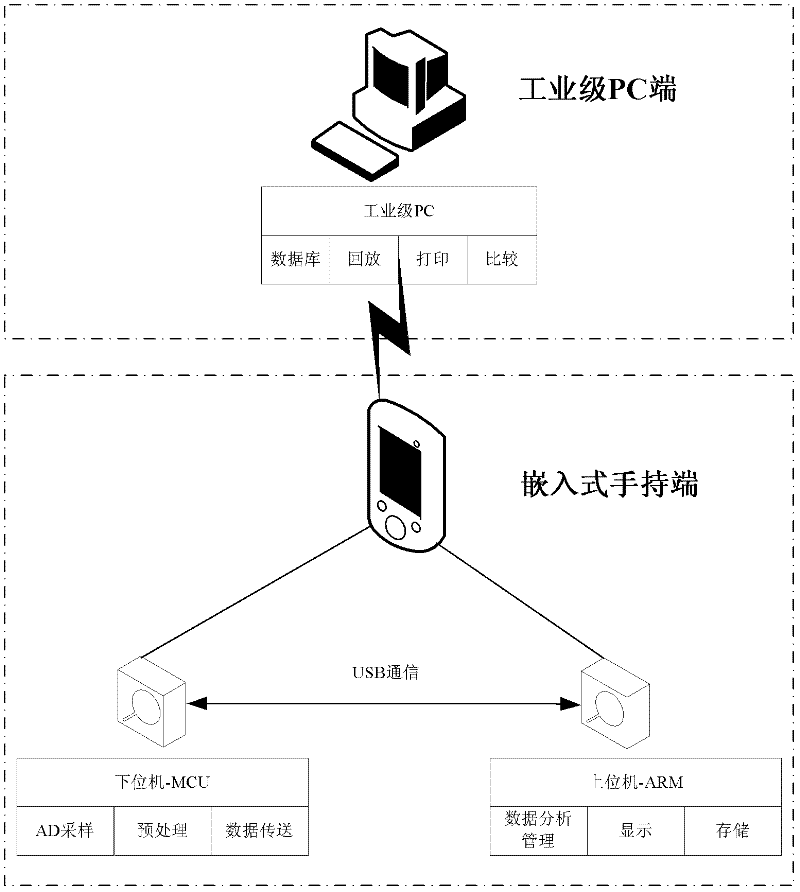

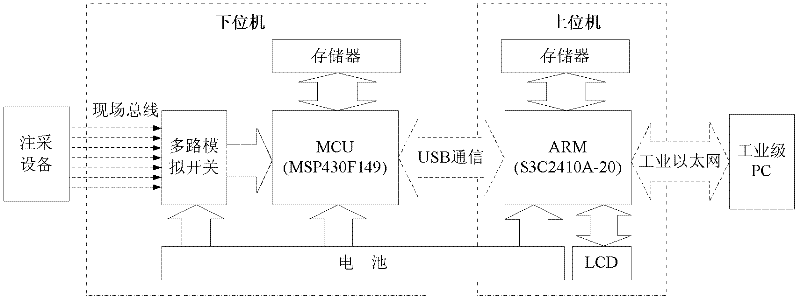

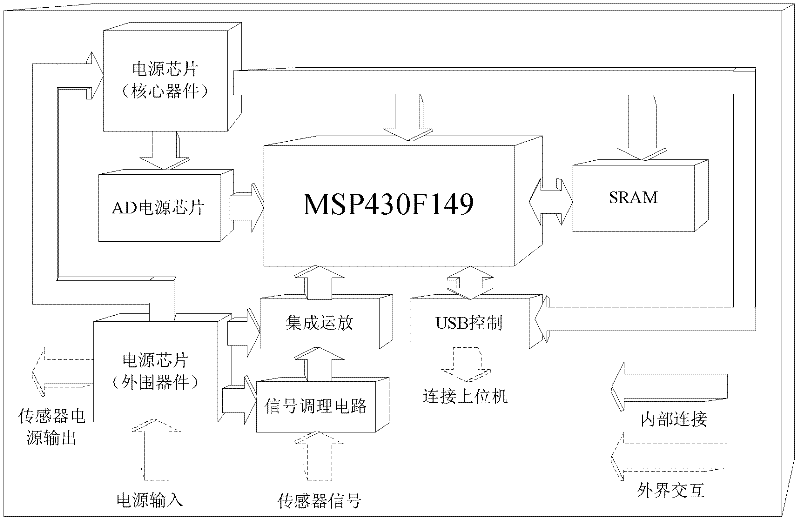

Handheld type condition monitoring and fault diagnosing system orienting to oil field injection-production equipment

InactiveCN102536203AReduce power consumptionReduce volumeConstructionsData analysis systemTrend prediction

The invention provides a handheld type condition monitoring and fault diagnosing system orienting to oil field injection-production equipment. The system comprises an embedded handheld end and an industrial-grade PC (Personal Computer) end, wherein the embedded handheld end is of a dual embedded processor structure of an upper computer and a lower computer and is composed of a lower computer real-time data acquisition system and an upper computer data processing analysis system, the lower computer real-time data acquisition system is a data acquisition card based on a mixed signal processing micro control unit, and the upper computer data processing analysis system is a condition monitoring card based on an advanced reduced instruction set computing machine; and the industrial-grade PC end is a depth data analysis system which is positioned in a control room of an oil field oil production plant, and is used for finishing off-line analysis tasks including related analysis, comparative analysis, trend prediction of equipment performance and generation and actuation of expert knowledge. The handheld type condition monitoring and fault diagnosing system orienting to the oil field injection-production equipment provided by the invention has the advantages of good flexibility, low requirement for working environment, wide application range, simple structure, simplicity and convenience in operation and lower cost.

Owner:ZHEJIANG UNIV OF TECH

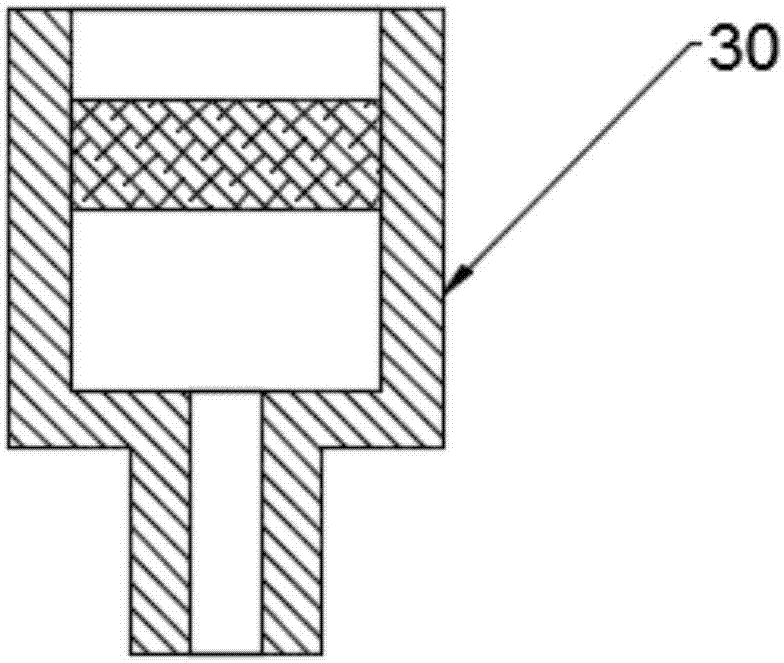

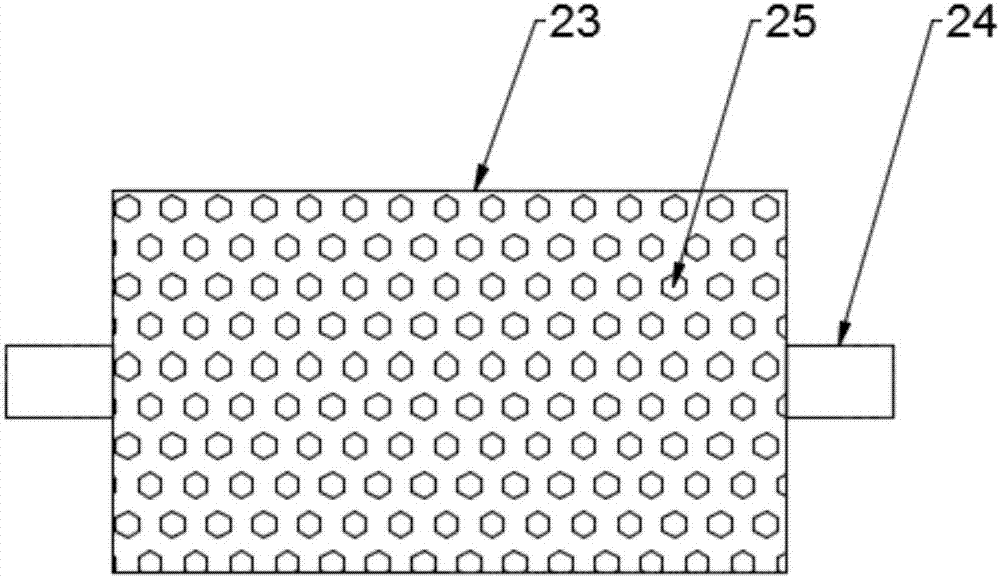

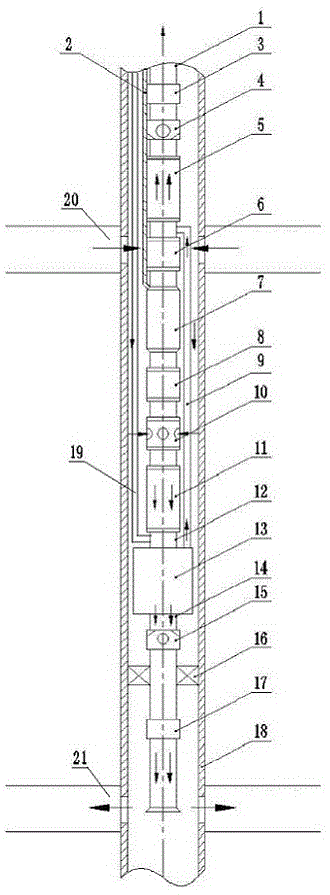

Offshore large-displacement downhole oil-water separation device with chemical agent injection function

InactiveCN104389578AImprove separation efficiencyReduce processingFluid removalChemical separationOil production

The invention discloses an offshore large-displacement downhole oil-water separation device with a chemical agent injection function, belongs to the field of oil and gas production and mainly aims to solve the problems of large oil-water separation treatment capacity of domestic and overseas offshore oilfields and limited space of offshore platforms at present. The device is characterized in that a hydrocyclone and demulsifying agents are applied at the same time, and physical separation and chemical separation are combined, so that separation efficiency is improved remarkably. In the whole device, a power portion comprises a motor, a high-voltage cable connector and a cable; a pressure boosting portion comprises pumps which can be electric submersible centrifugal pumps; an oil-water separation portion comprises the single-stage or multi-stage serial-parallel-connection hydrocyclone, a packer, an outer bypass pipe, a demulsifying agent injection pipe and the like. The device achieves single-well injection-production of the offshore oilfields by separating downhole oil-water mixture of the offshore oilfields, reinjecting separated water into an injection layer and lifting separated oil to the ground. The offshore large-displacement downhole oil-water separation device with the chemical agent injection function has the advantages of capabilities of decreasing treatment capacity of the oil-water mixture of the offshore platforms, reducing oil production cost, improving economic benefit and the like.

