Improved natural gas drive oil production method

A technology for natural gas and natural gas injection, which is applied in the field of oil recovery and development effect of oil recovery and natural gas injection to produce crude oil, can solve the problems of lower displacement efficiency, less crude oil, natural gas channeling, etc. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Taking a block with an oil reservoir pressure of 12 MPa as an example to carry out an improved natural gas flooding recovery process, the detailed description will be given.

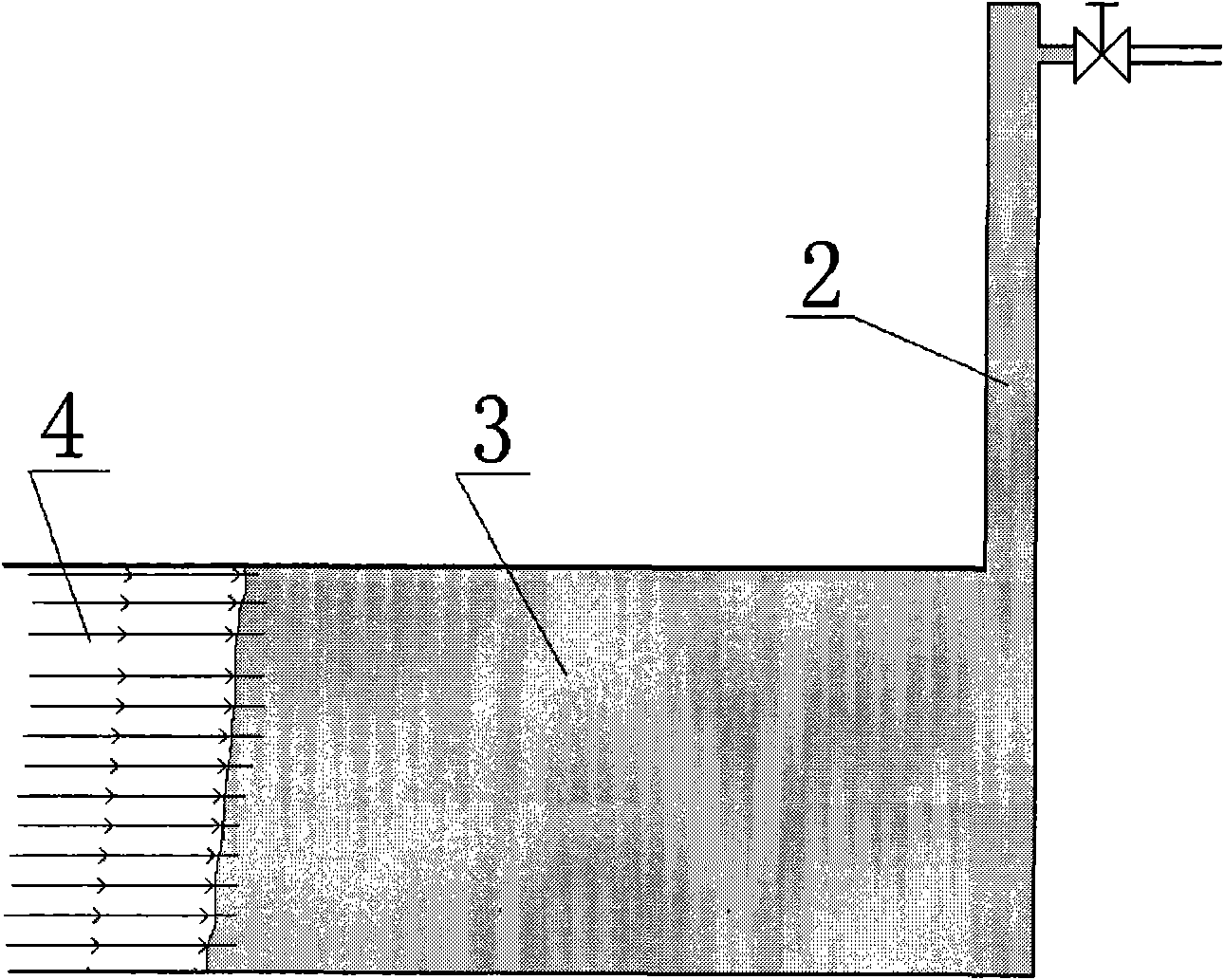

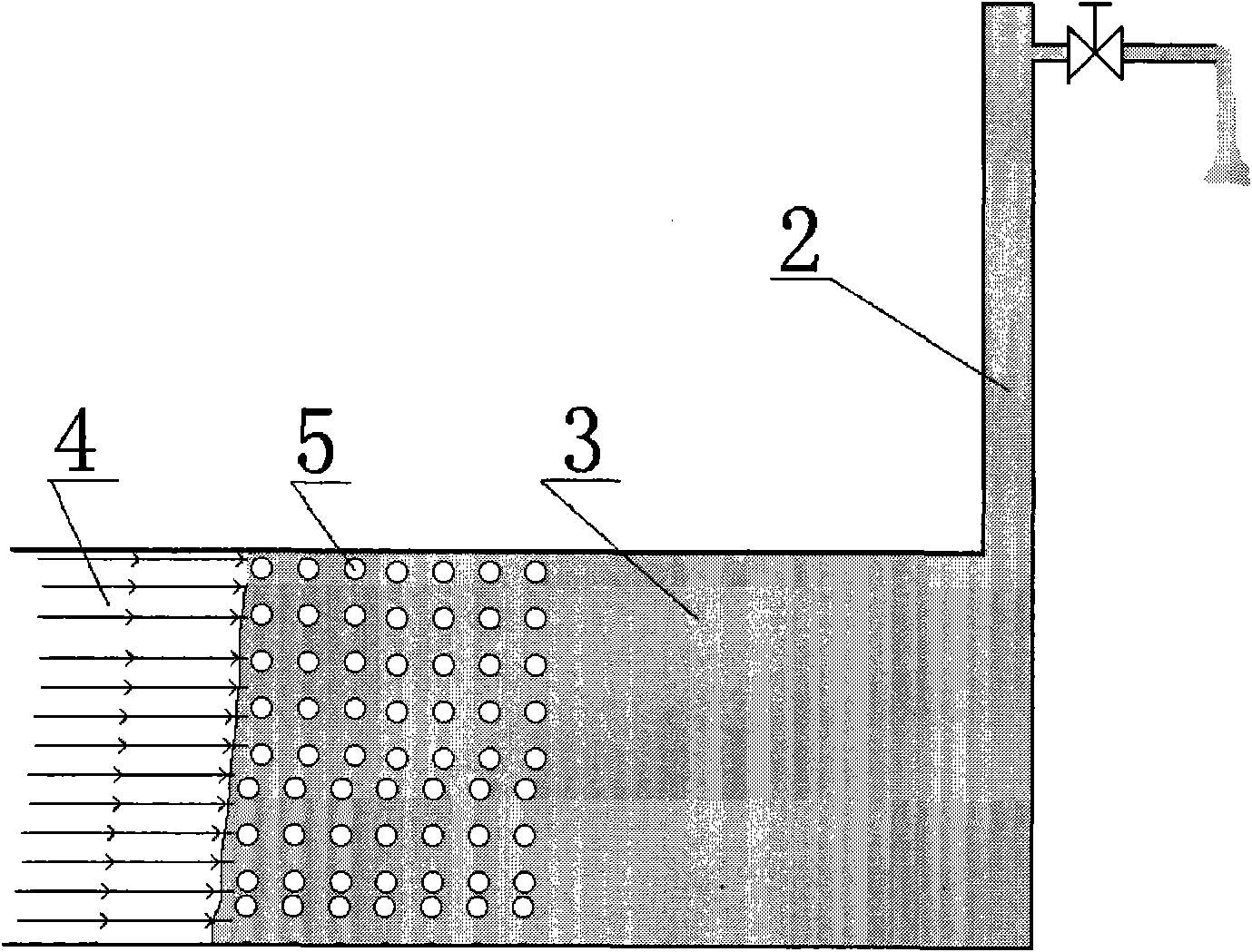

[0035] In a block of an oilfield, the depth of the oil layer is 1800 meters, and the thickness of the oil layer is 10 meters, and the depletion production has been carried out. Reservoir pressure is 12 MPa after depleted production. A decision was made to develop improved natural gas flooding.

[0036] refer to Figure 4 . Step 1: Well pattern in the natural gas flooding area: a nine-point well pattern is adopted, the gas injection well 1 is in the middle, and there are 8 production wells 2 around it, and the 8 production wells 2 are arranged in a rectangle. The gas injection well 1 is 100-200 meters away from the near production well 2, and 140-280 meters away from the far production well 2. In the present embodiment, there are 150 meters away from the nearer production well 2, ...

