System for controlling material drop volume in three dimensional object printing

A material drop and object technology, applied in the direction of manufacturing tools, additive manufacturing, additive processing, etc., can solve problems such as increasing time and increasing printer costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] For a general understanding of the context of the devices disclosed herein, as well as details of the devices, reference is made to the accompanying drawings. In the drawings, like reference numerals denote like elements.

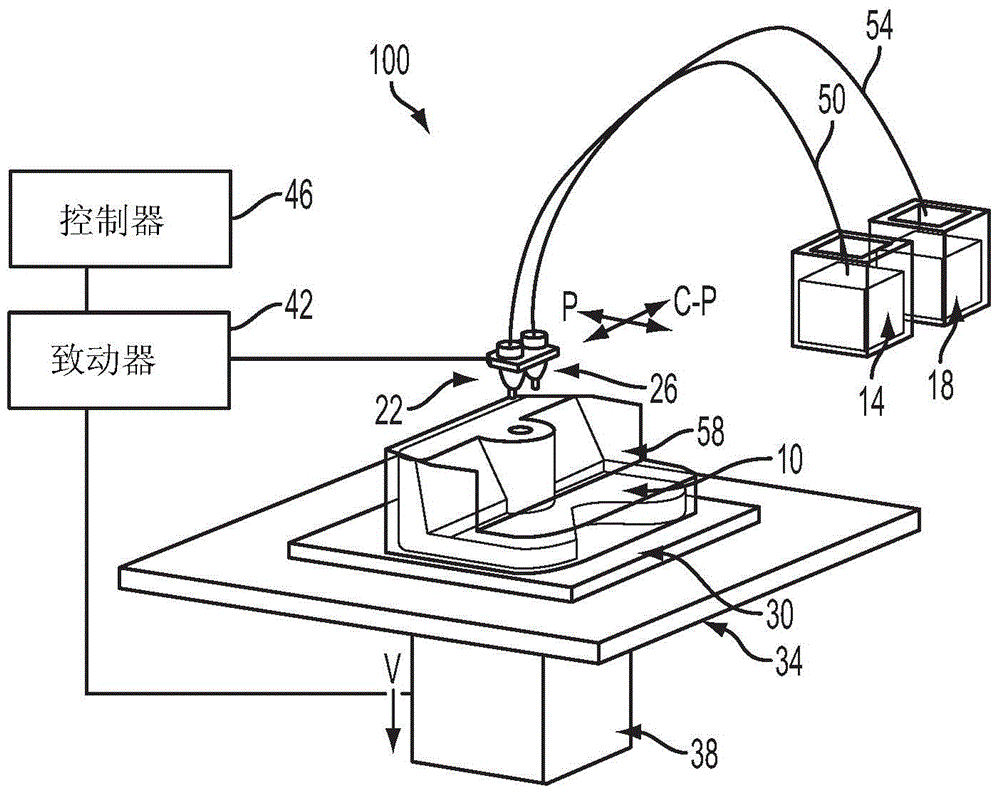

[0017] figure 1 The arrangement of components in the printer 100 that produces the three-dimensional object part 10 is shown. Printer 100 includes support material container 14 , build material container 18 , a pair of inkjet printheads 22 , 26 , build substrate 30 , planar support member 34 , columnar support member 38 , actuator 42 , and controller 46 . Tubing 50 connects printhead 22 to support material container 14 and tubing 54 connects printer 26 to build material container 18 . The two inkjet printheads are operated by the controller 46 with reference to the three-dimensional image data in memory operatively connected to the controller to eject the support and build material supplied to each respective printhead. When building the part, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com