Owner:BEIJING UNIV OF CHEM TECH

Preparation of long-chain alkyl acyl benzene sulfonic acid sodium salt and application thereof in enhancing oil recovery rate

InactiveCN101935522ASolve the problem of limited sources and insufficient outputWide variety of sourcesSulfonic acids salts preparationDrilling compositionSodium saltDodecylbenzene

The invention discloses the preparation of a long-chain alkyl acyl benzene sulfonic acid sodium salt and an application thereof in enhancing oil recovery rate and belongs to the technical fields of colloid and interface chemistry. Industrial-grade dodecylbenzene and fat acyl chloride are taken as raw materials, and the long-chain alkyl acyl benzene sulfonic acid sodium salt is prepared by carrying out acidylating reaction, sulfonation reaction and neutralization reaction on the raw materials. Experiments show that dodecyl lauroyl benzene sulfonic acid sodium salt DLBS (5mM) below 45DEG C can enable the interfacial tension of C7-C16 n-alkane and water to be reduced to the order of magnitude of 10-1mM / m, if being compounded with HABS1#, the interfacial tension of crude oil in No.4 Oil Production Plant of Daqing Oilfield Company Ltd. and imitation stratum water in the NaOH concentration range of 0.5 percent to 1.0 percent can be reduced to the order of magnitude of 10-3mM / m, and especially, and if being compounded with HABS1# and a little ampholytic surfactant, the interfacial tension of crude oil in No.4 Oil Production Plant of Daqing Oilfield Company Ltd. and imitation stratum water in the Na2CO3 concentration range of 1.2 percent to 2.0 percent can be reduced to the order of magnitude of 10-3mM / m. The product is expected to replace HABS2# and is applicable to strong base, especially weak base ASP combination flooding.