Embodiment 2

[0042] Embodiment 2: Taking a block with an oil reservoir pressure of 25 MPa as an example to carry out an improved natural gas flooding recovery process, the detailed description will be given.

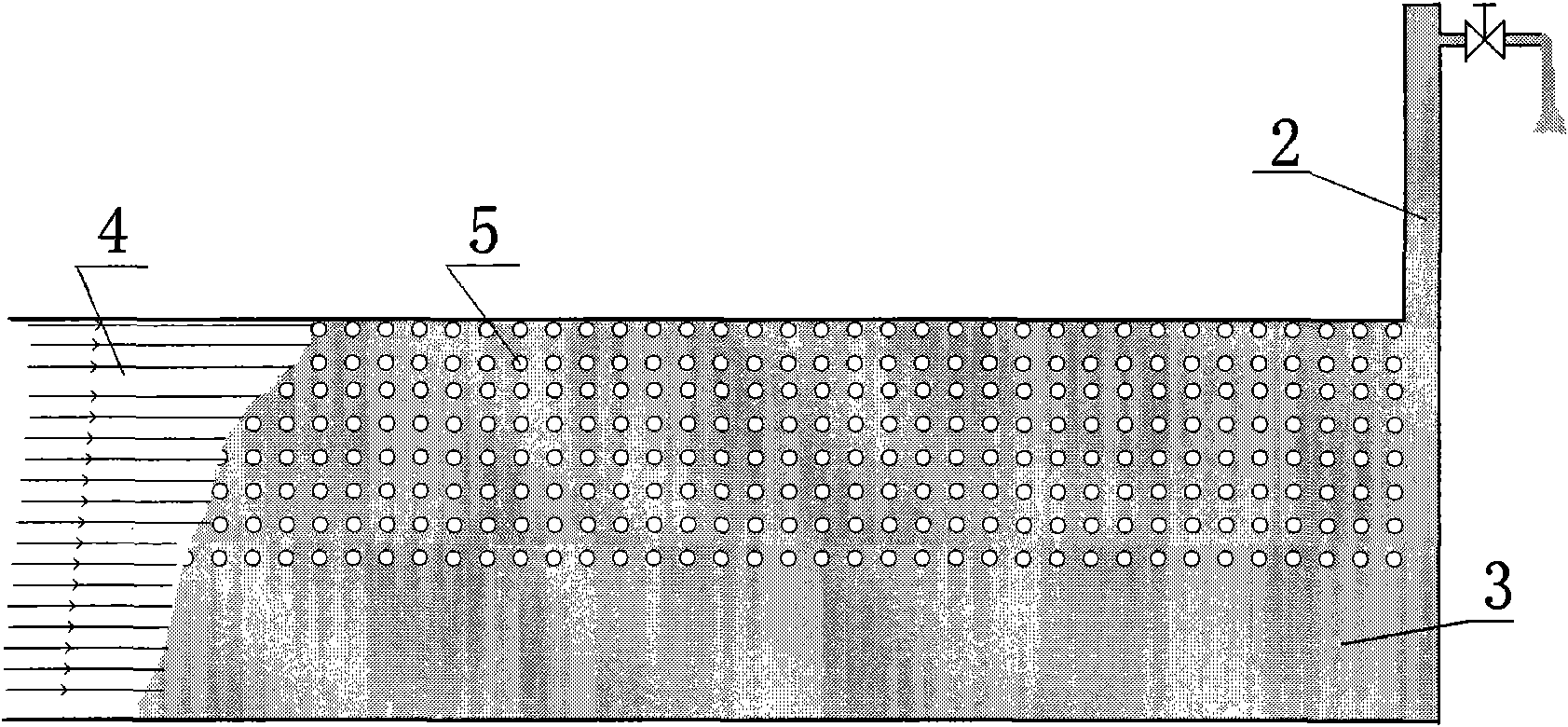

[0043] In a block of an oilfield, the depth of the oil layer is 3000 meters, and the thickness of the oil layer is 18 meters, and the depletion production has been carried out. Reservoir pressure is 25 MPa after depleted production. A decision was made to develop improved natural gas flooding.

[0044] refer to image 3 . Step 1: Improve the well pattern in the natural gas flooding area, adopt a nine-point well pattern, the gas injection well is in the middle, and there are 8 production wells around it. The distance between the production well 2 and the gas injection well 1 is 150 meters, and the distance between the production well 2 and the gas injection well 1 is 200 meters. . Gas injection equipment is connected to gas injection wells, and oil production equipment is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com