Dehydroabietylamide ethyl sulfonate surfactant, synthesis method and application of surfactant in tertiary oil recovery

A technology of ethyl sulfonate and surfactant, applied in the direction of sulfonate preparation, chemical instruments and methods, drilling composition, etc., can solve the problem of not measuring low interfacial tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

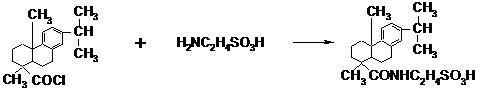

[0029] Embodiment 1, the preparation of dehydroabietamide ethylsulfonate sodium surfactant:

[0030] 1. Preparation of dehydroabietic acid chloride: 60.1g of dehydroabietic acid (industrial product, Zhejiang Wanan Plastic Co., Ltd.) was dissolved in 100.0g of toluene and added to a four-necked bottle, and an electric stirrer, reflux condenser, Connect the gas absorption device, thermometer and constant pressure dropping funnel to the four-necked bottle, put 35.7g of thionyl chloride into the constant pressure dropping funnel, heat the system to 30°C under stirring condition, and slowly add chlorine dropwise Add thionyl oxide to the system, drop it within 30 minutes, keep the system at 30°C and continue to react for 10 hours, distill off toluene and excess thionyl chloride, and distill under reduced pressure to obtain dehydroabietoyl chloride;

[0031] 2. Preparation of dehydroabietamide ethyl sulfonic acid: Dissolve 31.3g of taurine in a mixed solvent of 100.0g of acetone and ...

Embodiment 2

[0033] Embodiment 2, the surface tension test of dehydroabietamide ethyl sulfonate sodium surfactant

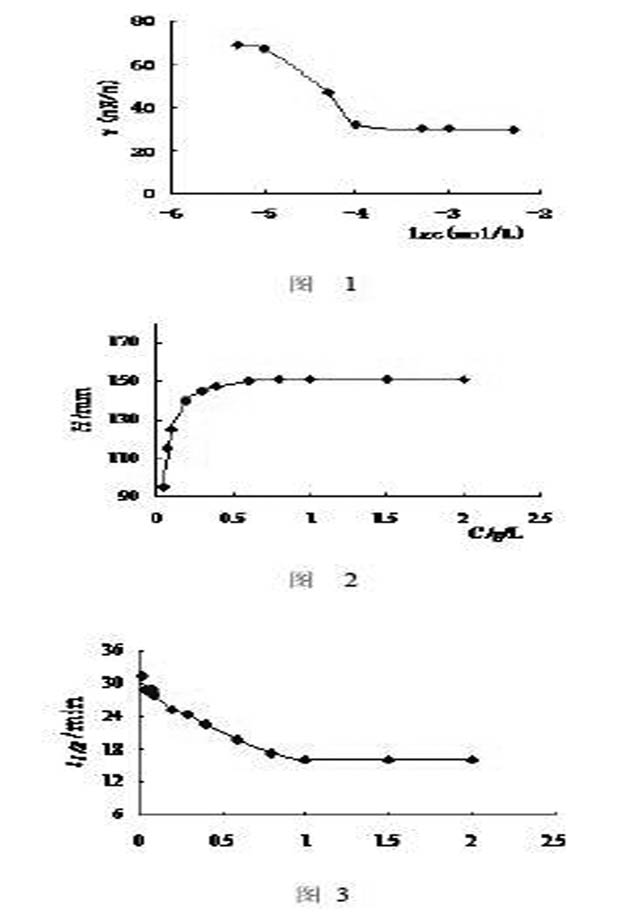

[0034]Get the sodium dehydroabietamide ethyl sulfonate prepared in Example 1, take distilled water as solvent, prepare the dehydroabietamide sodium ethyl sulfonate aqueous solution of different concentrations, measure its surface tension at 25 ℃ with drop volume method, measure the result Such as figure 1 shown.

[0035] The curve in the figure shows that the surface tension of the solution begins to decrease slightly with the increase of concentration, then decreases rapidly, and finally tends to remain unchanged, which is consistent with the surface tension of general surfactants. sodium ethyl sulfonate cmc =1.0×10 -4 mol / L, gamma cmc =31.99mN / m, showing that the synthesized sodium dehydroabietamide ethyl sulfonate has better surface activity.

Embodiment 3

[0036] Embodiment 3, the foaming of dehydroabietamide ethyl sulfonate sodium surfactant, foam stabilizing performance experiment

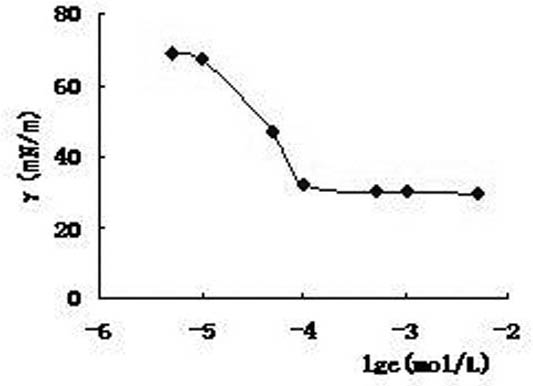

[0037] With reference to the improved Ross-Miles method specified in GB / T 7462-94, get the sodium dehydroabietamide ethyl sulfonate prepared in Example 1, and prepare the aqueous solutions of dehydroabietamide ethyl sulfonate with different concentrations, and prepare the dehydroabietamide ethyl sulfonate aqueous solution at 25°C Determination of its foaming performance under the test results are as follows figure 2 shown. Depend on figure 2 It can be seen from the curve that as the active agent concentration increases, its foaming height ( H ) increases, and when the active agent concentration reaches 0.6g / L, the foaming height tends to be stable and reaches above 150mm, indicating that the synthetic surfactant has good foaming property.

[0038] image 3 Provided is the foam stabilizing property of sodium dehydroabietamide ethyl sulfonate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com