Oil-water interface measuring device of crude oil storage tank and measuring method thereof

A crude oil storage tank, oil-water interface technology, used in measuring devices, lubrication indicating devices, liquid/fluid solids measurement, etc., to achieve the effect of improving the level of modernization and informatization, improving measurement accuracy, and realizing comprehensive automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

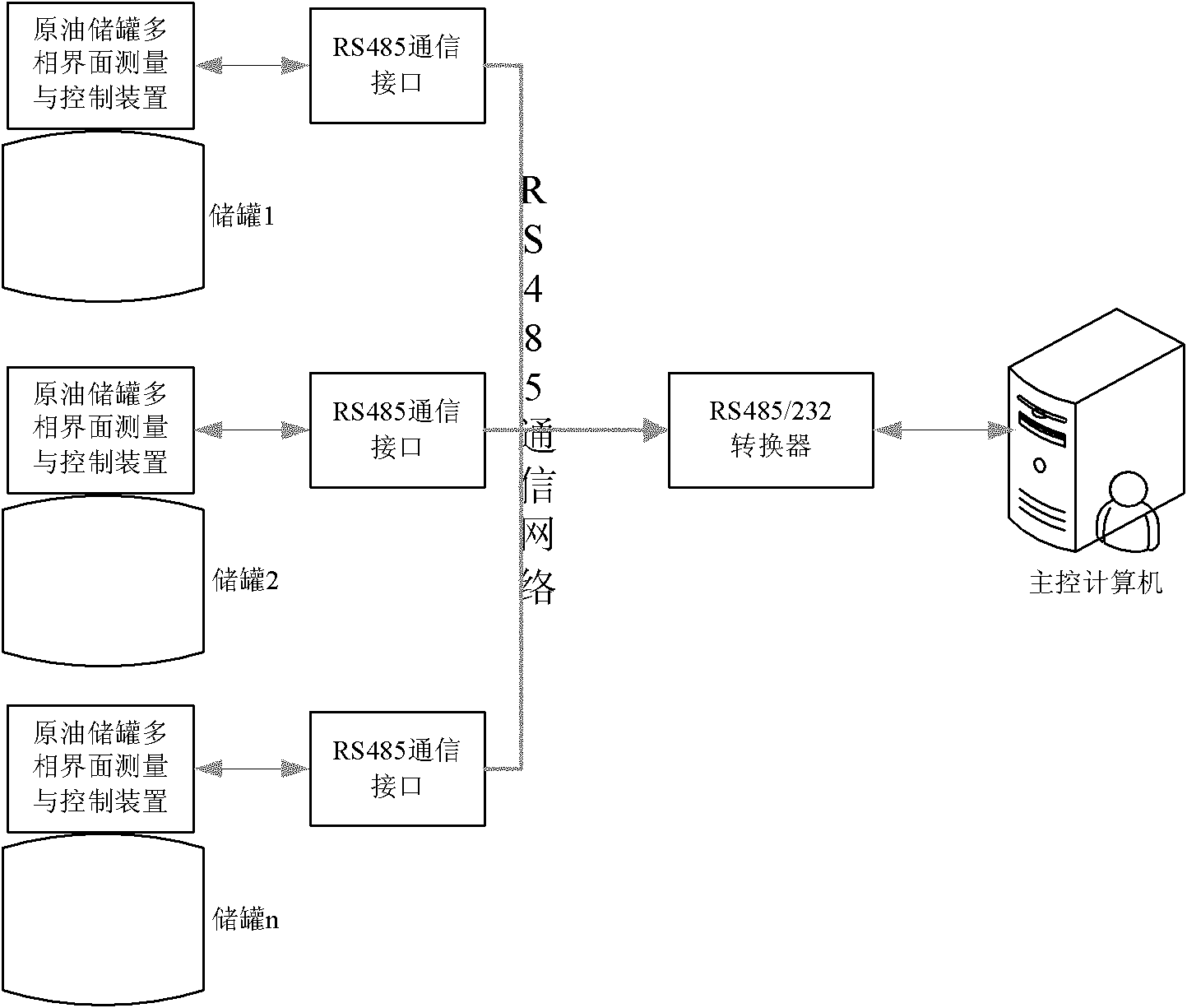

