Marking device for automatic cloth inspecting machine

A technology of cloth inspection machine and marking device, which is applied in the direction of marking textile materials, textiles and paper making, etc. It can solve the problems of excessively large marks, easily damaged cloth, and unclear marking positions, so as to improve work efficiency, avoid damage to cloth, Drip set fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

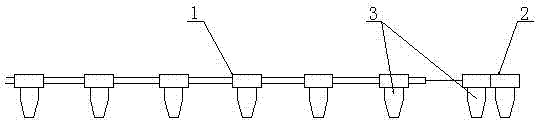

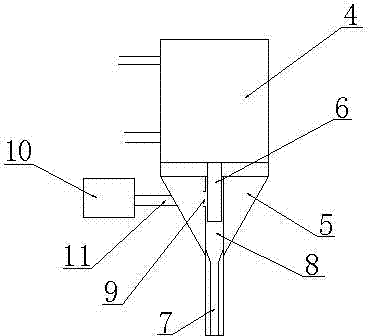

[0016] As shown in the figure, a marking device for an automatic cloth inspection machine includes a defect marking device 1 and a code marking device 2. The defect marking device 1 is composed of marker extruders 3 arranged at intervals along the horizontal direction, and the marker extruders The distance between the device 3 and the number of settings are set according to the width of the cloth, the shorter the interval between the two marker extruders 3, the more accurate the mark. The code marking device 2 is arranged at one end of the defect marking device 1, and the code marking device 2 is composed of more than three marker extruders 3 distributed in an array, and the marker extruder 3 includes a marker storage tank 5 and Extruding mechanism, the extruding mechanism is connected with marker storage tank 5 , and an extrusion port 7 is arranged at the lower end of marker storage tank 5 .

[0017] The extruding mechanism is used to extrude the markers in the marker storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com