Patents

Literature

67 results about "Drop volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1 Drop is equal to 0.0648524 Milliliter. 1 drop = 0.0648524 mL. Used very commonly in medicine and cooking, a drop is a unit of volume defined as the volume of a liquid in one drop.

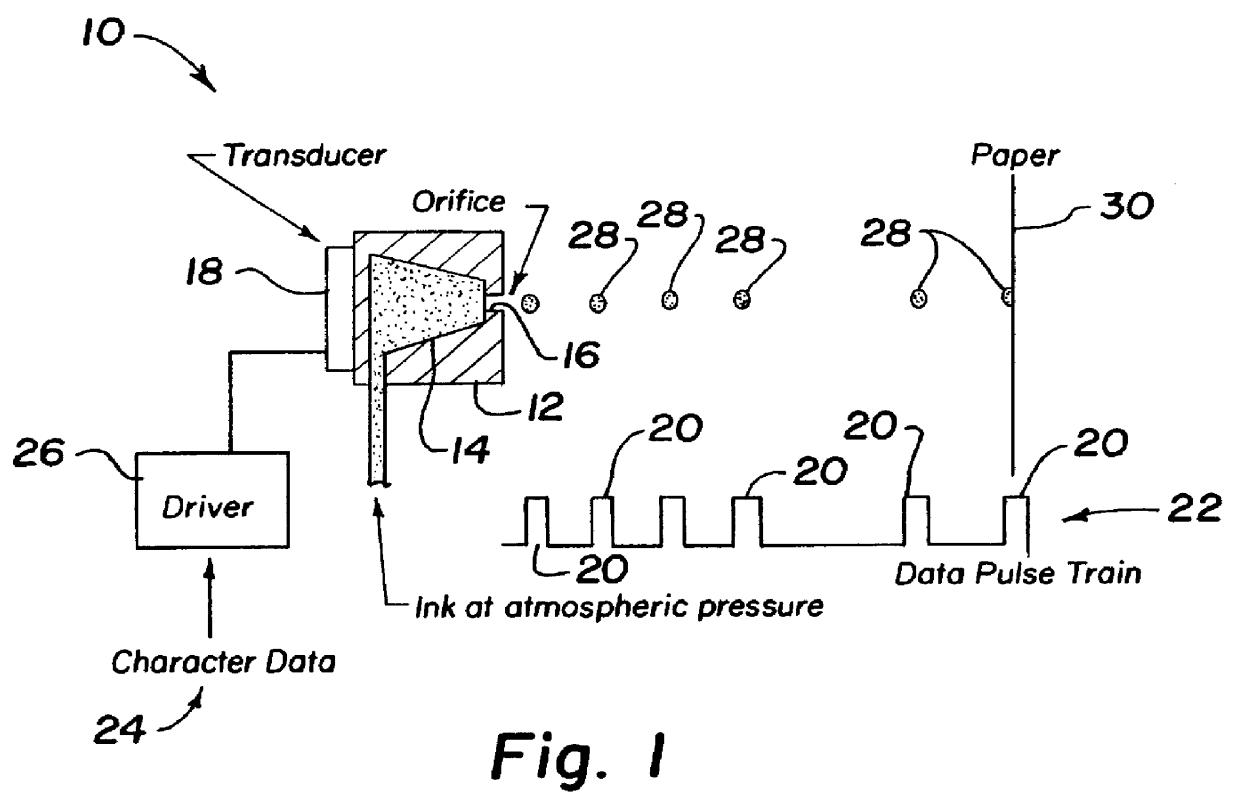

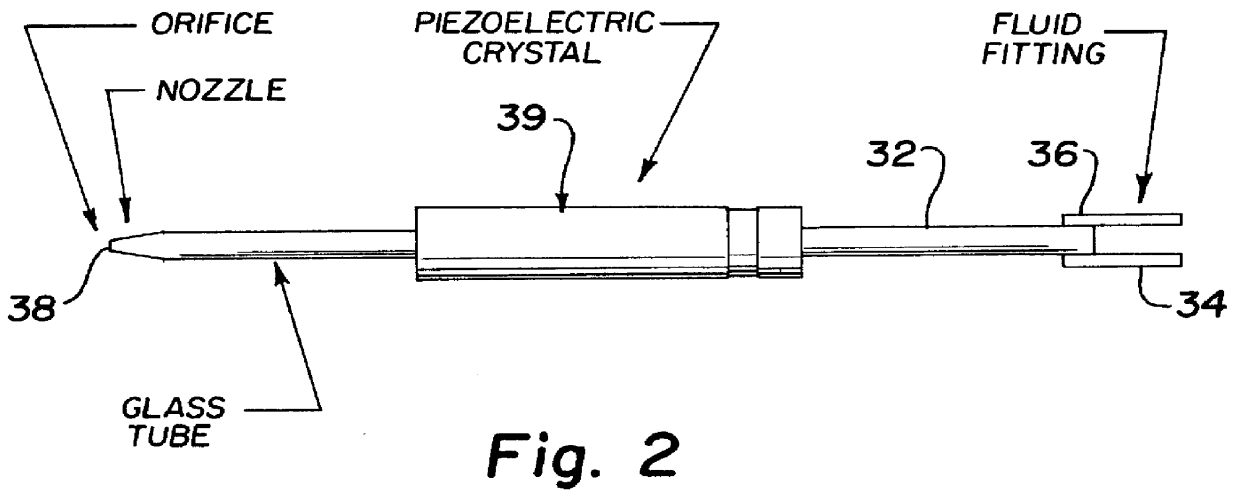

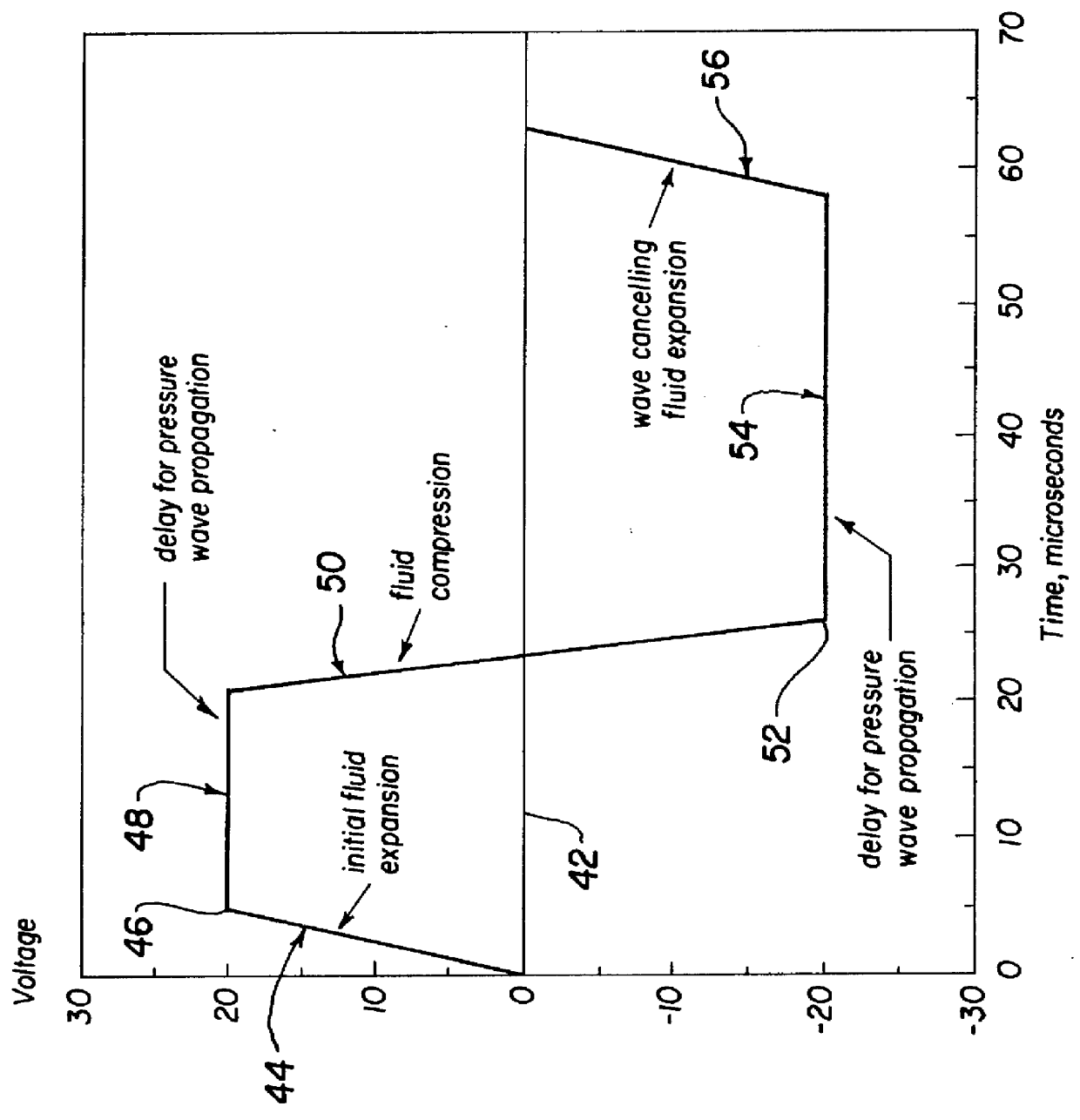

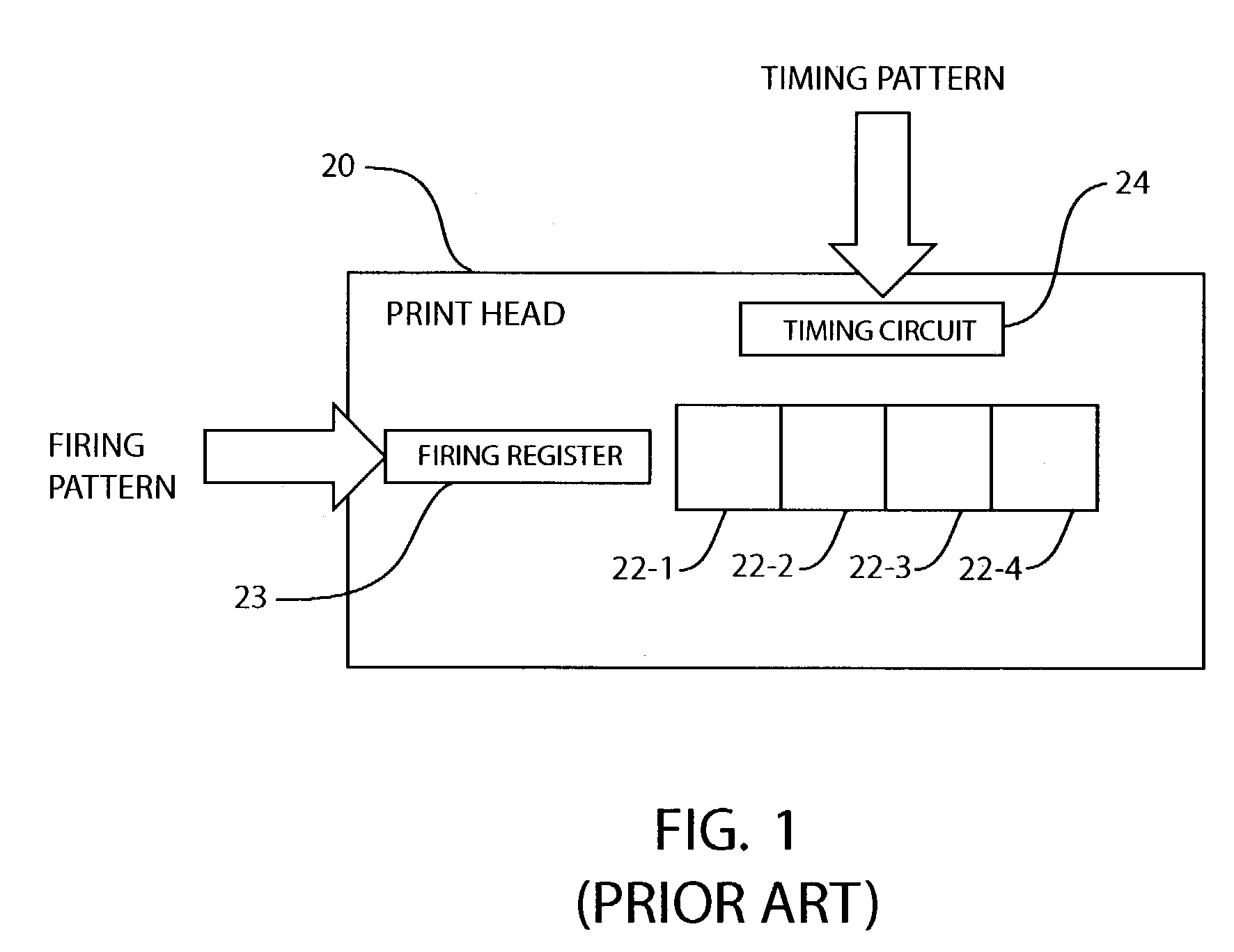

Method of drop size modulation with extended transition time waveform

The present invention uses a novel waveform to allow the droplet volume dispensed from a demand mode inkjet type device to be increased and selected according to easily controllable parameters. The current invention departs from the conventional drive method by significantly increasing the time for energy input in the initial instance as well is in all later application of the drive voltage to the device. In shape, the waveform is the same whether a unipolar or bipolar pulse is utilized; however, the transition times in the initial instance are up to three times the acoustic resonance and the delay times are of the same order. Droplet diameter can be varied from 1X the orifice diameter to 2X the orifice diameter resulting in an 8:1 range of droplet volume. Since the volume modulation results from changes in the waveform used to drive the solder jet device, the drop volume can be changed and altered in real time.

Owner:MICROFAB TECH

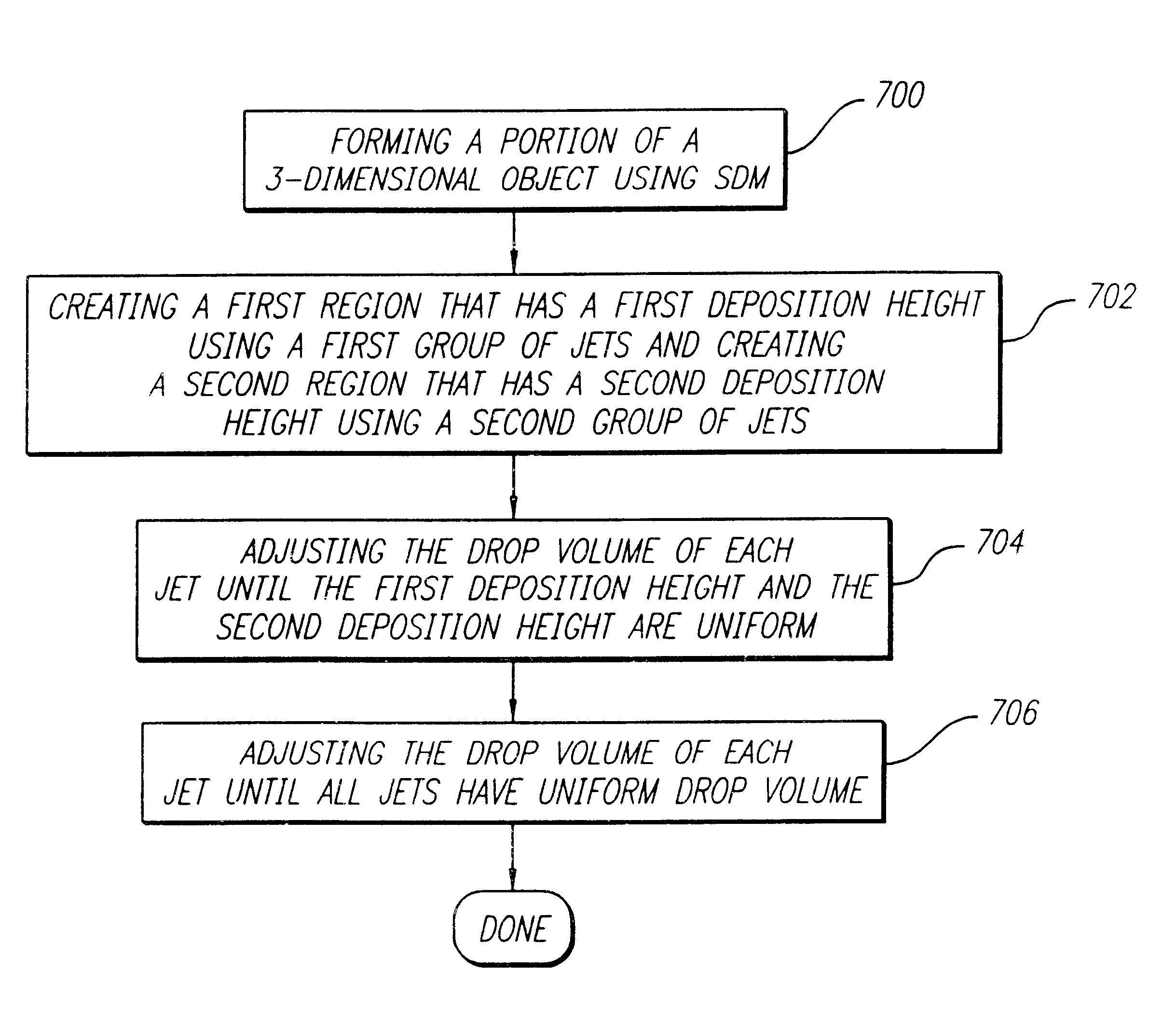

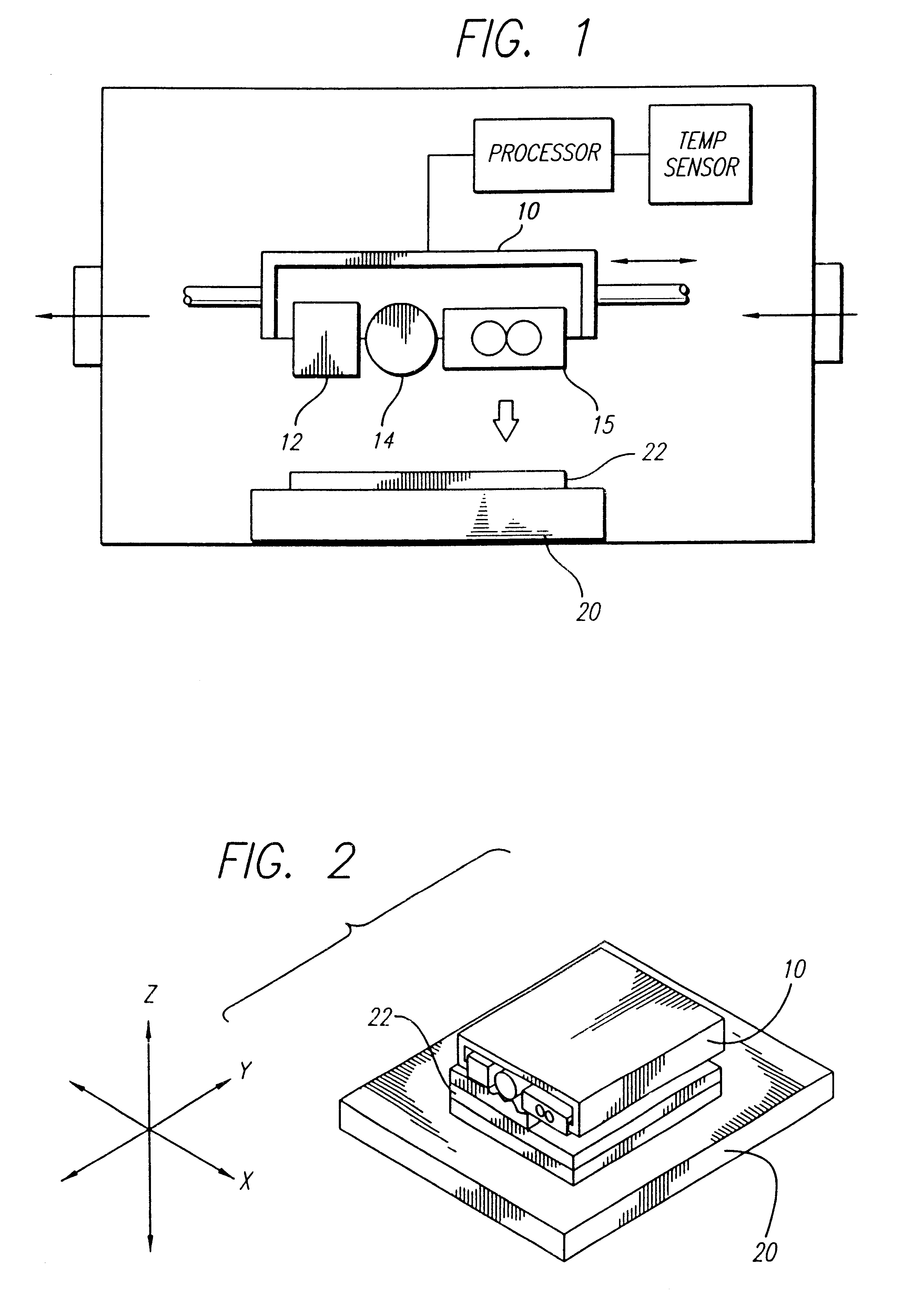

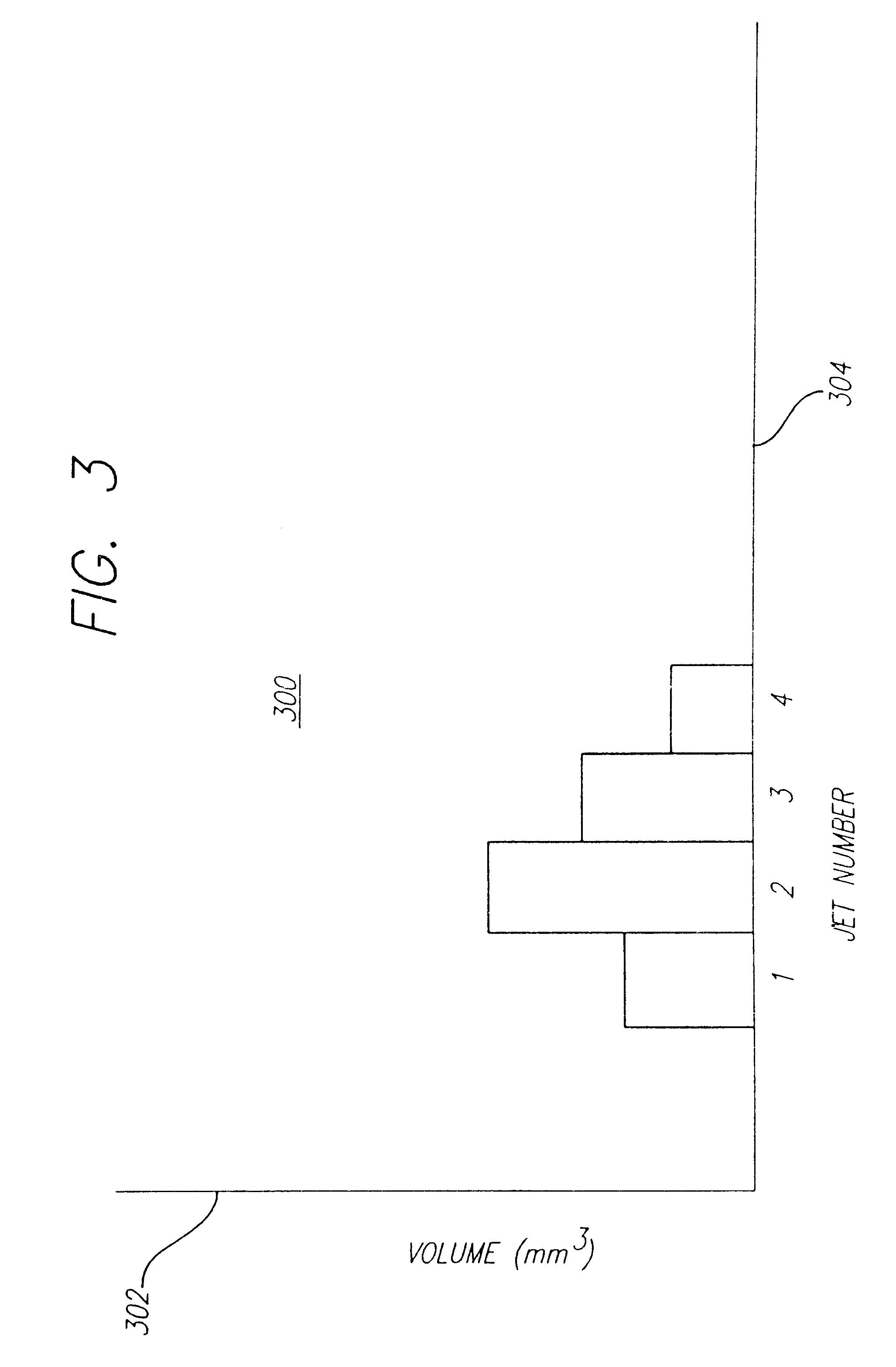

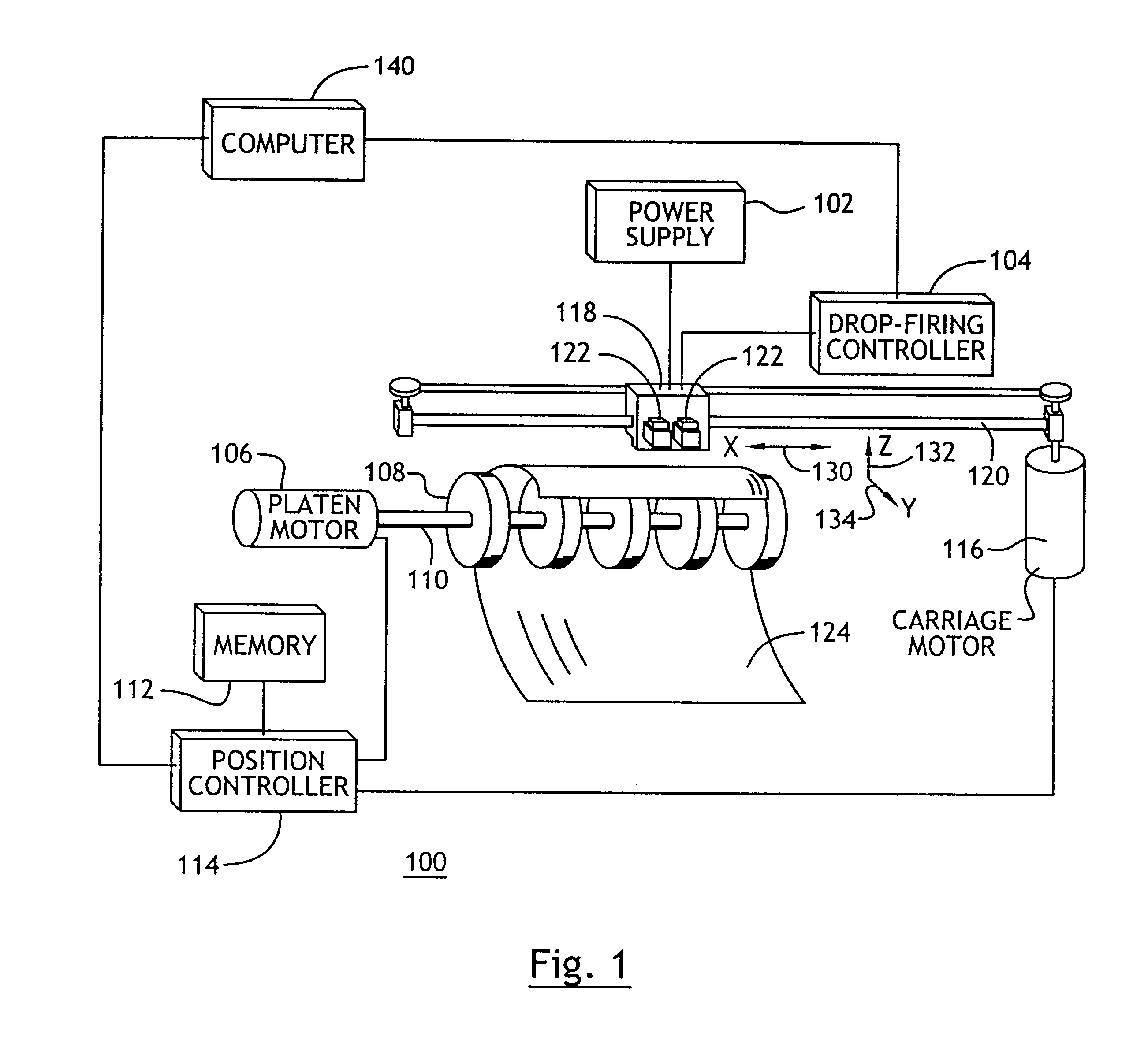

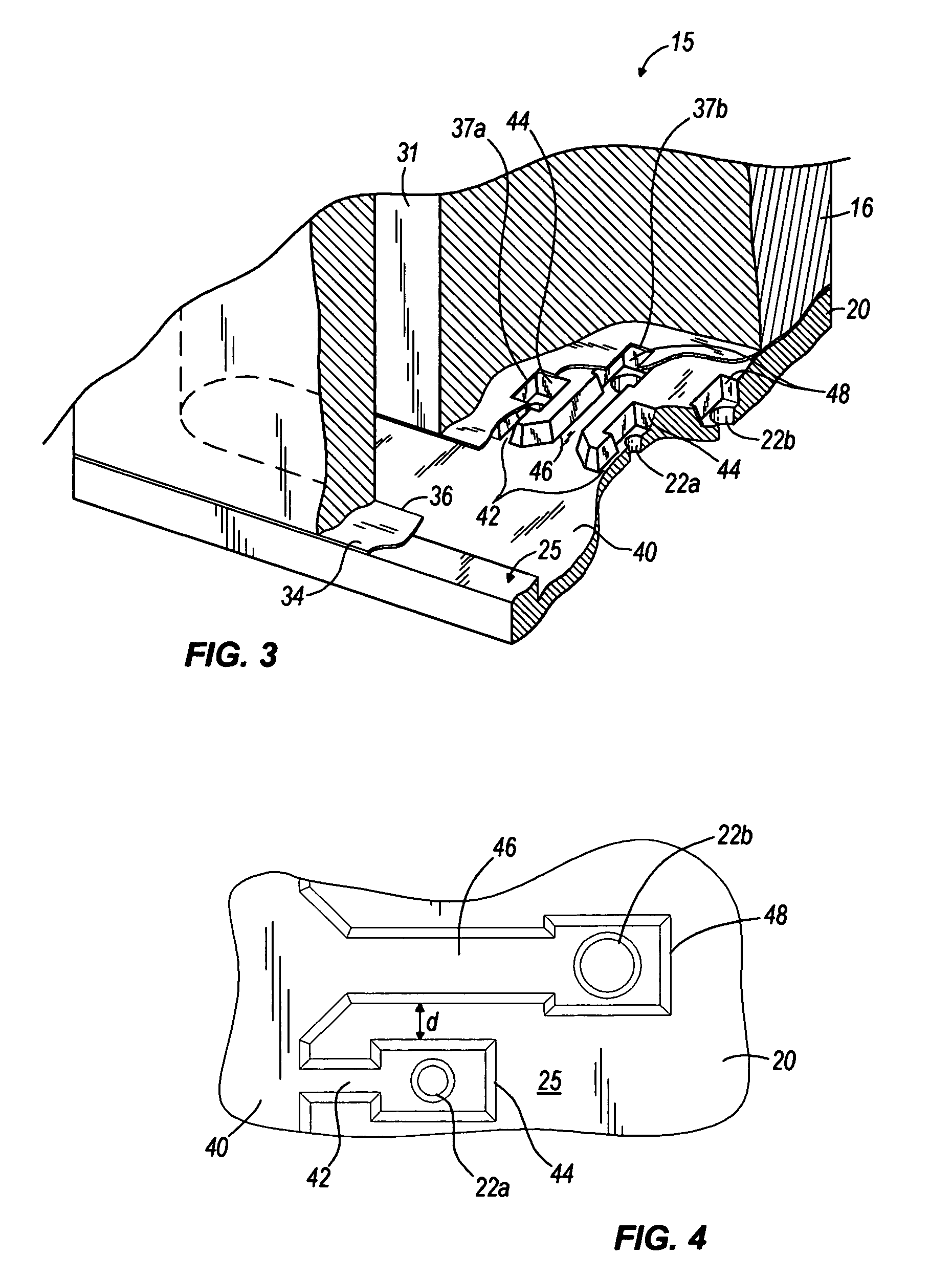

Method and apparatus for controlling the drop volume in a selective deposition modeling environment

InactiveUS6347257B1Additive manufacturing apparatus3D object support structuresEngineeringSelective deposition

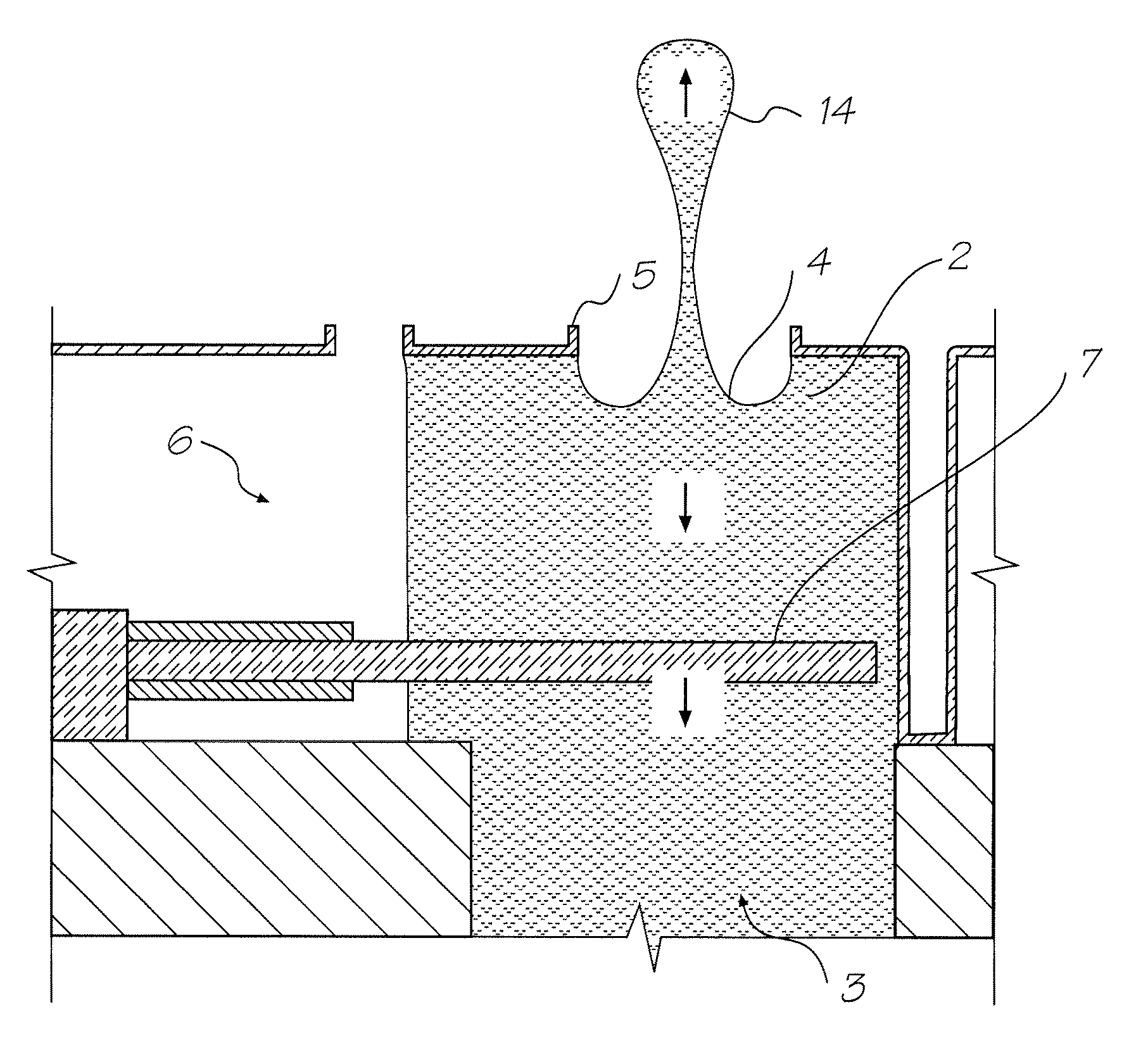

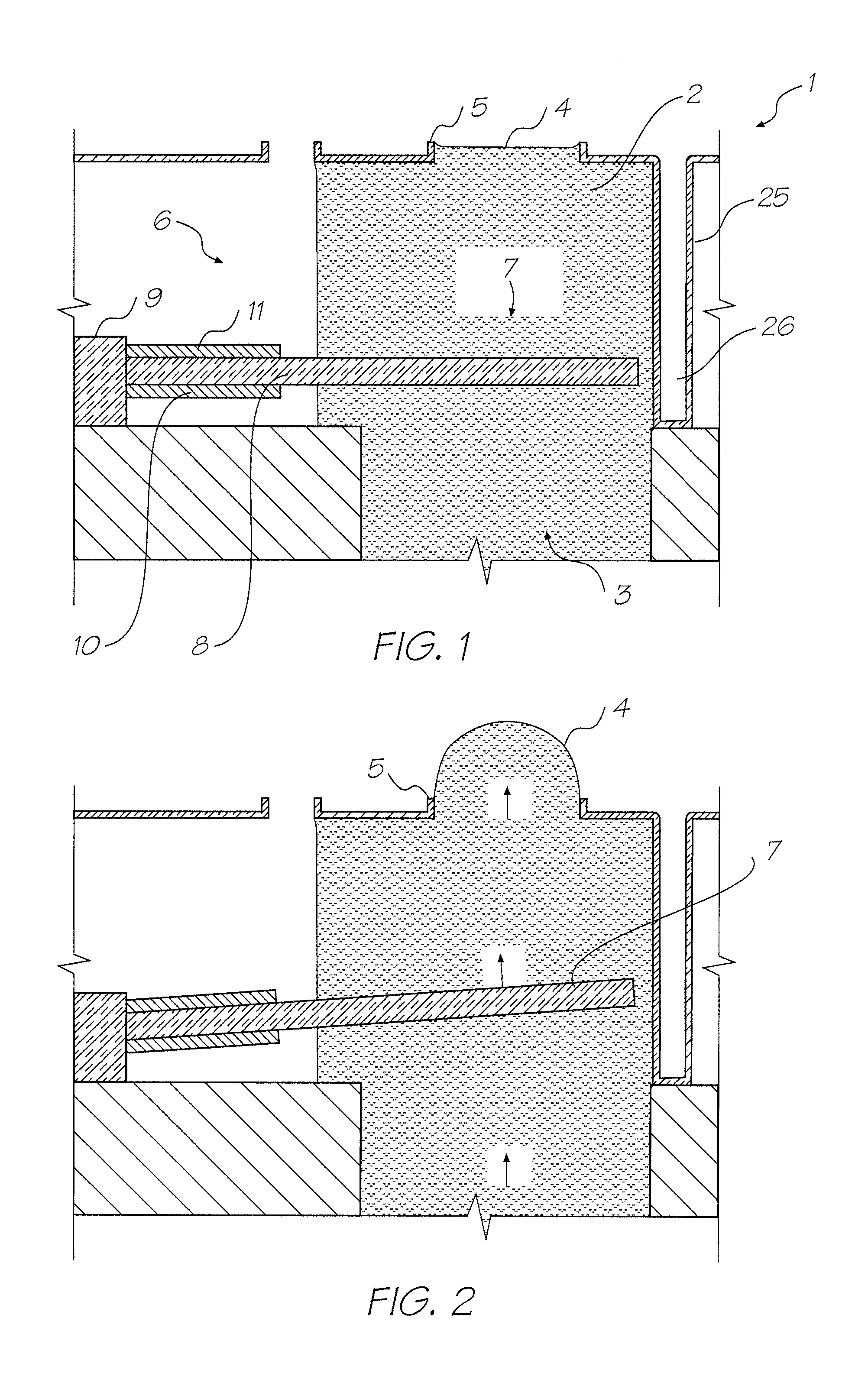

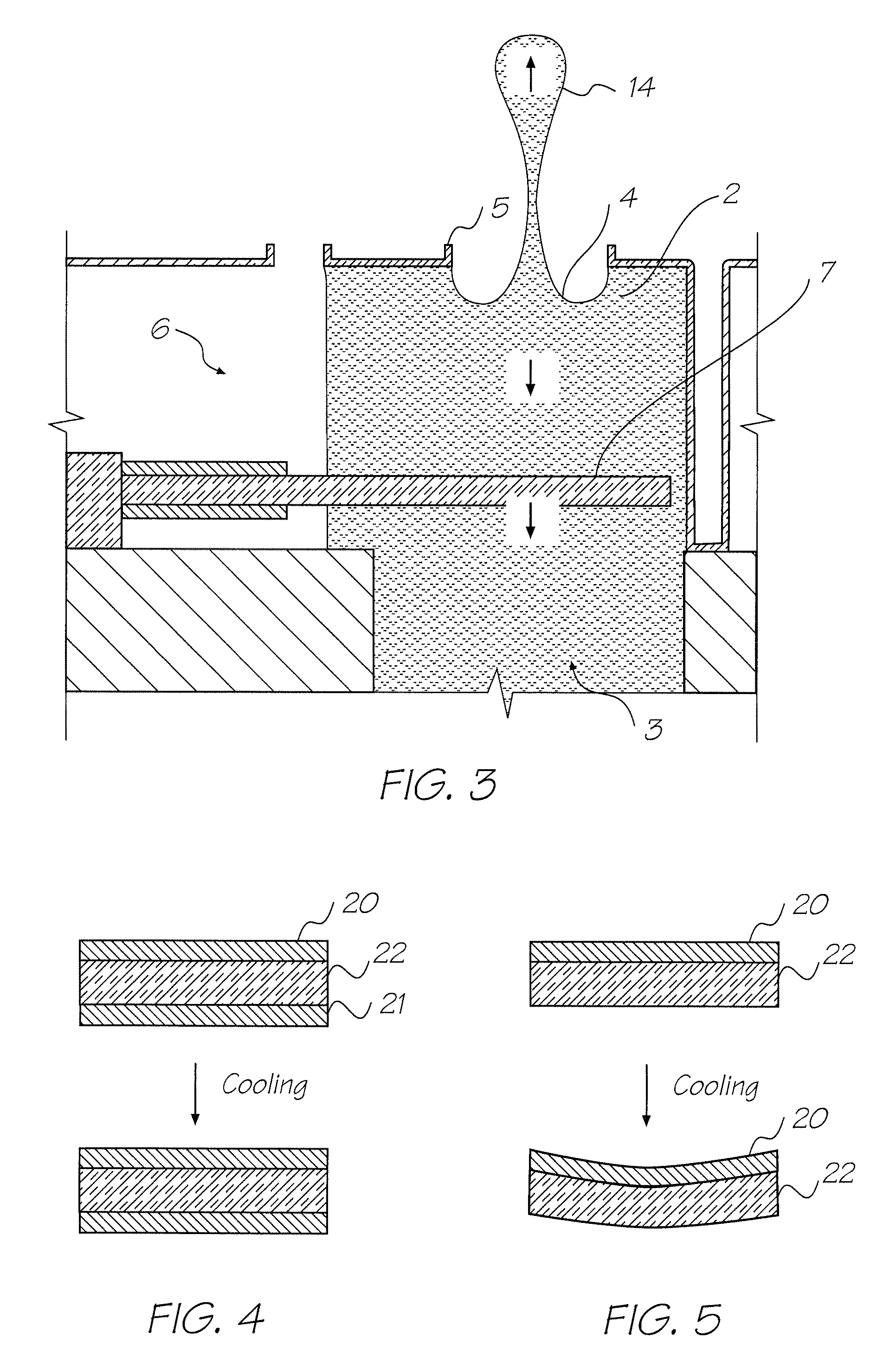

A method, system and apparatus for forming a three-dimensional object on a layer-by-layer basis involves forming a portion of the three-dimensional object using selective deposition modeling (SDM). SDM involves using at least one orifice, such as a jet, which dispenses a droplet of a flowable material that solidifies upon being dispensed. A drop volume capability of each orifice is adjusted until substantially all orifices have a uniform drop volume capability and all dispensed droplets of the flowable material have a uniform volume.