Owner:JIANGNAN UNIV

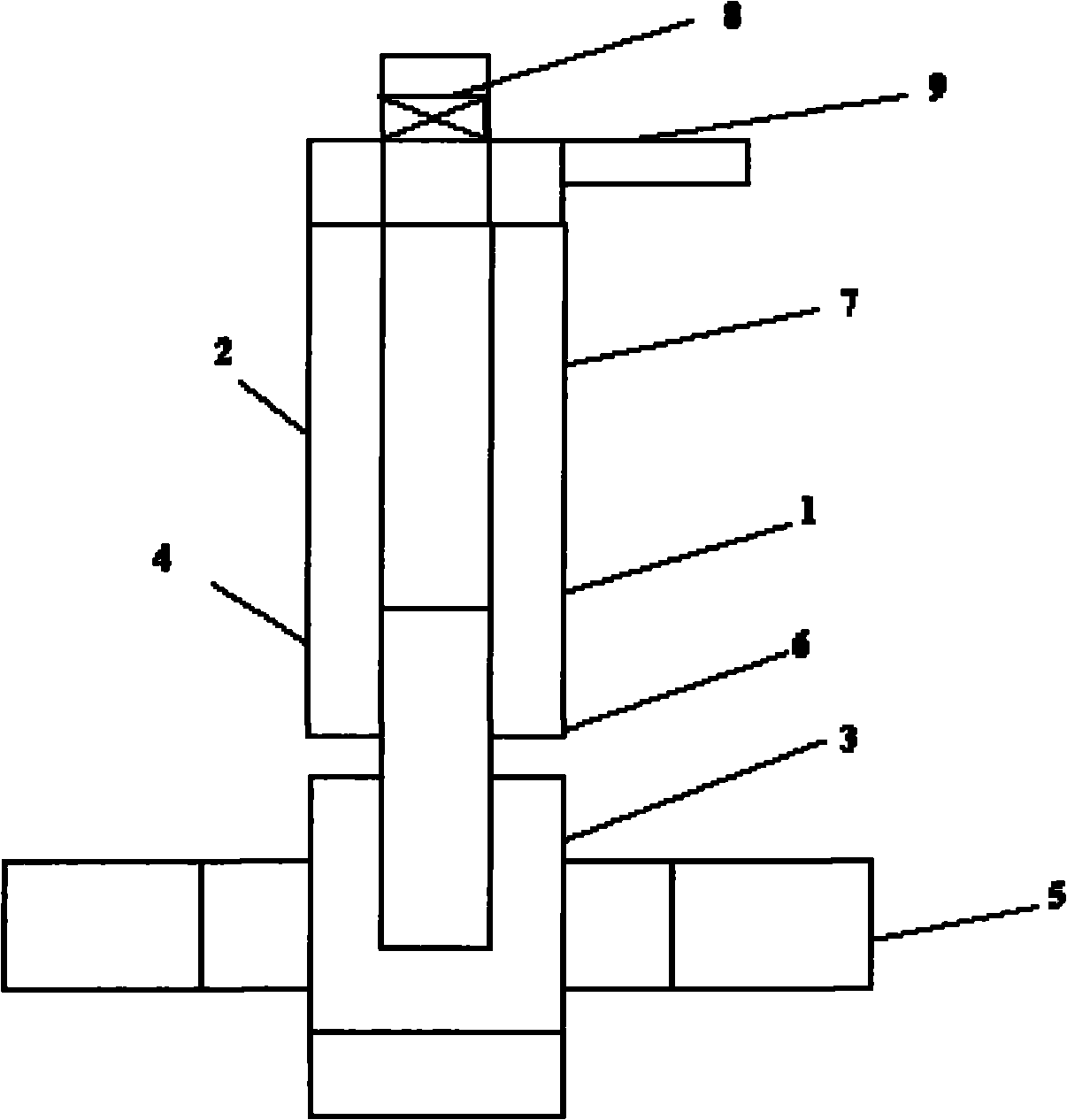

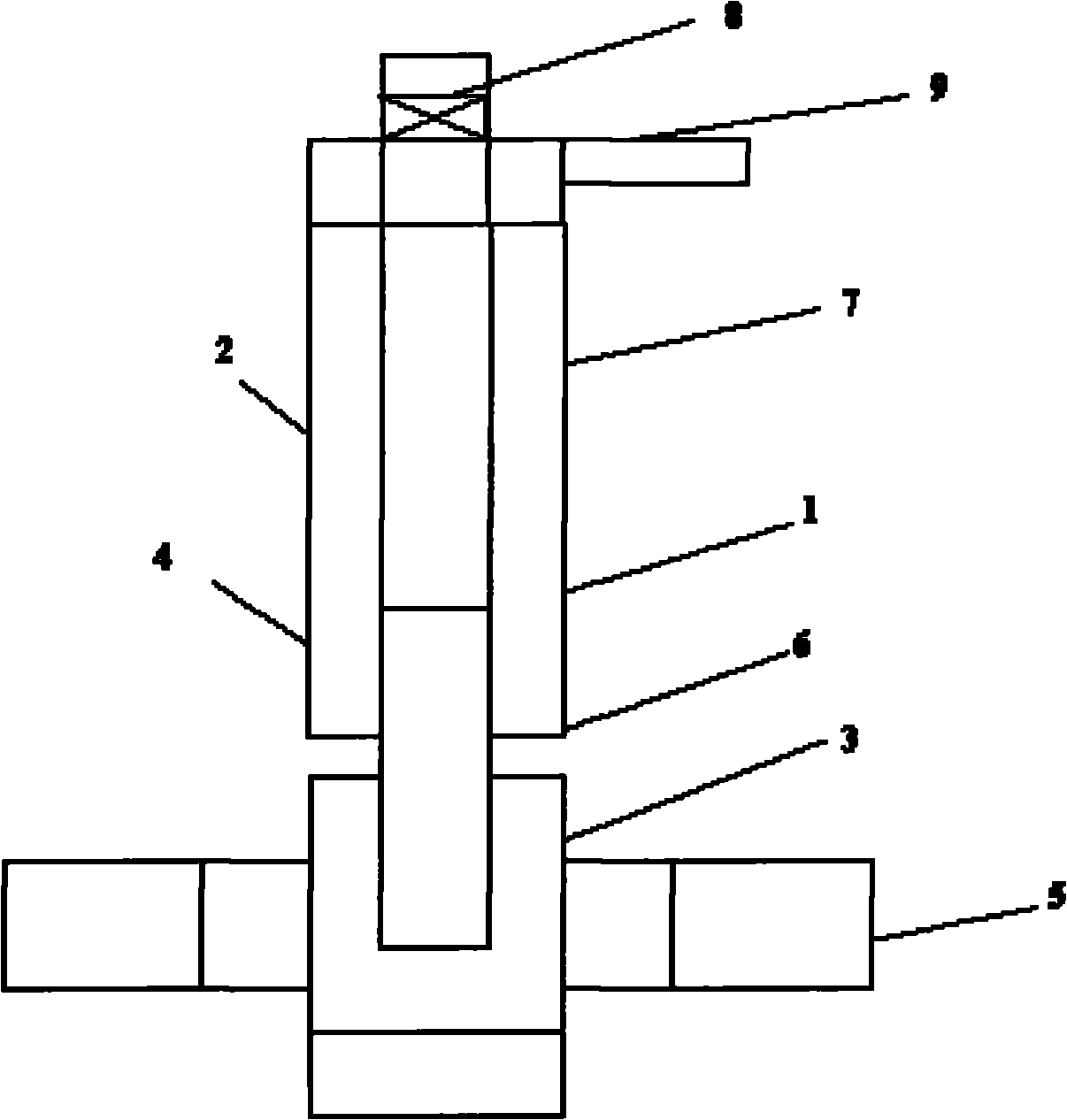

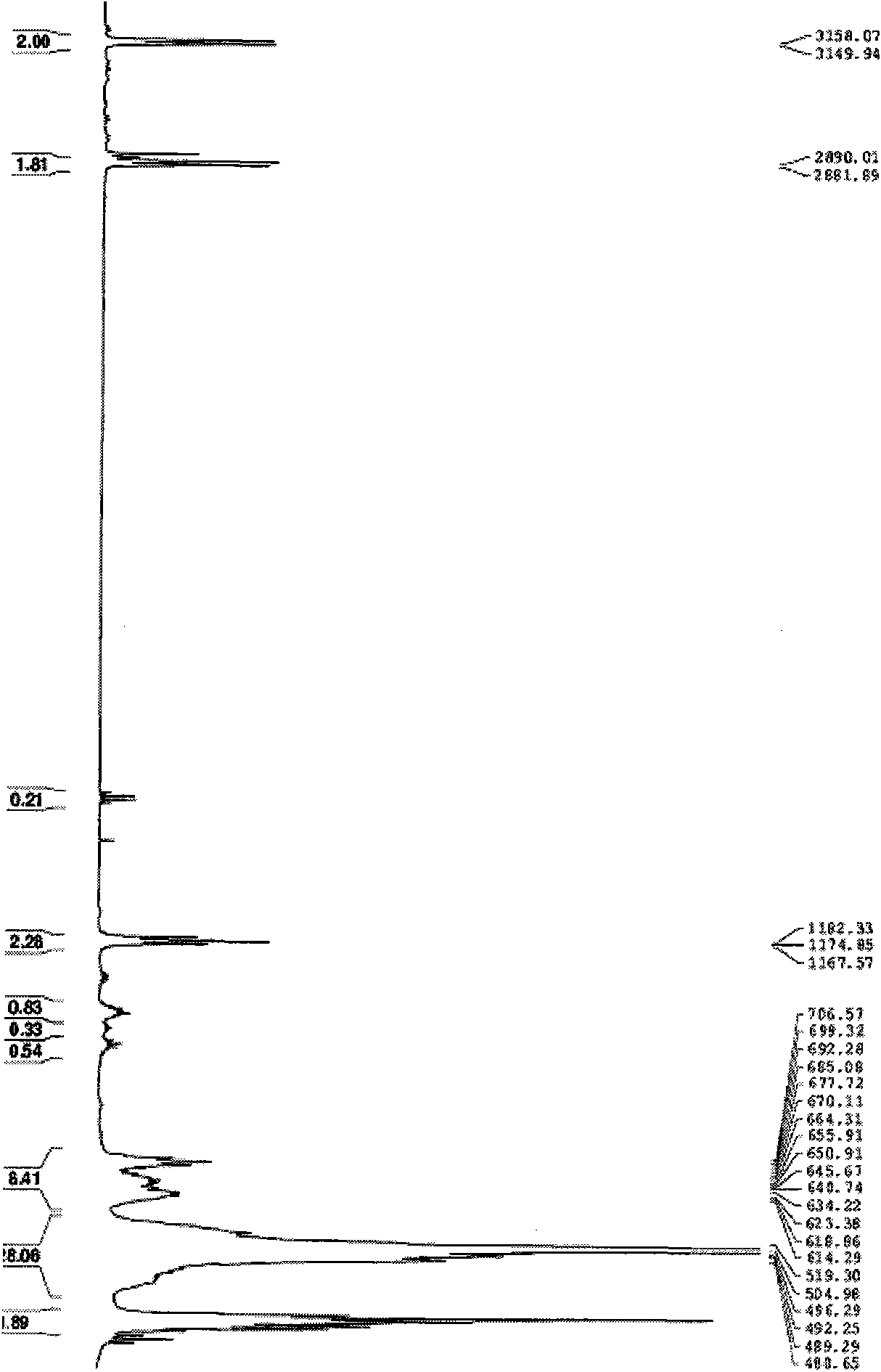

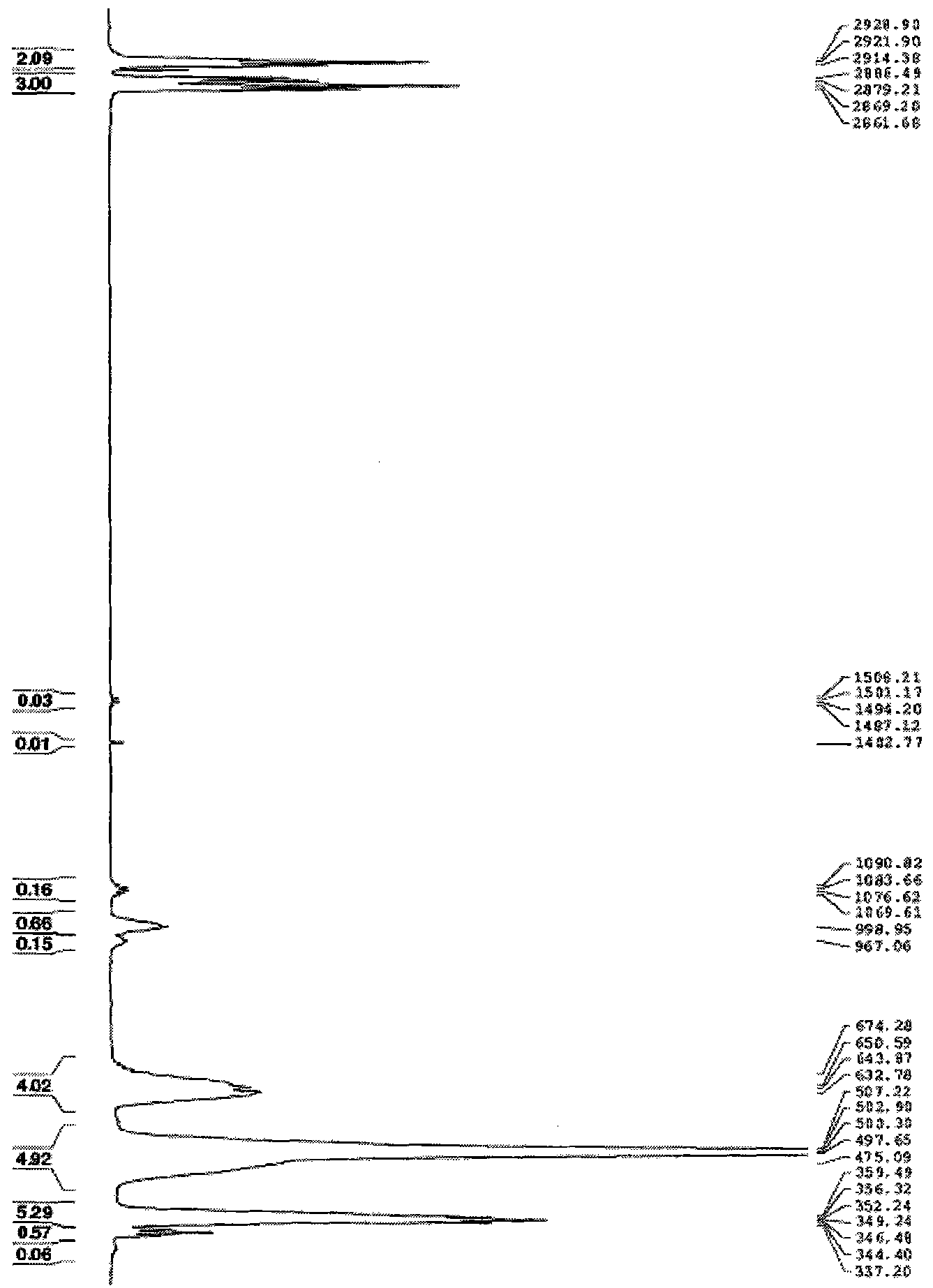

Heavy oil reservoir natural gas huff-and-puff oil production process system and oil production method

ActiveCN103470233AReduce viscosityRealize Huff and Puff Oil RecoveryFluid removalProcess systemsOil production

The invention relates to a heavy oil reservoir natural gas huff-and-puff oil production process system and an oil production method. The method comprises the steps of drilling a well in a target area of an oil reservoir, drilling through a stratum layer, an oil layer, an isolating layer and a natural gas layer from the top to the bottom and perforating the oil layer and the gas layer, wherein a shaft is communicated with the oil layer and the gas layer; selecting and determining the length of a perforated pipe and installing a flowmeter, a pressure gauge and a flow control valve; lowering a production string and a cable, wherein the production string is sequentially and serially connected with a first oil pipe, an oil pump, the perforated pipe, a packer and a second oil pipe, and the cable is used for transmitting signals; setting the packer; installing a Christmas tree and an oil pumping unit; closing the well and opening the flow control valve to enable natural gas to flow into the oil layer; closing the flow control valve for soaking; after the design soaking time is reached, opening the well for oil production. The heavy oil reservoir natural gas huff-and-puff oil production process system and the oil production method have the advantages that the high-pressure energy of the natural gas layer is fully utilized, the natural gas is enabled to directly flow into the heavy oil layer from the gas layer through the shaft, the problems of complex process flow, high operating cost and great energy consumption are avoided, the huff-and-puff efficiency of the natural gas is higher and the oil production efficiency is greatly improved.

Owner:PETROCHINA CO LTD

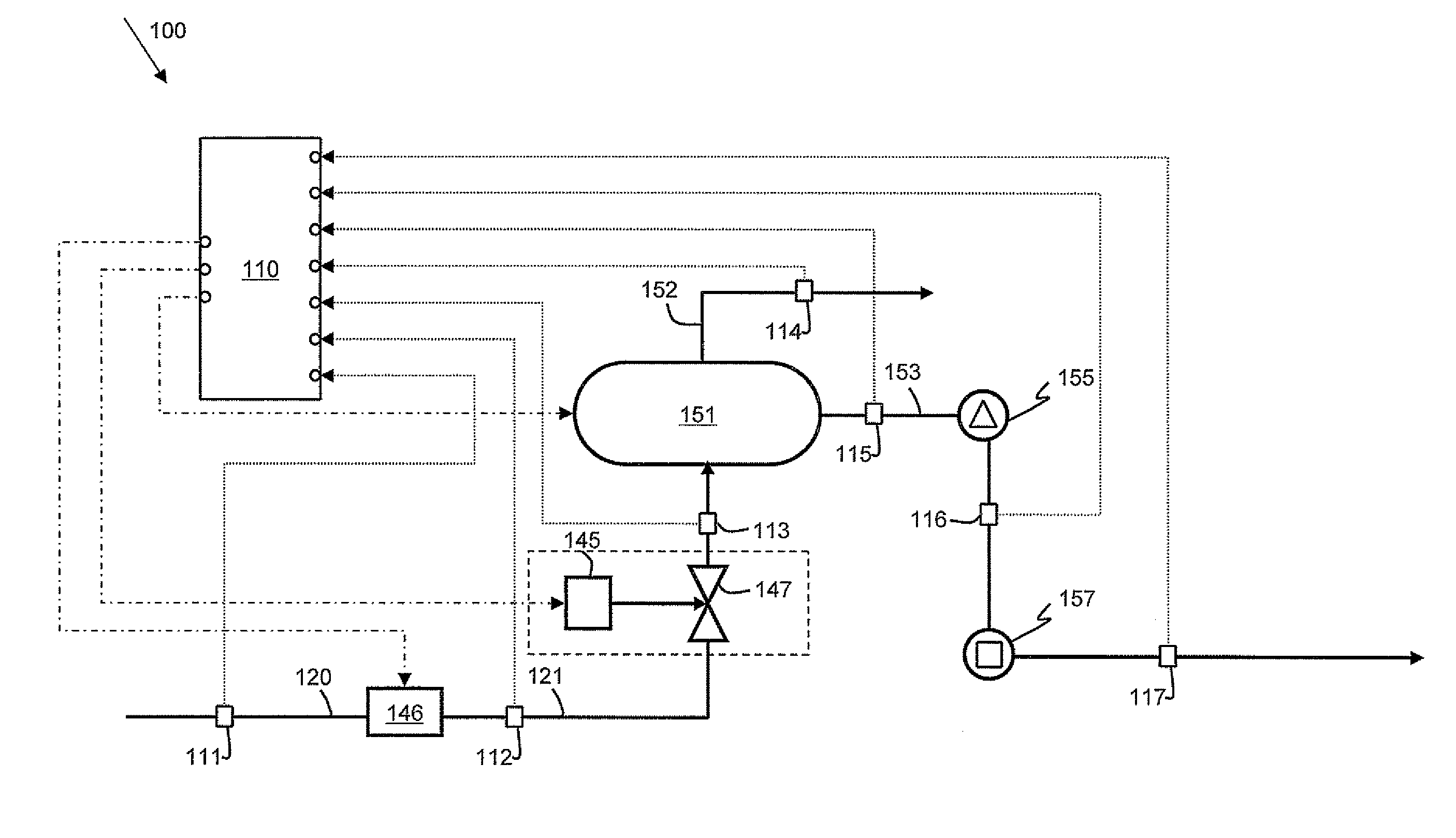

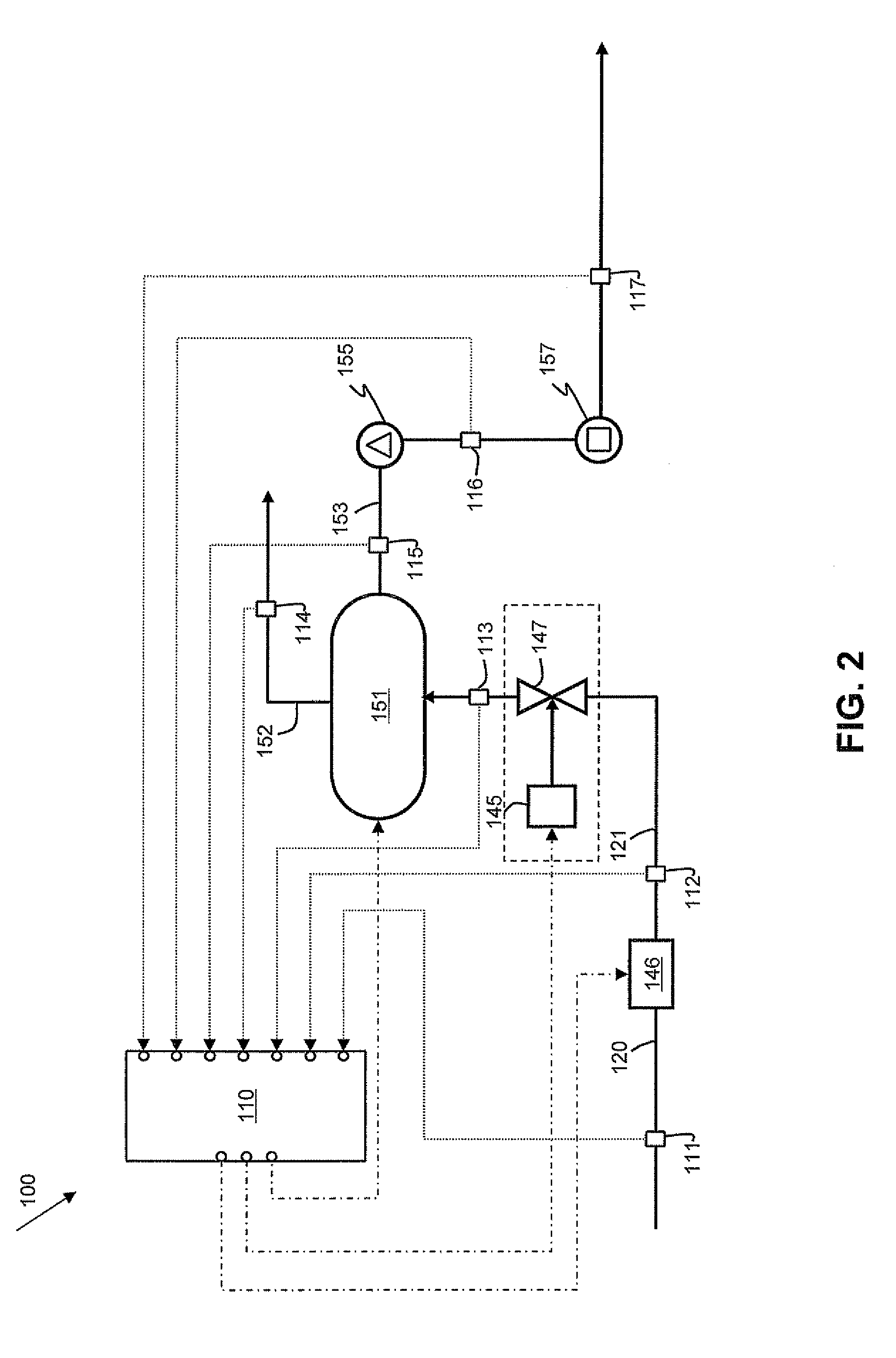

Dynamic demulsification system for use in a gas-oil separation plant

ActiveUS9555345B2Liquid separation auxillary apparatusLiquid separation by electricityMicrowaveOil separation

A dynamic water / oil demulsification system for a gas-oil separation plant (GOSP) includes:an in-line microwave treatment subsystem upstream of one or more of each of a dehydrator vessel, desalter vessel and / or water / oil separator vessel, each of which vessels receives a water-oil emulsion;sensors that monitor and transmit data corresponding to properties of the water-oil emulsion in or downstream of the respective vessel(s); anda processor / controller associated with the in-line microwave treatment subsystem that initiates the application of microwave energy to the emulsion(s) based on the data from the sensors.

