Drop volume measuring device

A technology for measuring device and droplet volume, which is applied in the direction of measuring device, volume measuring instrument/method, liquid/fluid solid measurement, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

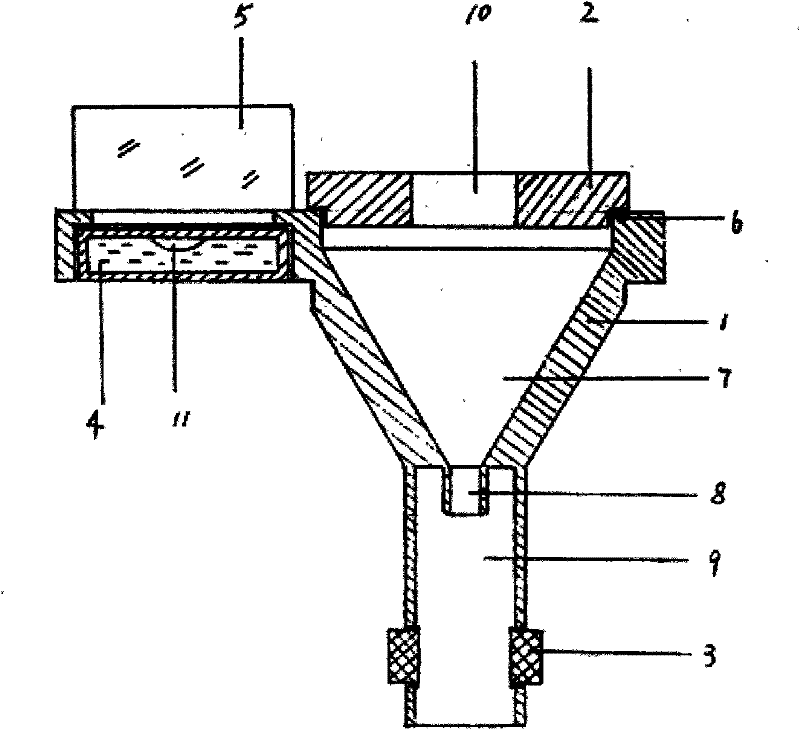

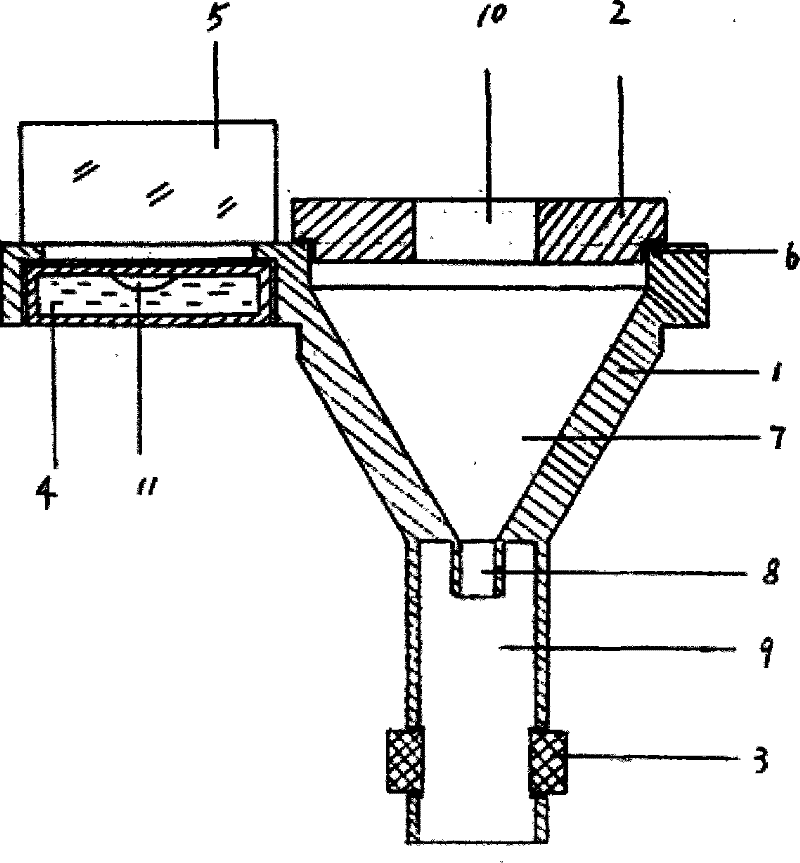

[0005] The object of the present invention is achieved in that the droplet volume detection device of the present invention is installed at the liquid outlet of the liquid to be measured, and the device is made up of a funnel, a funnel cover, a photoelectric sensor, a vial, a mirror, and a magnet. The liquid outlet of the liquid to be tested is inserted into the eccentric liquid inlet of the funnel cover, and is fixed after being in contact with the wall of the funnel liquid collection cavity. The purpose of the eccentricity is to prevent the liquid to be measured from dripping directly into the drip port, resulting in inaccurate measurement. The liquid collecting chamber is used to balance the speed of the liquid, and is equipped with a filter screen, which can filter out impurities mixed in the liquid. The droplet drips out through the droplet, and after falling for a certain distance, the photoelectric sensor measures the double-peak pulse width generated by the droplet, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com