Owner:3D SYST INC

Drop volume measurement and control for ink jet printing

A system and method is presented for measuring the volume of an ink-jet droplet or the relative volumes of a plurality of ink-jet droplets using their electrical properties. In a preferred embodiment a single small capacitor or an array of capacitors is used to measure the dielectric properties of ink-jet droplets and the absolute drop volumes are derived. In an alternative preferred embodiment the relative differences in drop volumes are determined. A feedback circuit, such as one using lock-in technique, may be used to automatically adjust subsequent drop volumes.

Owner:DOLYA HOLDCO 5 LTD

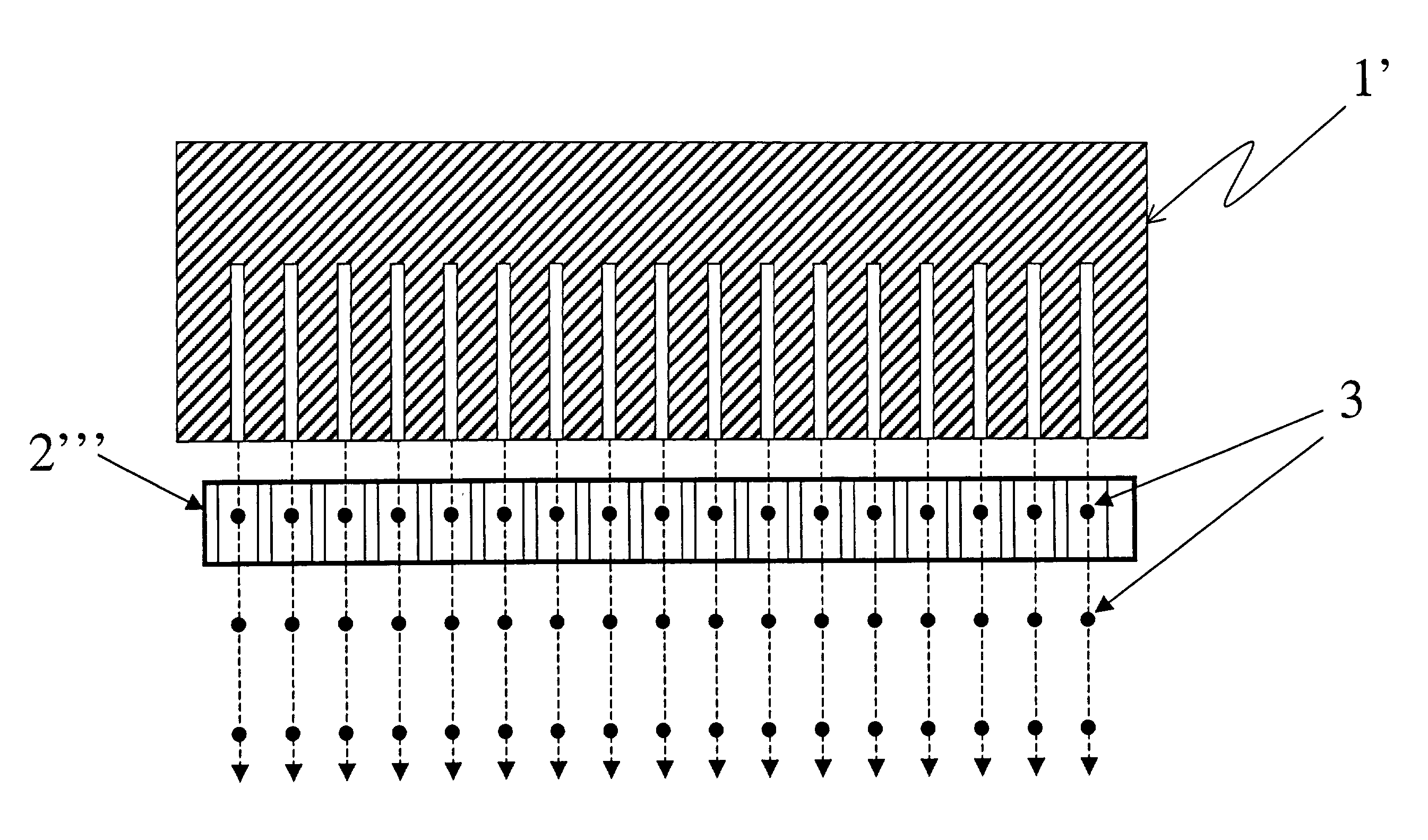

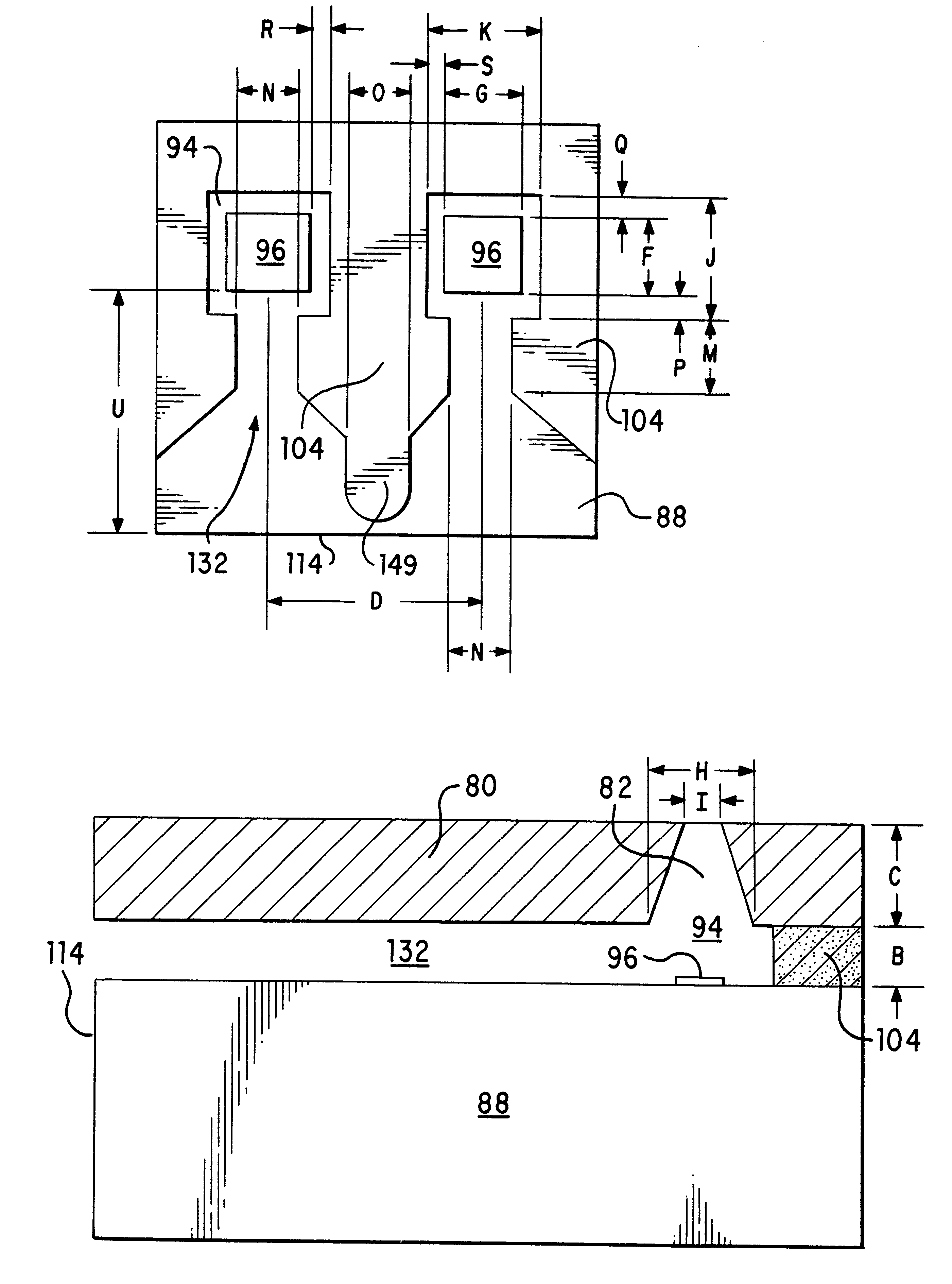

High nozzle density printhead ejecting low drop volumes

InactiveUS7677686B2Avoid flowReduce the overall heightInking apparatusOther printing apparatusWater basedSquare Millimeter

A printhead assembly that has a printhead substrate having a plurality of drop generators formed thereon at an area density of at least six drop generators per square millimeter. The droplets emitted have a drop volume less than 8 pico liters. The fluid forming the droplets has a viscosity in the range of 2 to 5 centipoise. A high area density of drop generators and relatively low droplet volume of water-based ink provides high print resolutions and energy efficient operation.

Owner:MEMJET TECH LTD +1

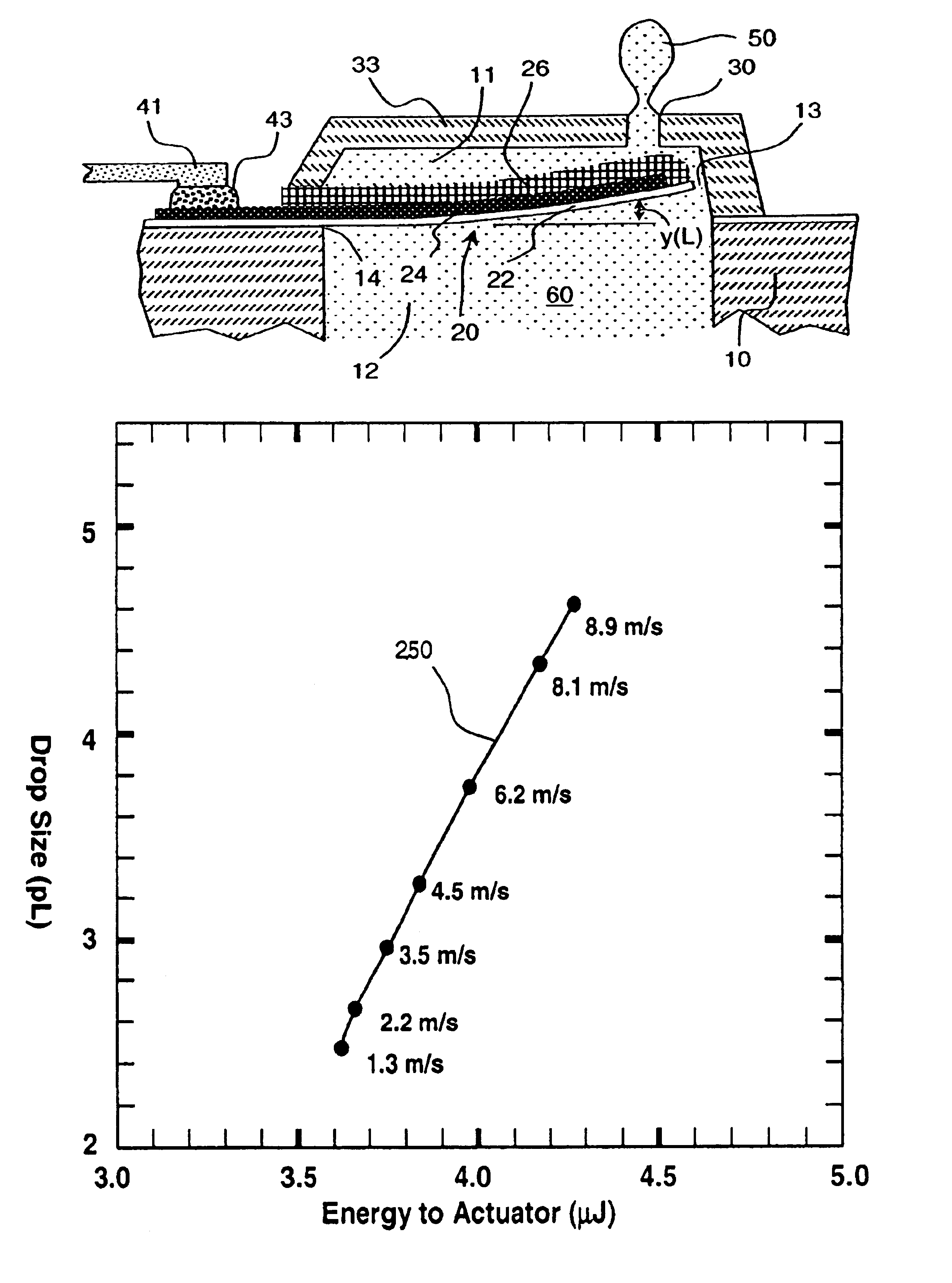

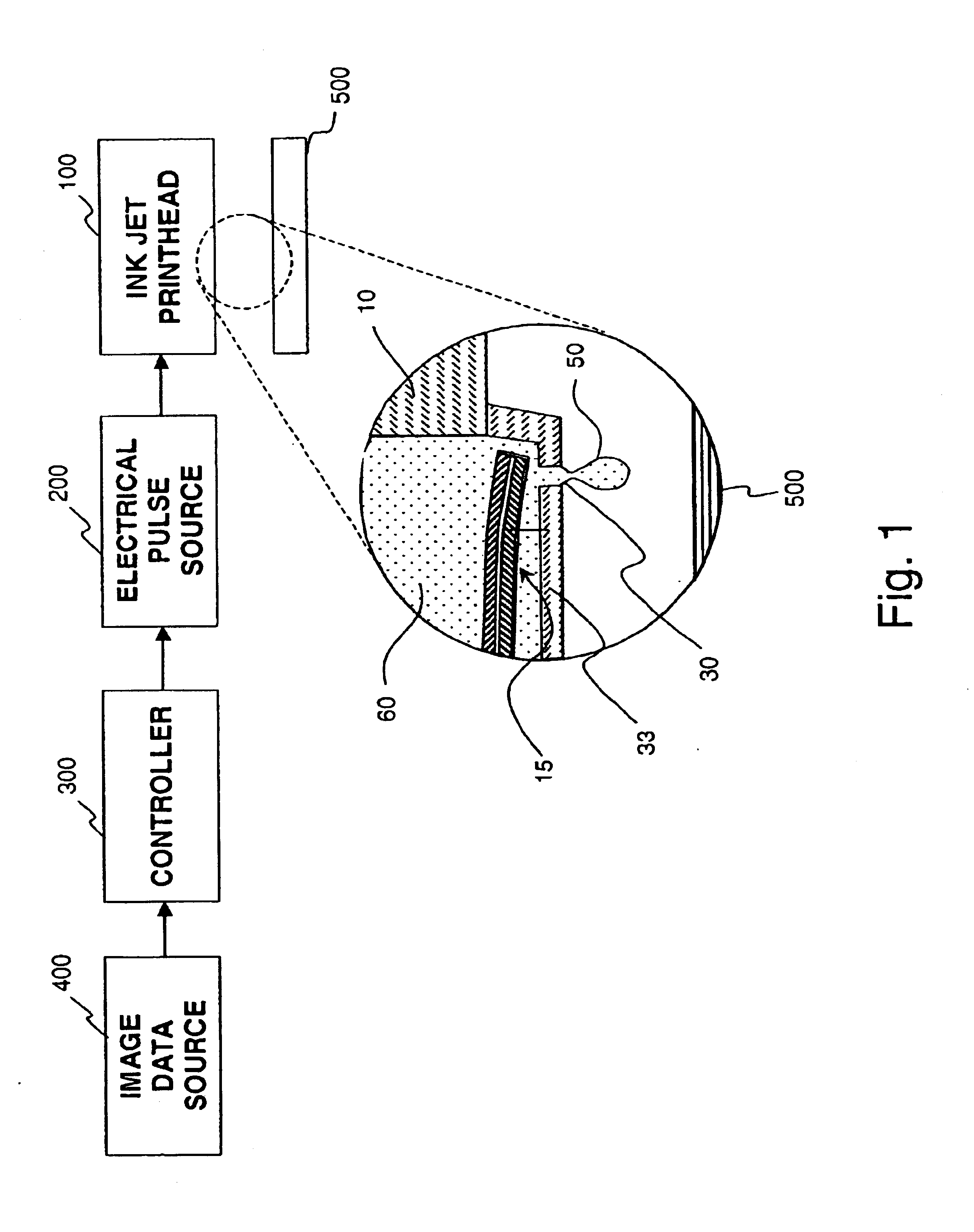

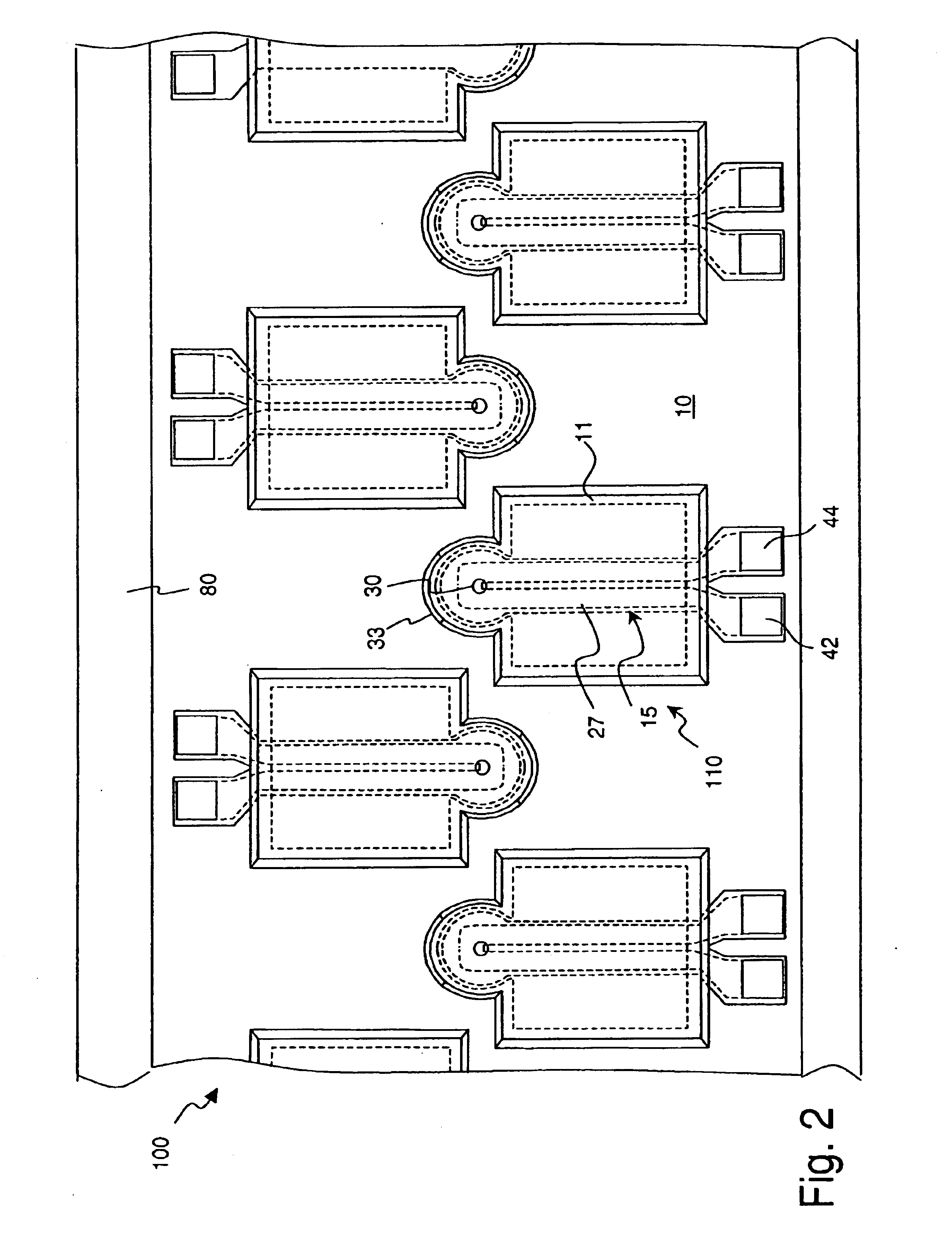

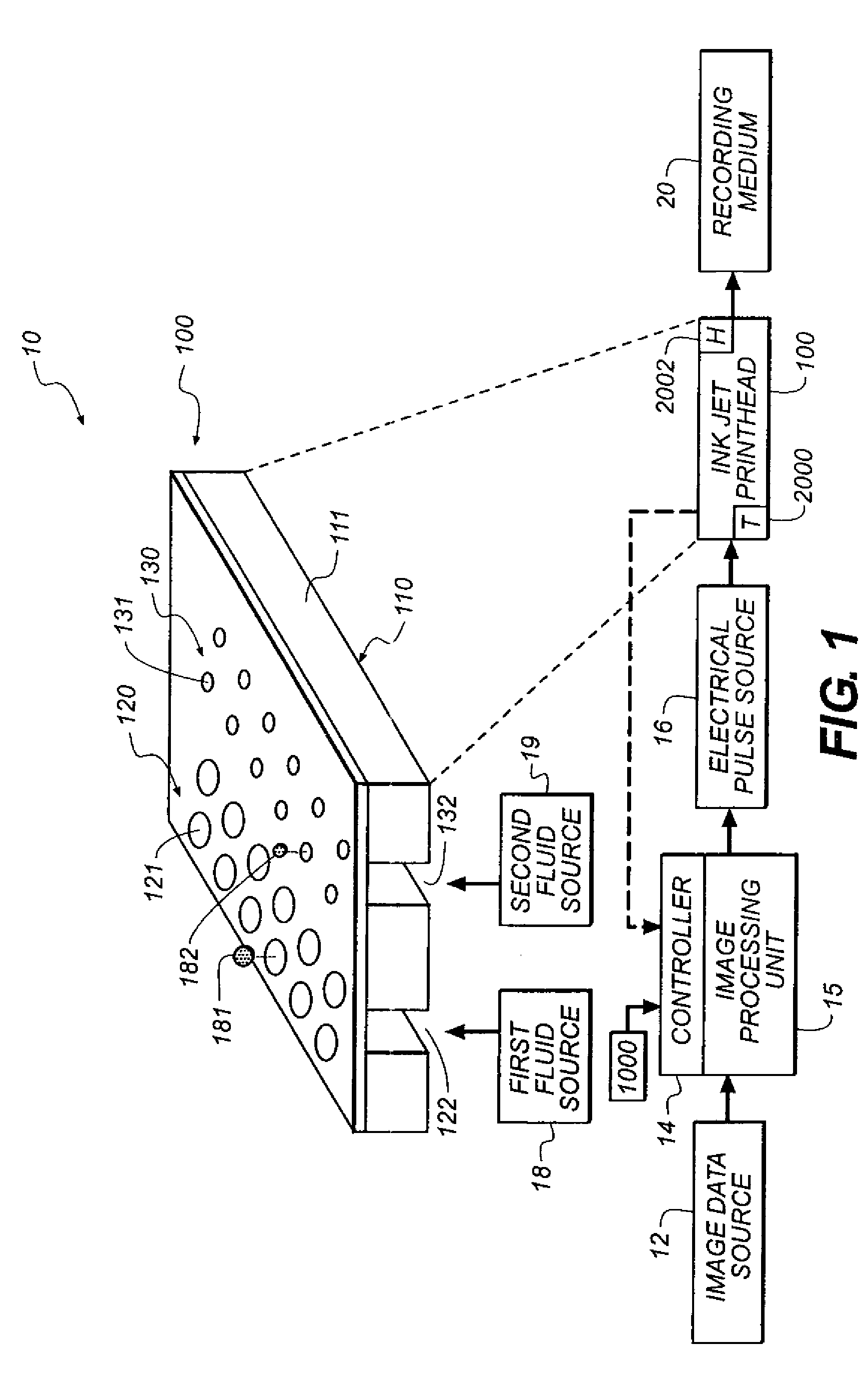

Thermo-mechanical actuator drop-on-demand apparatus and method with multiple drop volumes

InactiveUS6896346B2Data switching by path configurationOther printing apparatusEngineeringArrival time

An apparatus and method of operating a liquid drop emitter, such as an ink jet device, for emitting liquid drops of different volumes. The liquid drop emitter comprises a chamber, filled with a liquid, having a nozzle for emitting drops of the liquid, a thermo-mechanical actuator having a moveable portion within the chamber for applying pressure to the liquid at the nozzle, and apparatus adapted to apply heat pulses to the thermo-mechanical actuator. The method for operating comprises applying a first heat pulse having a first power P1, first pulse duration τp1, and first energy E1=P1×τp1, displacing the movable portion of the actuator so that a drop is emitted having a first drop volume Vd1, and traveling substantially at the target velocity v0; and applying a second heat pulse having a second power P2, second pulse duration τp2, and second energy E2=P2×τp2, displacing the movable portion of the actuator so that a drop is emitted having a second drop volume Vd2 and traveling substantially at the target velocity v0, wherein Vd2>Vd1, E2>E1, τp2>τp1, and P2<P1. An alternate method for operating causes the emission of drops having different volumes traveling at different velocities wherein all velocities are within a pre-determined drop velocity range, vd min to vd max. Further methods for operating an ink jet printhead cause the emission of drops having different volumes and velocities wherein the triggering of the drop emission is delayed so as to result in synchronized arrival times at a print plane.

Owner:EASTMAN KODAK CO

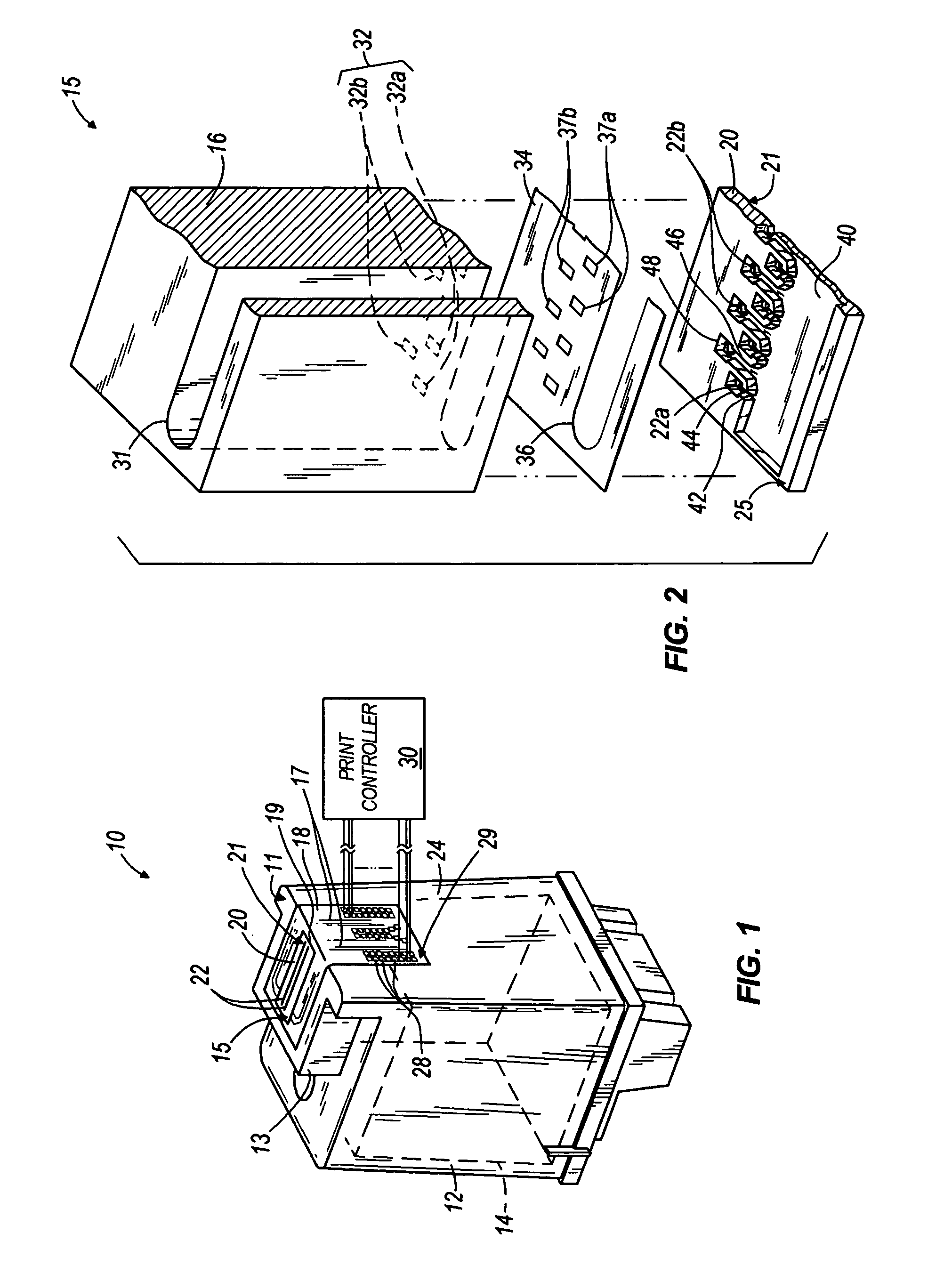

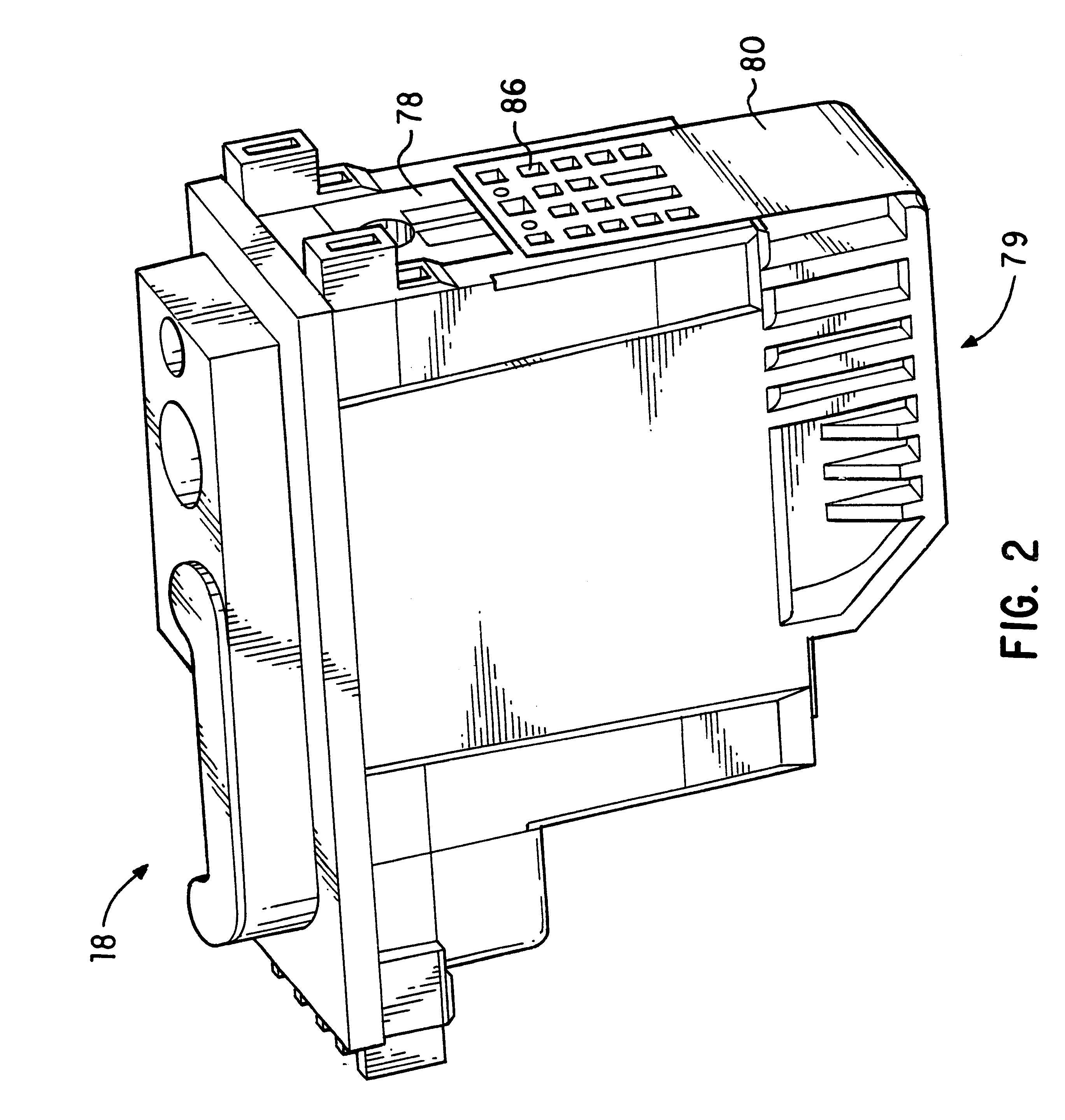

Segmented heater resistor for producing a variable ink drop volume in an inkjet drop generator

A segmented heater resistor is provided for producing a variable ink drop volume in an inkjet drop generator. The segmented heater resistor includes multiple heater resistor segments to which a voltage may be selectively applied, resulting in a variable amount of energy dissipated by the segmented heater resistor, a variable amount of heat transferred to ink in the ink drop generator, and a variable ink drop volume expelled by the inkjet drop generator.