Owner:SAUDI ARABIAN OIL CO

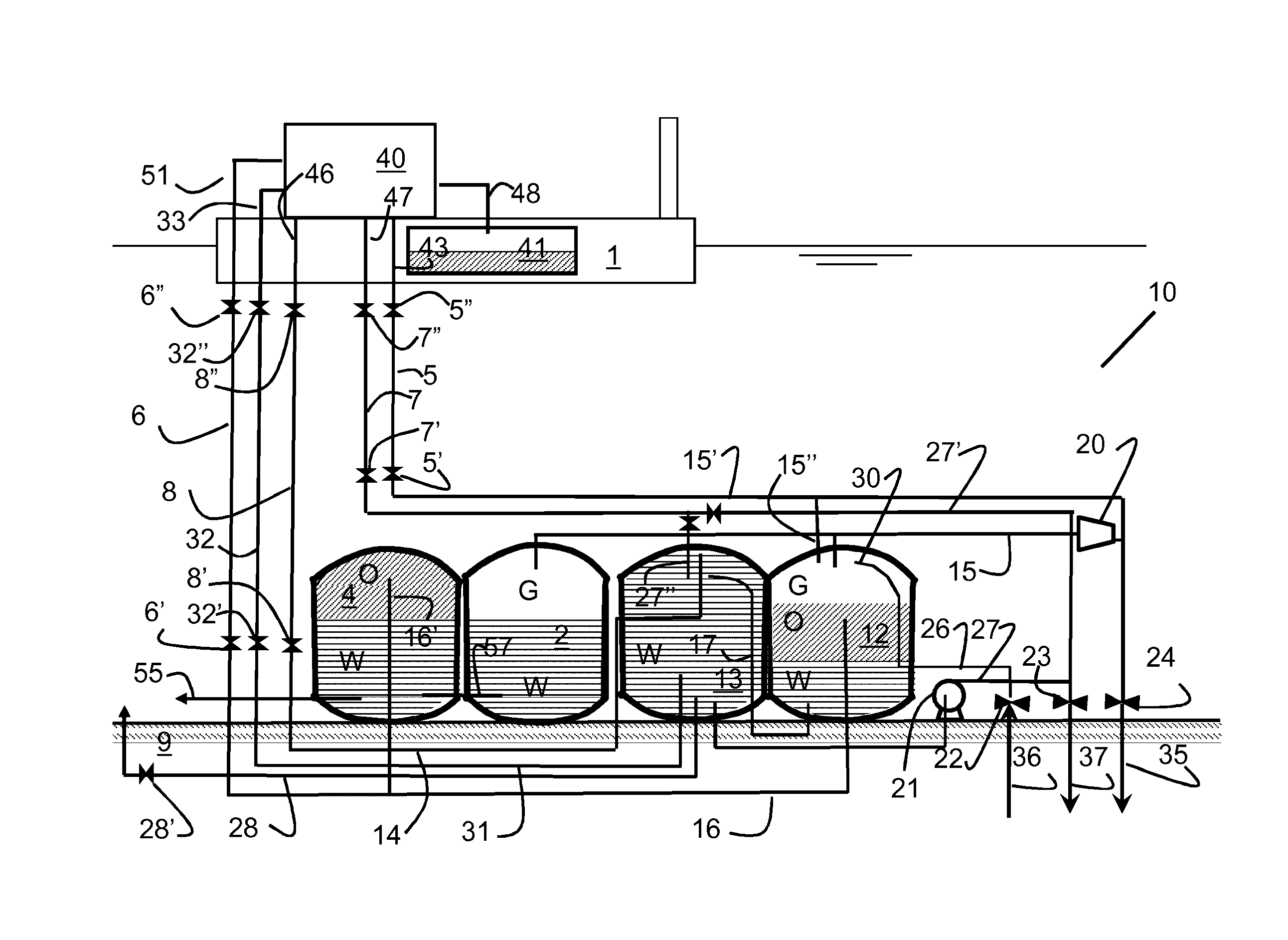

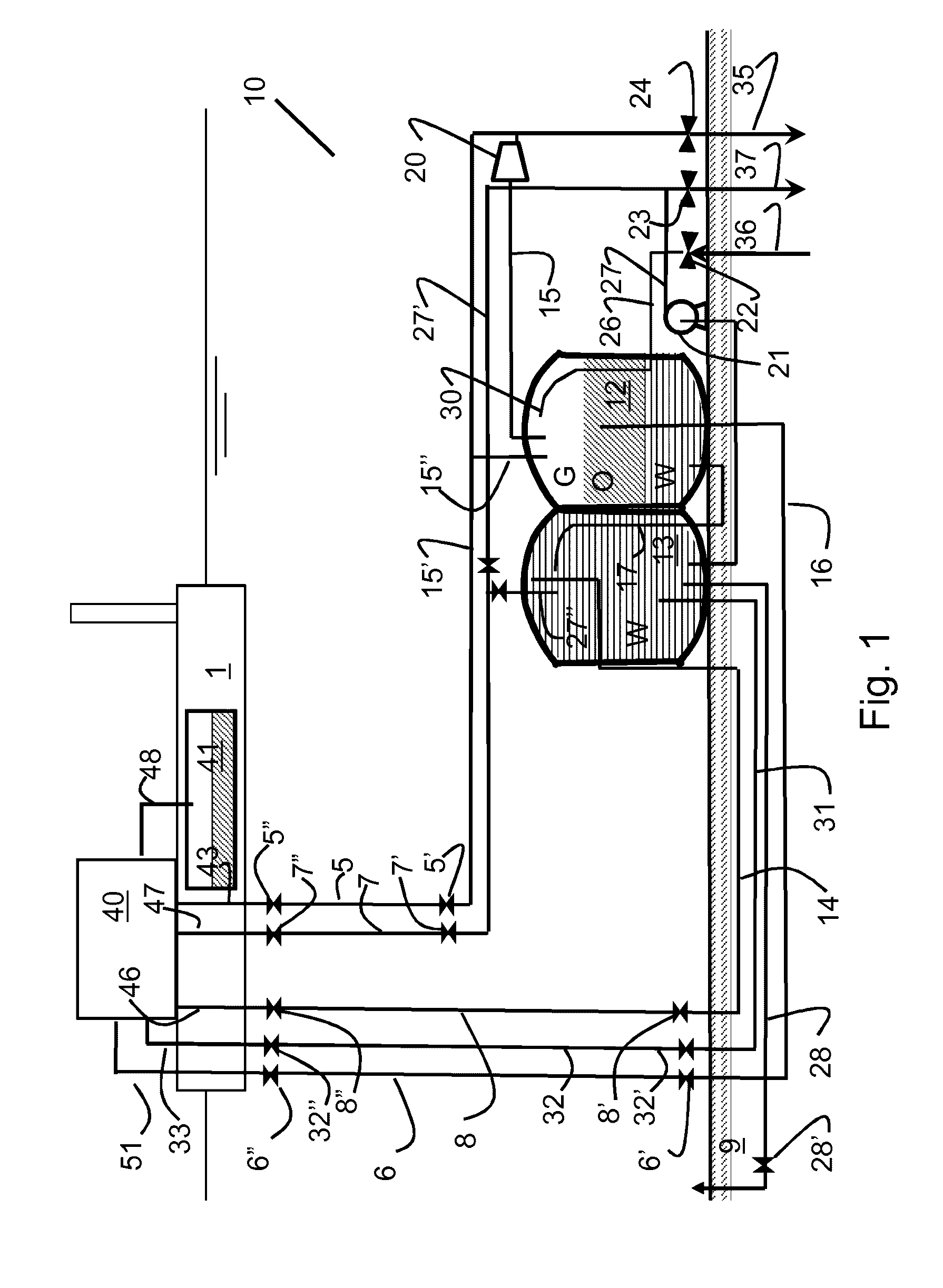

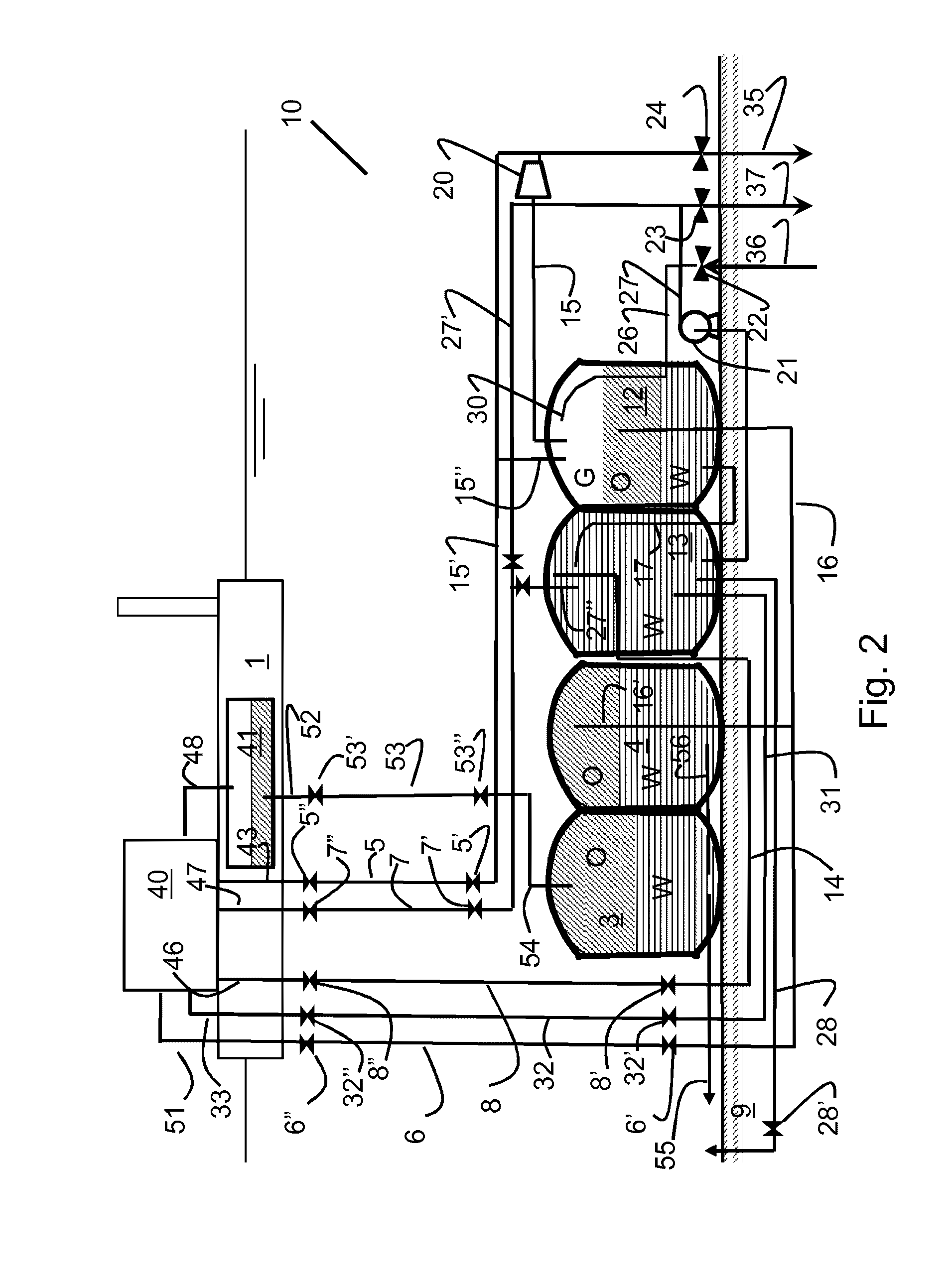

Methods and apparatus for increasing and extending oil production from underground formations nearly depleted of natural gas drive

InactiveUS20050084393A1Improve productivityLow viscosityLiquid separation auxillary apparatusSemi-permeable membranesProduct gasOil production

Methods and apparatus employing inert gases injected into the lower level of sloping underground oil-bearing formations as a driving mechanism and water injected into the upper level of the formations as a gas blocking mechanism for increasing and extending the production of oil from underground formations is described. Also described is an inert gas oil production system comprising an exhaust gas processing system, a well inert gas and water injection system, an oil production well system, and a fuel gas generator. A hydraulically operated crude oil pump is also described.

