Single drop electrostatic spraying system stable work regulation method

An electrostatic spraying and system stabilization technology, which is applied in spraying devices, spray discharge devices, liquid supply devices, etc., can solve problems such as droplet instability, achieve consistent shapes, and meet the effects of high-precision scientific research experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

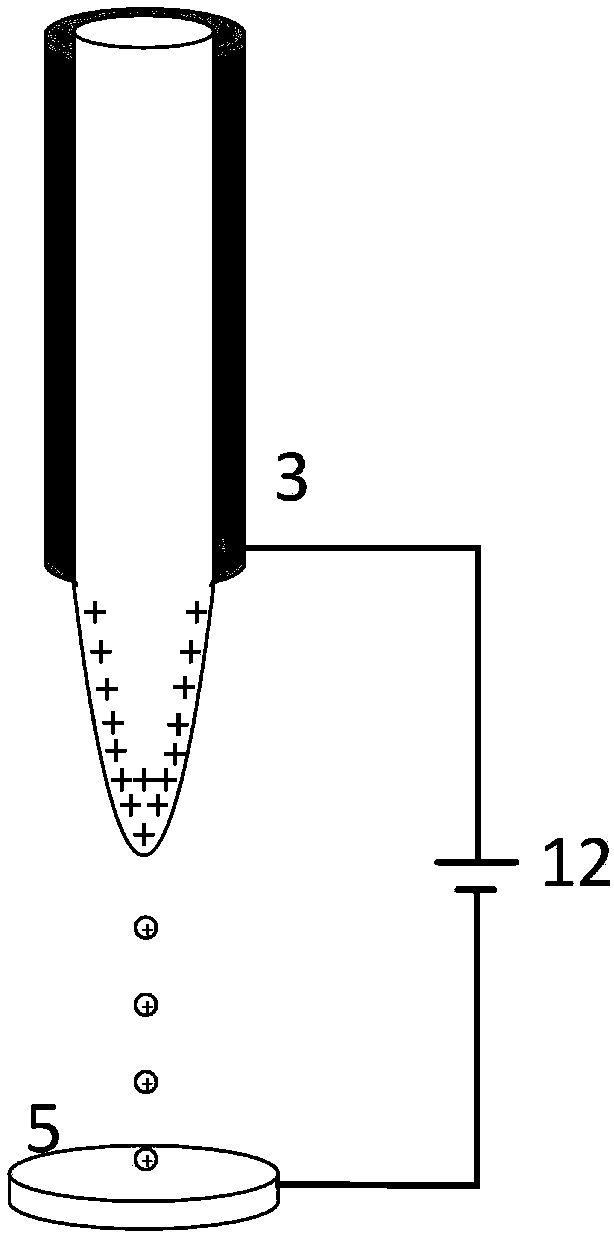

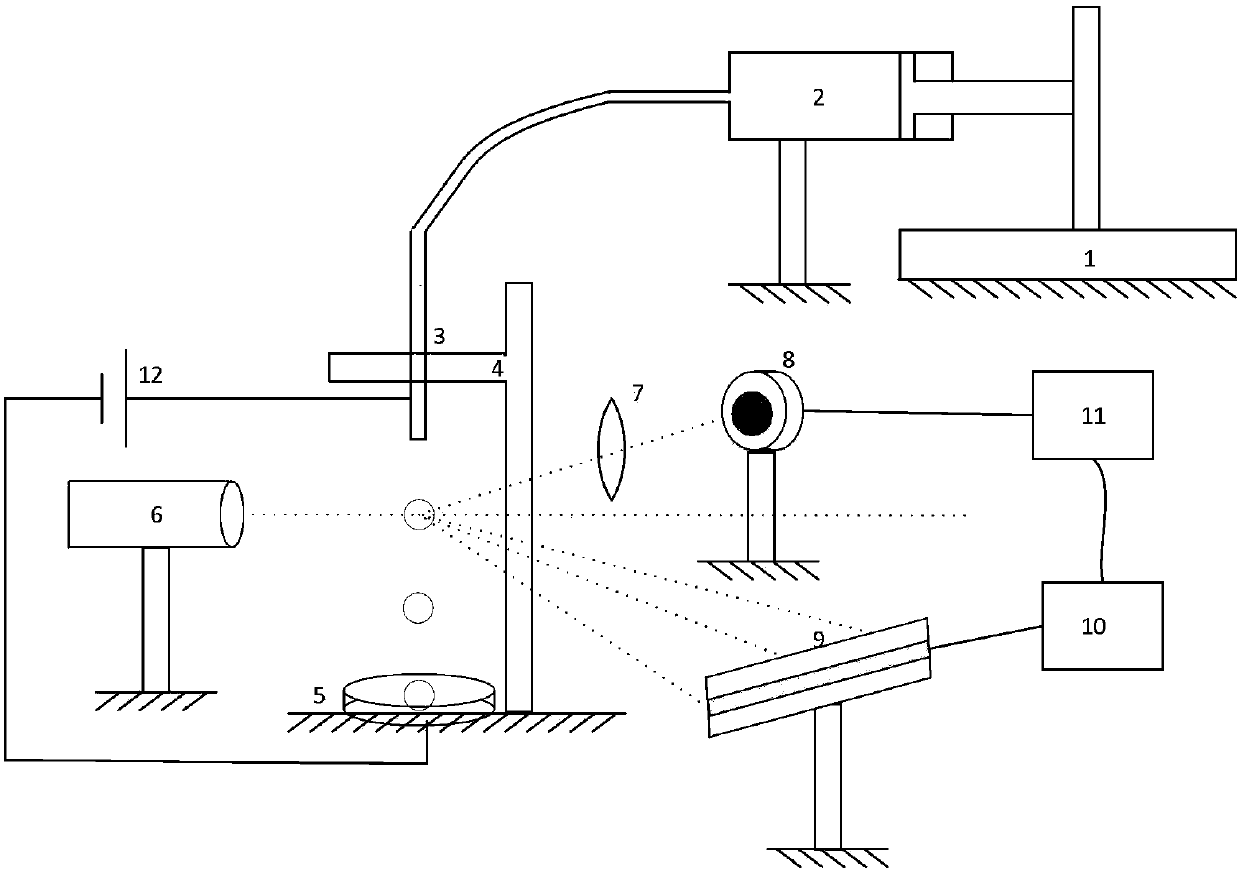

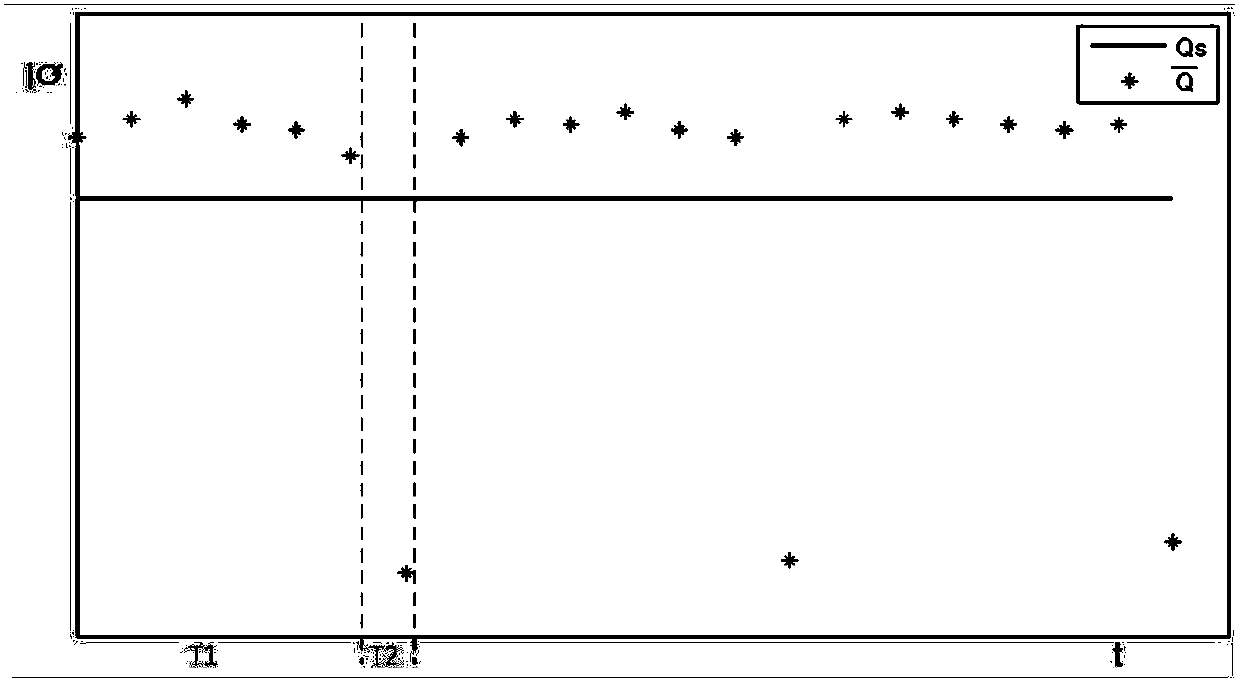

[0020] Such as figure 2 As shown, the system is mainly composed of drive motor 1, injector 2, nozzle 3, nozzle holder 4, droplet collector 5, laser 6, lens 7, photomultiplier tube 8, linear array CCD 9, analog-to-digital converter ADC 10, Composed of FPGA 11 and high voltage power supply 12. An adjustment and control device is added to the electrostatic droplet spraying device, which consists of six parts: laser 6, lens 7, photomultiplier tube 8, linear array CCD 9, analog-to-digital converter ADC 10 and FPGA 11. The laser beam emitted by the laser 6 is in the same horizontal plane as the lens 7 , the photomultiplier tube 8 and the linear array CCD 9 , and is located 1 cm below the nozzle 3 . Lens 7 and photomultiplier tube 8 are respectively placed at 10cm and 20cm away from the vertical direction of nozzle 3, and form a certain angle (for example, 45 degree angle) with light beam in horizontal direction; An included angular orientation (for example, a 45-degree angle). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com