Owner:HEWLETT PACKARD DEV CO LP

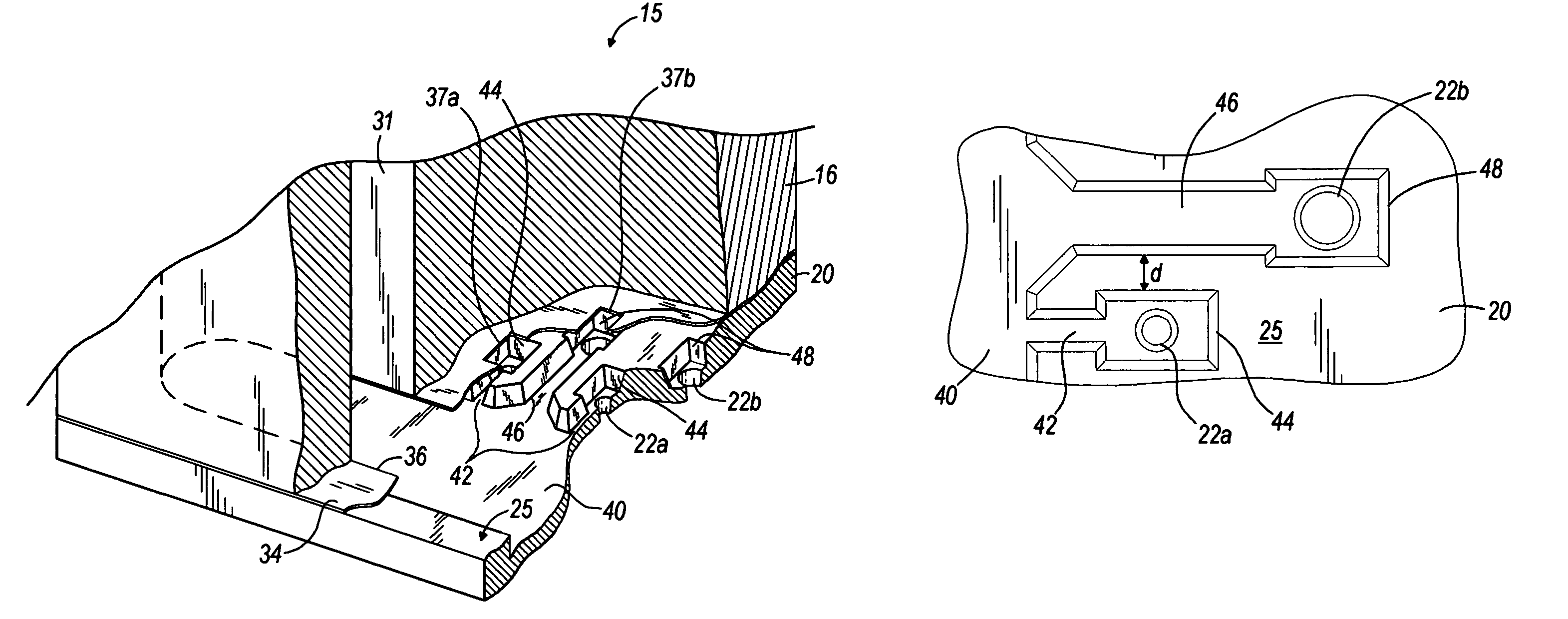

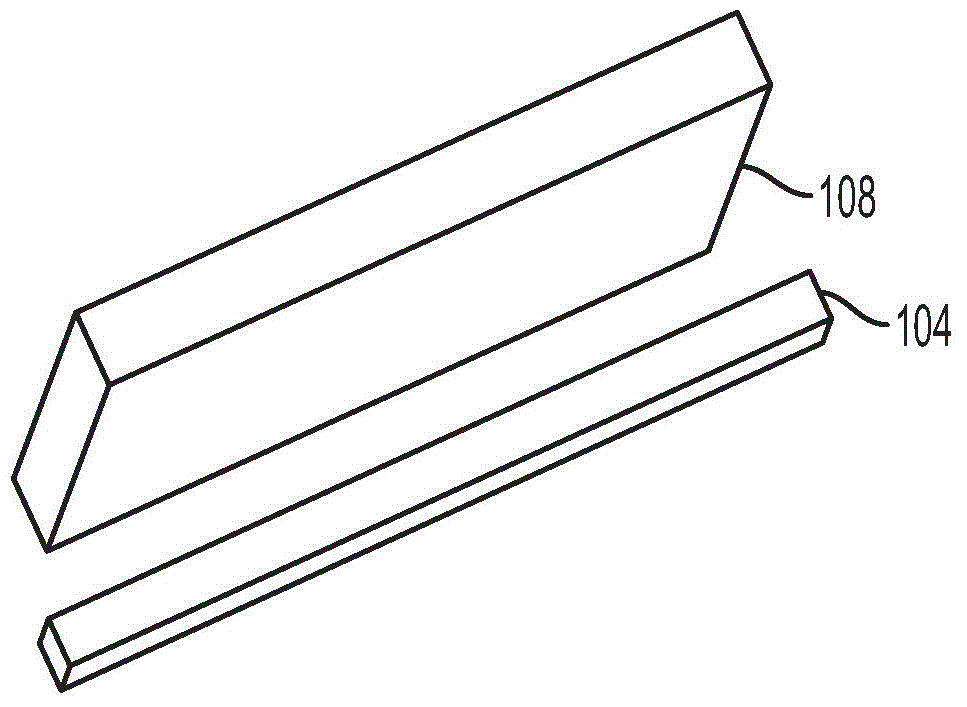

Multiple drop-volume printhead apparatus and method

ActiveUS6959979B2Minimizes nozzle plate delaminationImprove printing qualityPrintingEngineeringDrop volume

Flow features in an inkjet printhead. The flow features can include a plurality of first channels, each of the plurality of first channels having a first length and positioned to fluidly communicate with an ink reservoir, and each of the plurality of first channels terminating in a first nozzle. The flow features can further include a plurality of second channels, each of the plurality of second channels having a second length greater than the first length and positioned to fluidly communicate with the ink reservoir, each of the plurality of second channels terminating in a second nozzle, each second nozzle being larger than each first nozzle.

Owner:SLINGSHOT PRINTING LLC

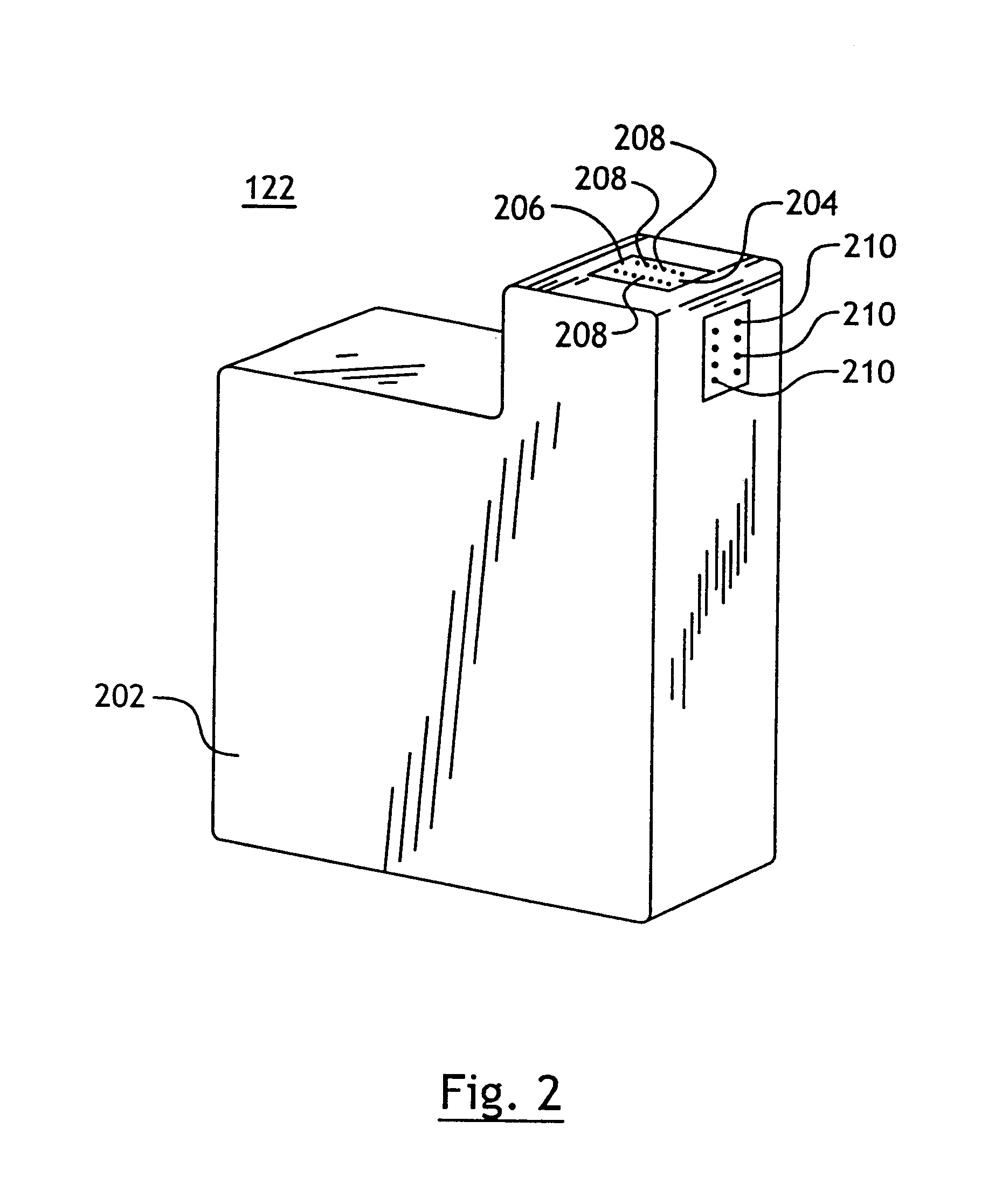

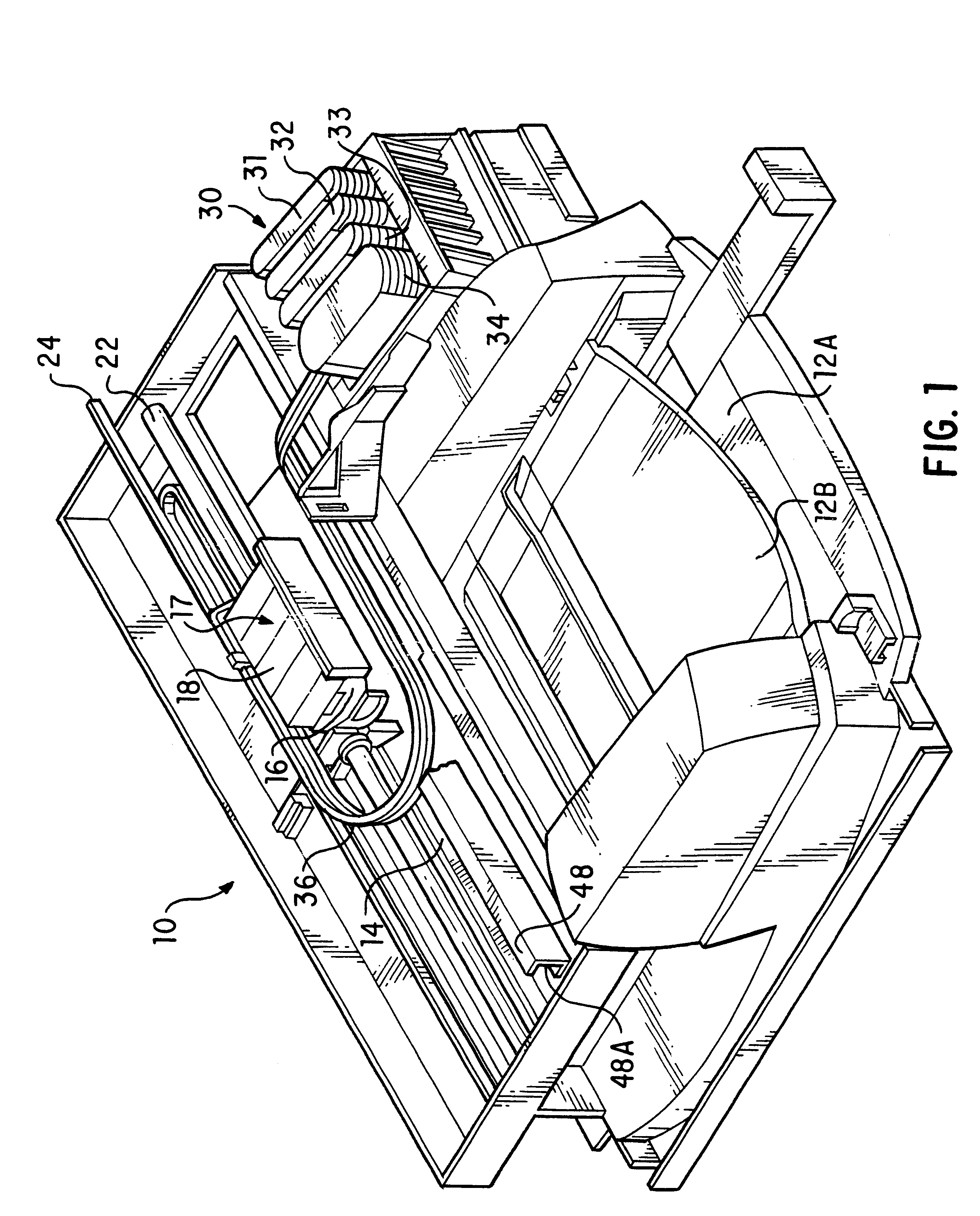

Apparatus for generating small volume, high velocity ink droplets in an inkjet printer

Disclosed is an inkjet print cartridge including an ink supply, a substrate having a plurality of individual ink ejection chambers defined by a barrier layer formed on a first surface of the substrate and having an ink ejection element in each of the ink ejection chambers, for ejecting drops of ink having a predetermined drop volume and drop velocity. The ink ejection chambers each have the same inlet channel length and are arranged in an array spaced so as to provide a predetermined resolution. A nozzle member having a plurality of ink orifices formed therein is positioned to overlie the barrier layer with the orifices aligned with the ink ejection chambers. An ink channel connects the reservoir with the ink ejection chambers. The inkjet print cartridge has several advantages of over previous printing systems in creating high quality images by using very small individual ink drops of low volume and high velocity. Highlight regions may be formed by using single low volume drops to form a dot. The individual drops are nearly invisible and can be used to form highlights with low graininess. As the density of the image increases, multi-drop dots are formed from two or more drops merging on the media to form a composite drop.

Owner:HEWLETT PACKARD DEV CO LP

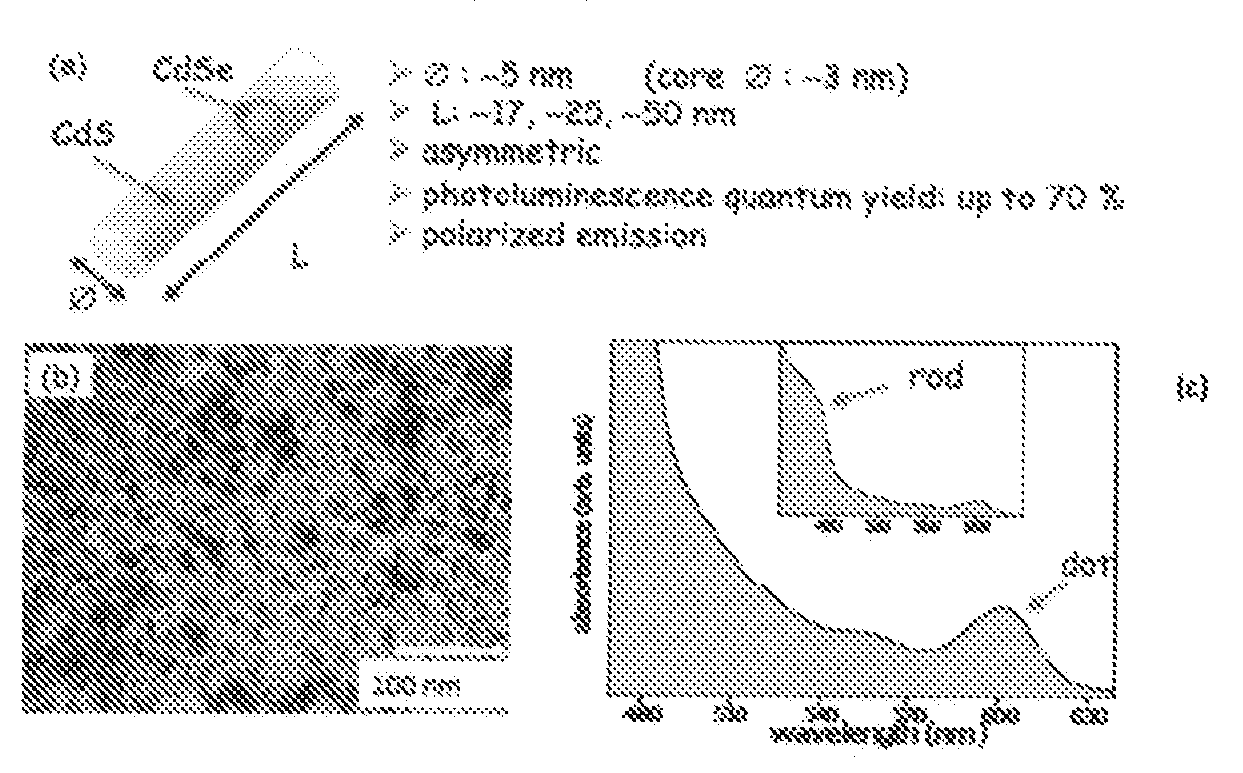

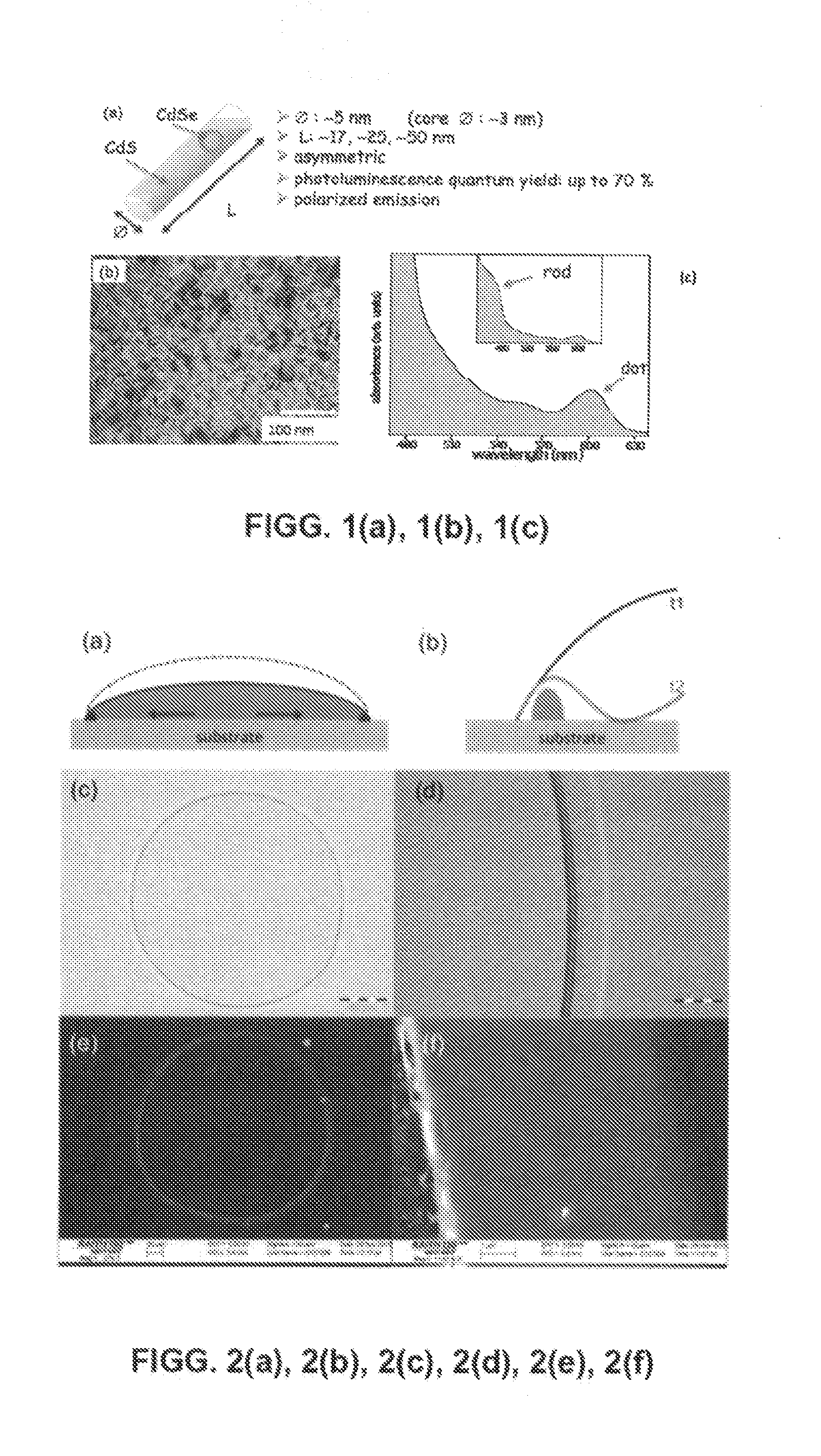

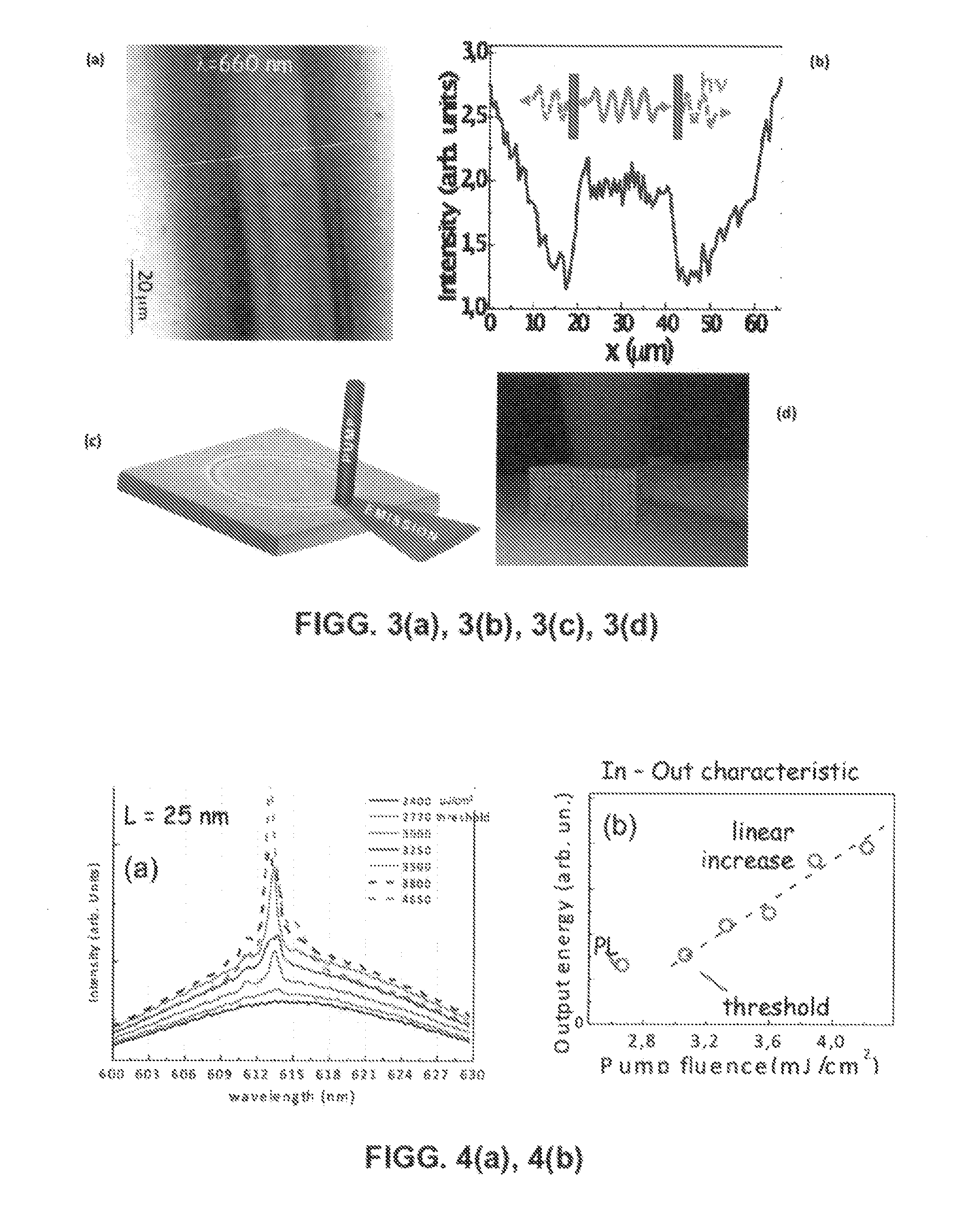

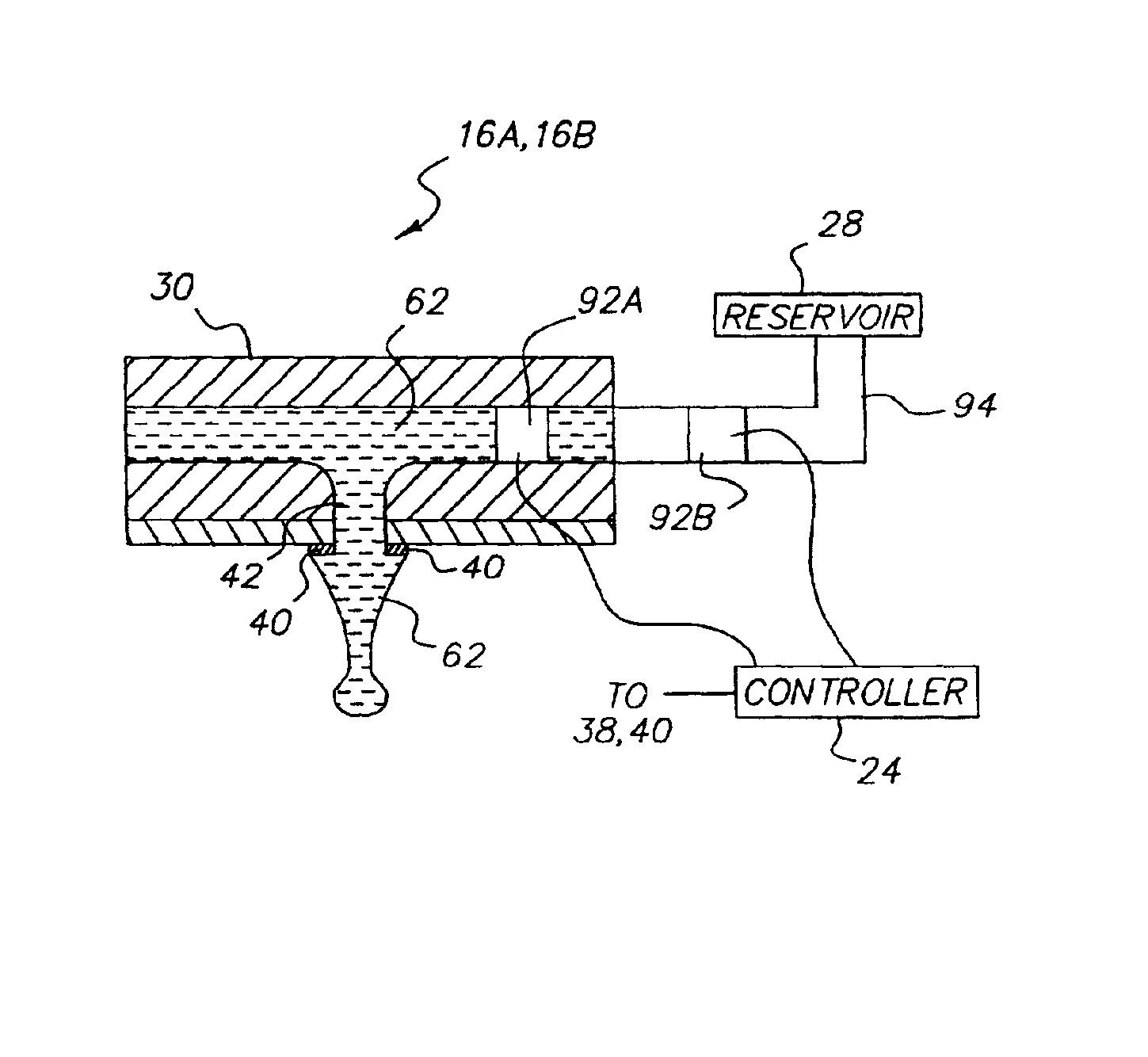

Fabrication of lasing microcavities consisting of highly luminescent colloidal nanocrystals

ActiveUS20120201265A1Reduce necessityPolycrystalline material growthFrom normal temperature solutionsResonant cavityColloid

A method of producing a lasing microsource of colloidal nanocrystals. The method includes the steps of preparing a nanocrystal solution in a solvent; depositing at least a drop of the nanocrystals solution with a drop volume below 1 nl on a flat substrate; and evaporating the solvent to dryness thereby to obtain at the edge of the evaporated drop a single annular stripe including a domain wherein the nanocrystals are arranged in an ordered array, wherein the ordered nanocrystals in the domain constitute an active region capable of lasing and the radially inner and outer edges of the stripe define a resonant cavity in which the active region is inserted.