Owner:HYDROTREAT

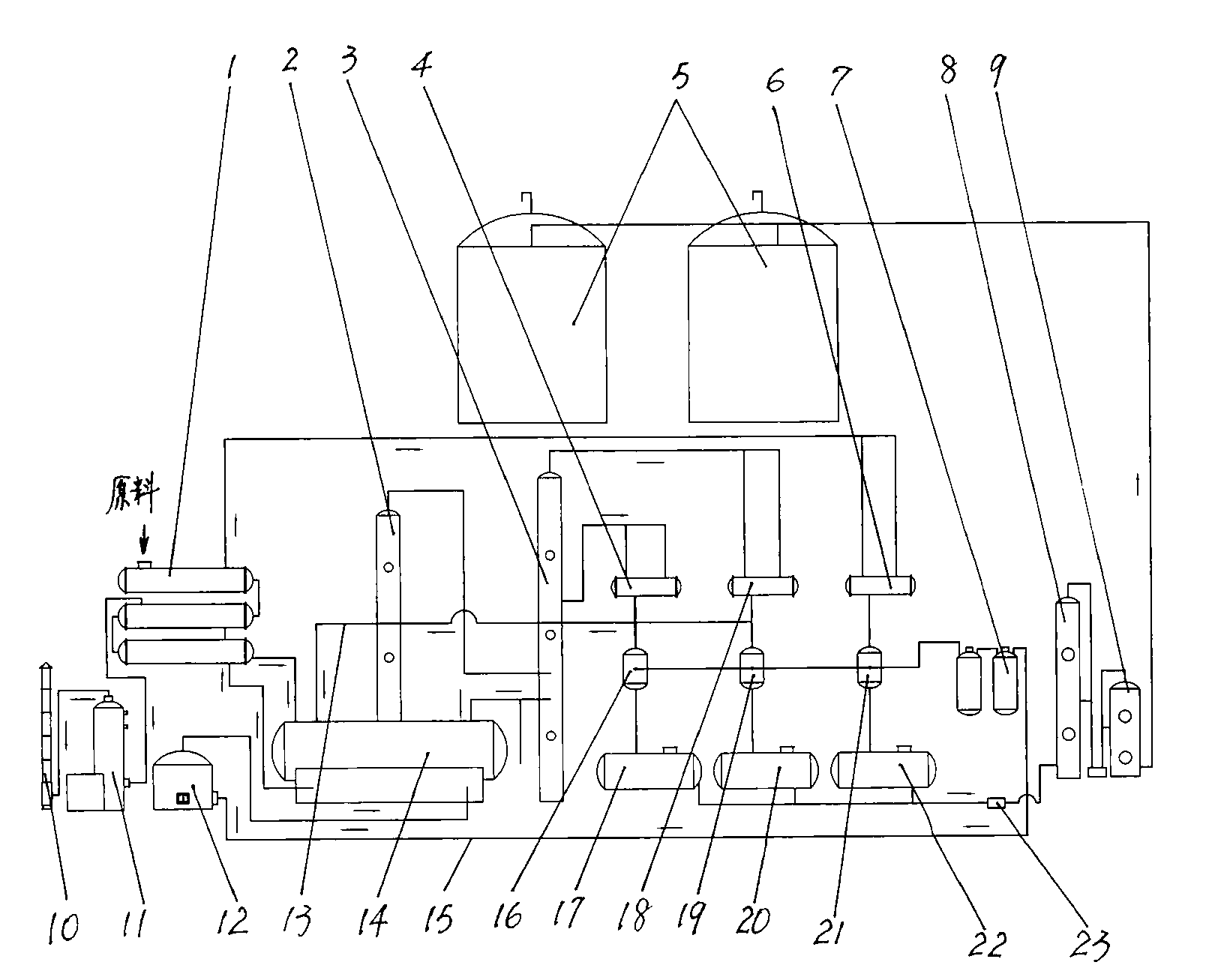

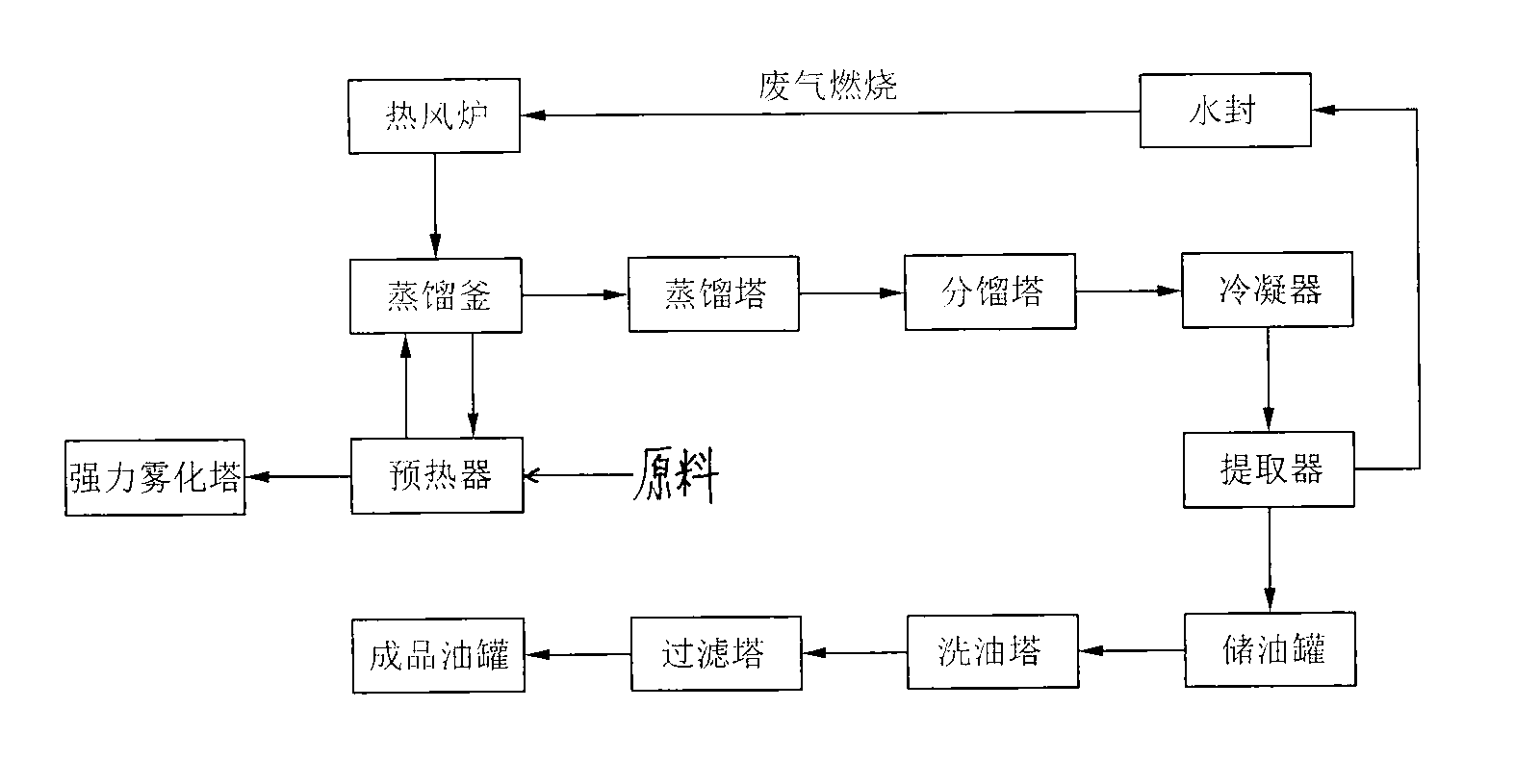

Waste machine oil/tire oil/plastic oil distillation device and technique

InactiveCN102851065AQuality improvementEliminate secondary pollutionTreatment with plural serial stages onlyFiltrationDistillation

The invention relates to a waste machine oil / tire oil / plastic oil distillation device and technique. The waste machine oil / tire oil / plastic oil distillation device is composed of a preheater, a hot-blast furnace, a distillation still, a distillation tower, a fractionating tower, condensers, oil storage tanks, oil washing towers, filtration towers and finished product oil tanks, wherein the preheater is connected with an oil inlet of the distillation still; the hot-blast furnace is connected with the distillation still; the distillation tower is arranged on the distillation still; an oil gas outlet on the top of the distillation tower is connected with the fractionating tower; a reflux port on the lower part of the fractionating tower is connected with the distillation still; a light component oil gas port and a medium component oil gas port of the fractionating tower are respectively connected with the corresponding condensers, the condensers are respectively connected with corresponding extraction towers and the corresponding oil storage tanks; and each oil storage vessel is connected with the finished product oil tank through an oil pump, the oil washing tower and the filtration tower. The technological device is simple and convenient to operate, and has the advantages of high treatment accuracy and no leakage; the invention improves the working environment, has high production efficiency, and thoroughly eliminates secondary pollution; and the treated oil product is better than the oil product obtained by common distillation, can substitute the raw material for oil production plants for large-size ships, has high economic benefit, and can effectively save resources and energy sources.