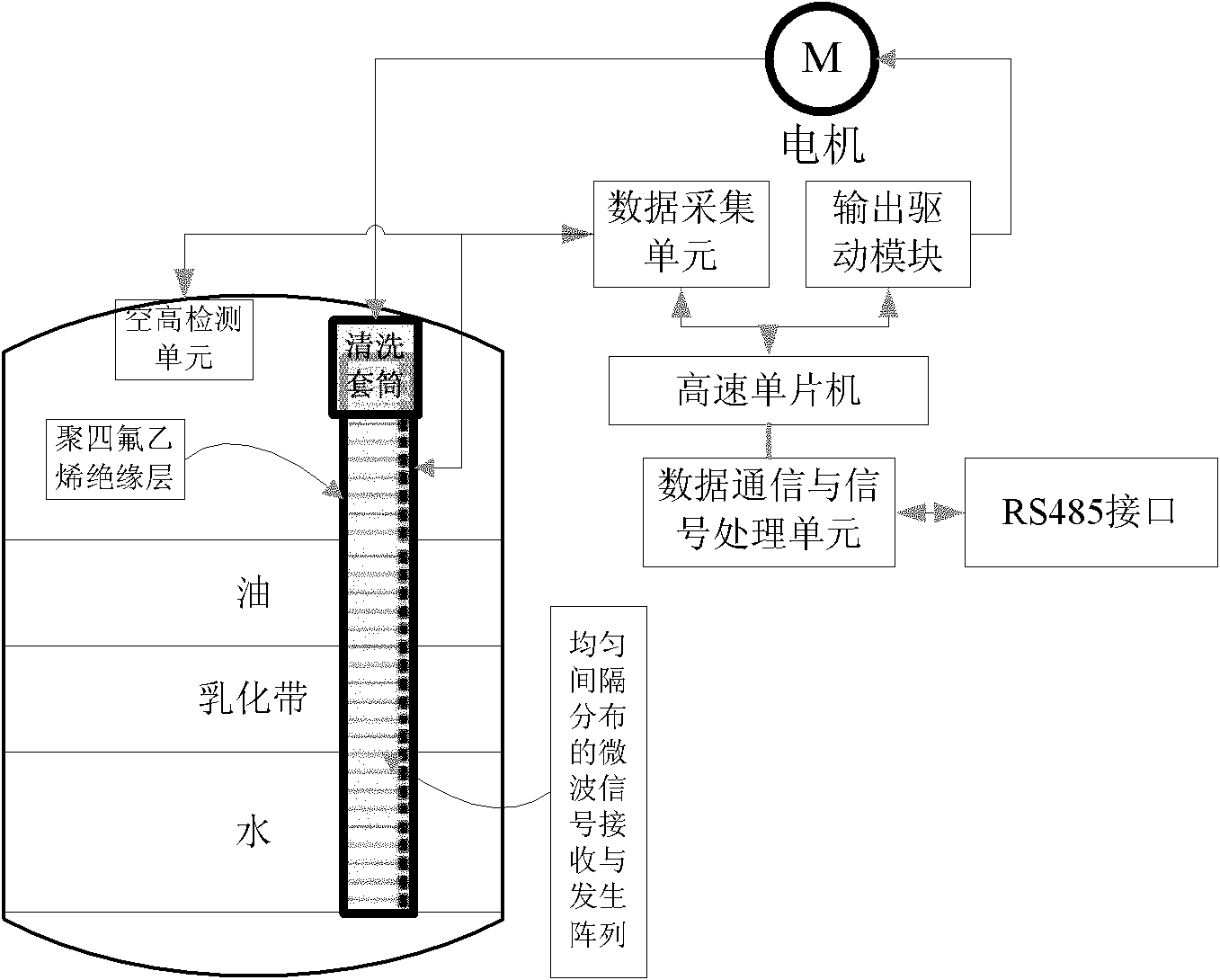

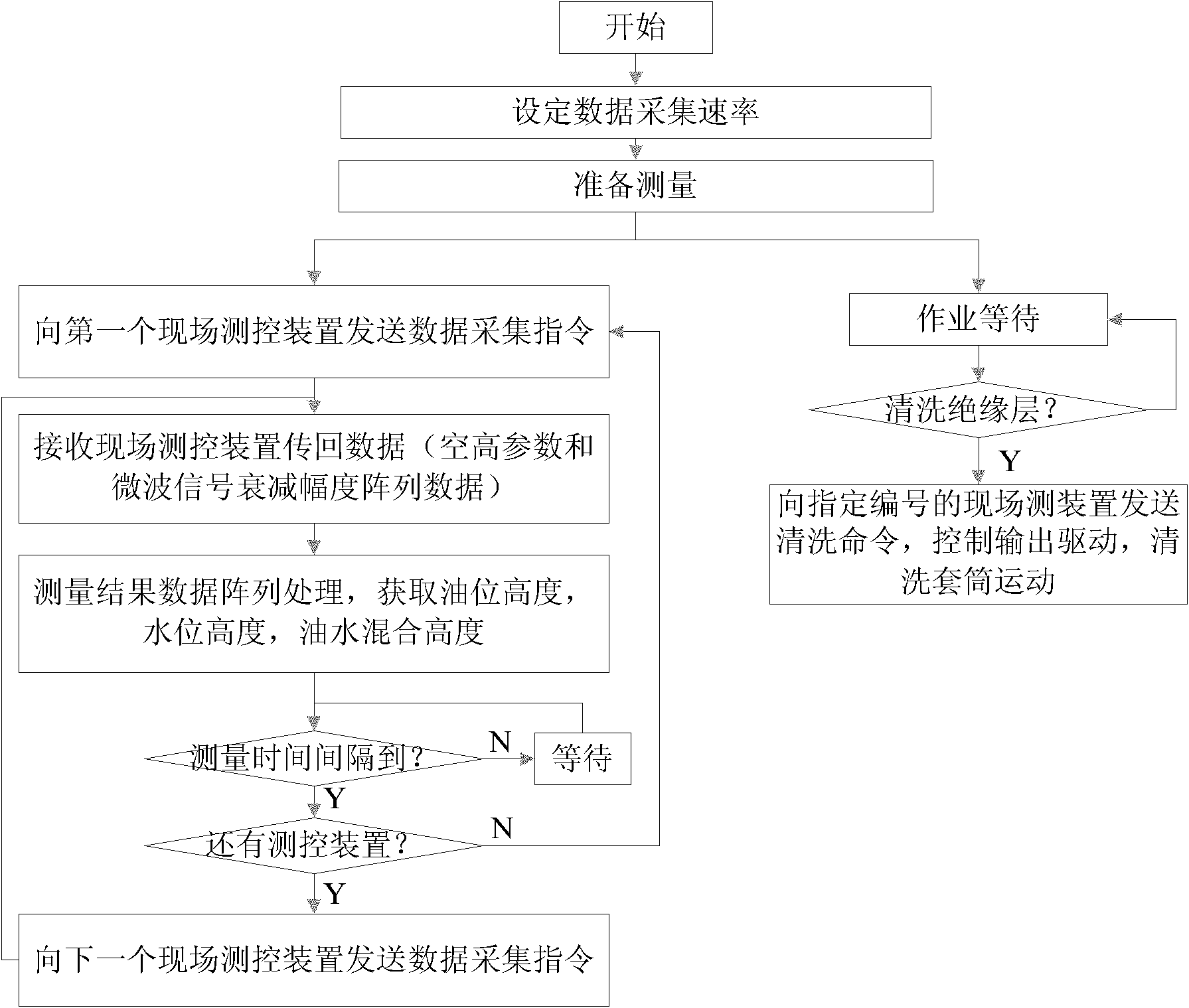

[0027] see figure 1 The oil-water interface measurement system of the crude oil storage tank includes a main control computer, an RS485 communication network and an on-site measurement and control device. The main control computer is an industrial PC and the corresponding software system. The main control computer is connected to the RS485 communication network through the RS485 / 232 converter, and the RS485 communication network is connected to multiple on-site measurement and control devices through the RS485 communication interface. The on-site measurement and control device includes a data communication and signal processing unit, a single-chip microcomputer, a data acquisition unit, a single-chip microcomputer output drive module, a measurement array probe jacket cleaning unit, an empty height detection unit and a multi-phase interface tomography unit. The data ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com