Owner:FOND INST ITAL DI TECH

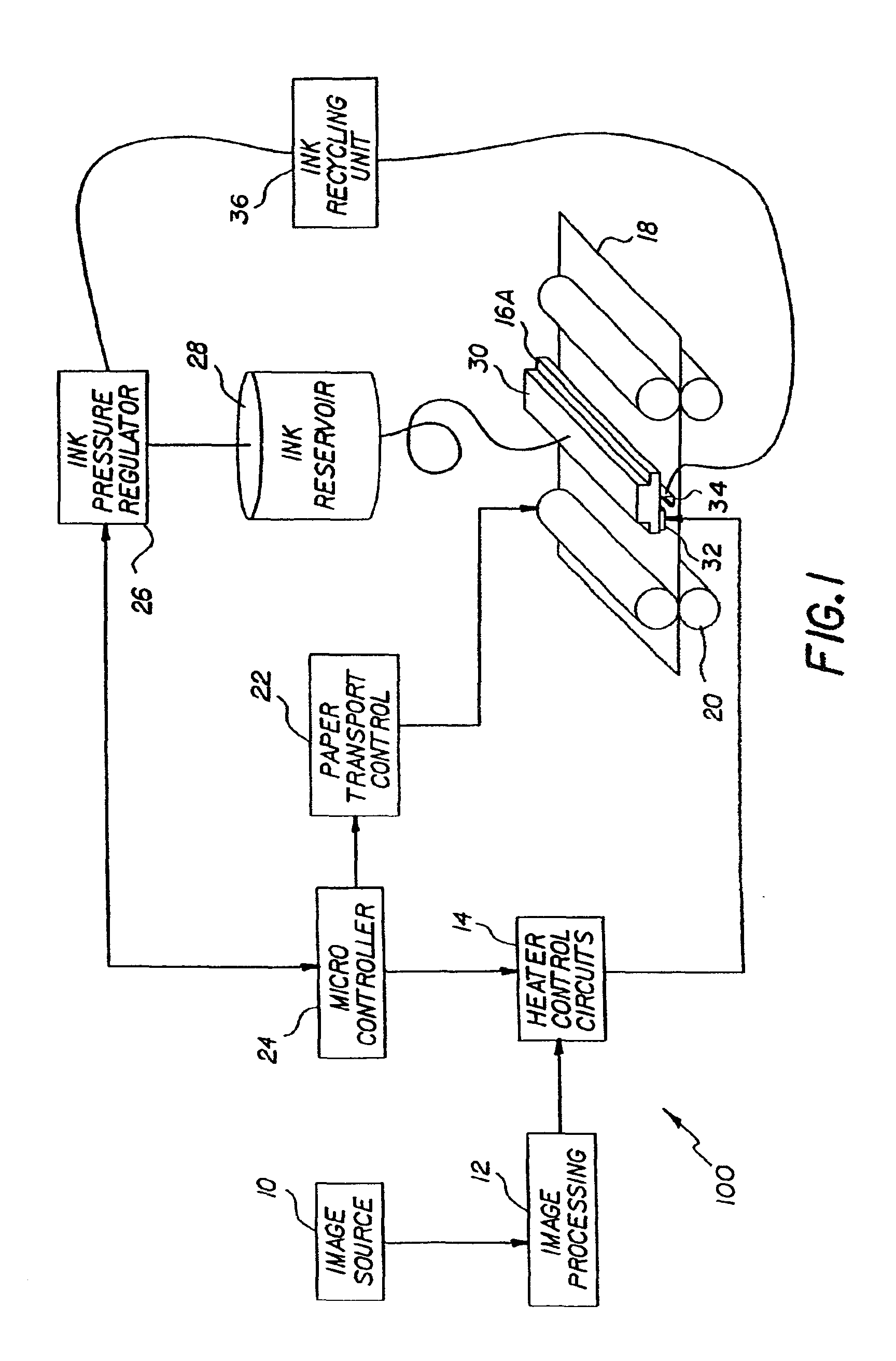

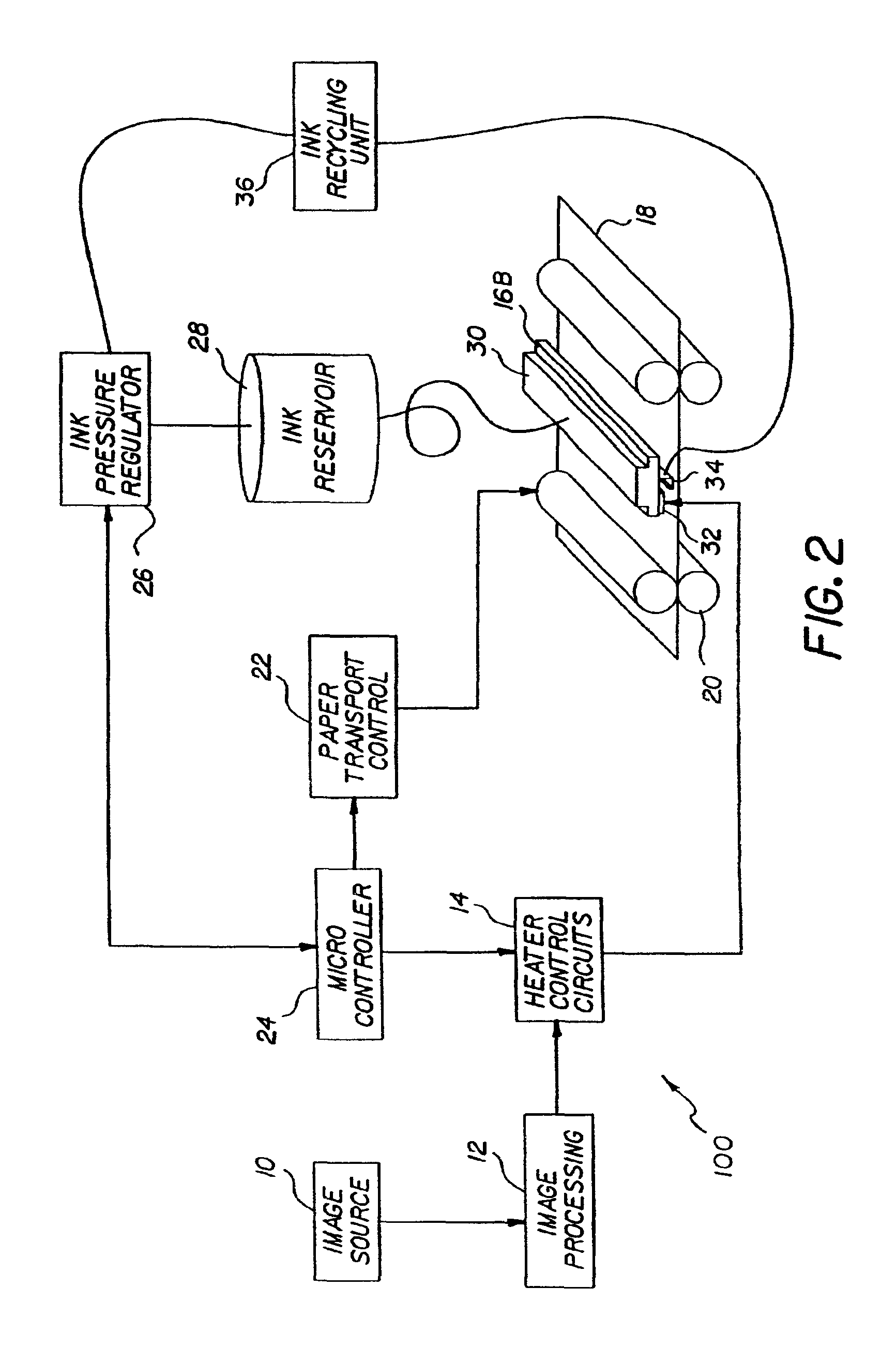

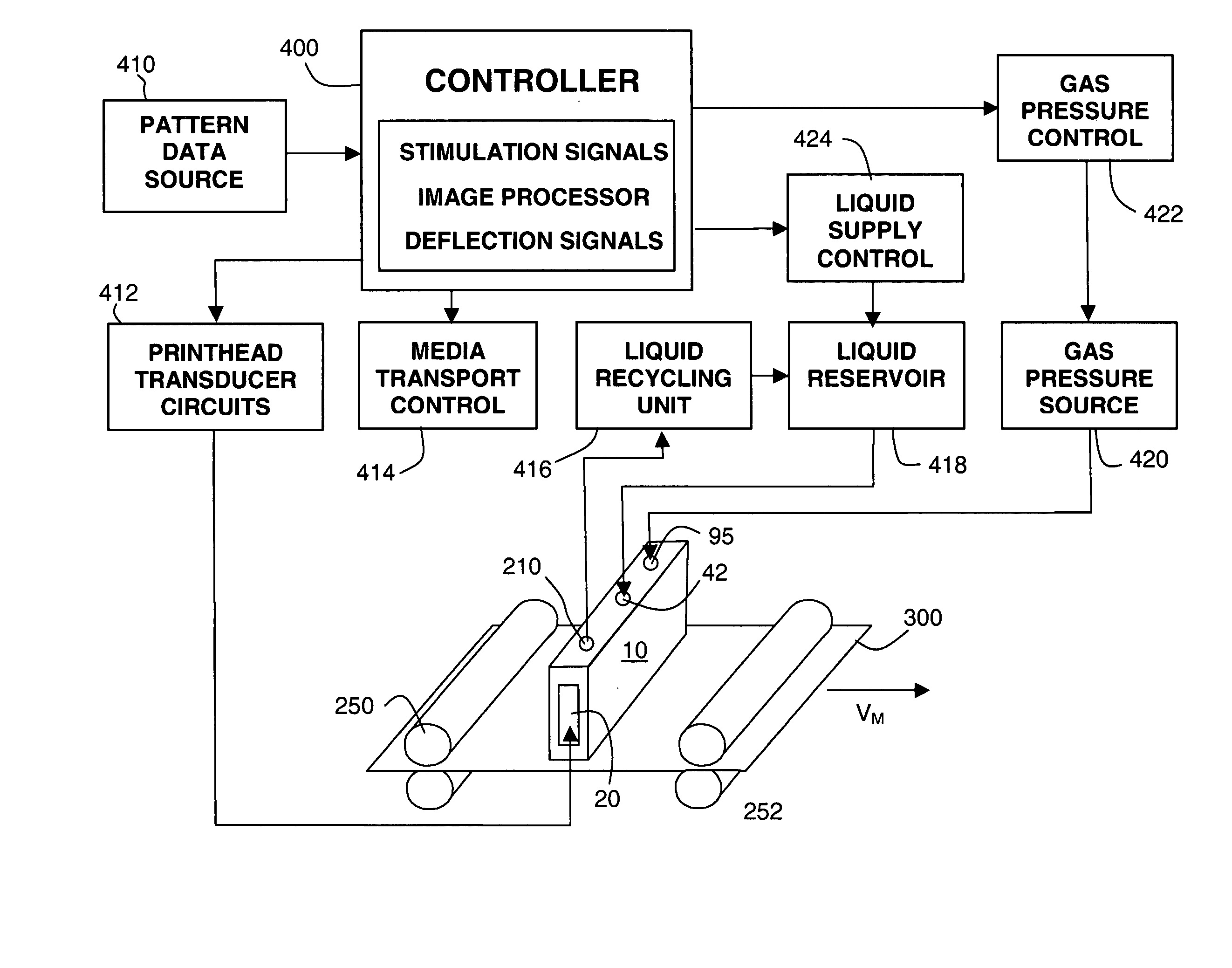

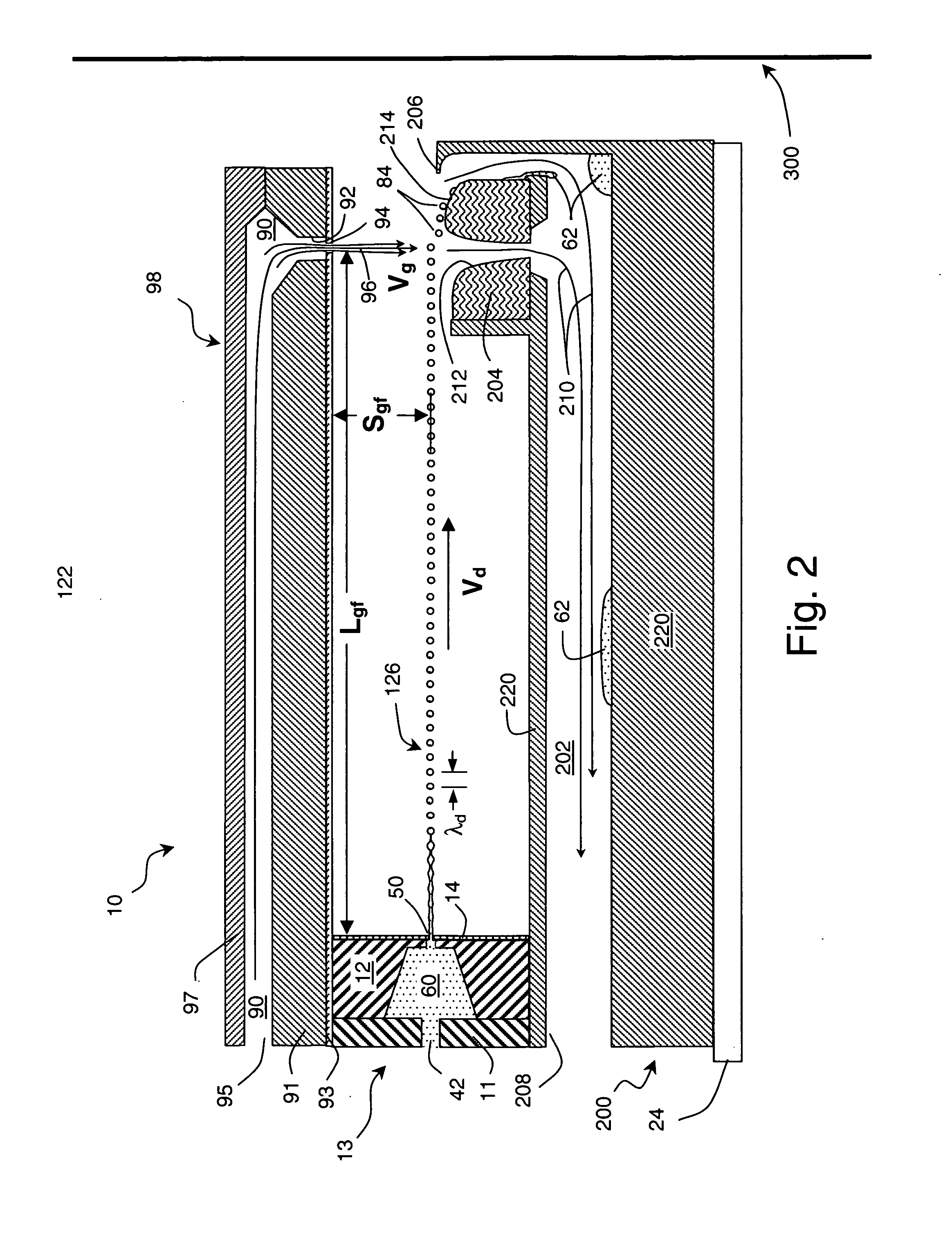

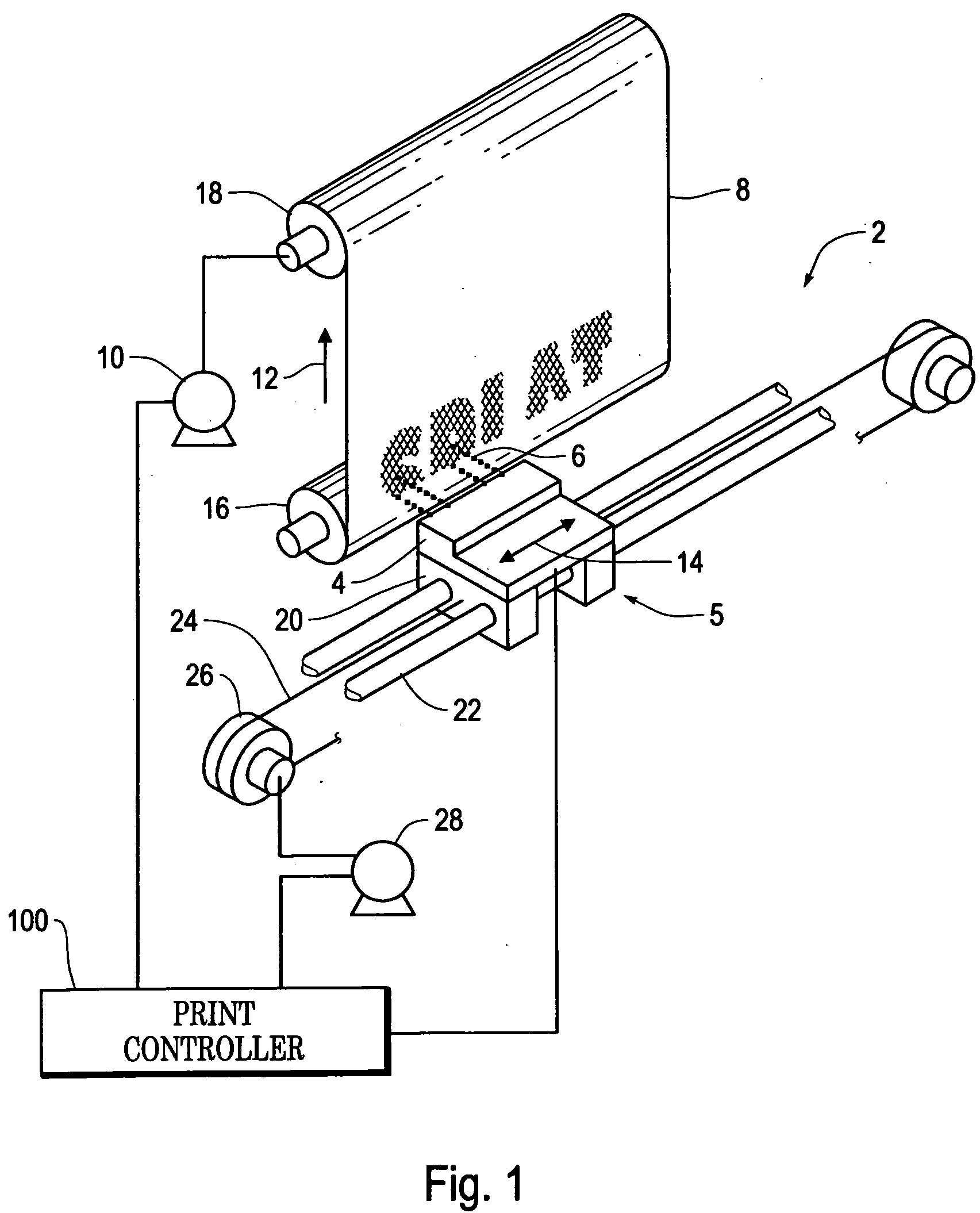

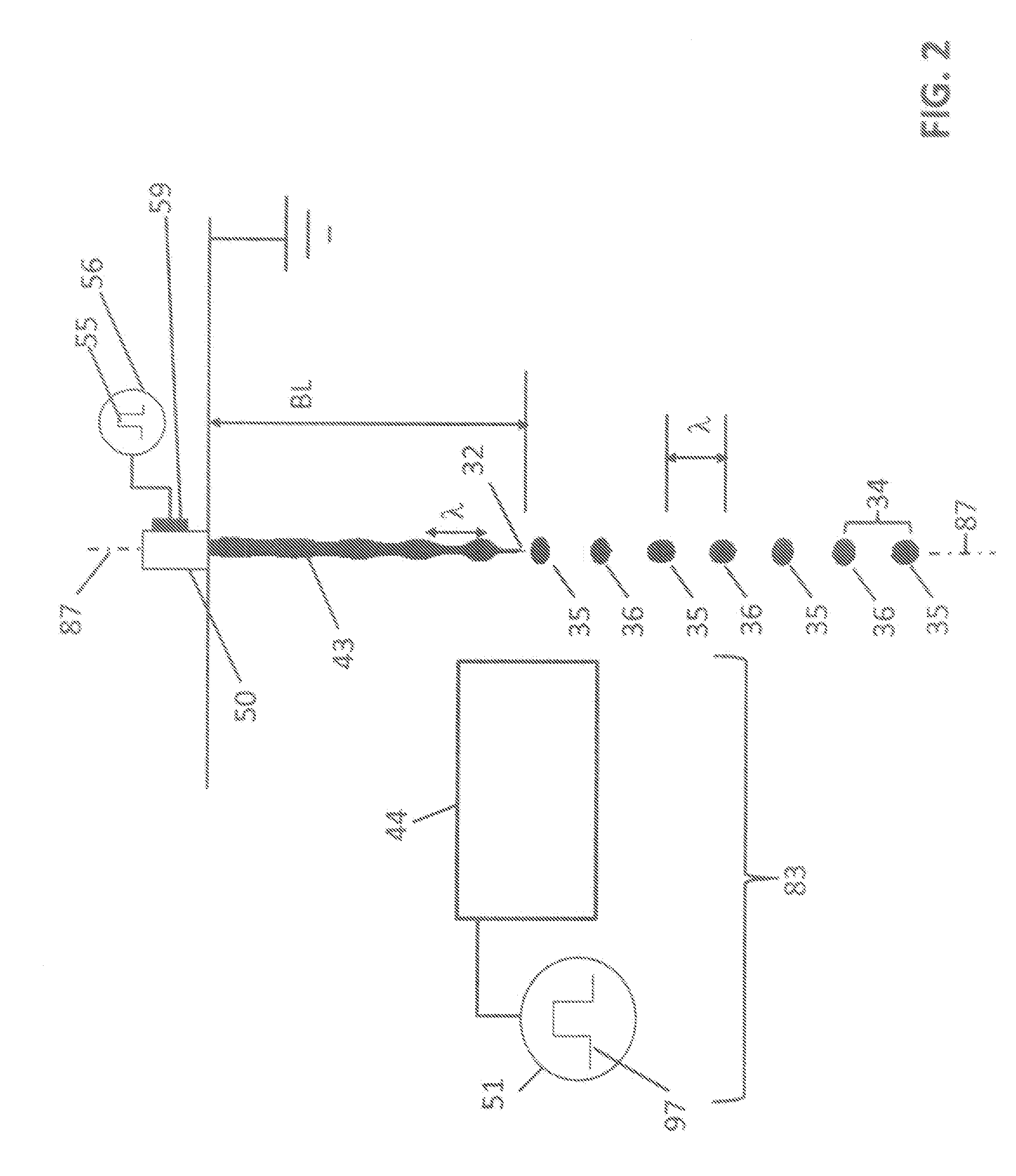

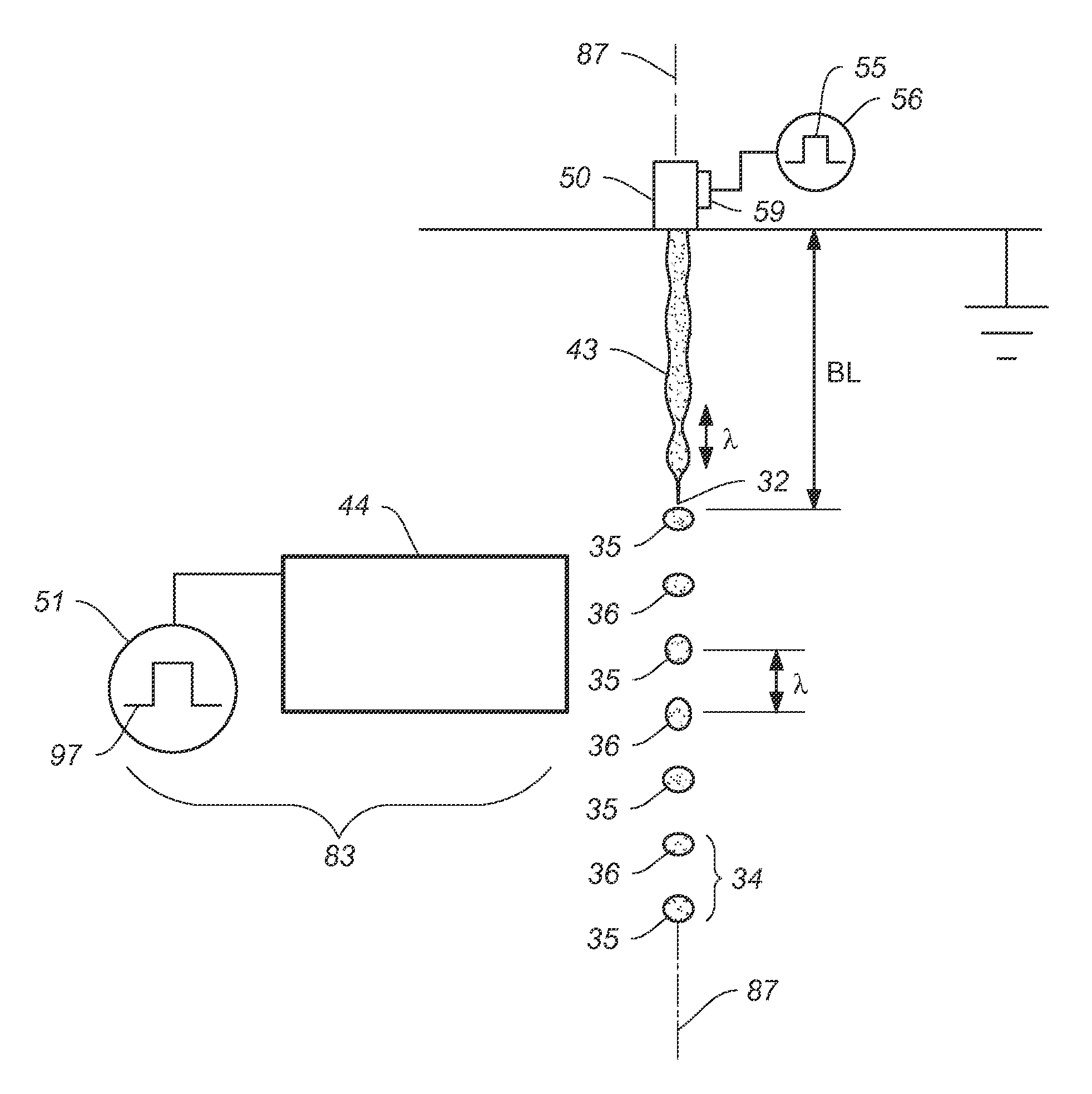

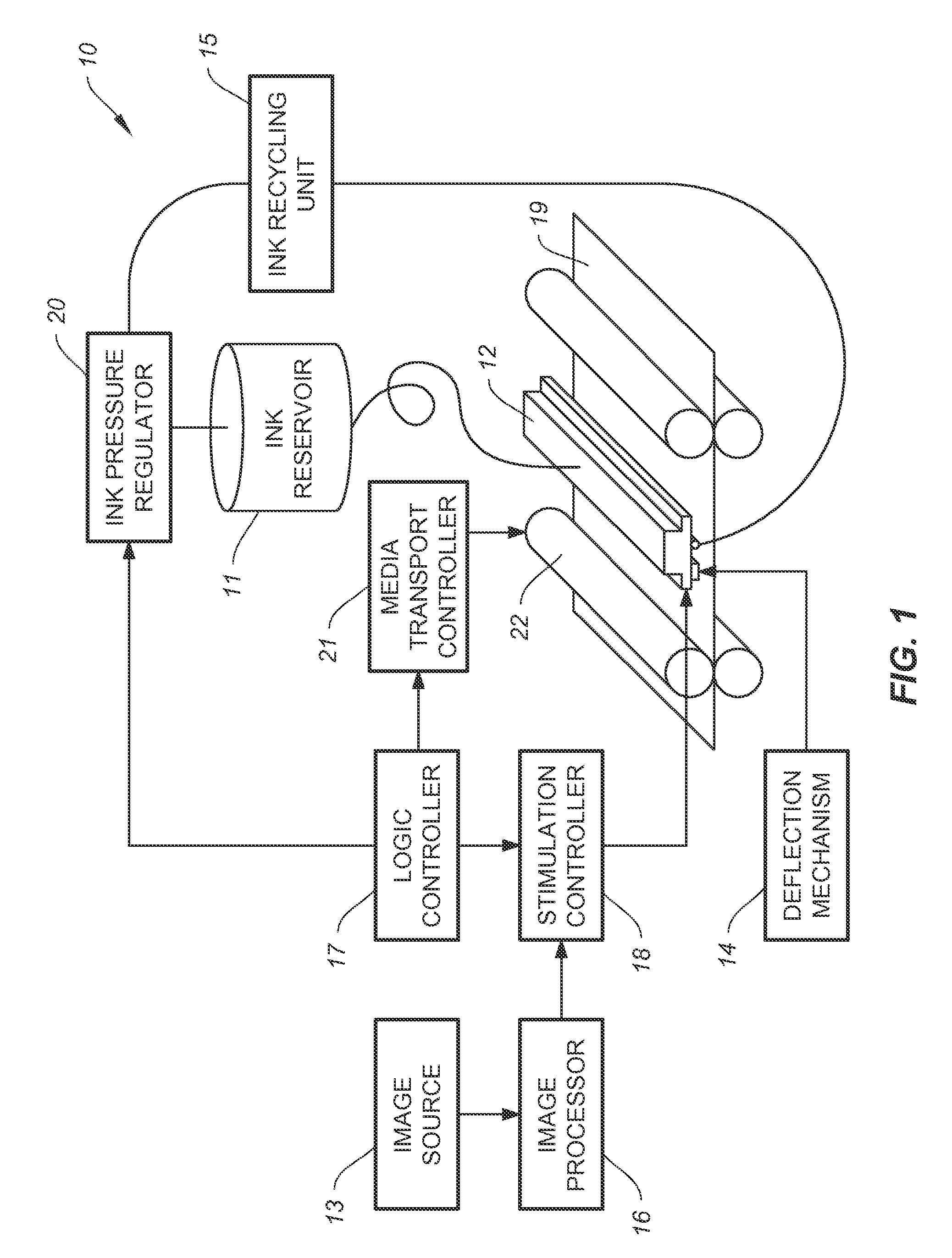

Apparatus and method for maintaining constant drop volumes in a continuous stream ink jet printer

A method an apparatus for maintaining a predetermined ejected ink drop volume in a continuous inkjet printer is provided. An ink parameter, for example, temperature, velocity, flow rate, viscosity, is monitored. A time period between activation control signals provided to an ink drop forming mechanism is varied in response to a change in the ink parameter. The apparatus includes an ink parameter monitoring device which provides an input signal to a controller. The controller varies the time period between activation control signals provided to the ink drop forming mechanism.

Owner:EASTMAN KODAK CO

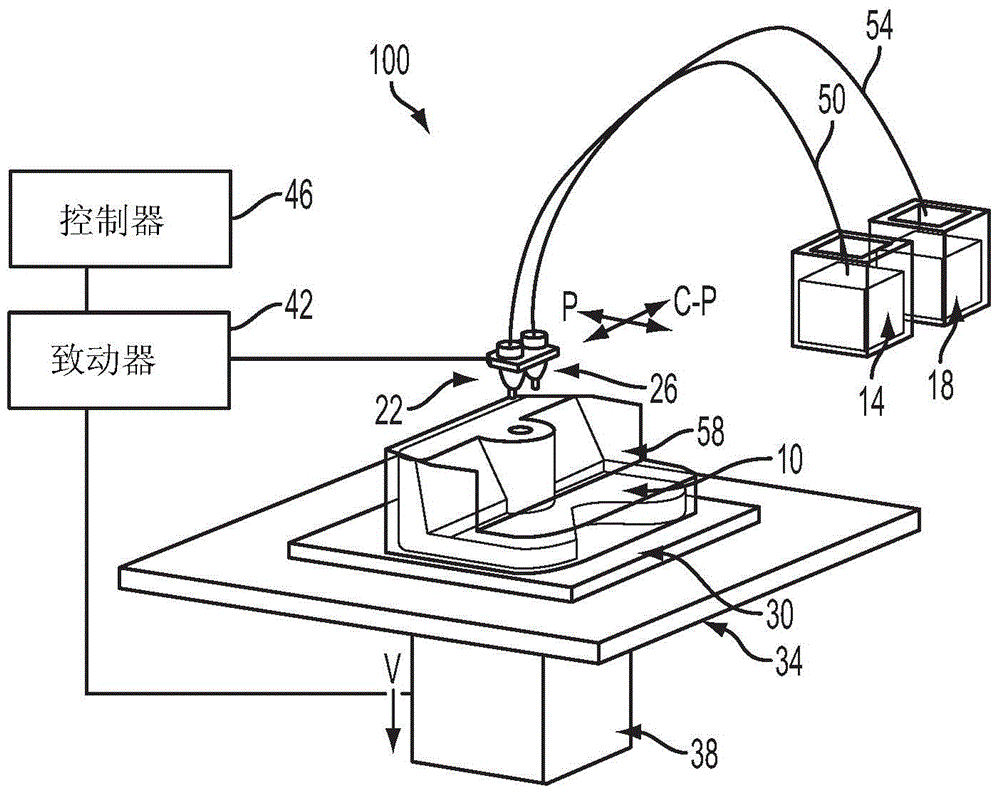

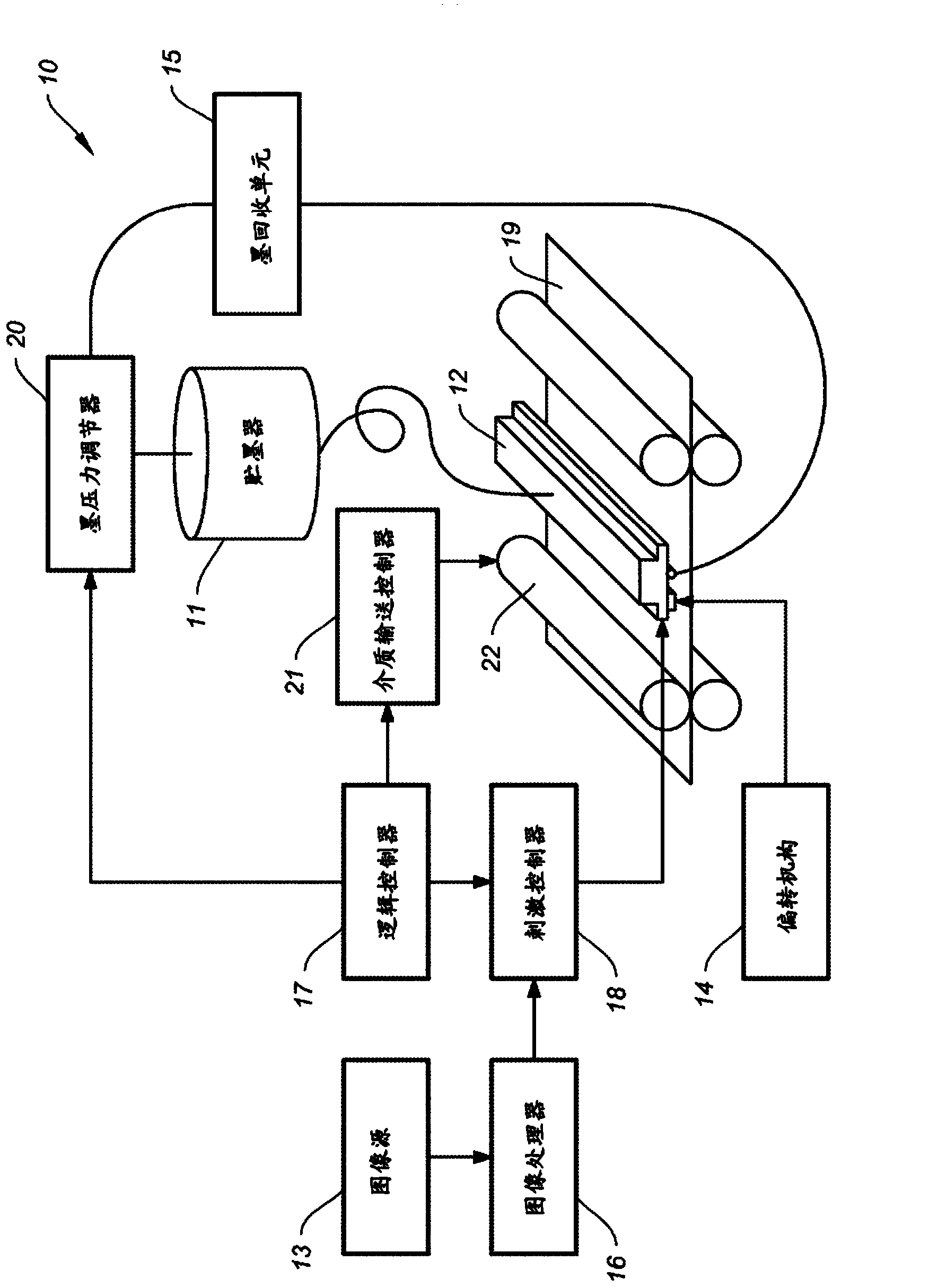

System for controlling material drop volume in three dimensional object printing

ActiveCN104802402AAccurate placementAdditive manufacturing apparatus3D object support structuresSensor arrayClosed loop

A printer uses closed loop control to keep material drops ejected by a printhead within a predetermined range. The printer forms at least two objects on a support member and then operates a specular sensor array to obtain image data of the two objects on the support member. The two objects have different predetermined heights to enable a controller in the printer to identify the mass or volume of the material drops forming the objects to adjust operational parameters of the printer to maintain the mass or volume of the material drops in the predetermined range.

Owner:XEROX CORP

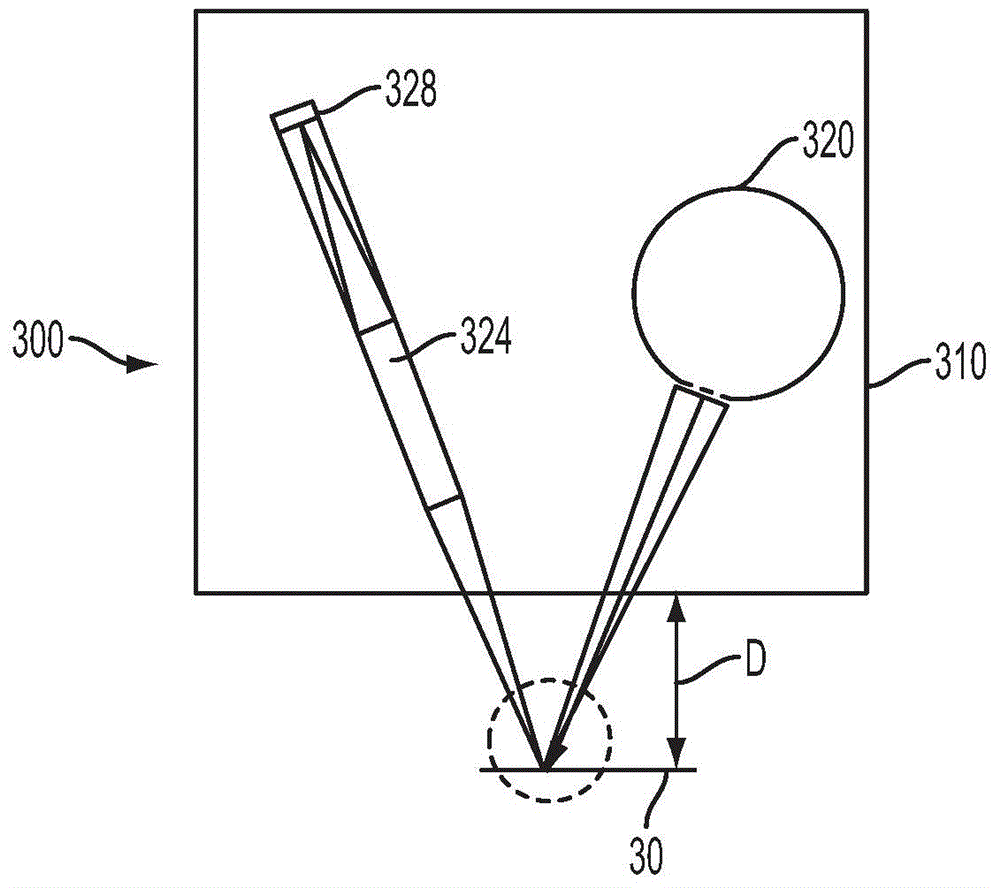

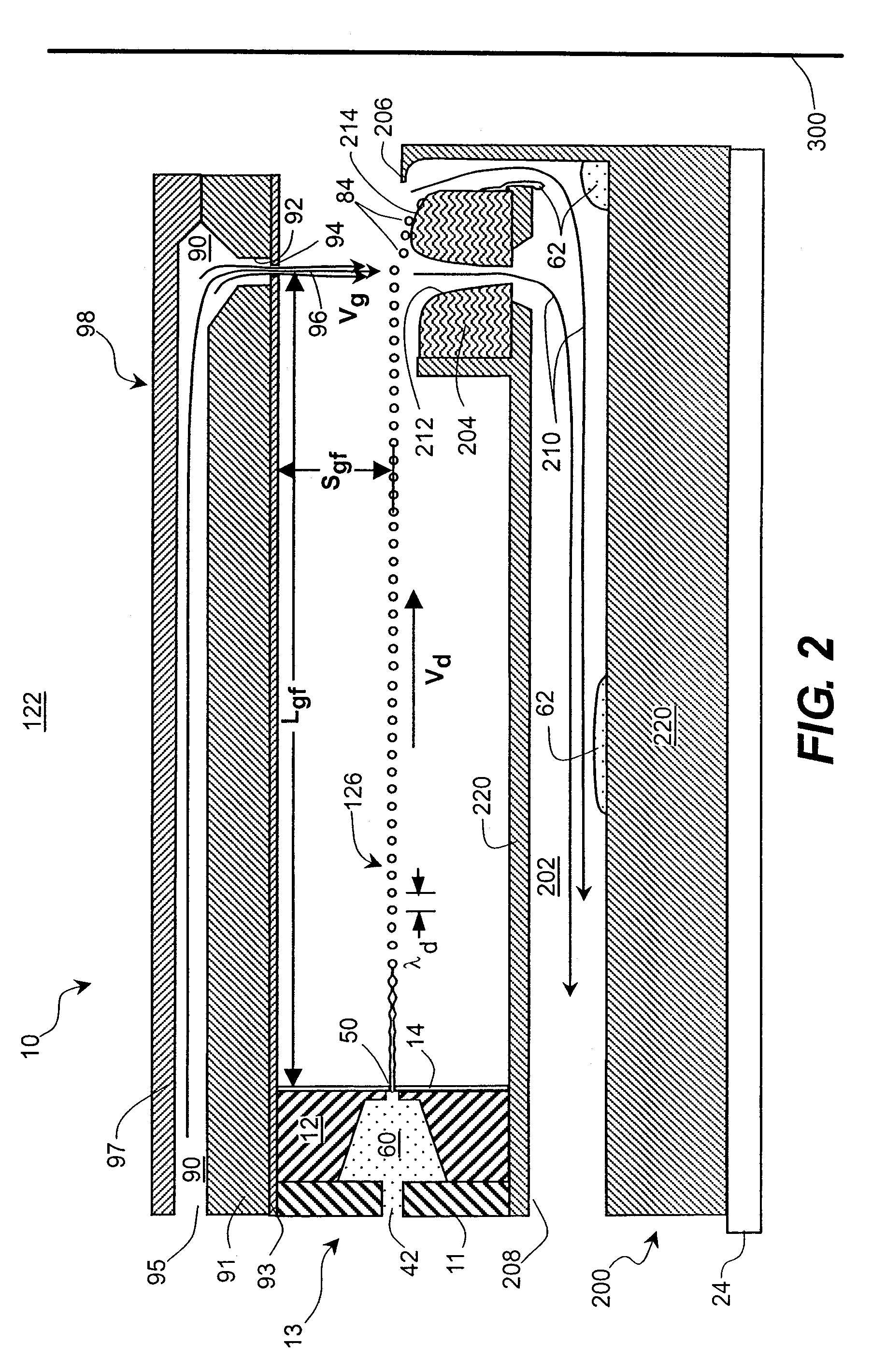

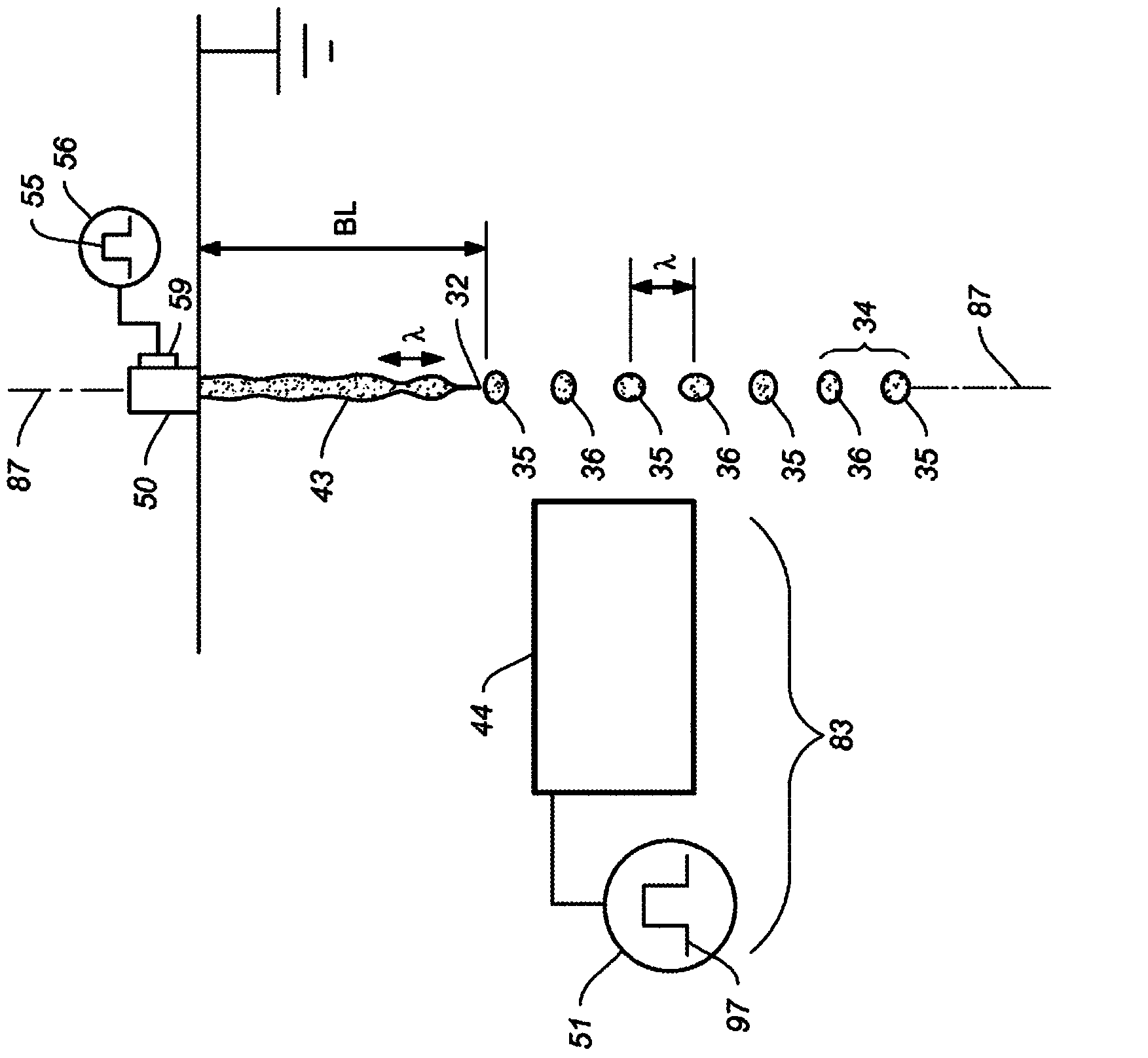

Deflected drop liquid pattern deposition apparatus and methods

Drop deflector apparatus and methods for a continuous drop emission system comprising a plurality of drop nozzles emitting a plurality of continuous streams of a liquid that break up into streams of drops of substantially uniform drop volume having nominal flight paths that are substantially within a nominal flight plane are disclosed. A plurality of path selection elements corresponding to the plurality of continuous streams of drops is provided operable to firstly deflect individual drops from the corresponding continuous stream of drops along a first deflection flight path diverging from the nominal flight path based on pattern data. A plurality of gas nozzles is provided which generate a plurality of localized gas flows, positioned along one of the first deflection flight paths or the nominal flight paths, wherein the localized gas flows are oriented so as to cause a substantial second deflection of one of the firstly deflected drops or the nominal drops in a direction perpendicular to the nominal flight plane without causing a substantial deflection of drops following the other of the first deflection flight paths or the nominal flight paths. Secondly deflected drops are captured before they impinge a receiver medium. An image pattern is thereby deposited by either firstly deflected or undeflected drops.