Owner:SHANGQIU YILONG MACHINERY EQUIP

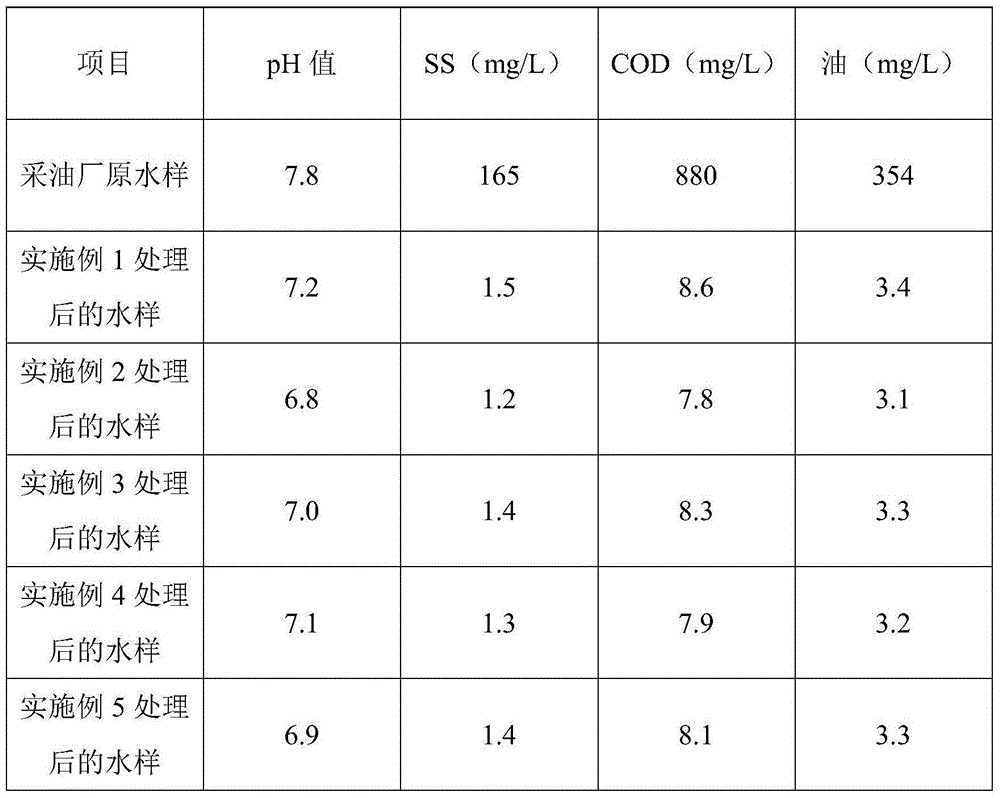

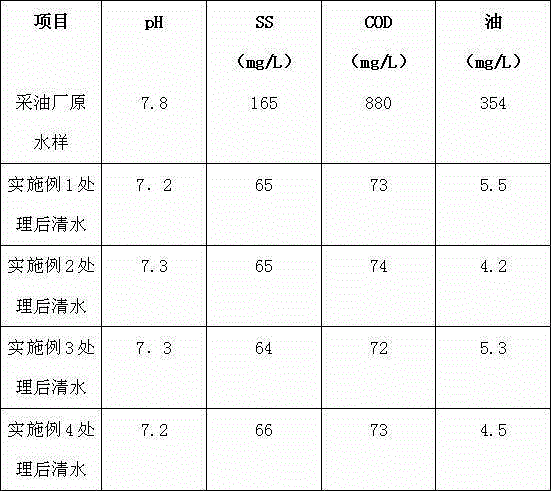

Sewage treatment agent for oil production plant

ActiveCN105198055AIncrease sedimentation rateImprove water qualityWater/sewage treatment by flocculation/precipitationWater qualityOil production

The invention discloses a sewage treatment agent for an oil production plant, belonging to the technical field of preparation of the sewage treatment agent. The sewage treatment agent for the oil production plant is prepared from the following raw materials in parts by weight: 40 to 80 parts of demulsifier, 30 to 60 parts of flocculant, 30 to 60 parts of foaming agent, 20 to 50 parts of flotation agent, 15 to 35 parts of fungicide, 10 to 20 parts of slow rot scale inhibitor, and 10 to 20 parts of deoxidant. The treatment agent provided by the invention for the oil production plant has the advantages of high deposition rate, good effluent quality, low treatment cost, no corrosive effect, nontoxicity, no pollution, safety in use, and the like; after oil production plant sewage is treated by adopting the treatment agent provided by the invention, the pH value basically reaches neutral pH, the SS removing rate can reach 99.09% to 99.27%, the COD removing rate can reach 99.02% to 99.11%, and the oil removing rate can reach 99.04% to 99.12%.

Owner:嘉兴沃特泰科环保科技股份有限公司

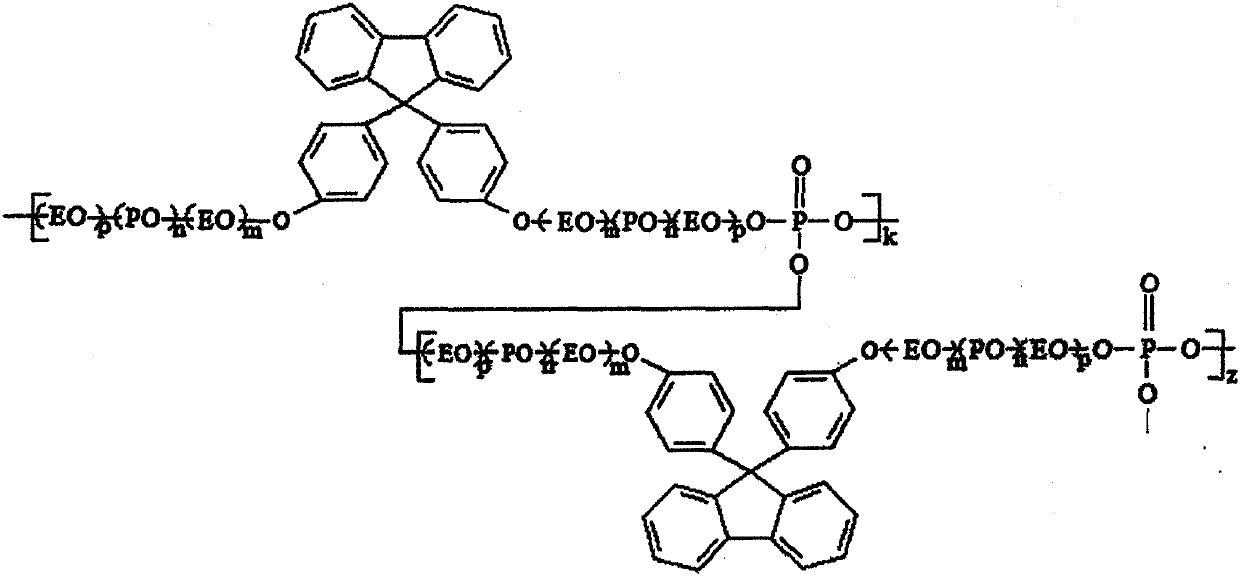

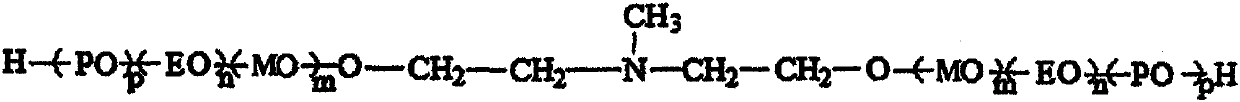

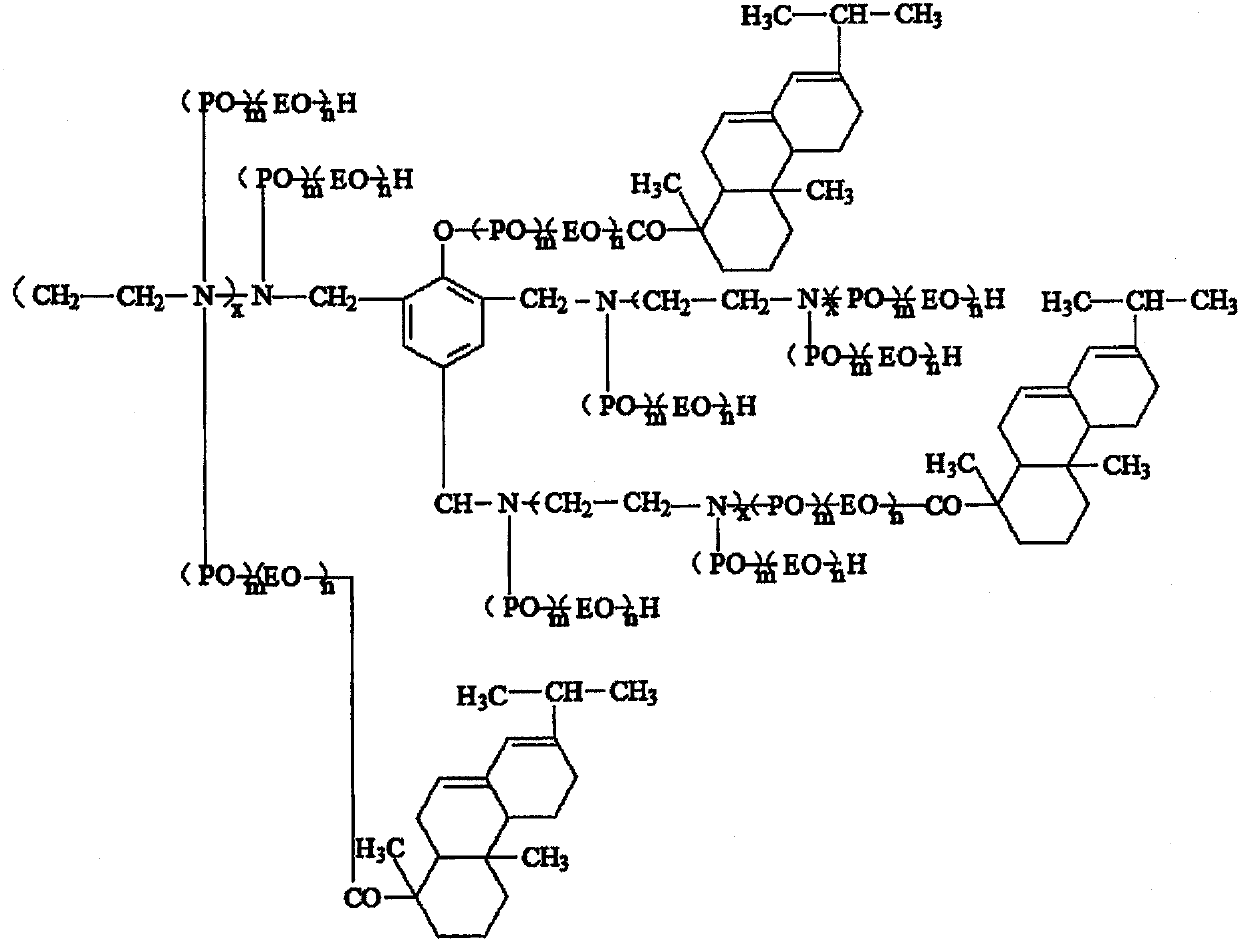

A kind of super heavy oil demulsifier and preparation method thereof

ActiveCN107474873BImprove Diffusion BehaviorSolve uneven defectsDewatering/demulsification with chemical meansDemulsifierActive agent

Owner:盘锦富隆化工有限公司

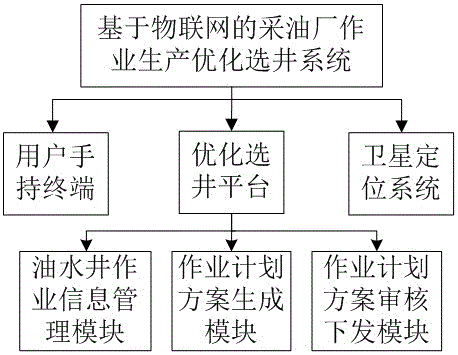

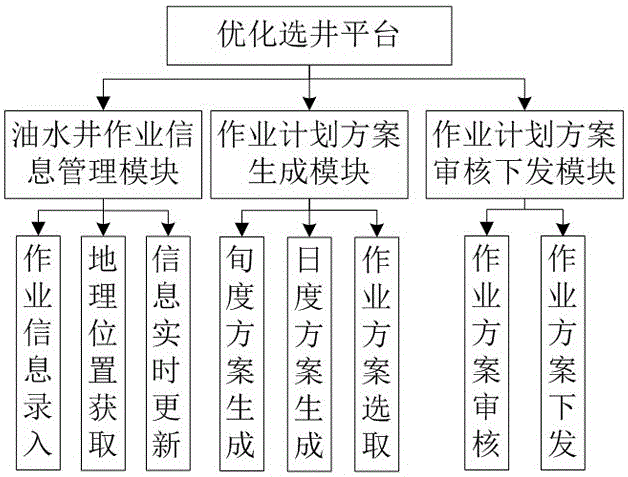

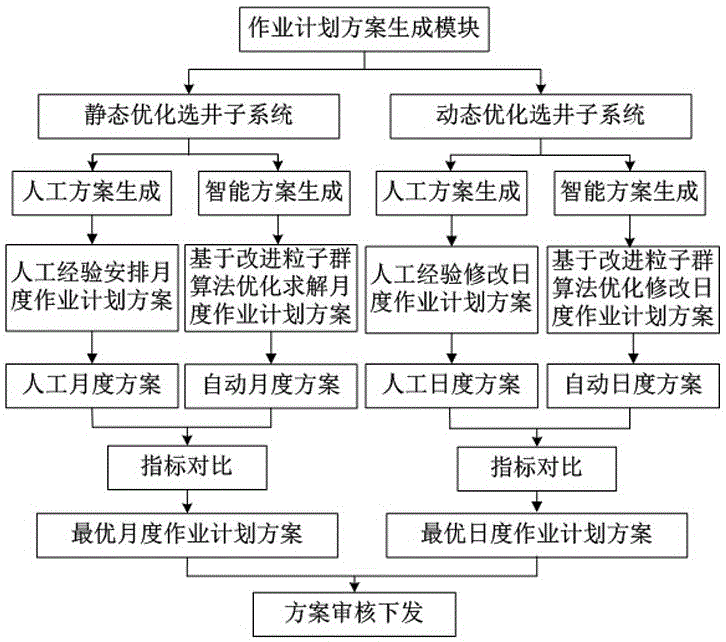

Oil production plant production optimization well selecting system based on internet of things

InactiveCN106327017AIntelligent optimization and integrated managementImprove timelinessForecastingProduction optimizationThe Internet

The invention discloses an oil production plant production optimization well selecting system based on the internet of things. The system comprises an optimization well selecting platform, a user handheld terminal and a satellite positioning system; the user handheld terminal reports an operation task and update information of operation power equipment to the optimization well selecting platform; the satellite positioning system reports position information of the operation power equipment to the optimization well selecting platform; the optimization well selecting platform realizes an operation generating function of a mouthy or daily oil production plant operation scheme by designing a static and dynamic combined oil production plant production optimization well selecting method; and a transmission module is checked via an operation scheme of mutual communication between the wireless network and the user handheld terminal, so that a mobile office function of check and transmission in the operation scheme are realized. The rationality of arrangement of the oil production plant operation scheme and the qualification rate of oil production plant oil-water well production are improved.

