Variable drop volume continuous liquid jet printing

一种液体射流、液体的技术,应用在印刷等方向,能够解决投射距离短等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

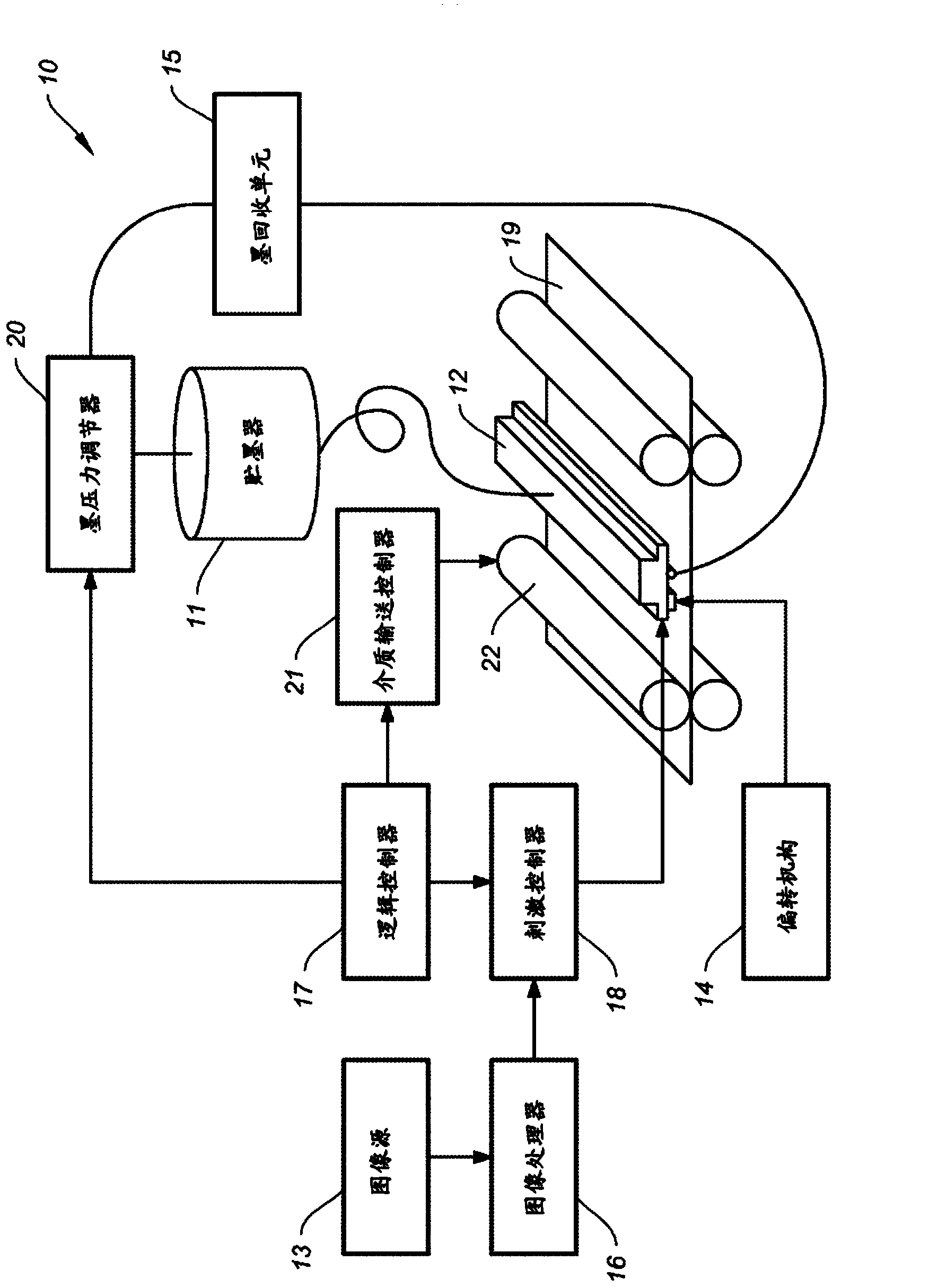

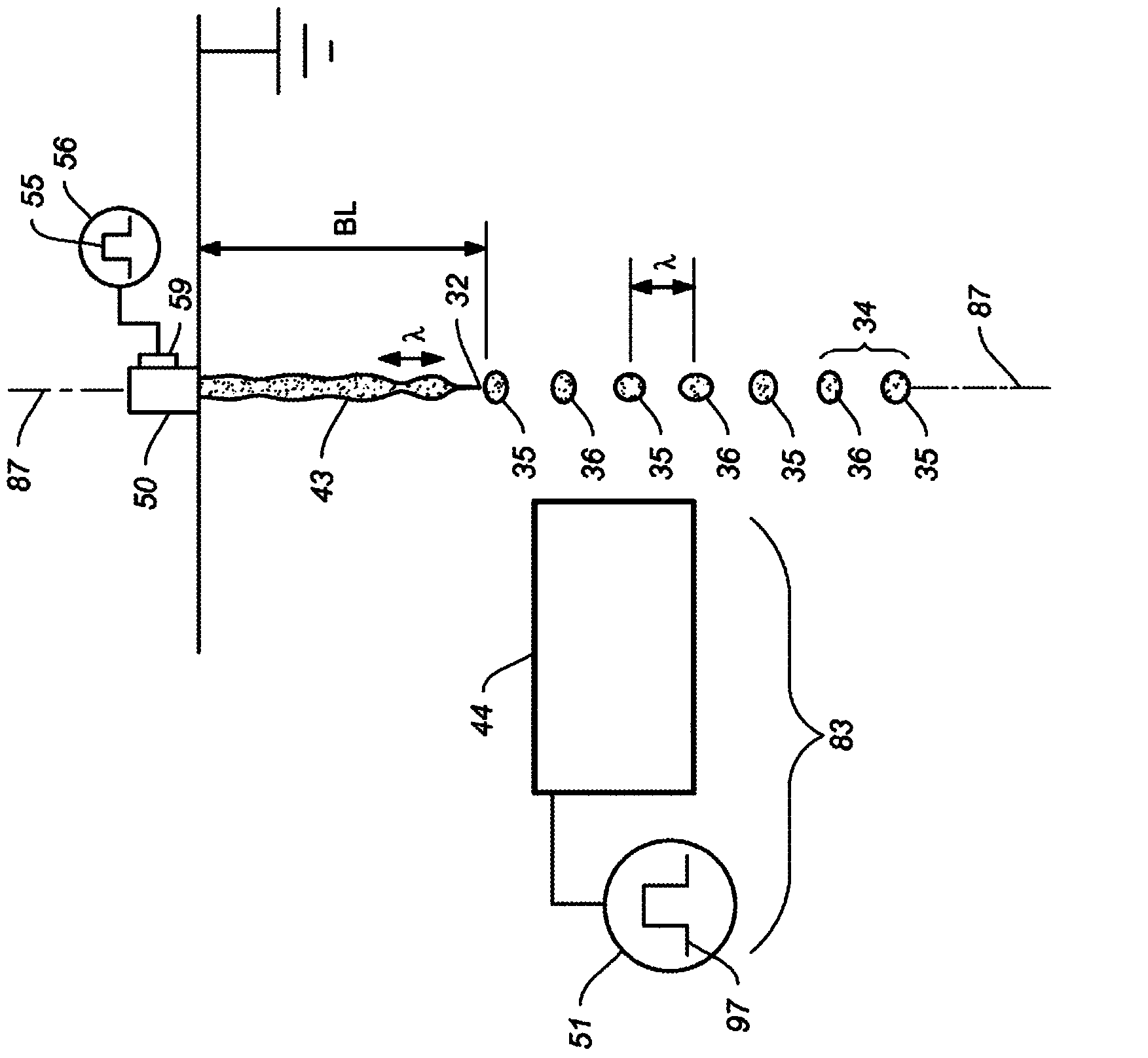

[0026] The description relates in particular to elements forming part of, or cooperating more directly with, a device according to the invention. It is to be understood that elements not specifically shown or described may take various forms well known to those skilled in the art. In the following description and drawings, the same reference numerals are used to designate the same elements, where possible.

[0027] For the sake of clarity, the exemplary embodiments of the present invention are shown schematically and not to scale. Those of ordinary skill in the art will readily be able to determine the specific dimensions and interconnections of the elements of the exemplary embodiments of the present invention.

[0028] Exemplary embodiments of the present invention, as described herein, provide a printhead or printhead components typically used in inkjet printing systems. In such systems, the liquid is the ink used to print on the recording medium. However, other applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com