Owner:EASTMAN KODAK CO

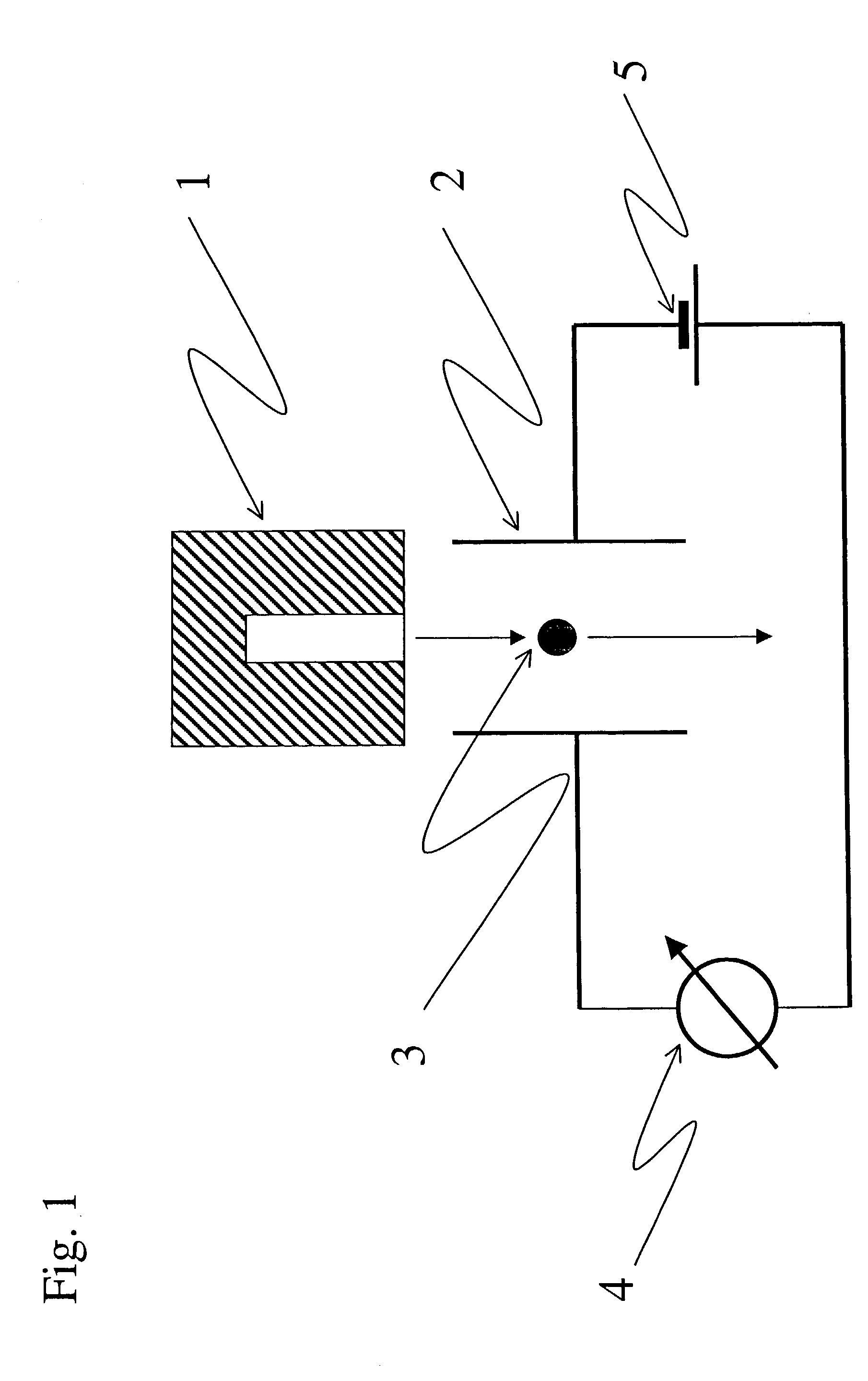

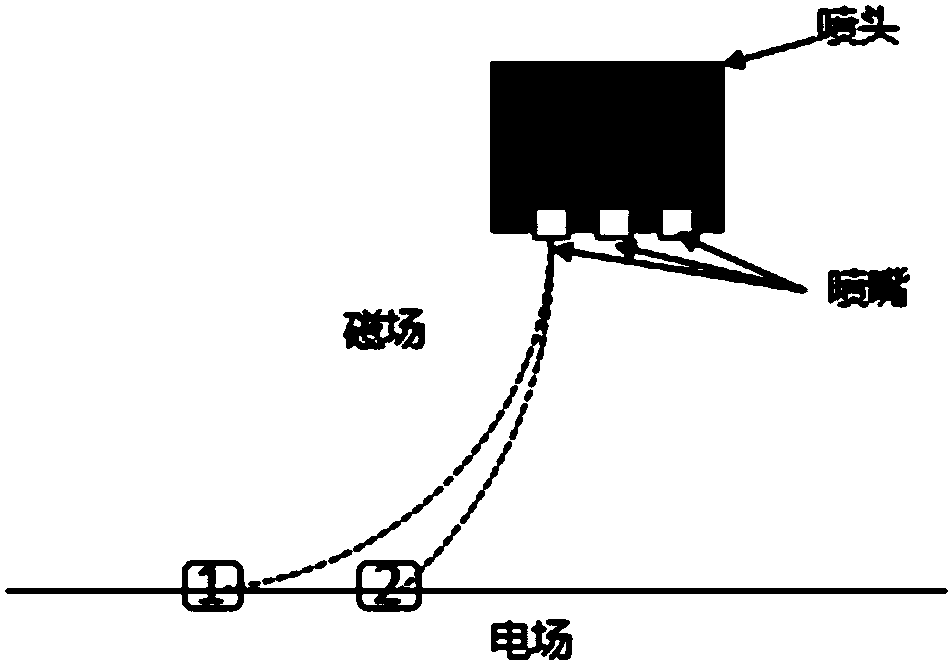

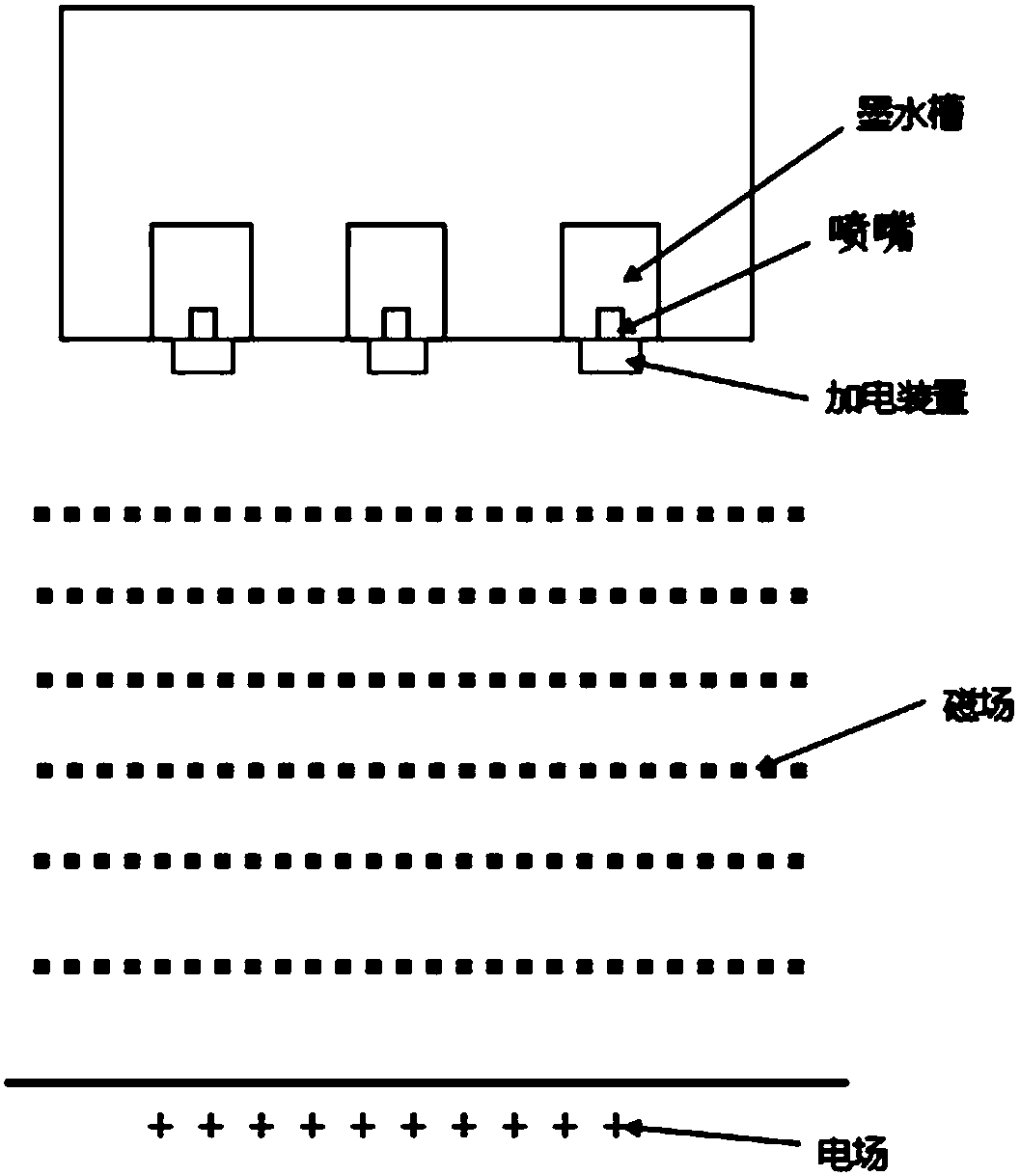

Ink jet printing spray head, ink jet amount measuring system and method and ink jet amount control method

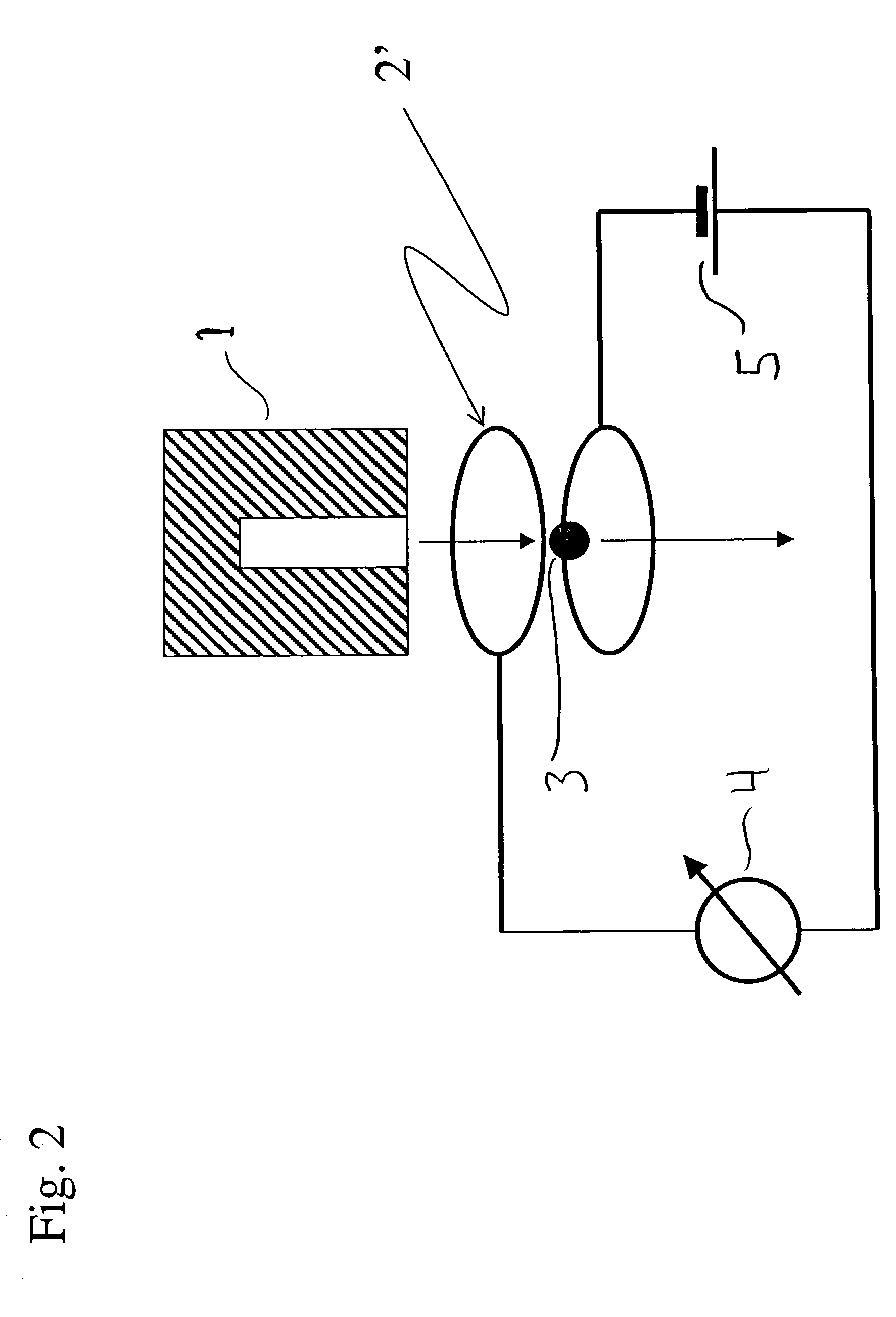

The invention discloses an ink jet printing spray head, an ink jet amount measuring system and method and an ink jet amount control method. The ink jet printing spray head comprises a cavity used forcontaining ink, and multiple nozzles communicating with the cavity and used for conducting ink jet printing. The printing spray head further comprises an electricity applying device used for applyingelectric charges to ink drops passing through the nozzles, ink jet signals corresponding to the preset ink drop amount are applied to the nozzles. The charged ink drops pass through a magnetic field so that the dropping track of the ink drops can be deflected, the ink drop amount is calculated according to the ink drop dropping point positions, ink jet signals are adjusted after the ink jet amountis compared with the preset amount, and therefore the ink drops can have the preset amount. By means of the ink jet printing spray head, the ink jet amount measuring system and method and the ink jetamount control method, the deflection principle of charged particles in the magnetic field is used, the ink jet signals are changed, and the ink drop dropping positions are calculated and adjusted, so that the ink drop volume is determined, uniformity of the volume is ensured, and the ink jet printing precision of the equipment is improved.

Owner:BOE TECH GRP CO LTD

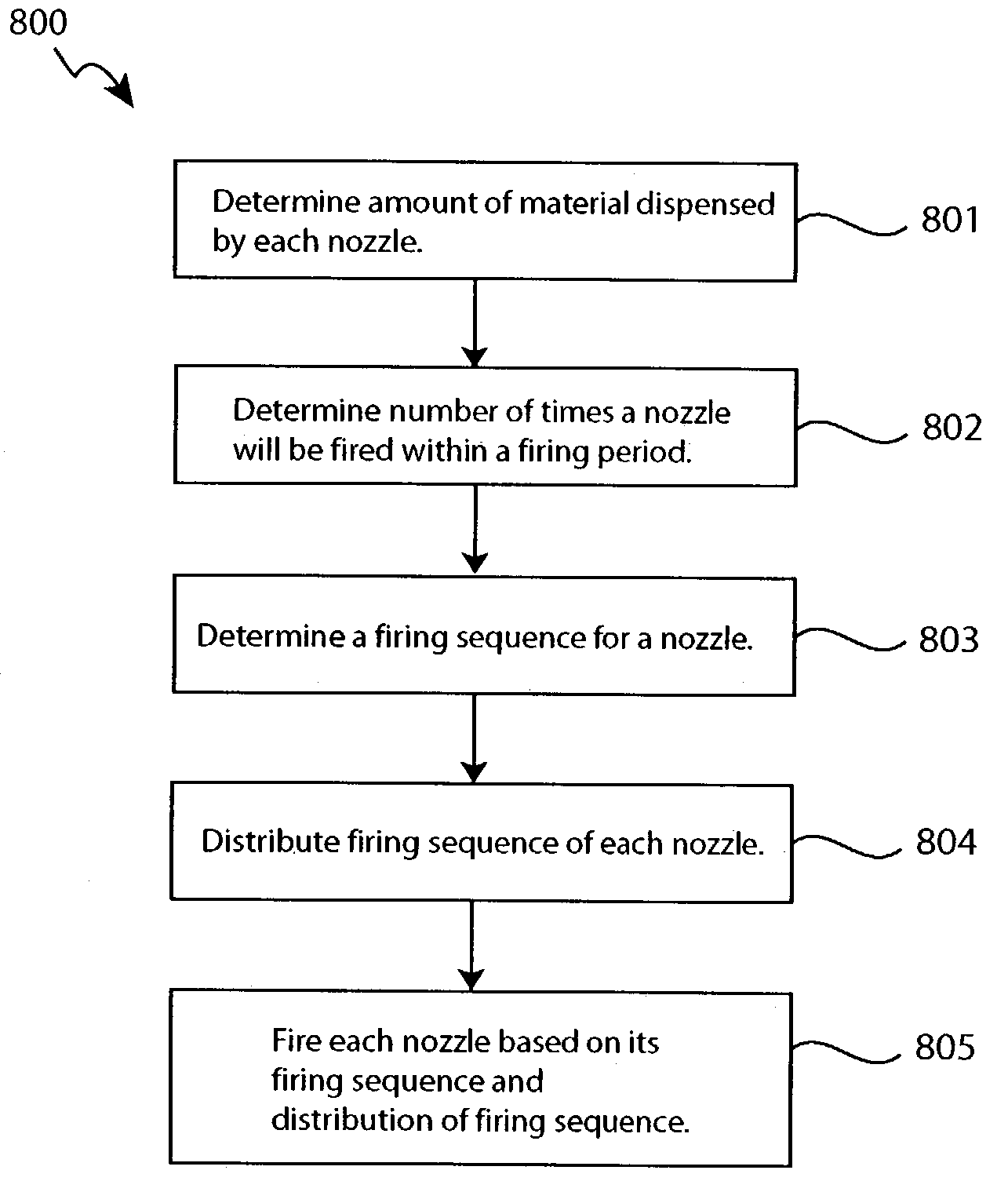

Deposition of integrated circuit fabrication materials using a print head

ActiveUS7091134B1Semiconductor/solid-state device testing/measurementSolid-state devicesDrop volumeIntegrated circuit fabrication

In one embodiment, an integrated circuit (IC) fabrication material is dispensed from a print head by dividing its nozzles into several groups, and sequentially allowing each group to fire. The nozzles may be grouped based on the amounts of material they dispense. For example, the nozzles may be grouped by drop volume or drop mass. In one embodiment, an IC fabrication material is dispensed on a substrate by controlling a firing sequence of a nozzle to promote merging of material on the substrate. The firing sequence may also be altered to take into account the firing sequence of adjacent nozzles.

Owner:NOVELLUS SYSTEMS

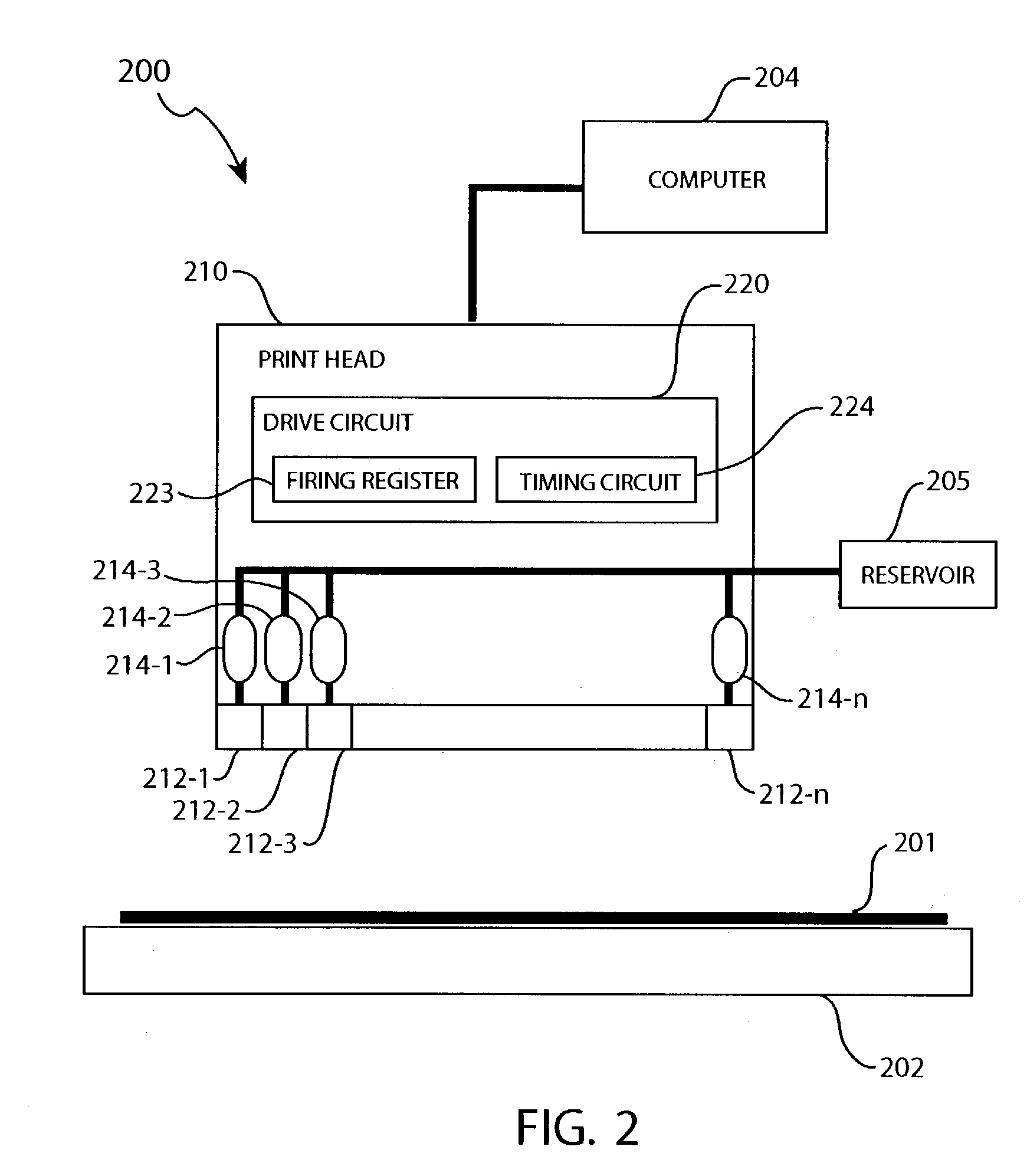

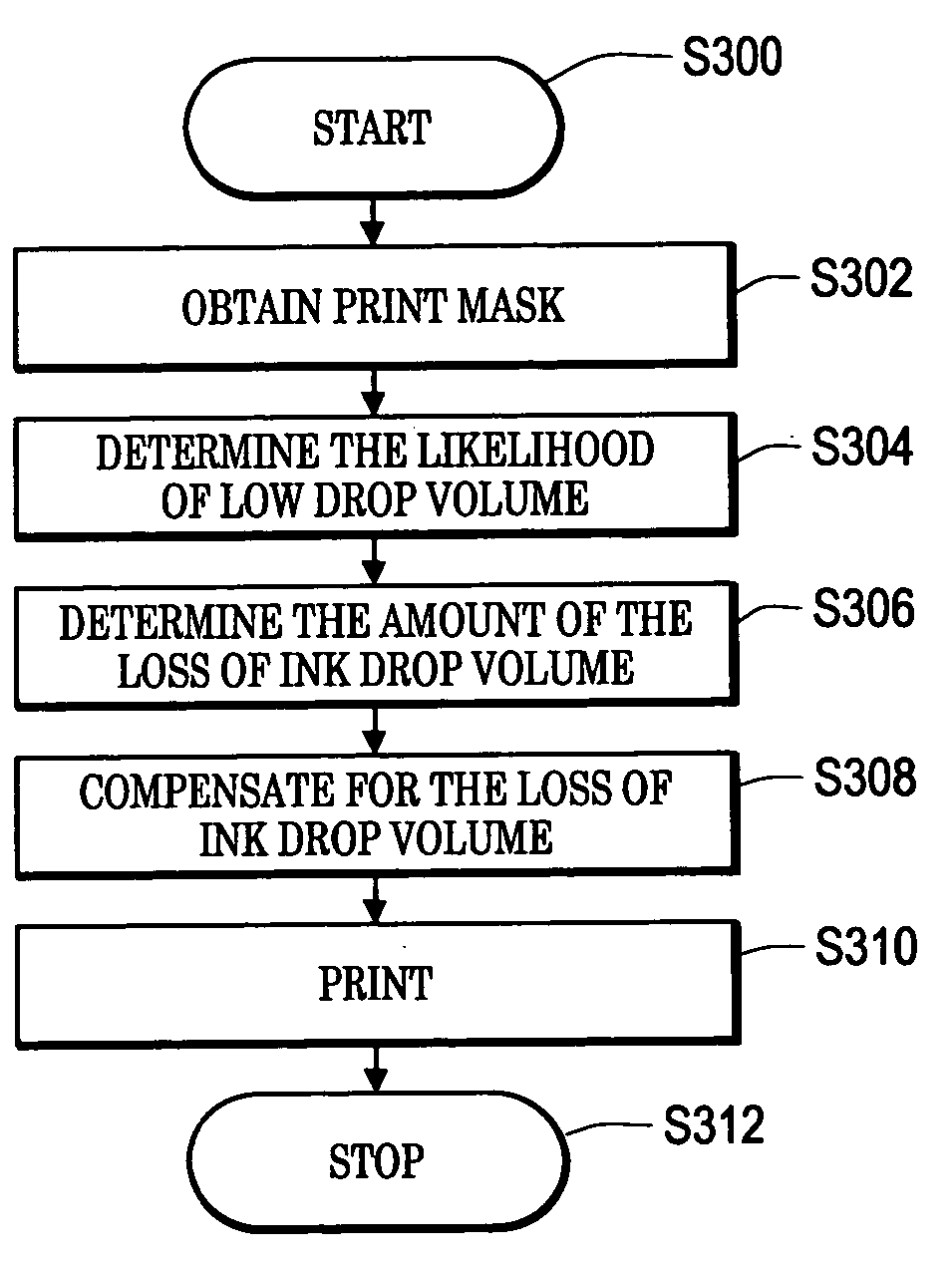

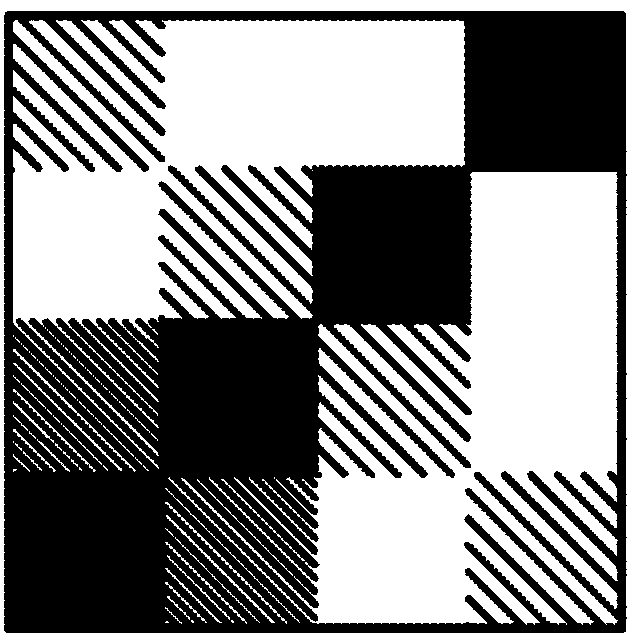

Image processing to mask low drop volume defects in inkjet printers

InactiveUS20050146543A1Low drop volume print defectVisual presentationOther printing apparatusImaging processingInk printer

A method and apparatus for masking low drop volume print defects in inkjet printers. In one exemplary embodiment, the invention obtains a print mask, determines a likelihood that an individual ink ejection nozzle will produce a low drop volume, determining a correction factor, and compensates for the low drop volume. The low drop volume may be compensated by increasing the drop intensity, modifying the print mask, or combinations of both.