Owner:SINOPEC SHENGLI OILFIELD

Novel sewage treatment agent

InactiveCN105060441AImprove precipitation effectRapid precipitationWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationPotassium persulfateSodium Bentonite

The invention relates to a novel sewage treatment agent, which contains polyferric trichloride, potassium persulfate, aluminum sulfate, polyacrylamide, polyethyleneimine and bentonite, i.e. 20 to 30 percent by weight of polyferric trichloride, 15 to 25 percent by weight of potassium persulfate, 5 to 15 percent by weight of aluminum sulfate, 20 to 35 percent by weight of polyacrylamide, 10 to 25 percent by weight of polyethyleneimine and the balance of water. For the waste water of oil production plants, the novel sewage treatment agent has a good precipitation effect, and the effluent quality is good; the treatment cost is low, and the novel sewage treatment agent is applicable to oily sewage of the oil production plants. After the agent is added into sewage, suspended matters immediately flocculate; produced flocs are big; the precipitation is rapid; the efficiency is high; the flocs have high strength and good hydrophobic property, which are favorable for filter pressing, and the novel sewage treatment agent is high in purity, and does not have impurities and dust.

Owner:湖州道场污水处理有限公司

Inhibiting breakthrough of driving fluid via a permeable geological layer into an oil production well

InactiveUS20060157238A1Efficient processImprove responseSurveyFluid removalOil productionInjection well

A method for selectively reducing the permeability of one or more relatively permeable geological layers of an oil-bearing formation, to inhibit breakthrough of driving fluid from a driving fluid injection well via at least one of said layers into an oil production well, which method comprises the steps of injecting a driving fluid comprising a first compound into the formation via the injection well; detecting the first compound in well fluid of the oil production well; upon detection, injecting a second compound into the formation via the oil production well, to react with the first compound in order to provide a flow restriction generated by a third compound which comprises a reaction product of the first and second compounds in at least one relatively permeable geological layer through which breakthrough of the driving fluid into the oil production well has occurred.

Owner:SHELL OIL CO

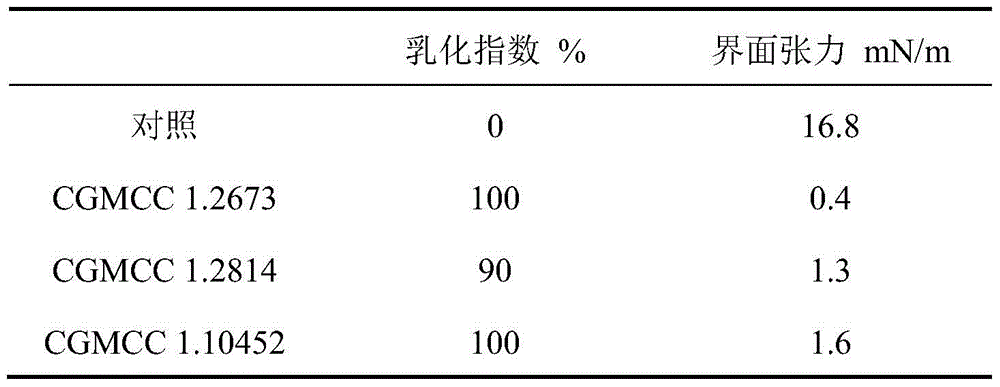

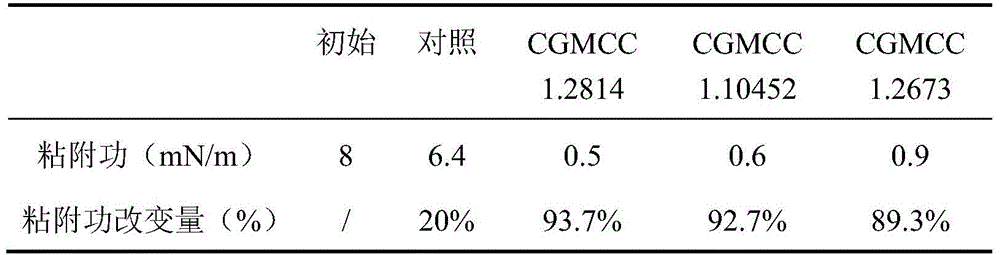

A kind of strong emulsifying microbial anti-wax agent and its application

ActiveCN104109516BStrong emulsifying abilityReduce interfacial tensionCleaning apparatusFluid removalInhibition zoneOil production

The invention discloses a strong emulsibility microbe wax cleaning and preventing bacterial agent and an application, which belongs to the oil field chemical technology field. The wax cleaning and preventing bacterial agent mainly comprises pseudomonas aeruginosa and geobacillus sp, has strong emulsification capability, and is capable of dispersing crude oil, promoting crude oil to flow, changing adherence force of borehole wall, preventing the accumulation of wax crystal on the borehole wall, and playing the paraffin inhibition and wax cleaning effects. By increasing the initial application amount of the bacteria liquid and prolong the well closing time, a stable paraffin inhibition zone can be formed due to adhesion of bacteria on borehole wall, near wellbore formation can be cleaned, and the paraffin inhibition and oil increase effects can be increased. After on-site enforcement, the well cleaning and chemical paraffin inhibition works can not be carried out in recent half year in the test wells, so that the wax cleaning and preventing bacterial agent has good paraffin inhibition effect in the well. The oil production is increased by about 30% daily, pump efficiency is increased about 10%, the surface tension of the output liquid is decreased to 20-25%, and the crude oil condensation point is decreased by 1-3 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

