Novel sewage treatment agent

A sewage treatment agent, a new type of technology, applied in the direction of flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problems of poor treatment effect, slow sedimentation speed, high chemical cost, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

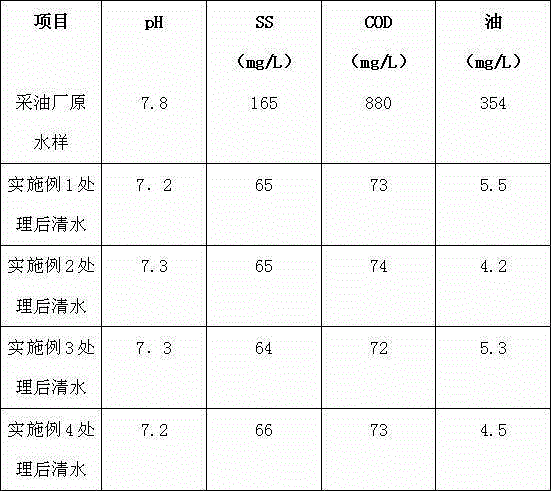

Examples

Embodiment 1

[0012] Calculated by weight percentage, it is: 30% of polyferric trichloride, 25% of potassium persulfate, 5% of aluminum sulfate, 20% of polyacrylamide, 10% of polyethyleneimine, and the balance of water. The above components are in proportion, stirred evenly at room temperature, all dissolved and ready to use.

Embodiment 2

[0014] Calculated by weight percentage, it is: 20% of polyferric trichloride, 15% of potassium persulfate, 15% of aluminum sulfate, 35% of polyacrylamide, 10% of polyethyleneimine, and the balance of water. The above components are in proportion, stirred evenly at room temperature, all dissolved and ready to use.

Embodiment 3

[0016] Calculated by weight percentage, it is: 22% of polyferric trichloride, 18% of potassium persulfate, 10% of aluminum sulfate, 30% of polyacrylamide, 20% of polyethyleneimine, and the balance of water. The above components are in proportion, stirred evenly at room temperature, all dissolved and ready to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com