Owner:FUJIFILM BUSINESS INNOVATION CORP

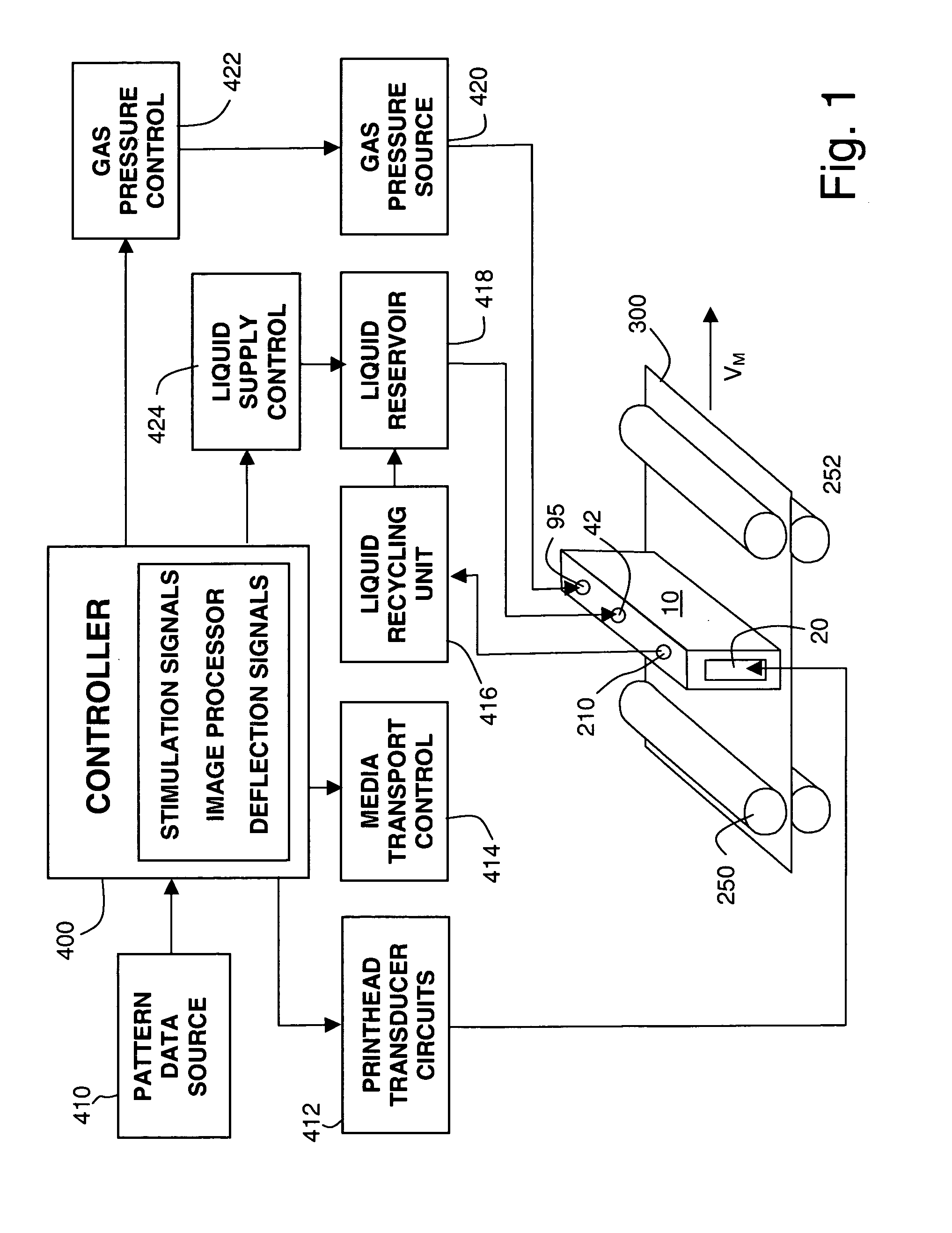

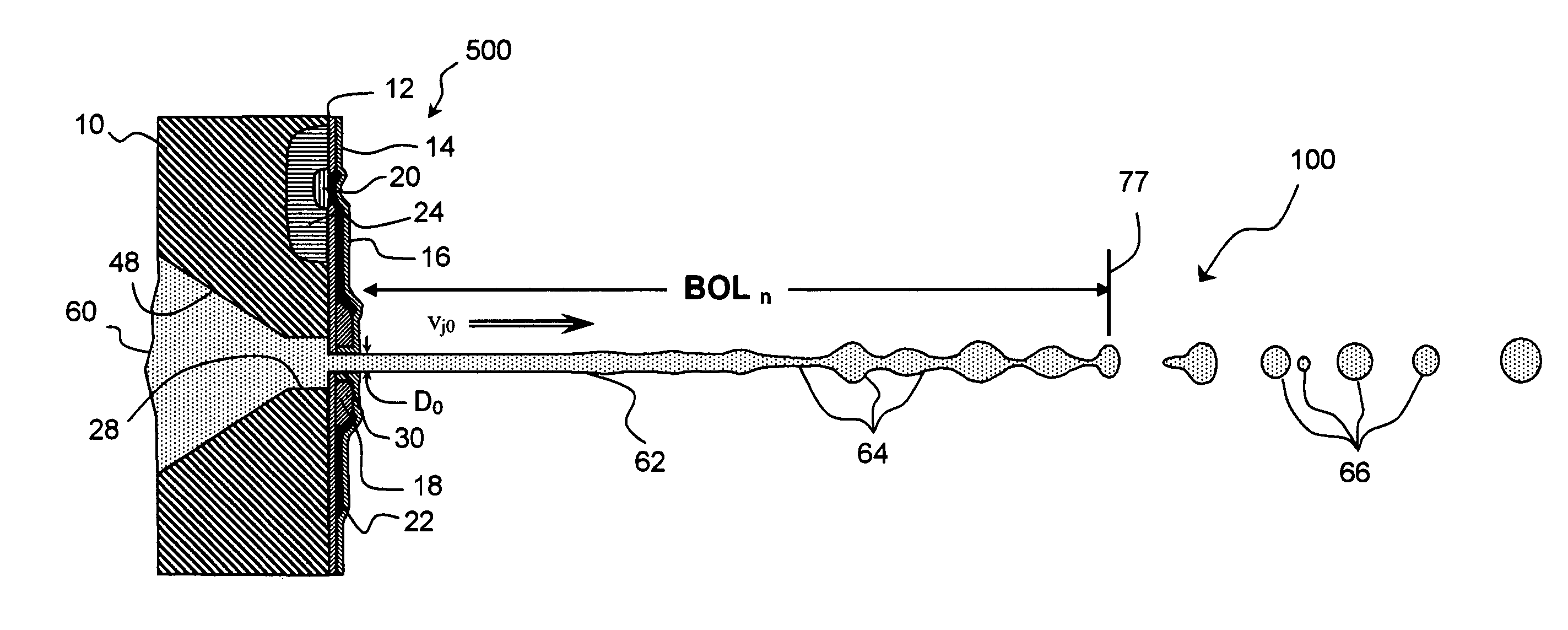

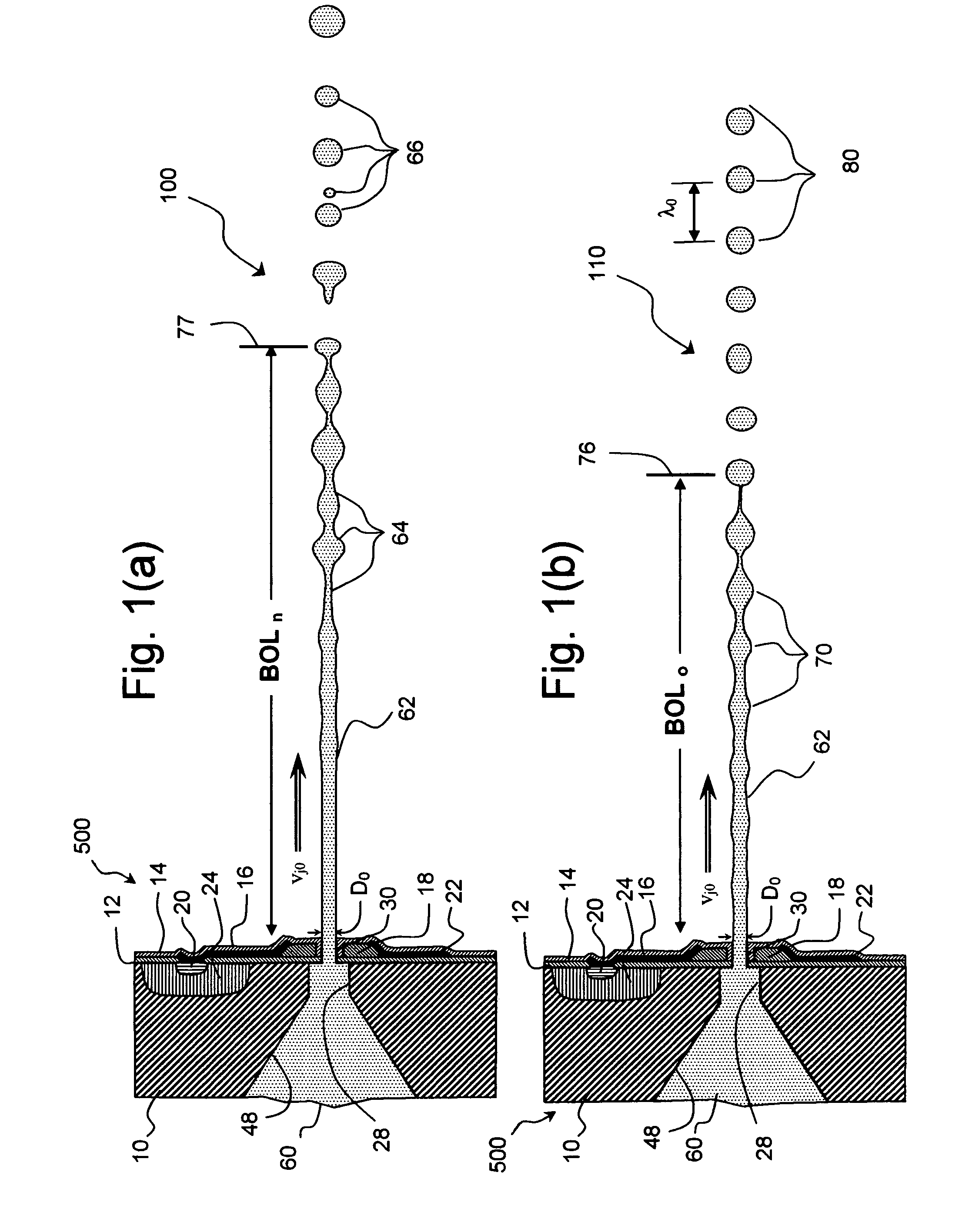

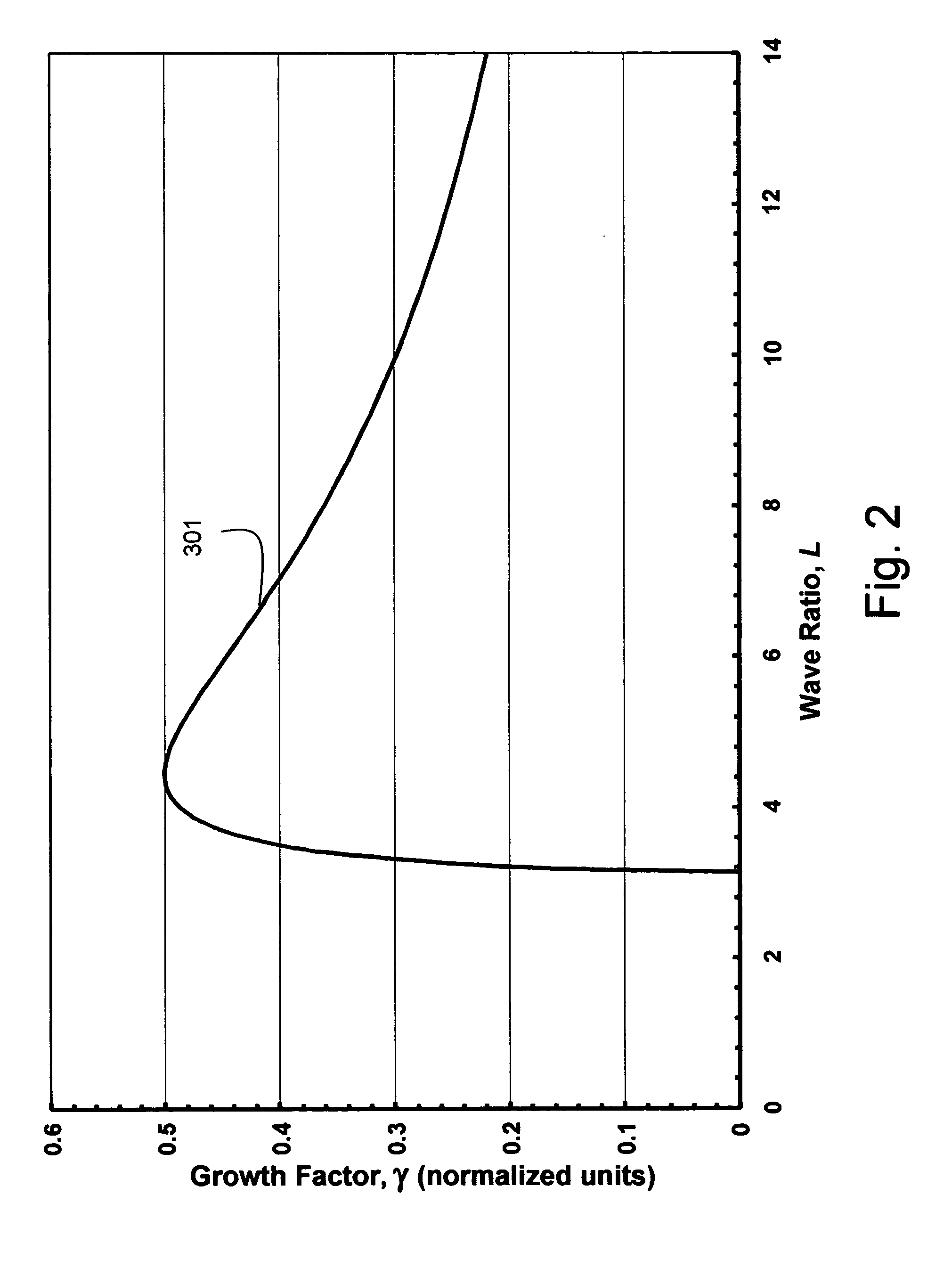

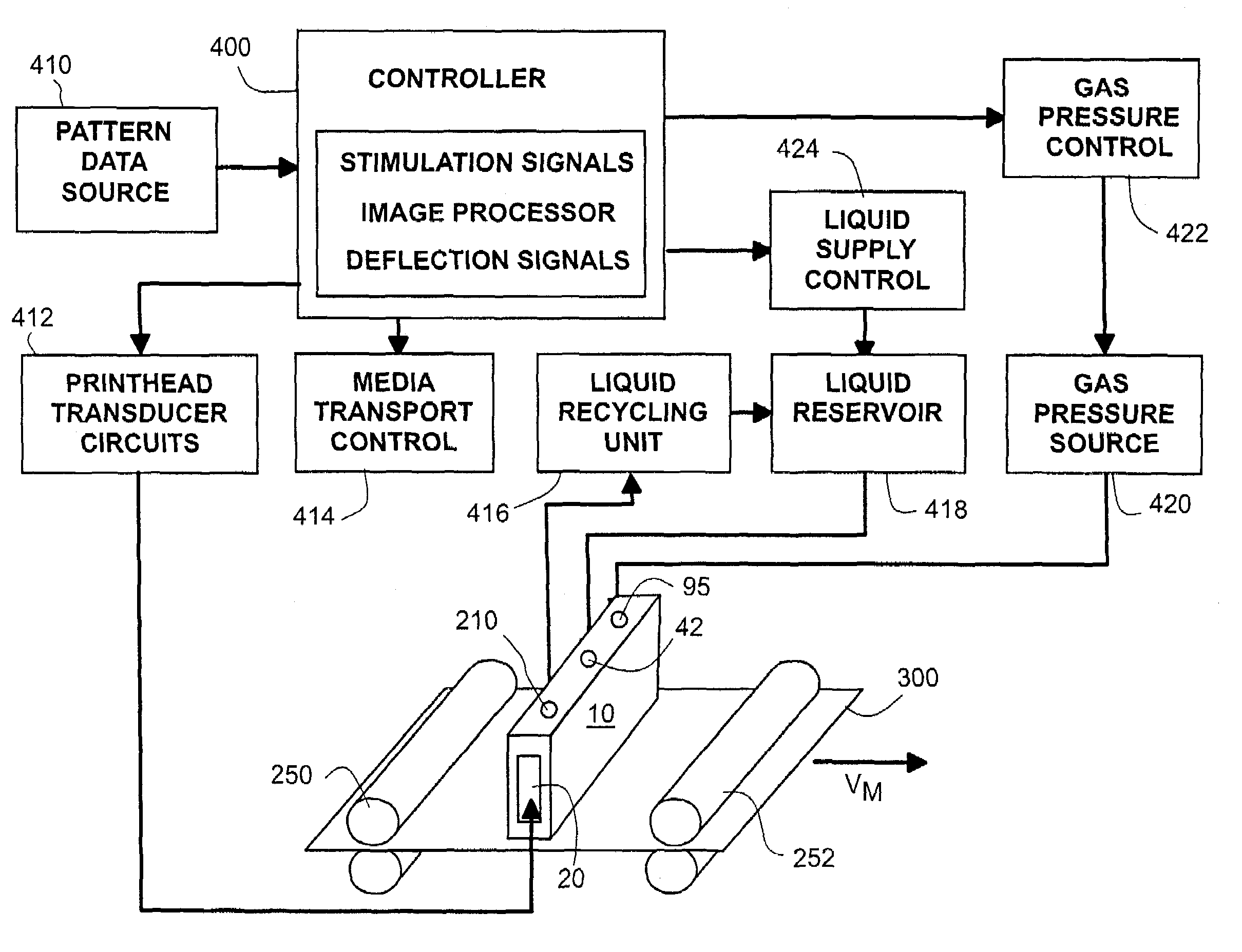

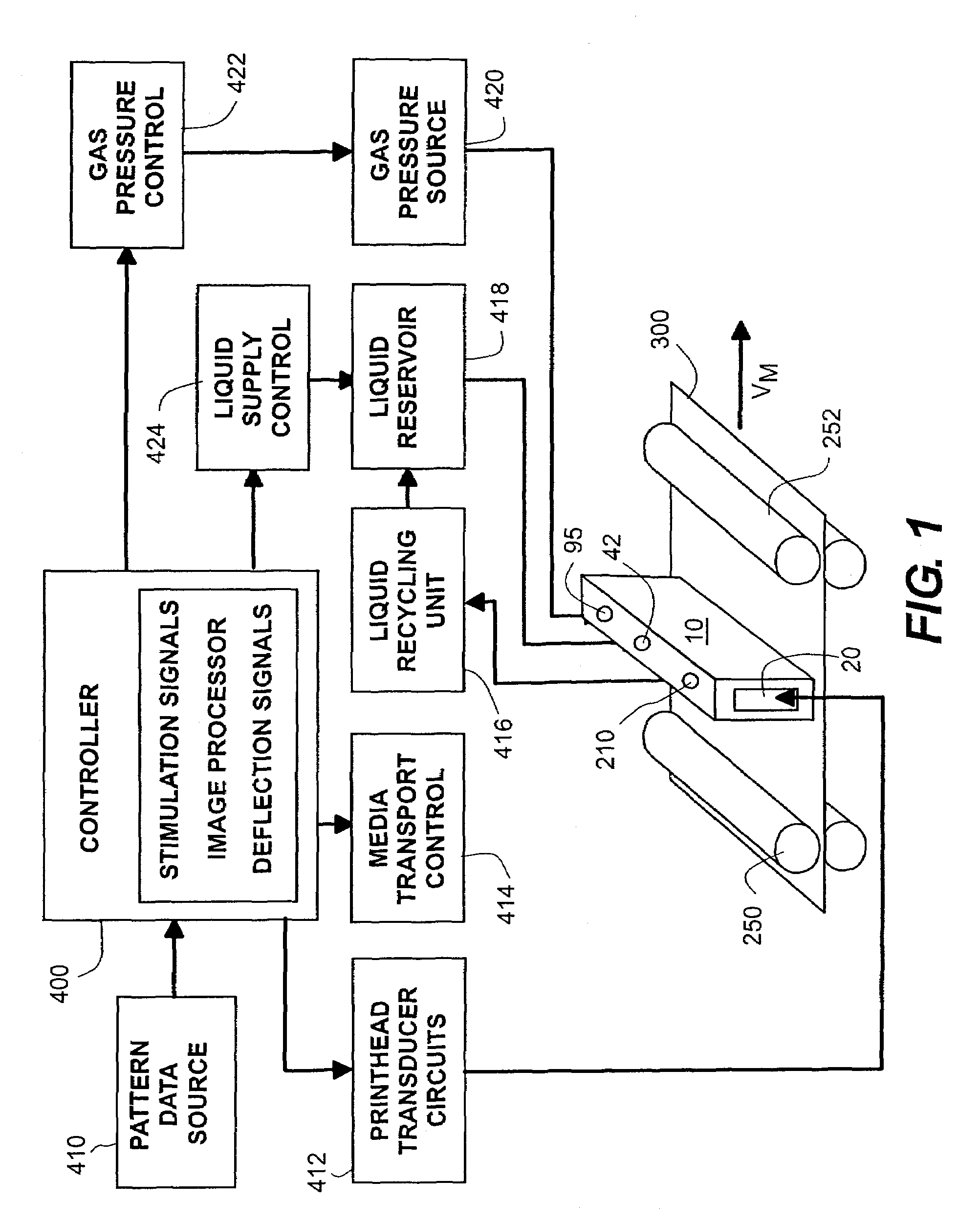

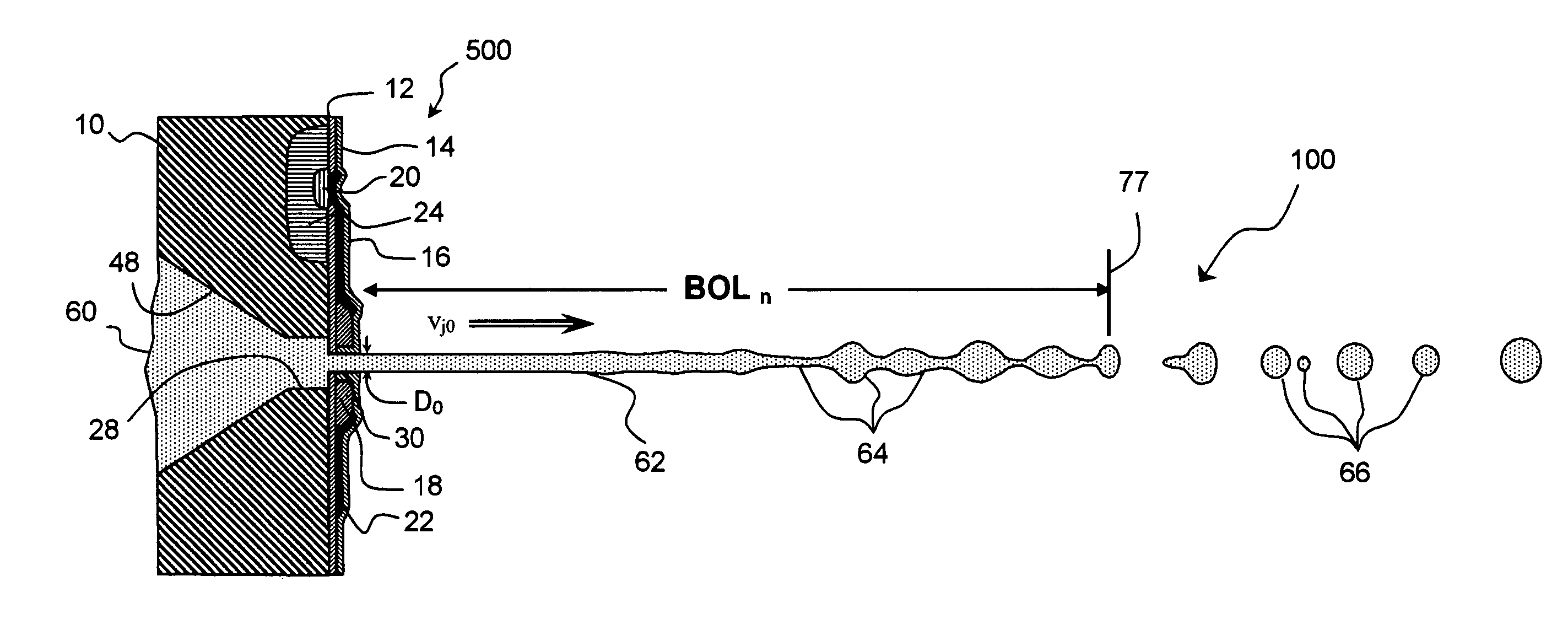

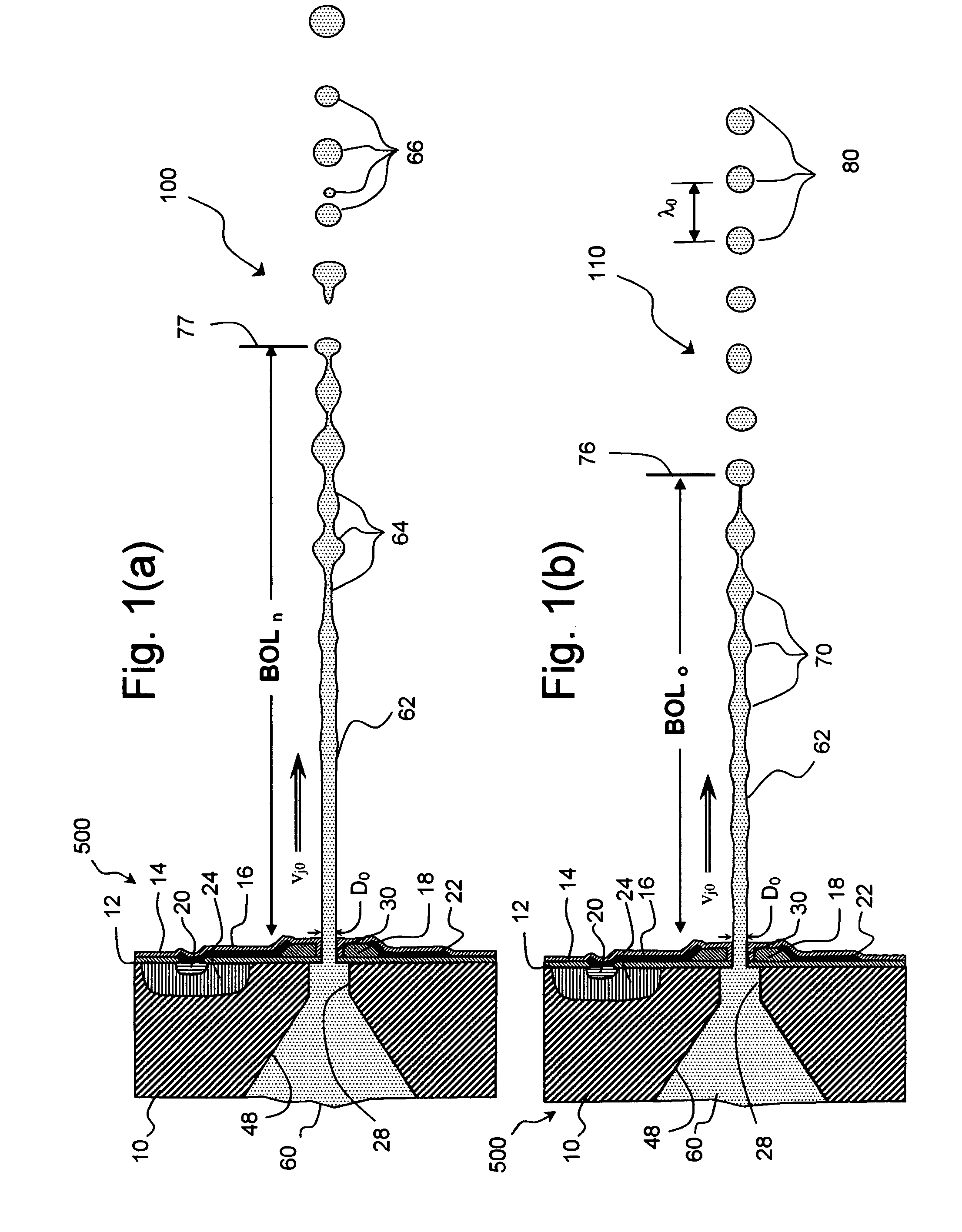

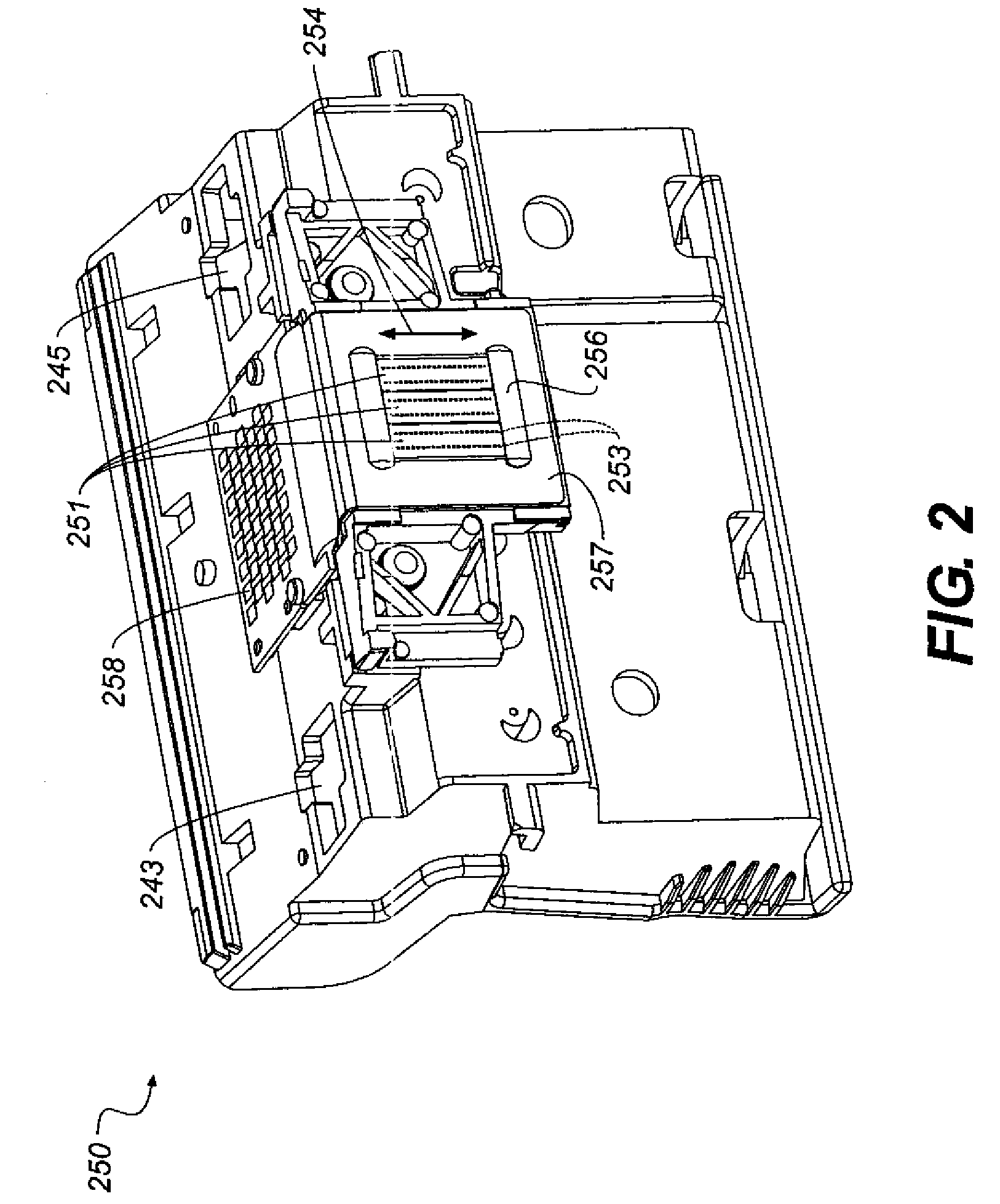

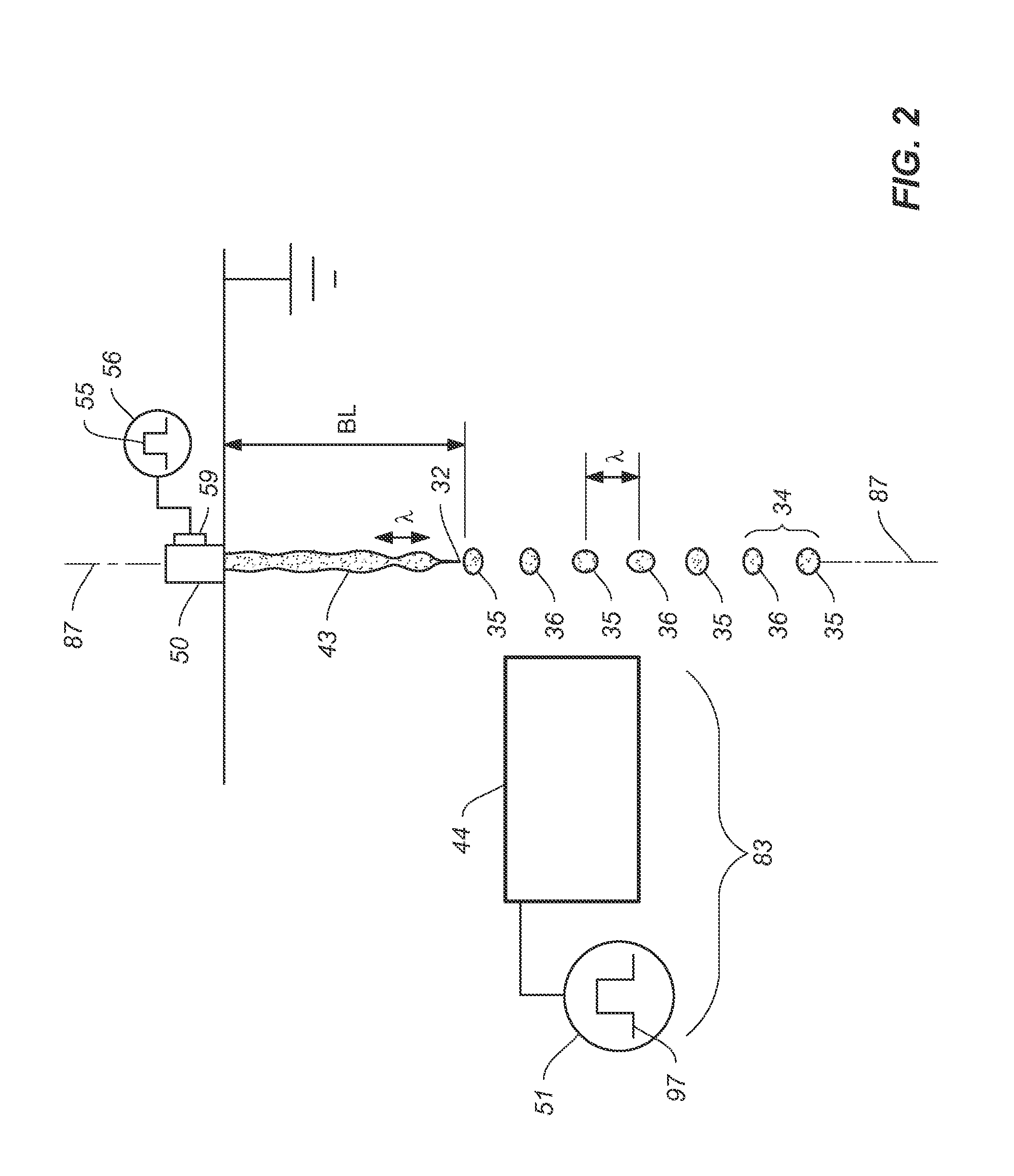

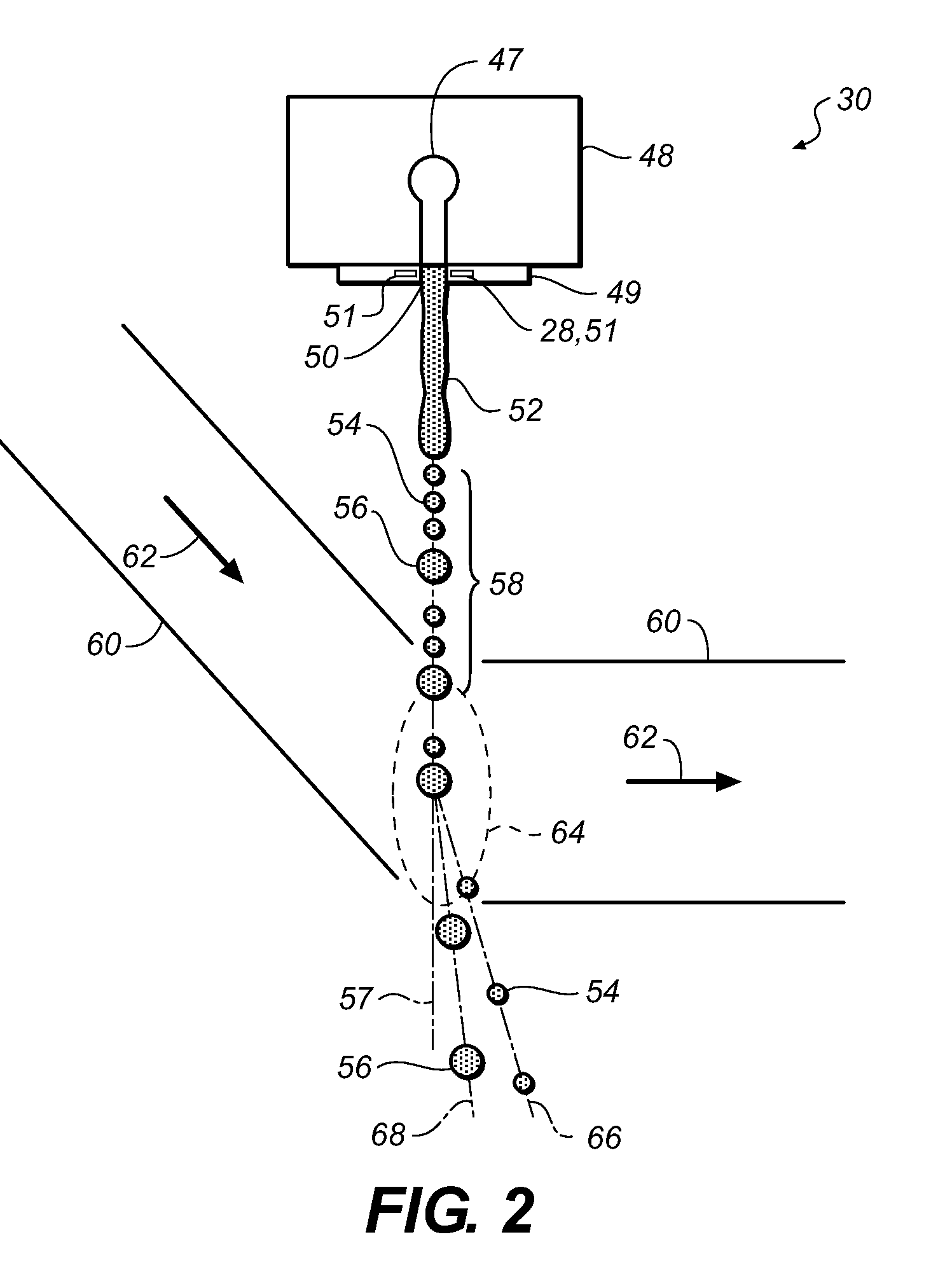

High speed, high quality liquid pattern deposition apparatus

InactiveUS7249829B2Fast processingMaintaining drop volume uniformityInking apparatusElectrical resistance and conductanceLiquid layer

A drop deposition apparatus for laying down a patterned liquid layer on a receiver substrate, for example, a continuous ink jet printer, is disclosed. The liquid deposition apparatus comprises a drop emitter containing a positively pressurized liquid in flow communication with a linear array of nozzles for emitting a plurality of continuous streams of liquid having nominal stream velocity vj0, wherein the plurality of nozzles have effective nozzle diameters D0 and extend in an array direction with an effective nozzle spacing Ly. Resistive heater apparatus is adapted to transfer thermal energy pulses of period τ0 to the liquid in flow communication with the plurality of nozzles sufficient to cause the break-off of the plurality of continuous streams of liquid into a plurality of streams of drops of predetermined nominal drop volume V0. Relative motion apparatus is adapted to move the drop emitter and receiver substrate relative to each other in a process direction at a process velocity S so that individual drops are addressable to the receiver substrate with a process direction addressability, Ap=τ0S. The effective nozzle spacing is less than 85 microns, the process speed S is at least 1 meter / sec and the addressability, Ap, of individual drops at the receiver substrate in the process direction is less than 6 microns. Drop deposition apparatus is disclosed wherein the predetermined volumes of drops include drops of a unit volume, V0, and drops having volumes that are integer multiples of the unit volume, mV0. Further apparatus is adapted to inductively charge at least one drop and to cause electric field deflection of charged drops.

Owner:EASTMAN KODAK CO

Deflected drop liquid pattern deposition apparatus and methods

Drop deflector apparatus and methods for a continuous drop emission system comprising a plurality of drop nozzles emitting a plurality of continuous streams of a liquid that break up into streams of drops of substantially uniform drop volume having nominal flight paths that are substantially within a nominal flight plane are disclosed. A plurality of path selection elements corresponding to the plurality of continuous streams of drops is provided operable to firstly deflect individual drops from the corresponding continuous stream of drops along a first deflection flight path diverging from the nominal flight path based on pattern data. A plurality of gas nozzles is provided which generate a plurality of localized gas flows, positioned along one of the first deflection flight paths or the nominal flight paths, wherein the localized gas flows are oriented so as to cause a substantial second deflection of one of the firstly deflected drops or the nominal drops in a direction perpendicular to the nominal flight plane without causing a substantial deflection of drops following the other of the first deflection flight paths or the nominal flight paths. Secondly deflected drops are captured before they impinge a receiver medium. An image pattern is thereby deposited by either firstly deflected or undeflected drops.

Owner:EASTMAN KODAK CO

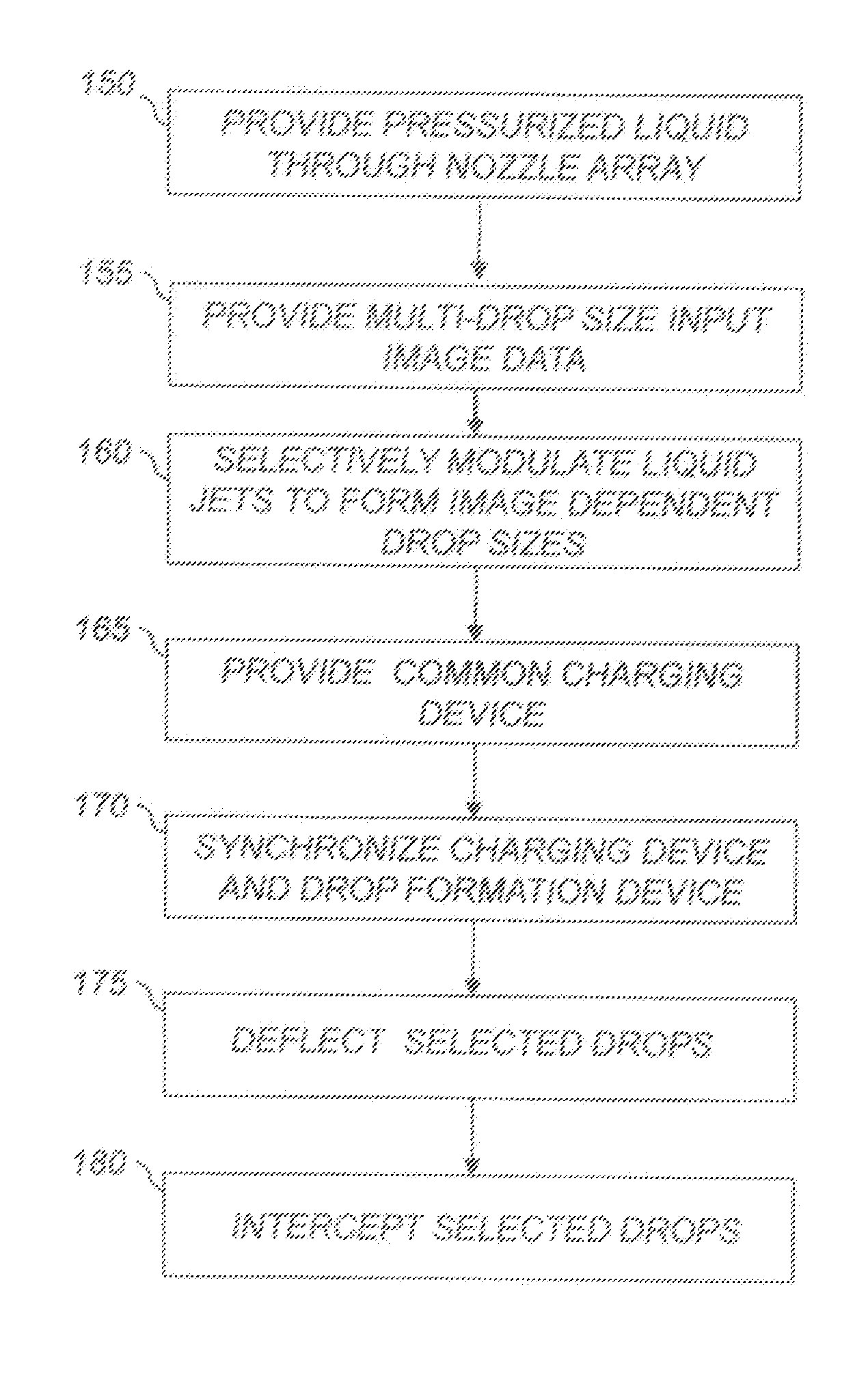

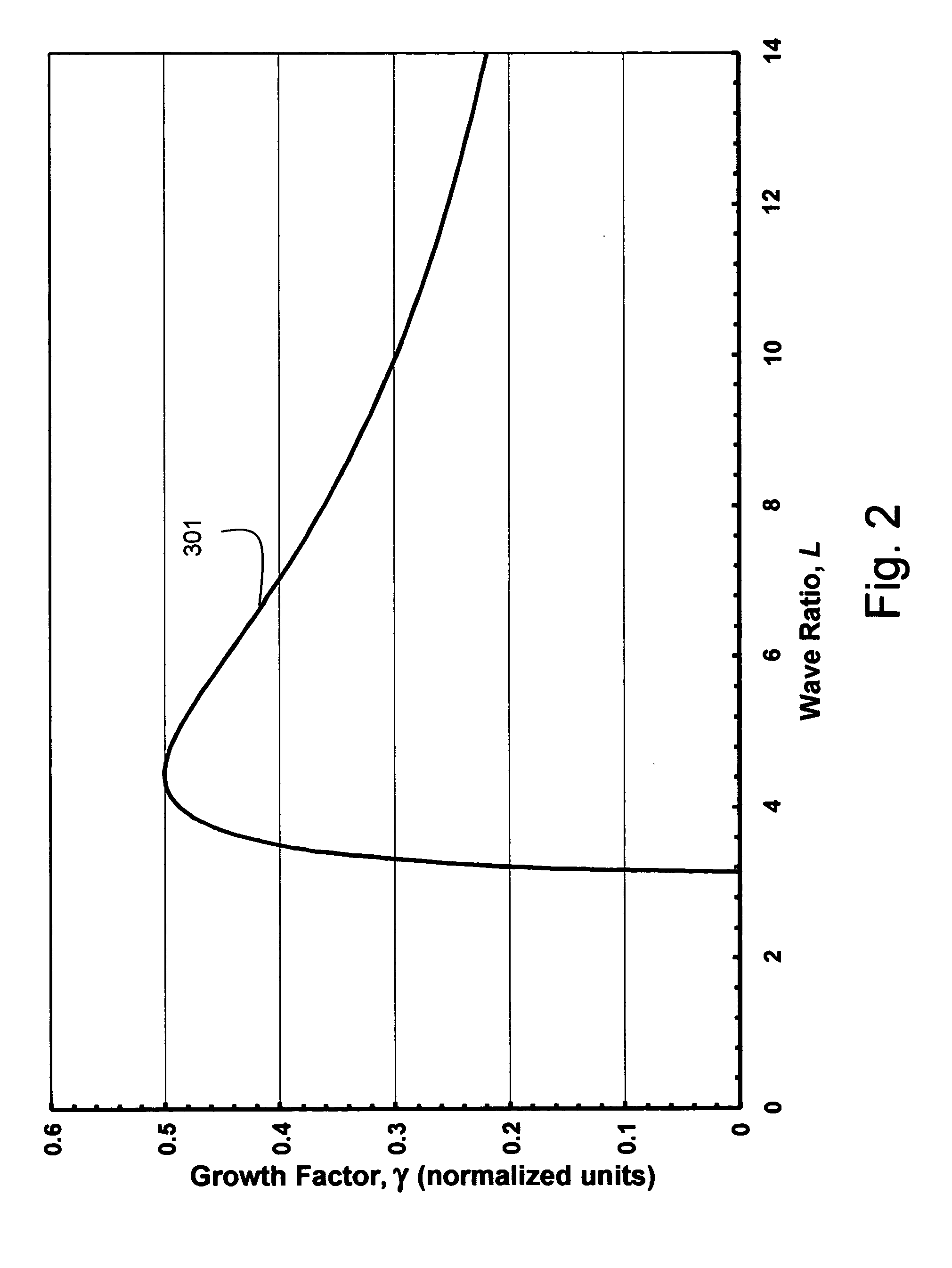

Variable drop volume continuous liquid jet printing

A liquid jet includes a fundamental period of jet break off. A print period is defined as N times the fundamental period of jet break off where N is an integer greater than 1. Input image data is provided having M levels per input image pixel including a non-print level where M is an integer and 2<M≦N+1. A charging device waveform, independent of the input image data, repeats during print periods and includes print and non-print drop voltage states. A drop formation device waveform, having a period equal to the print period, is selected in response to the input image data to form from the jet print drops having a volume corresponding to an input image pixel level. The devices are synchronized to produce a print drop charge to mass ratio and a non-print drop charge to mass ratio on drops breaking off from the jet.