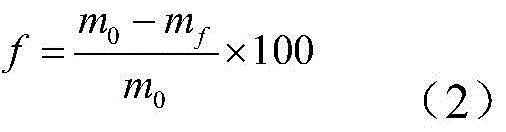

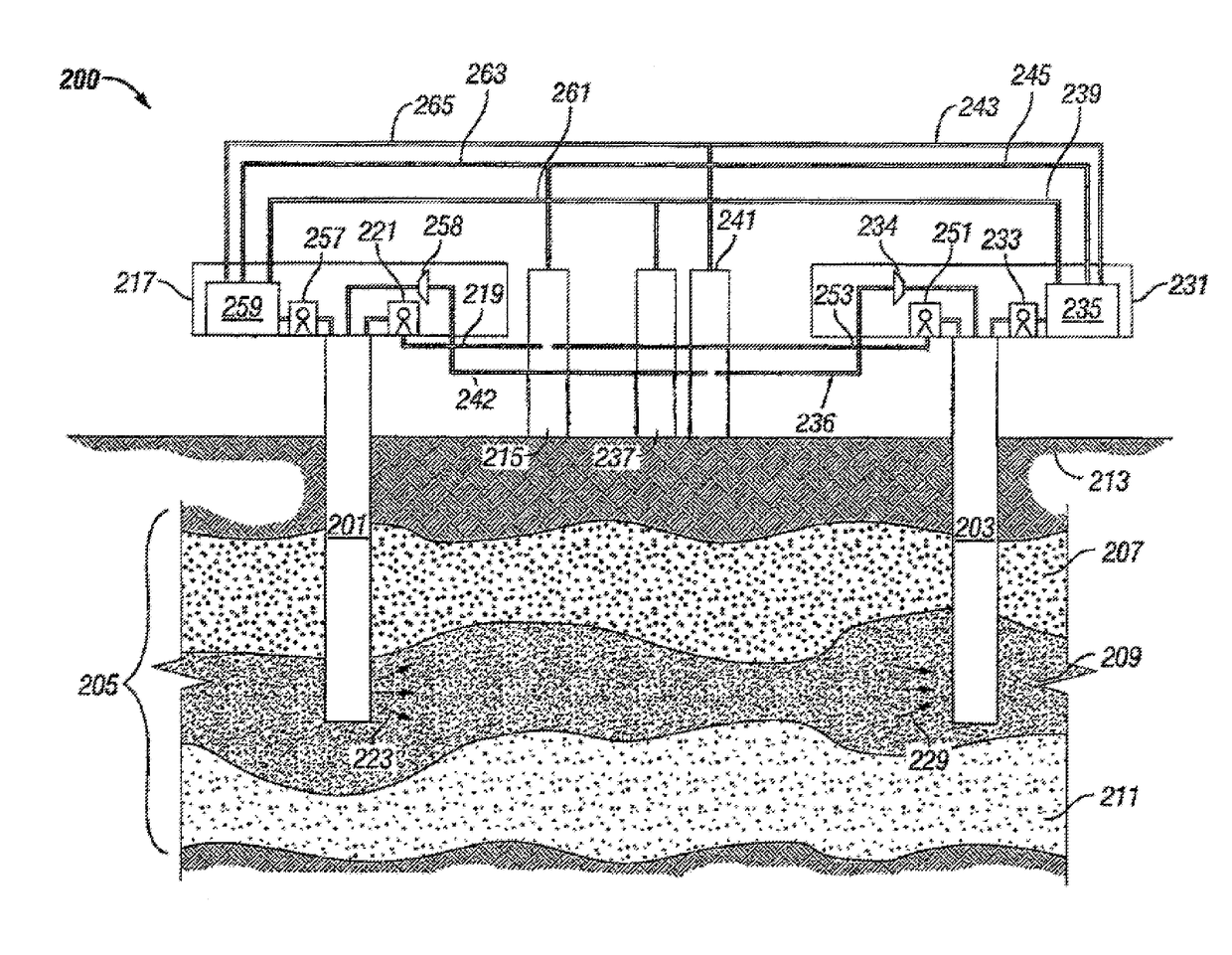

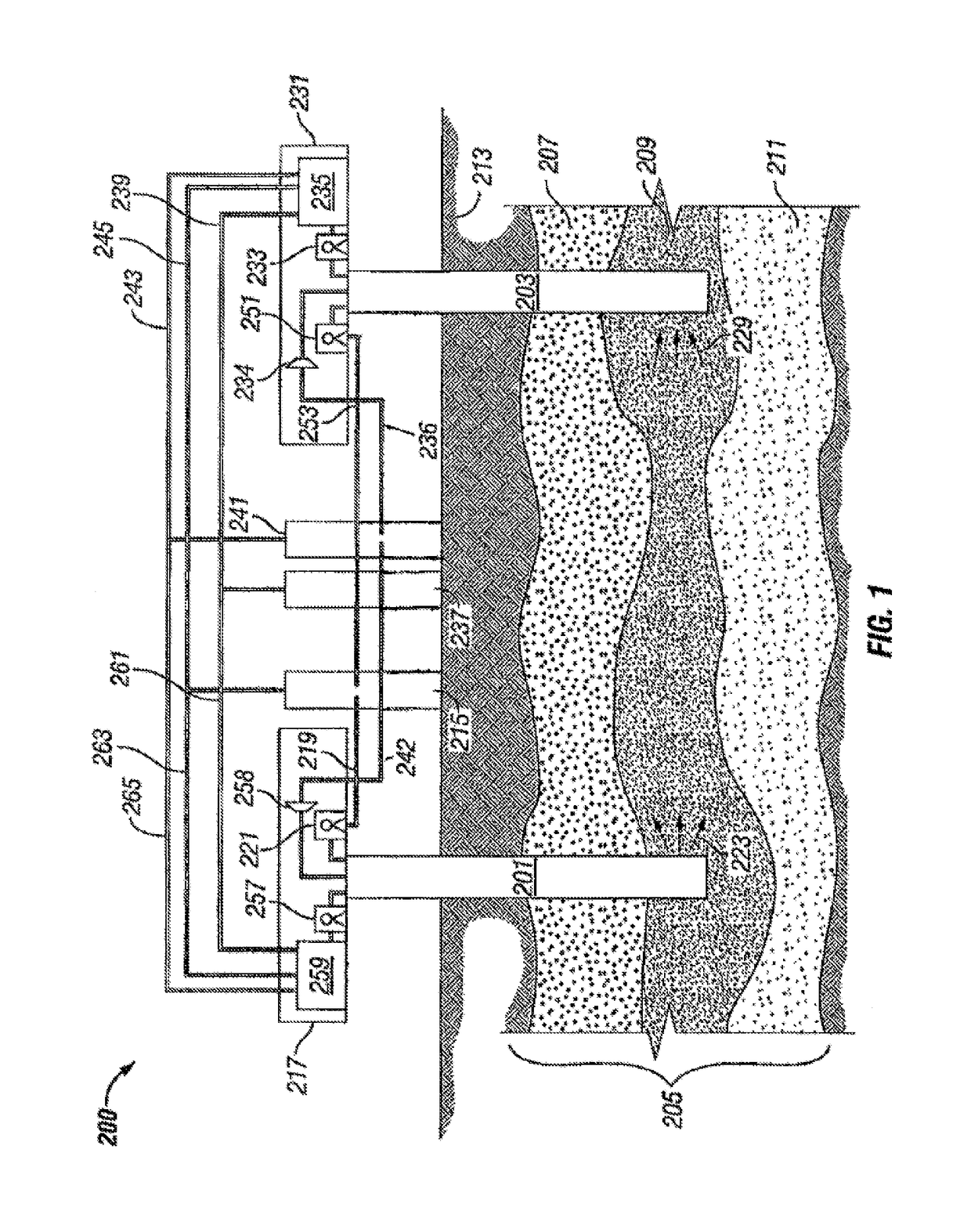

Oil production using multistage surfactant polymer chemical flood

ActiveUS20180002591A1Good water solubilityFluid removalDrilling compositionSolubilityCompound (substance)

A process for recovering oil from an oil-bearing formation is disclosed comprising providing a first oil recovery formulation comprising a first surfactant able to create low interfacial tension with reservoir crude oil; injecting the first oil recovery formulation into the oil-bearing formation via an injection well (201); providing a second oil recovery formulation having a second surfactant with a higher solubility in water than the first formulation; injecting the second oil recovery formulation into the oil-bearing formation via the injection well; and producing oil to a production well (203).

Owner:SHELL USA INC

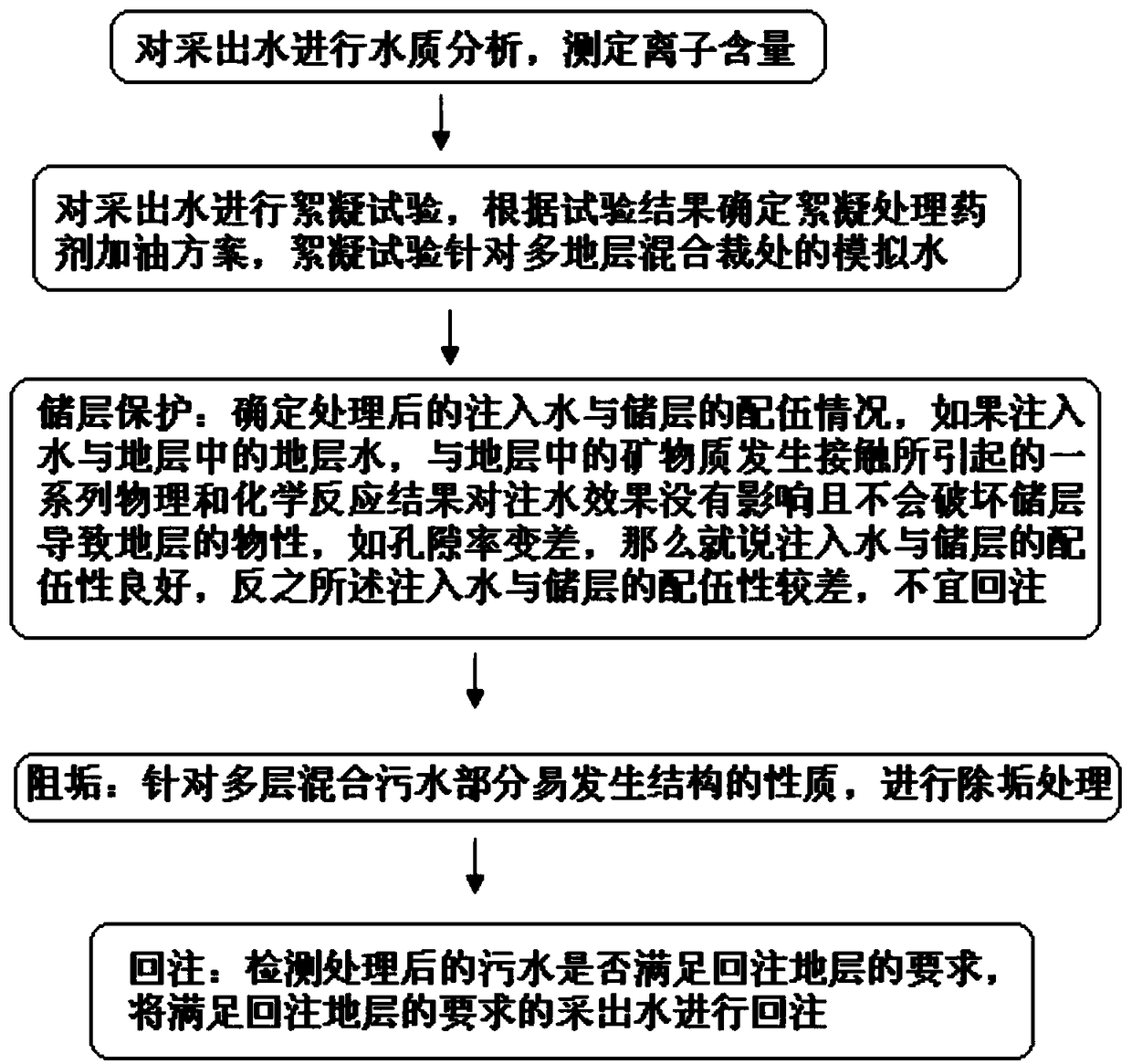

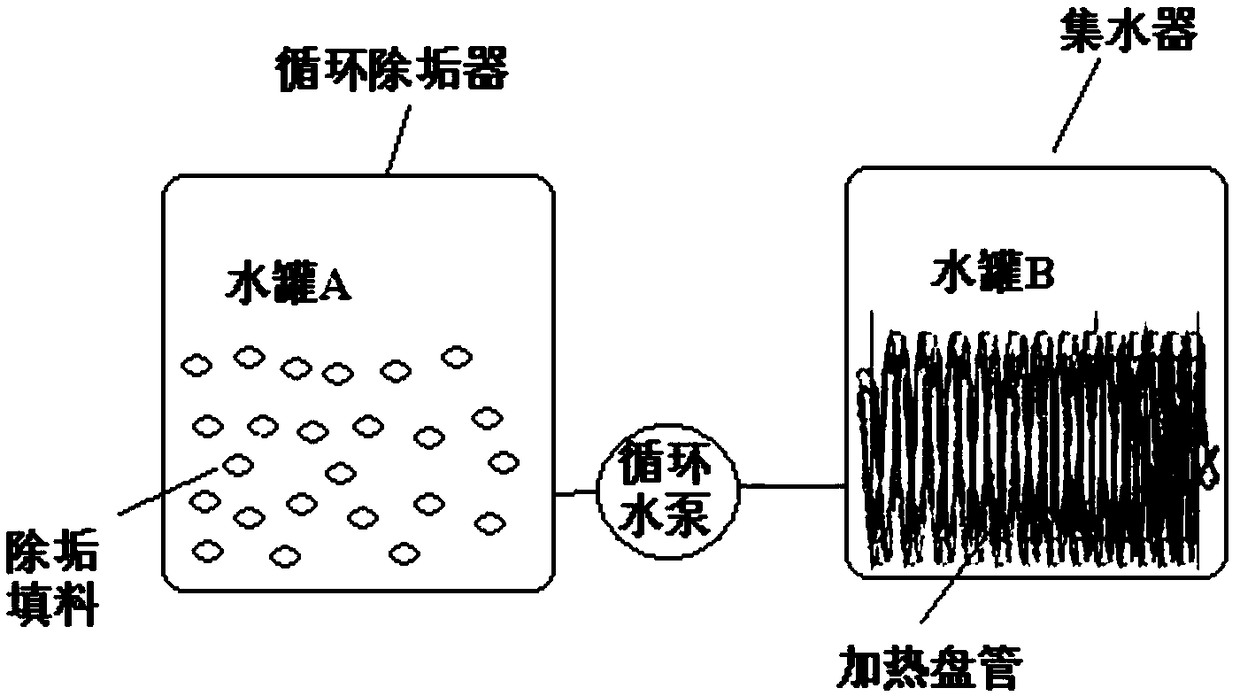

Oil production block produced water reinjection method

The invention provides an oil production block produced water reinjection method. The method comprises the steps that (1) produced water is subjected to water quality analysis, and the ion content ismeasured; (2) the produced water is subjected to a flocculation test, a flocculation treatment agent refueling scheme is determined according to test results, and the flocculation test is directed atsimulated water of multi-layer mixed cutting; (3) a reservoir is protected, specifically, the compatibility of injected water and the reservoir after treatment is determined; (4) scale inhibition is conducted, specifically, descaling treatment is conducted specific to the property of liable scaling of a multi-layer mixed sewage part; and (5) reinjection is conducted, specifically, whether treatedsewage meets the requirements of a reinjection formation is checked, and the produced water meeting the requirements of the reinjection formation is reinjected. The method forms an efficient and stable process technology integrating corrosion resistance, scale inhibition, sterilization, flocculation and reservoir protection, and thus the treated sewage can meet the requirements of the reinjectionformation.

Owner:张谦

Oily sludge treatment agent for oil production plant and preparation method thereof

InactiveCN111039526AGood processing effectSimple processSludge treatmentSodium bicarbonateAluminium chloride

The invention belongs to the technical field of sludge. The invention provides an oily sludge treatment agent for an oil production plant. The main raw materials are as follows in parts by weight: 3-5parts of saccharin sodium, 16-21 parts of montmorillonite, 7-18 parts of polyoxyethylene, 5-15 parts of humic acid, 0.5-1.3 parts of maleic anhydride, 7-10 parts of sodium bicarbonate, 3-7 parts of mozzie buster, 0.5-0.8 part of polyaluminum chloride, 8-13 parts of waste coconut peel, 2-7 parts of finger citron and 15-20 parts of chitosan. The invention relates to a preparation method of the oilysludge treatment agent for an oil production plant, which comprises the following steps: (1) uniformly mixing the saccharin sodium salt, the montmorillonite, the polyoxyethylene, the mozzie buster, the maleic anhydride and coconut peel, grinding the mixture into powder, and mixing the powder to obtain particles; (2) uniformly mixing the particles with the sodium bicarbonate, the humic acid, the finger citron, the chitosan and the polyaluminum chloride, and stirring and mixing at 40-55 DEG C for 2-3 hours. The oily sludge treatment agent has the advantages of simple treatment process, small dosage, good treatment effect and stable performance.

Owner:泰州恒泰环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com