Owner:EASTMAN KODAK CO

High speed, high quality liquid pattern deposition apparatus

InactiveUS20060262168A1Fast processingMaintaining drop volume uniformityInking apparatusLiquid layerThermal energy

A drop deposition apparatus for laying down a patterned liquid layer on a receiver substrate, for example, a continuous ink jet printer, is disclosed. The liquid deposition apparatus comprises a drop emitter containing a positively pressurized liquid in flow communication with a linear array of nozzles for emitting a plurality of continuous streams of liquid having nominal stream velocity vj0, wherein the plurality of nozzles have effective nozzle diameters D0 and extend in an array direction with an effective nozzle spacing Ly. Resistive heater apparatus is adapted to transfer thermal energy pulses of period τ0 to the liquid in flow communication with the plurality of nozzles sufficient to cause the break-off of the plurality of continuous streams of liquid into a plurality of streams of drops of predetermined nominal drop volume V0. Relative motion apparatus is adapted to move the drop emitter and receiver substrate relative to each other in a process direction at a process velocity S so that individual drops are addressable to the receiver substrate with a process direction addressability, Ap=τ0S. The effective nozzle spacing is less than 85 microns, the process speed S is at least 1 meter / sec and the addressability, Ap, of individual drops at the receiver substrate in the process direction is less than 6 microns. Drop deposition apparatus is disclosed wherein the predetermined volumes of drops include drops of a unit volume, V0, and drops having volumes that are integer multiples of the unit volume, mV0. Further apparatus is adapted to inductively charge at least one drop and to cause electric field deflection of charged drops.

Owner:EASTMAN KODAK CO

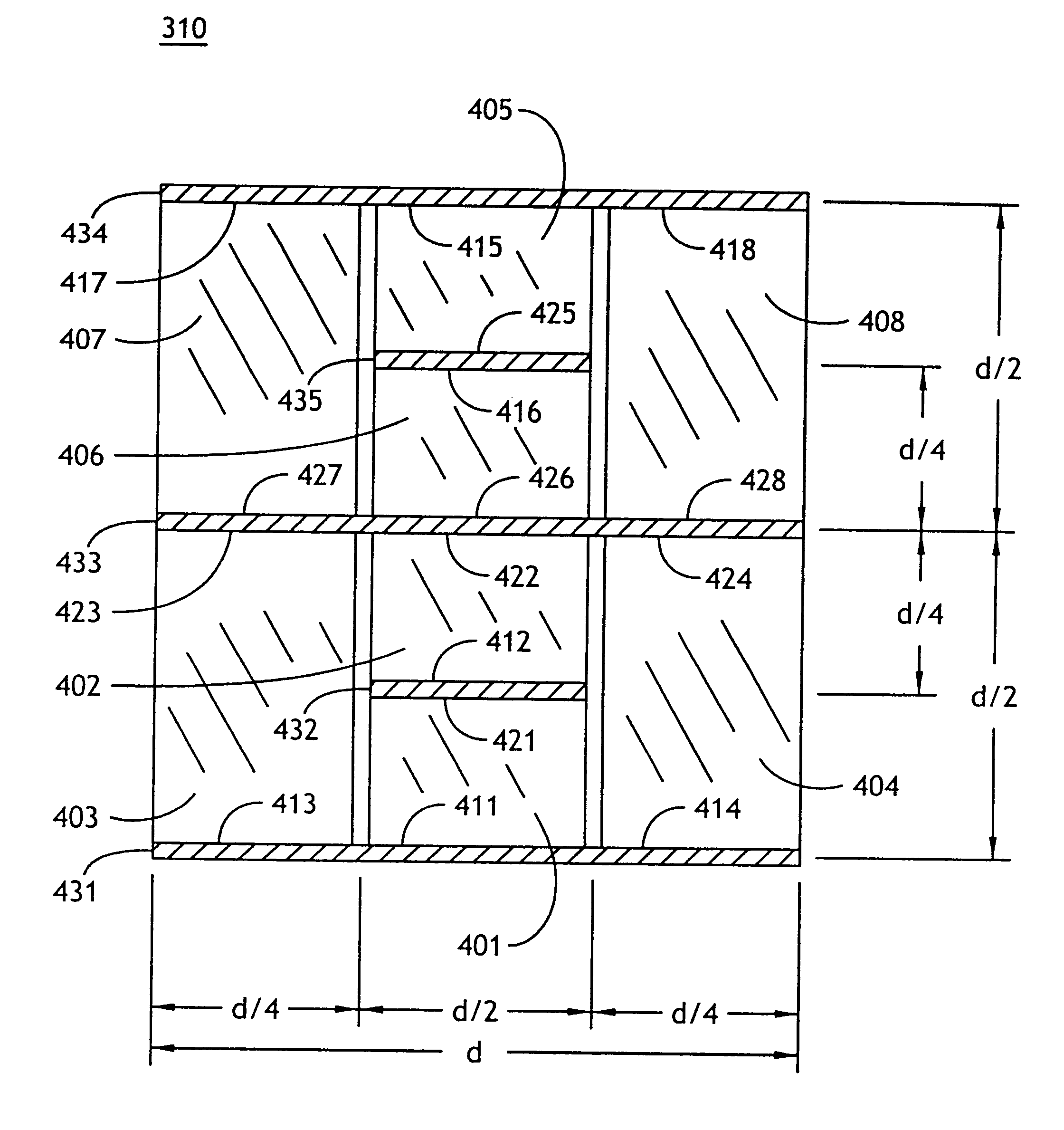

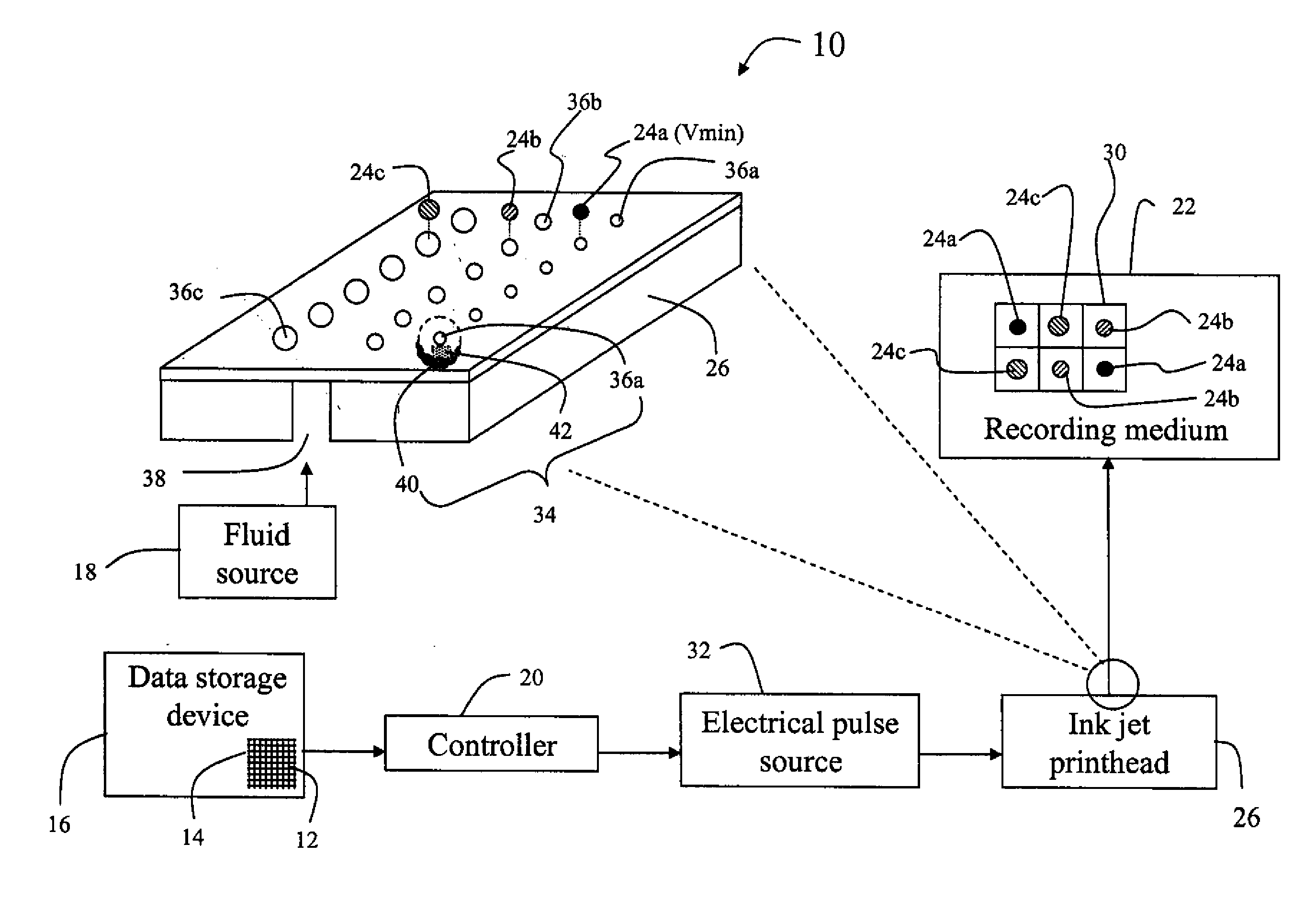

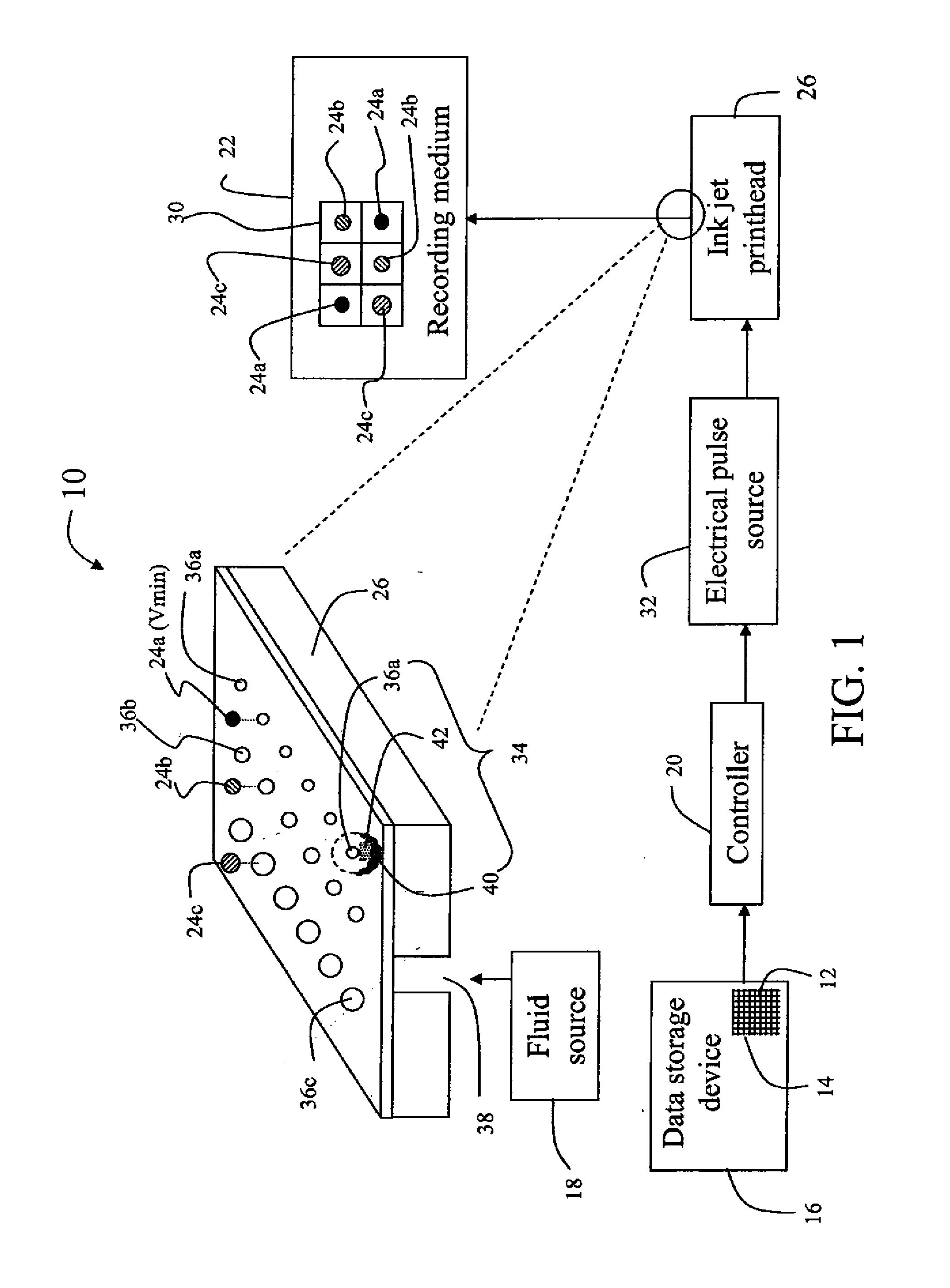

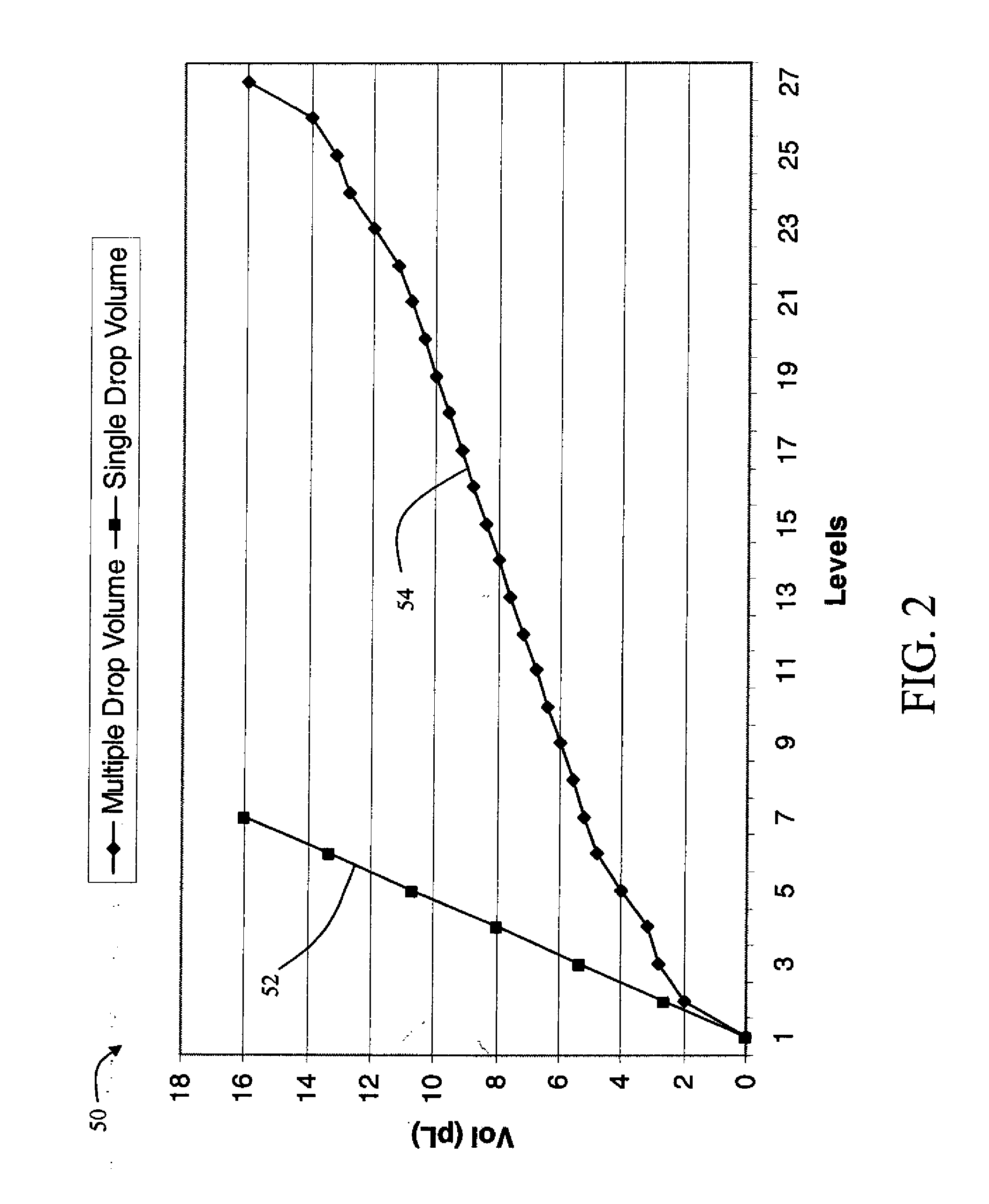

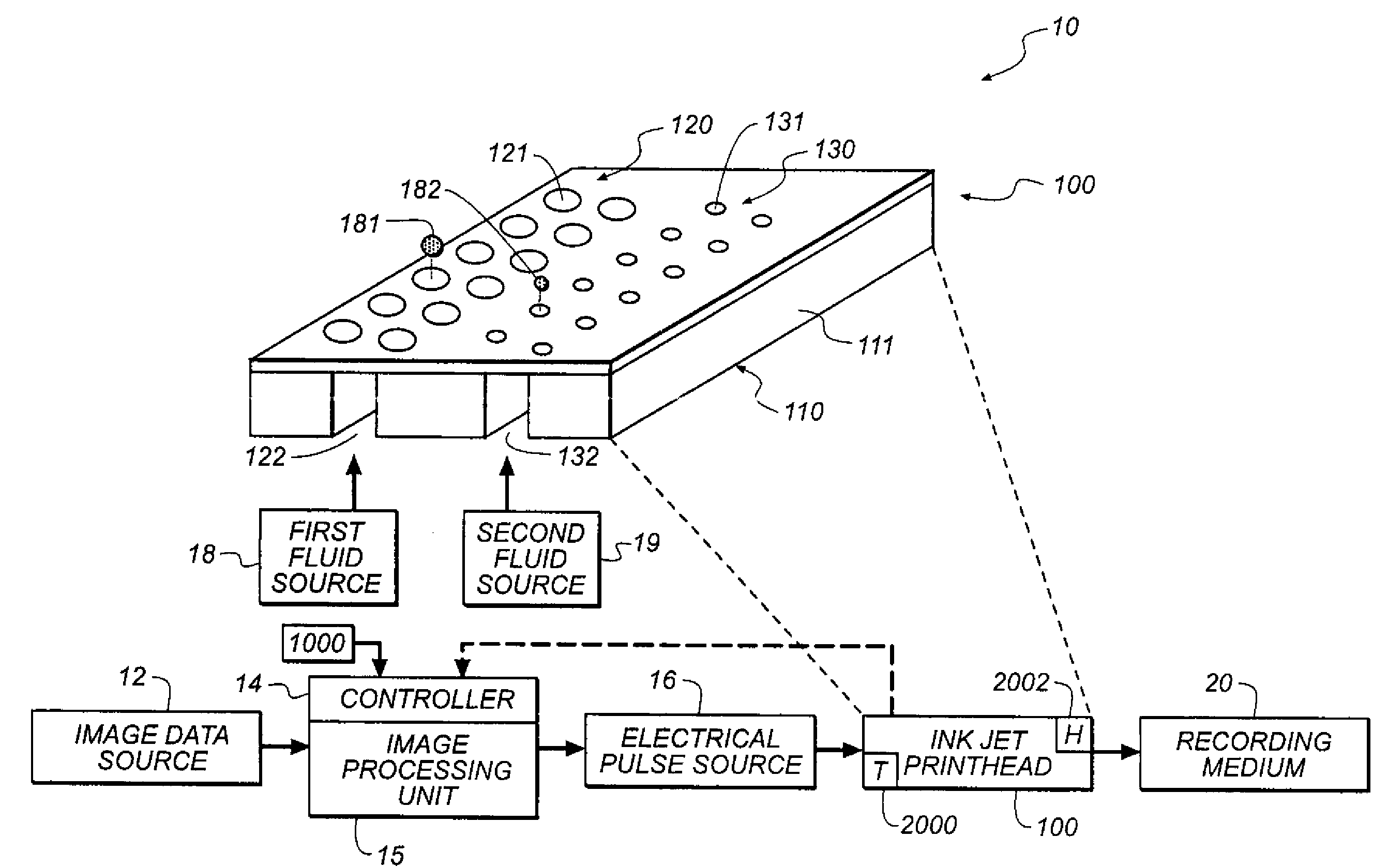

Inkjet printhead and method of printing with multiple drop volumes

A printhead and a method of ejecting liquid droplets are provided. The method includes providing a printhead operable to eject liquid drops having a plurality of drop volumes Vi, for i equal to 1 through n, where n≧2, with Vj>Vi when j>i. One of the plurality of drop volumes is a minimum drop volume Vmin, and a difference in drop volumes between successively larger drops equals (Vk+1−Vk) which is less than Vmin, for k equal to 1 through n-1. The method also includes ejecting liquid drops through the printhead.

Owner:EASTMAN KODAK CO

Drop volume compensation for ink supply variation

InactiveUS20090322822A1Maintain image qualityReducing unintended variationOther printing apparatusImaging qualityEngineering

The present invention relates to a method that enables image quality of a printed image to be maintained by reducing unintended variations in drop volume, through the adjustment of ink drop ejecting conditions depending on the amount of ink remaining in an ink tank chamber or reservoir, and / or the ink demand for printing an image. The method of printing of the present invention comprises: providing a printhead in fluid communication with an ink chamber or reservoir; detecting at least one parameter related to an amount of negative pressure provided to the printhead; and adjusting an ink drop ejecting condition of the printhead as a function of the parameter so that an amount of variation in size of ejected ink drop is reduced.

Owner:EASTMAN KODAK CO

Variable drop volume continuous liquid jet printing

A liquid jet includes a fundamental period of jet break off. A print period is defined as N times the fundamental period of jet break off where N is an integer greater than 1. Input image data is provided having M levels per input image pixel including a non-print level where M is an integer and 2<M≦N+1. A charging device waveform, independent of the input image data, repeats during print periods and includes print and non-print drop voltage states. A drop formation device waveform, having a period equal to the print period, is selected in response to the input image data to form from the jet print drops having a volume corresponding to an input image pixel level. The devices are synchronized to produce a print drop charge to mass ratio and a non-print drop charge to mass ratio on drops breaking off from the jet.

Owner:EASTMAN KODAK CO

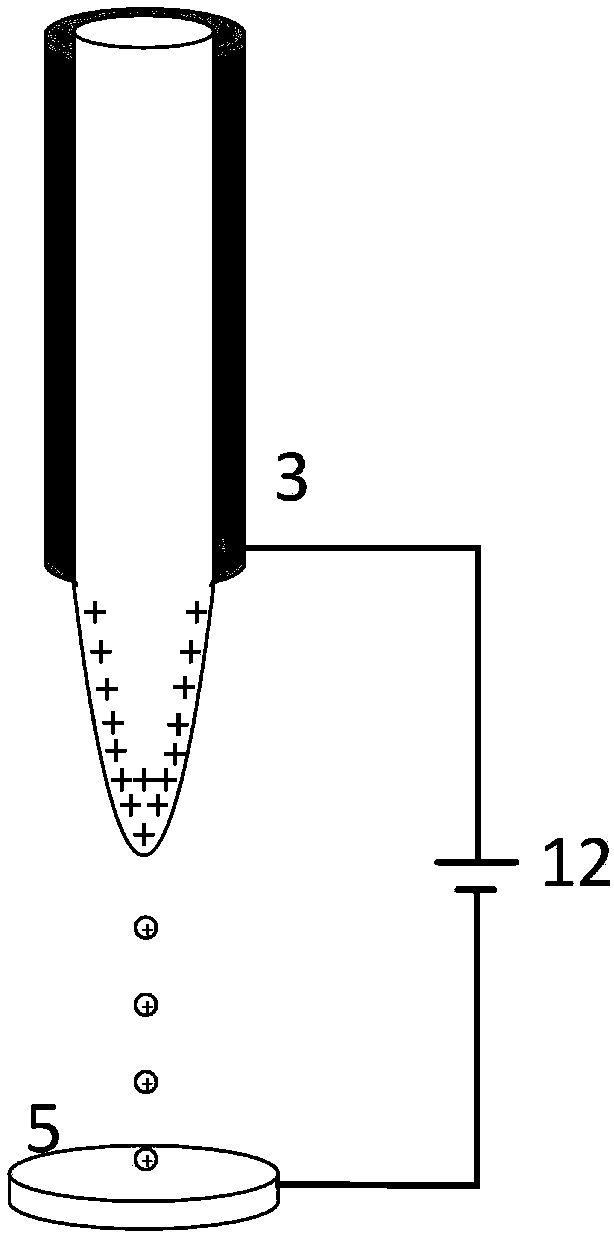

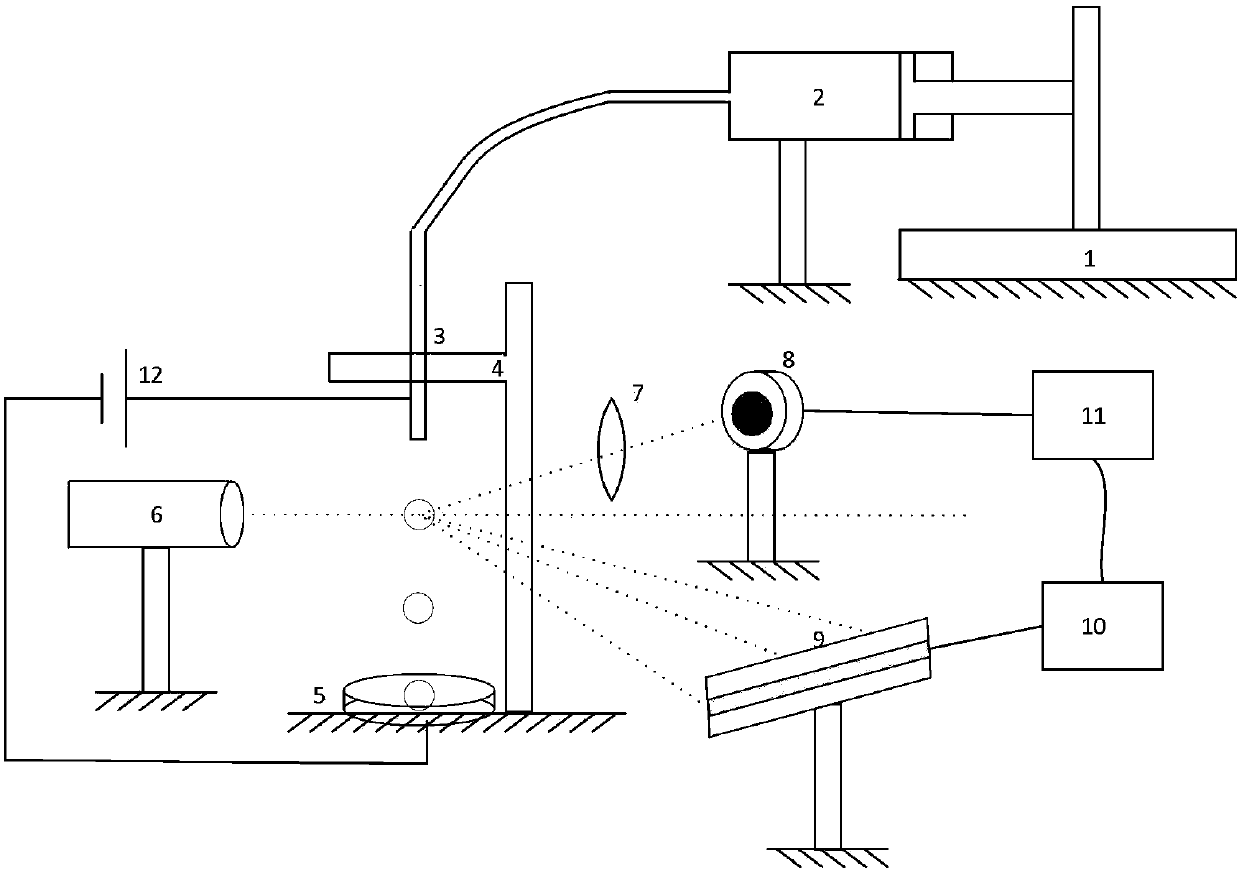

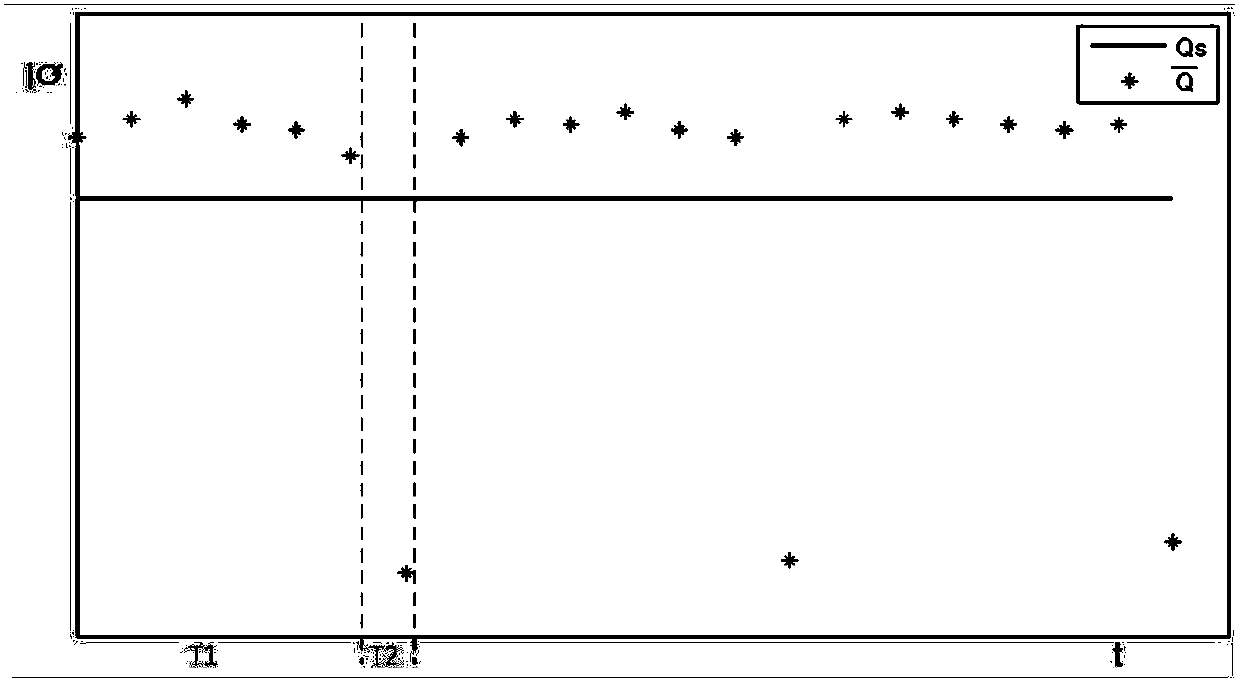

Single drop electrostatic spraying system stable work regulation method

InactiveCN108031573AVolume stabilityMeet the needs of high-precision scientific research experimentsLiquid supply arrangementsSpray discharge apparatusPhotomultiplierEngineering

The invention discloses a single drop electrostatic spraying system stable work regulation method and belongs to the technical field of electrostatic drop generation. A single drop electrostatic spraying system can monitor a moment t and a single drop volume V when a drop enters a laser beam irradiation range in real time and estimates a drop jetting average flow rate which is shown in the following description as a set reference value of an actual liquid supply flow rate Qs. By adopting the method, a photomultiplier is used as a starting circuit of a regulation and control device, when dripping drops enter the laser beam irradiation range, the light scattering phenomenon occurs, the photomultiplier converts a collected optical pulse signal to an electric pulse signal as a starting signalof a system; and through a photoelectric technology, the volume and the drop production time interval of the jet single drop are detected, and the drop jetting average flow rate, which is described inthe following description, is estimated as the set reference value of the actual liquid supply flow rate Qs, so that relative stability of the liquid volume at a nozzle can be realized, and thus thestability of the drop production time interval and the single drop volume is ensured.

Owner:BEIJING UNIV OF TECH

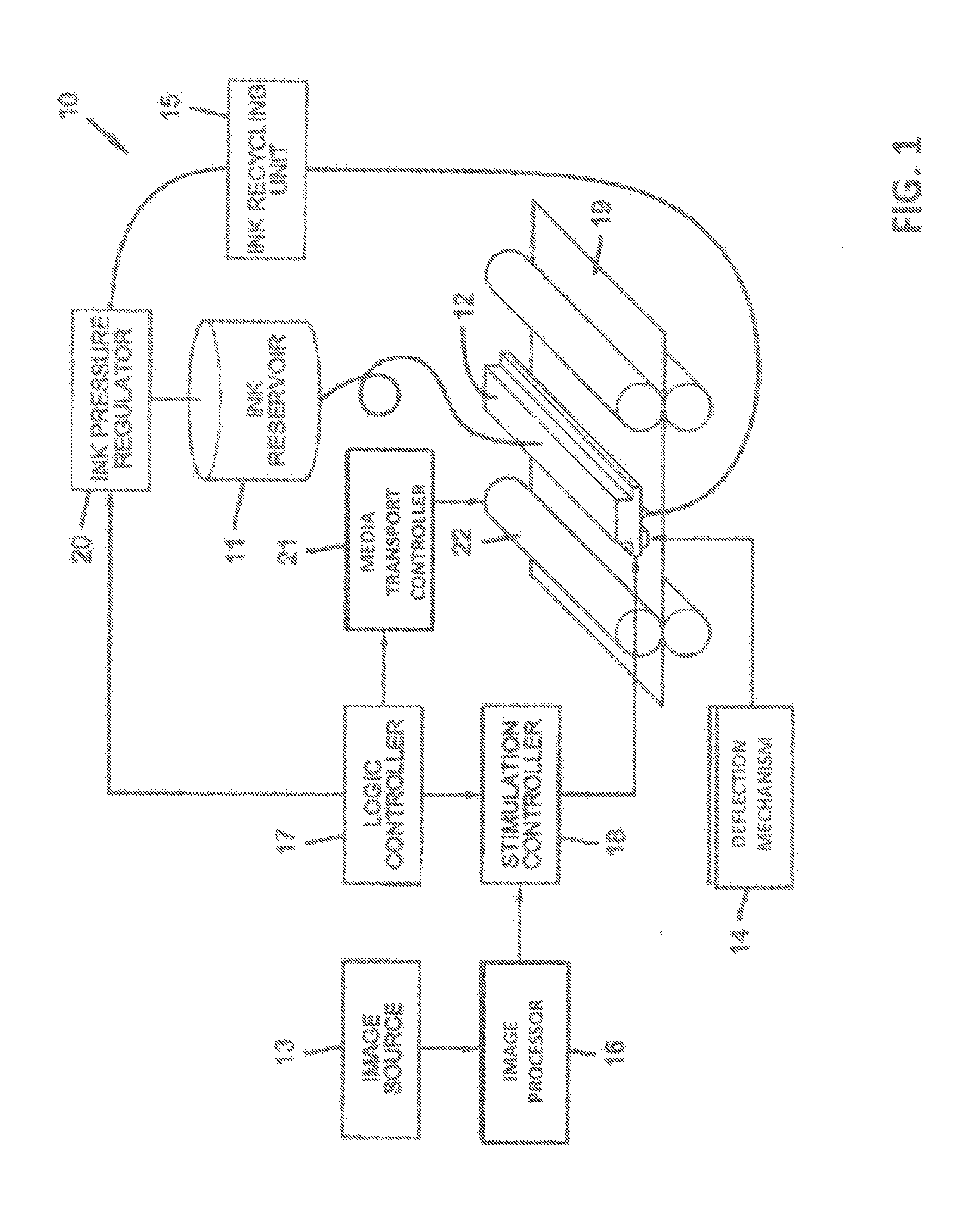

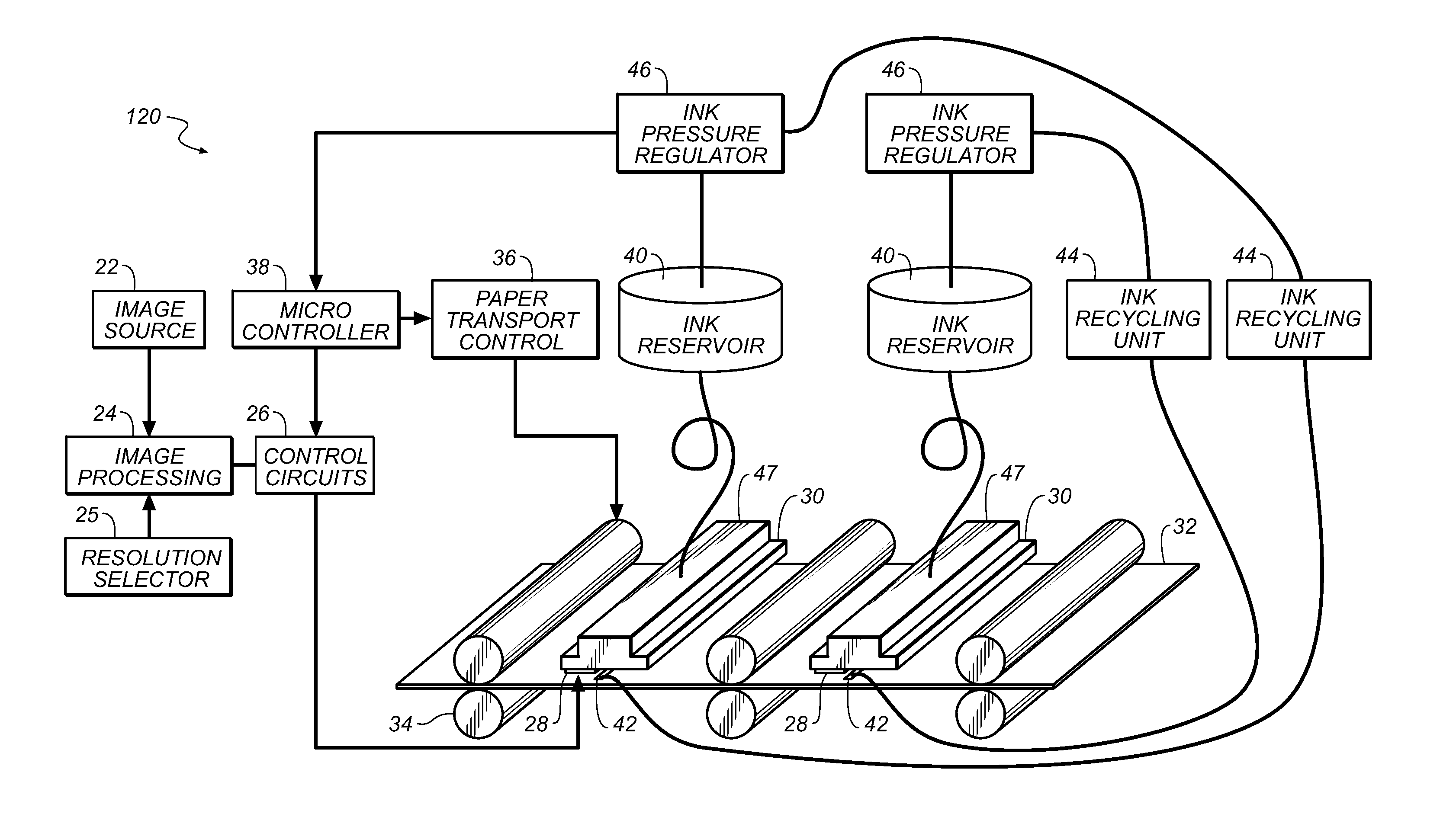

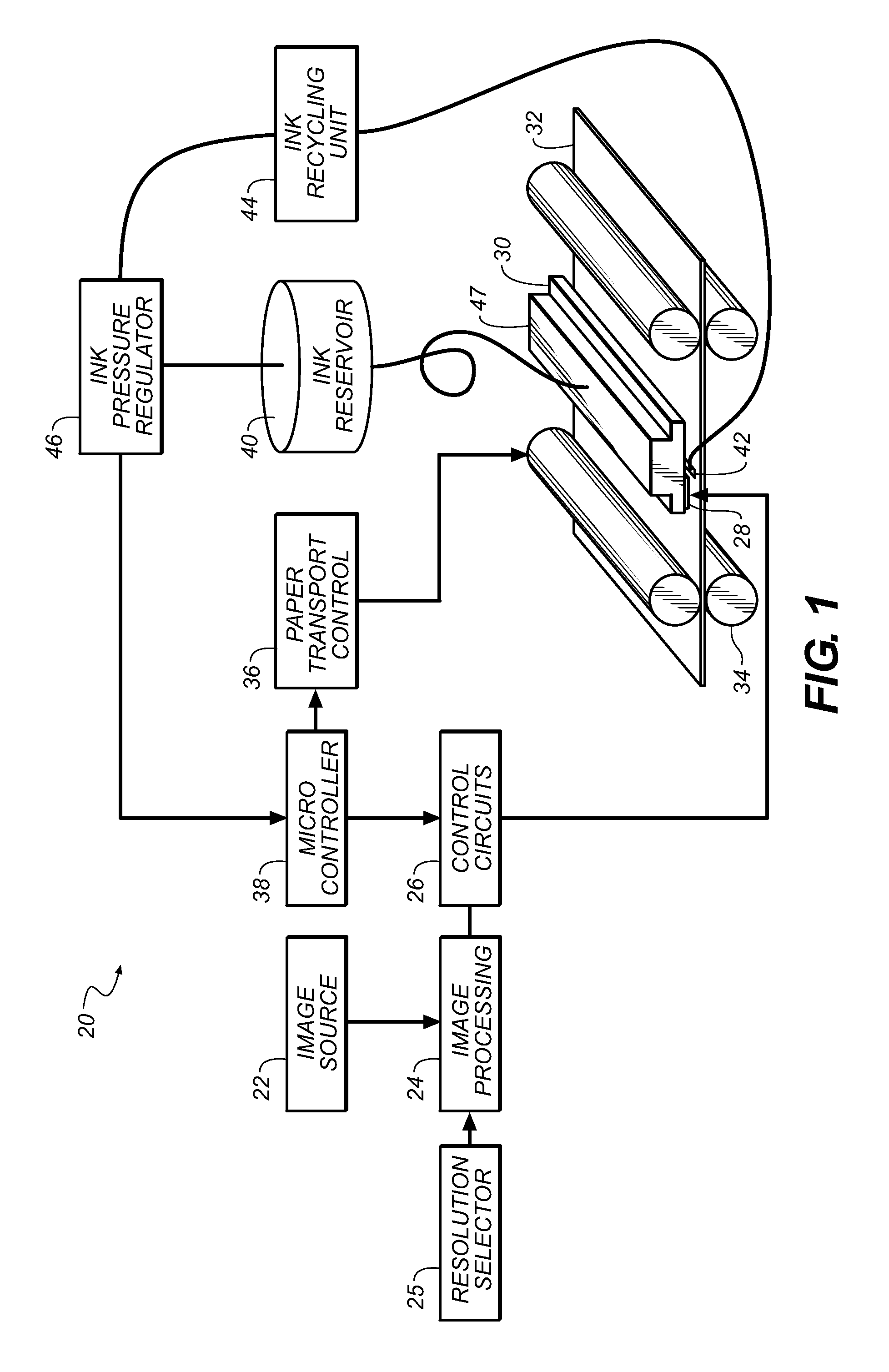

Multiple resolution continuous ink jet system

ActiveUS20120120163A1Great print job flexibilityLow equipment costInking apparatusImage resolutionSpray nozzle

A continuous ink jet printing system capable of printing at multiple predetermined print resolutions. The system comprises a drop generator having an array of nozzles for emitting a plurality of continuous streams of liquid for applying ink to media driven in a media advance direction having a source for pressurized liquid for supplying pressurized liquid to the plurality of nozzles. The plurality of nozzles have effective nozzle diameters D0 and a stimulation device associated with each nozzle of the plurality of nozzles for forming ink drops having predetermined drop volumes from the continuous streams of liquid. The predetermined drop volumes include non-print drops of a unit volume V0, and print drops having volumes that are integer multiples of the unit volume, mV0, wherein m is an integer greater than 1. A catcher collects the non-print drops and a selector selects a predetermined print resolution. Each predetermined print resolution has a corresponding print drop volume mV0.

Owner:EASTMAN KODAK CO

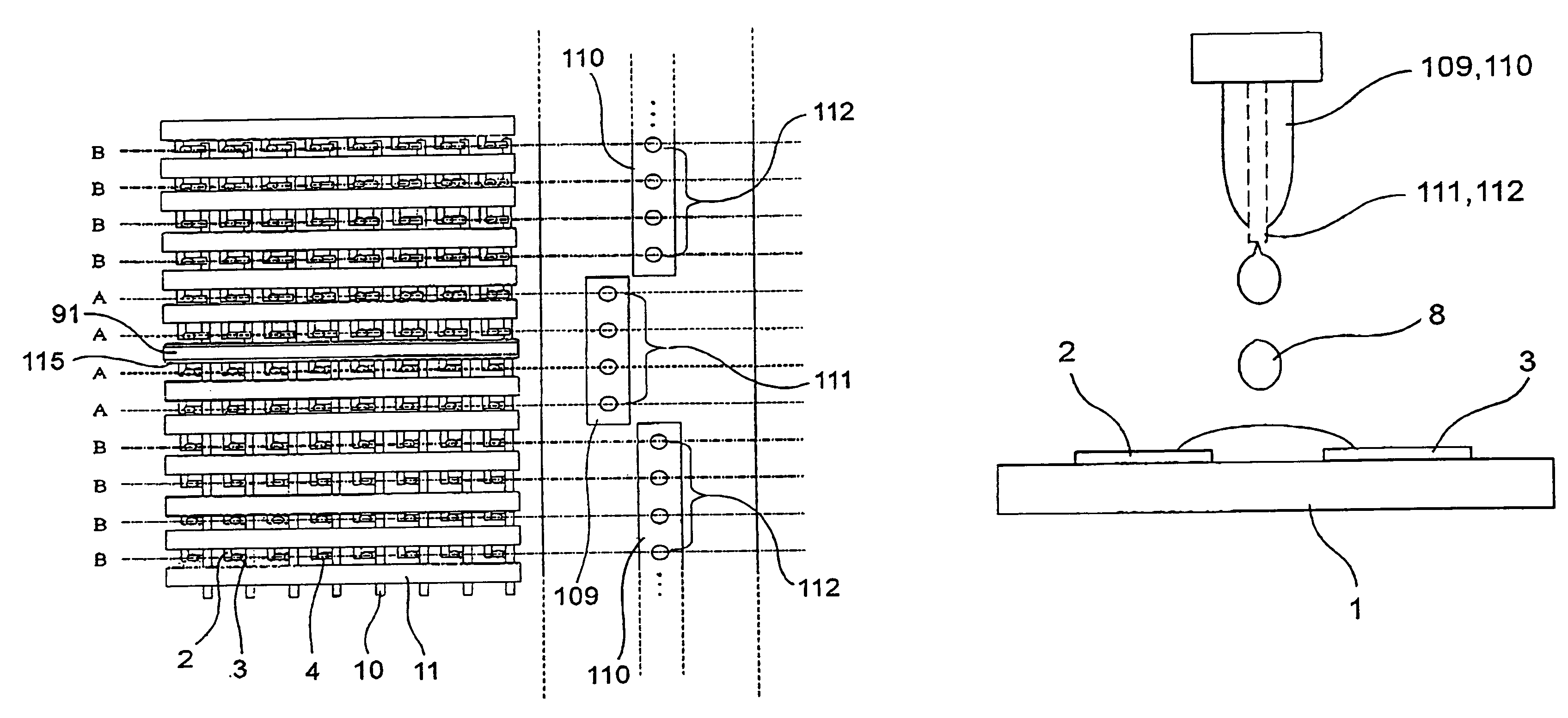

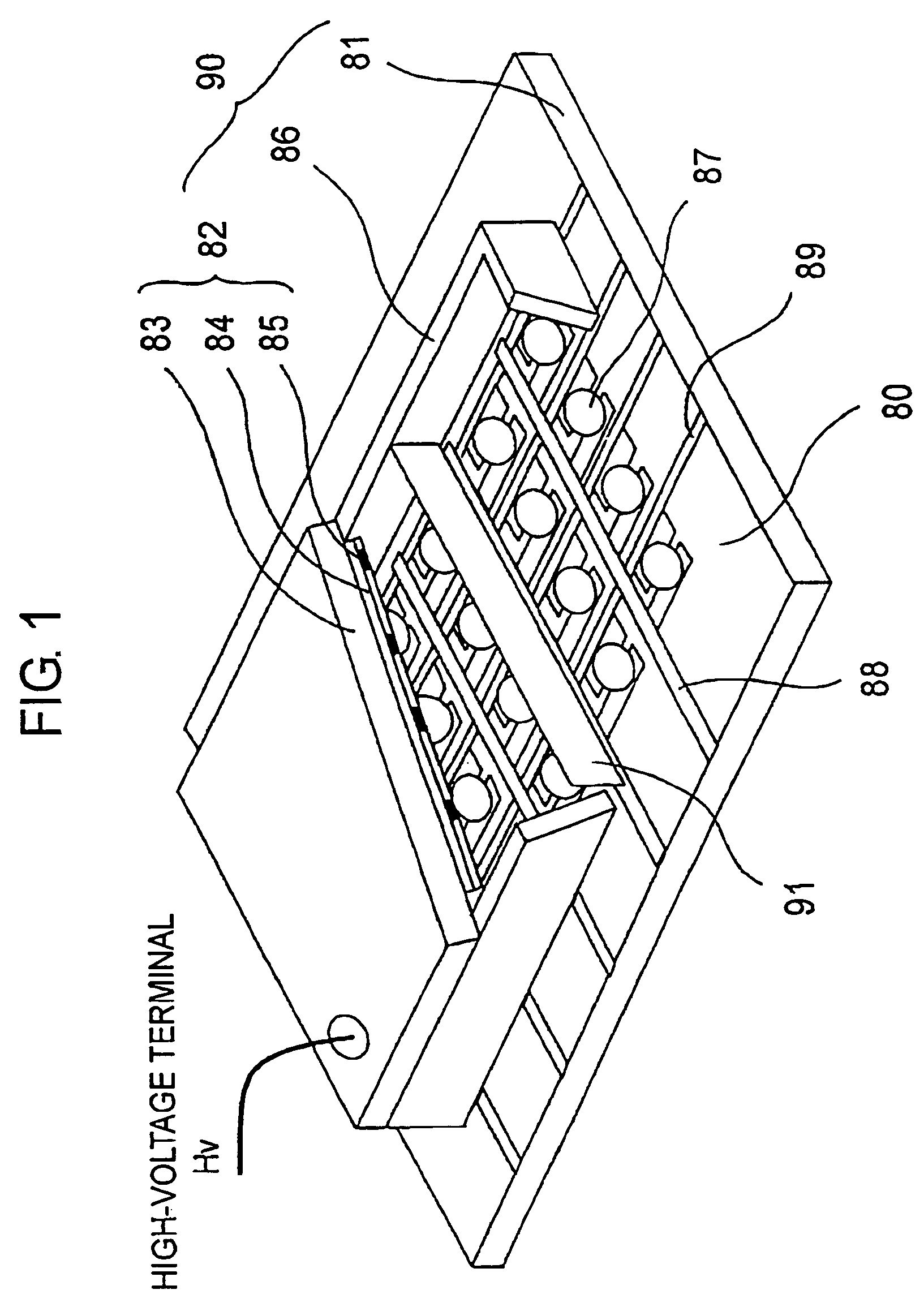

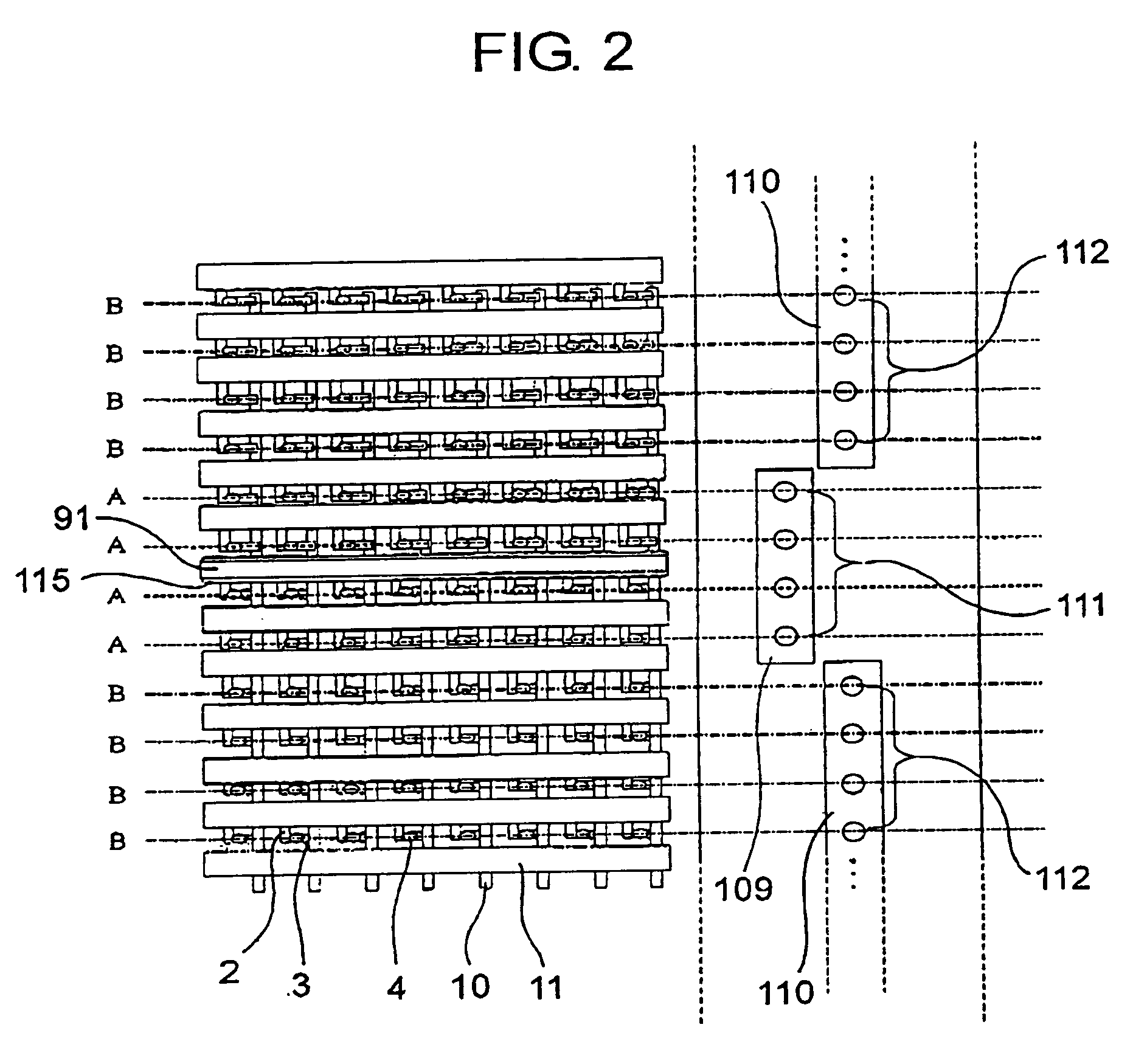

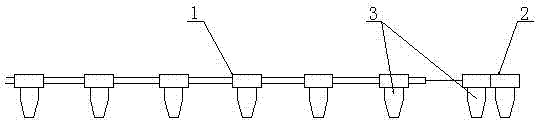

Method for manufacturing an electron source substrate

InactiveUS7037158B2Quality improvementLow costElectric discharge tubesSemiconductor/solid-state device manufacturingElectron sourceDrop volume

A plurality of kinds of ink jet devices are used for different regions, respectively. For element electrode pairs arranged in the vicinity of the fixed position of a spacer for example, there is used an ink jet device having an excellent performance in drop placement accuracy, drop volume accuracy or the like. For the remaining element electrode pairs, there are used ink jet devices having an inferior performance. As a result, an electron source substrate of a high quality can be manufactured at a low cost and with a high throughput.

Owner:CANON KK

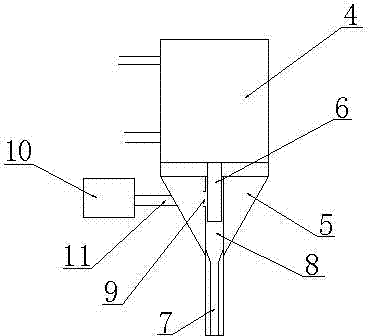

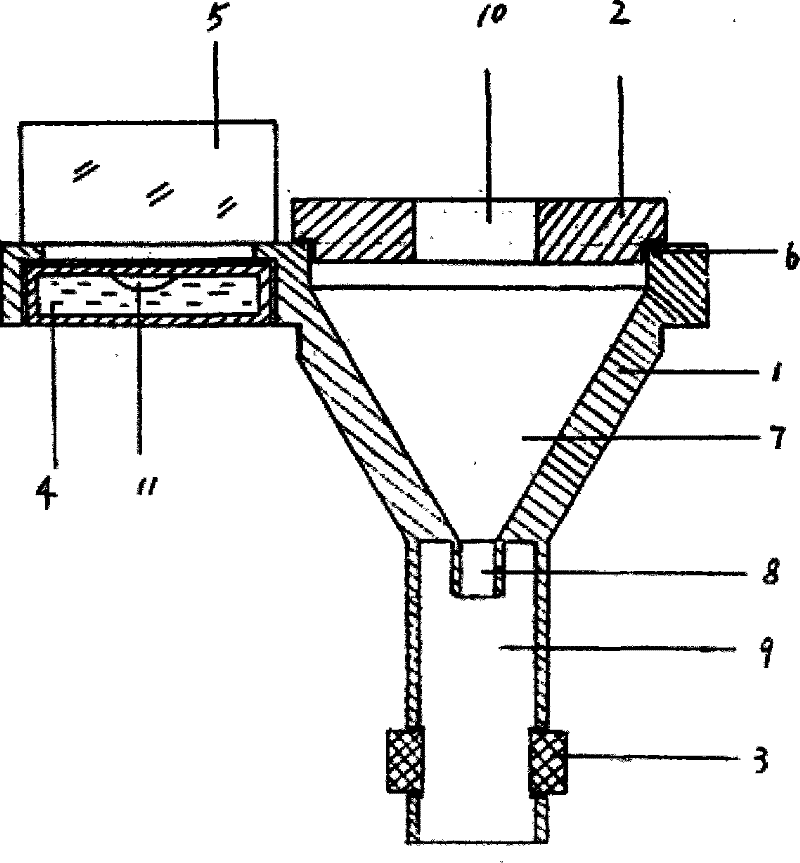

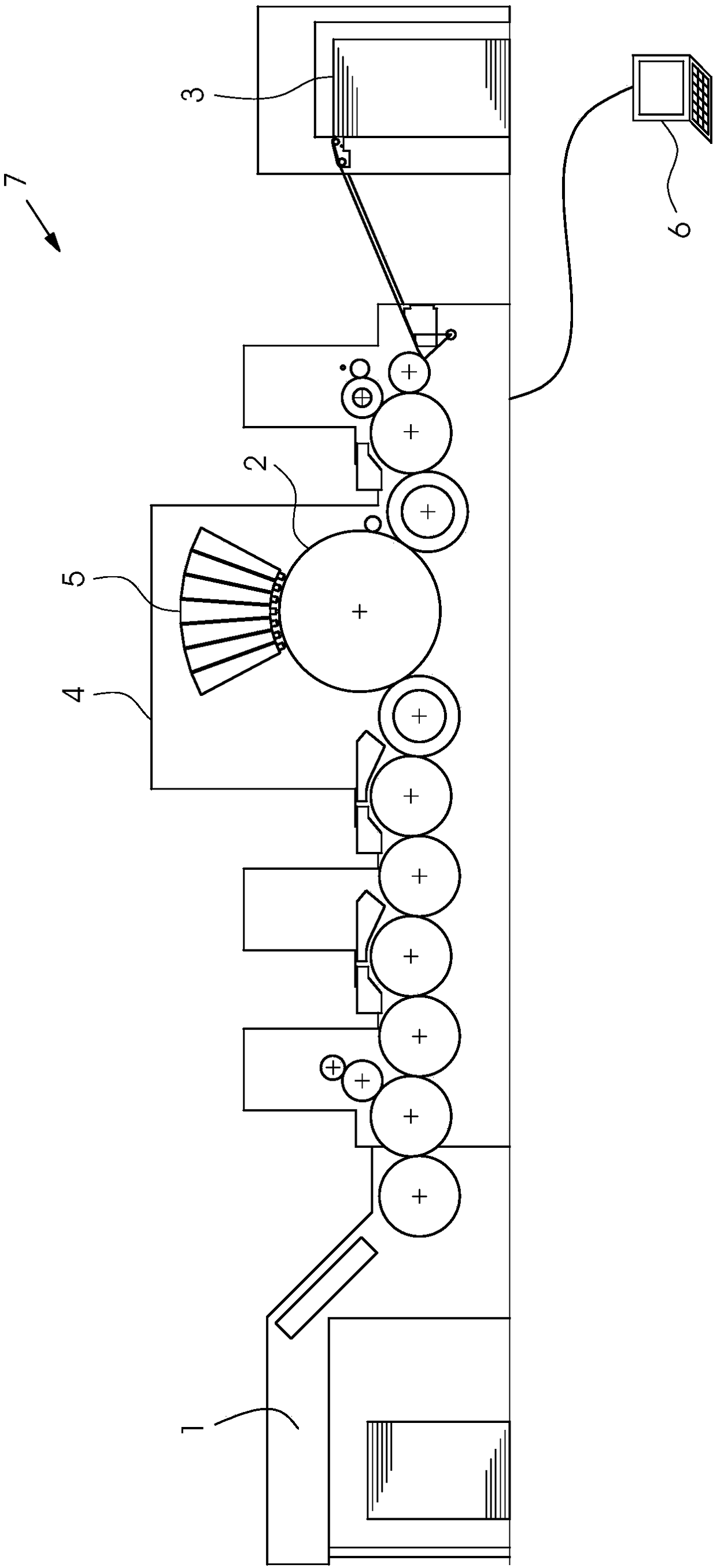

Marking device for automatic cloth inspecting machine

The invention relates to a marking device for an automatic cloth inspecting machine, comprising a defect marking device and a code marking device, wherein the defect marking device is composed of marker extruders which are arranged at intervals along the horizontal direction, the code marking device is arranged at one end of the defect marking device, the code marking device is composed of more than three marker extruders which are distributed in an array shape, the marker extruder comprises a marker storage tank and an extruding mechanism, the extruding mechanism is connected with the markerstorage tank, and an extruding hole is arranged at the lower end of the marker storage tank. The marking device in the structure can not be contacted with a cloth, and the cloth can not be damaged during relative motion. The marking device provided by the invention is used for dropping volume of the marker, and the dropping speed is fast, a produced mark is a point, the position of a defect can be clearly and accurately marked, and the working efficiency of a subsequent working procedure is effectively improved.

Owner:LUOYANG FANGZHI MEASUREMENT & CONTROL

Gasoline sulfur-reducing composition and its preparing and using method

ActiveCN101100611AReduce sulfur contentHigh adsorption and desulfurization activityCatalytic crackingHydrocarbon oils refiningAlkaline earth metalSulfur

A gasoline sulfur-decreasing composite, its production and use are disclosed. The composite consists of copper with copper oxide 1-50 wt%, and spinelle composite 50-99 wt% with alkaline earth 20-70 wt% and aluminum 30-80 wt%. The average grain diameter of copper oxide is not greater than 30 nm. The usage level of copper-contained solution is 1.5-100 times of spinelle composite drop volume. It hasbetter desulfurizing activity and can be used as adsorbent and cracking accessories.

Owner:CHINA PETROLEUM & CHEM CORP +1

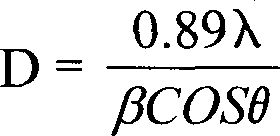

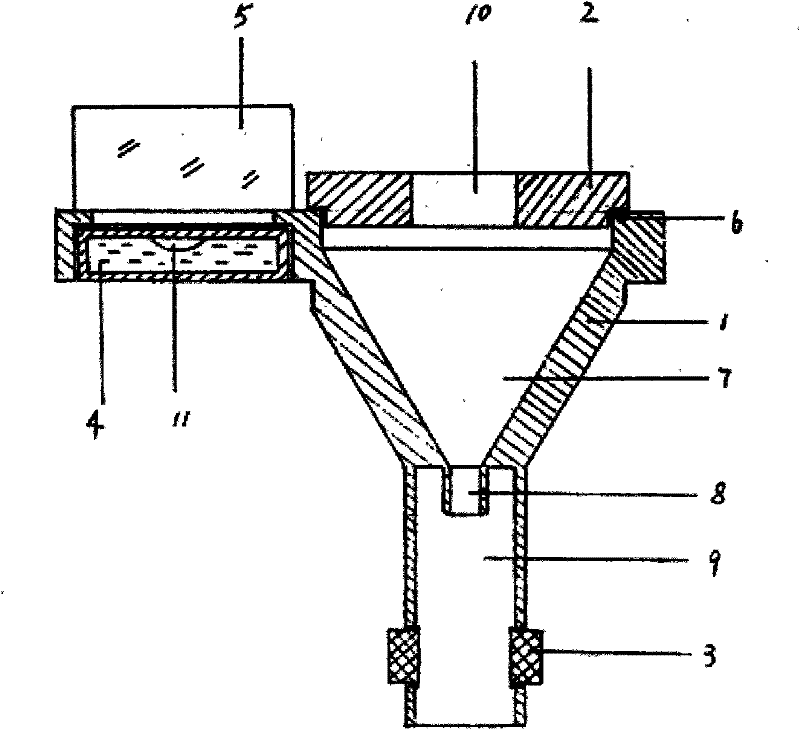

Drop volume measuring device

InactiveCN102650542AEliminate random errorsVolume measurement apparatus/methodsOptical detectionEngineeringPetrochemical

The invention discloses a drop volume measuring device, particularly to a drop measuring device for automatically measuring liquid volume in petrochemical industry. A drop volume detecting device is mounted at a to-be-detected liquid outlet and includes a funnel, a funnel cover, a photoelectric sensor, a level bubble, a mirror and magnetic steel. The to-be-detected liquid outlet is inserted into the eccentric liquid intake opening of the funnel cover and contacted with the liquid collecting wall of the funnel so as to be fixed. The drop drips out of a dripping outlet and falls for a distance, and then the double-peak pulse width produced by drop is measured by the photoelectric sensor, as a result, the liquid volume is measured according to a certain proportional relation.

Owner:谢维

Variable drop volume continuous liquid jet printing

A liquid jet includes a fundamental period of jet break off. A print period is defined as N times the fundamental period of jet break off where N is an integer greater than 1. Input image data is provided having M levels per input image pixel including a non-print level where M is an integer and 2<M@N+1. A charging device waveform, independent of the input image data, repeats during print periods and includes print and non-print drop voltage states. A drop formation device waveform, having a period equal to the print period, is selected in response to the input image data to form from the jet print drops having a volume corresponding to an input image pixel level. The devices are synchronized to produce a print drop charge to mass ratio and a non-print drop charge to mass ratio on drops breaking off from the jet.

Owner:EASTMAN KODAK CO

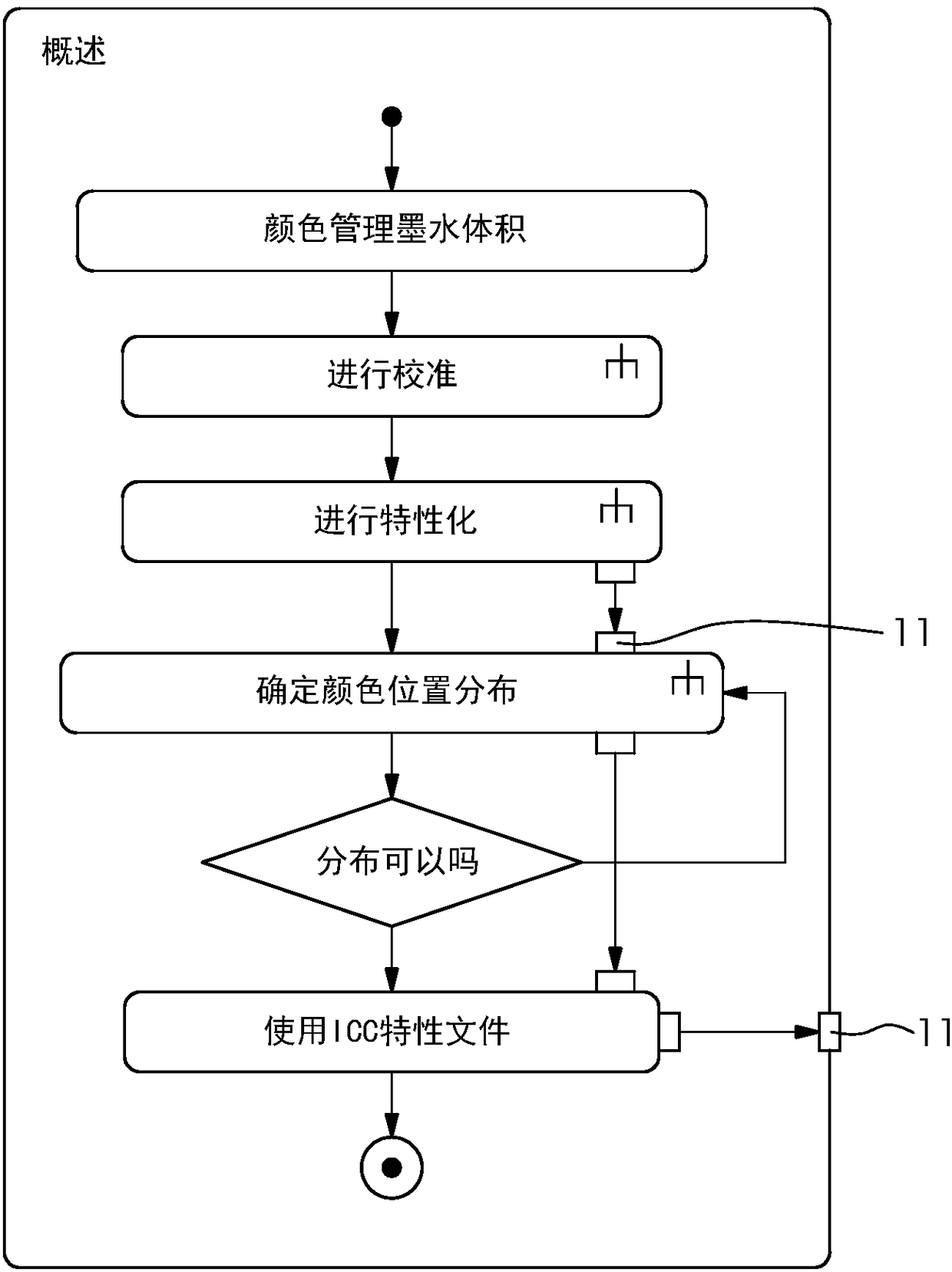

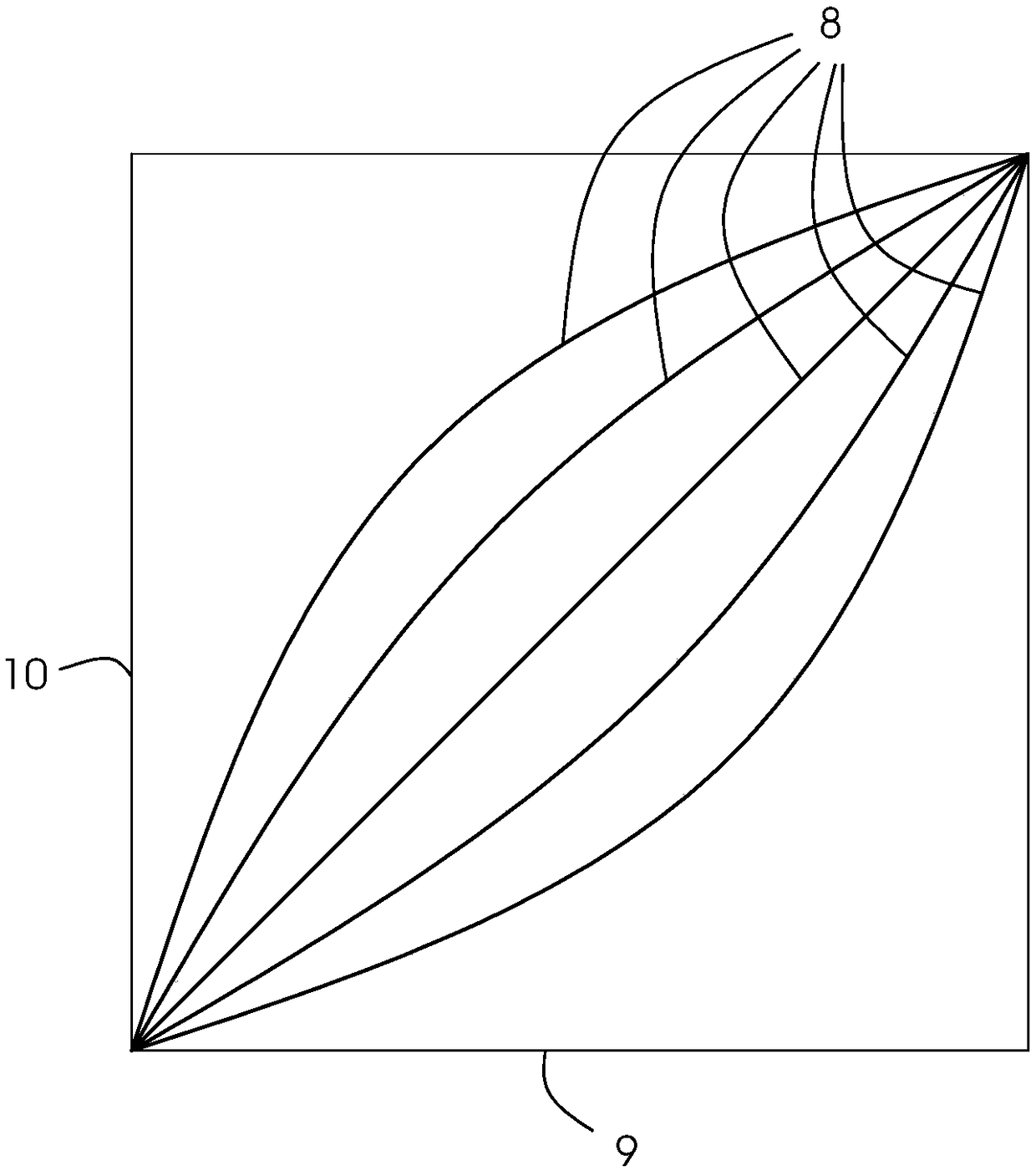

Method for carrying out printing operation on inkjet printing machine

ActiveCN108621567AEvenly distributedOther printing apparatusInput/output processes for data processingEngineeringPrinting press

A method for printing on an inkjet printing machine including color space transformation between target and process color spaces using a computer, includes calibrating the machine by printing and colorimetrically measuring a process color space test chart for printing in the target color space including printing-operation-related limitations in the applied ink amount. The generated measured valuescorrespond to sampling points in the measured target color space. The sampling points are interpolated to define further sampling points. The color space transformation uses sampling points in the target color space and input values from the chart in the process color space corresponding to sampling points in the target color space. The physical variable of ink drop volume is directly used for ink application limitations and input values in the process color space. The calibration of the machine is adapted and the printing operation is carried out.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com