Sewage treatment agent for oil production plant

A kind of sewage treatment agent, the technology of oil production plant, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of slow sedimentation speed, high cost, poor effect, etc., and achieve the effect of low water content, excellent quality and rapid sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

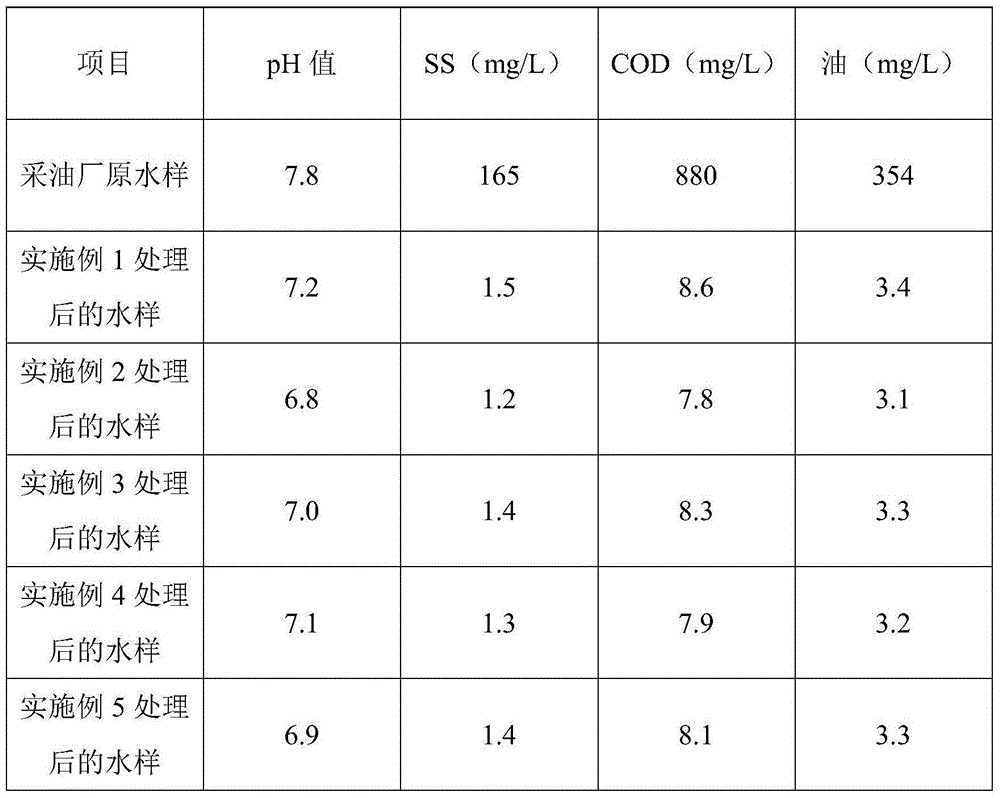

Examples

Embodiment 1

[0021] A sewage treatment agent for an oil production plant, which comprises the following raw materials in parts by weight: 40 parts of a demulsifier, 30 parts of a flocculant, 30 parts of a foaming agent, 20 parts of a flotation agent, 15 parts of a bactericide, and a corrosion inhibitor 10 parts, 10 parts of oxygen scavenger,

[0022] The demulsifier includes the following raw materials: 10 parts of fatty alcohol polyoxyethylene ether, 10 parts of polyethylene polyamine polyoxypropylene polyoxyethylene ether, 8 parts of secondary octylphenol polyoxyethylene ether, 6 parts of propylene oxide, 3 parts of ethylene oxide, 3 parts of potassium hydroxide;

[0023] The flocculant comprises the following raw materials: 12 parts of zirconium sulfate, 10 parts of aluminum sulfate, and 8 parts of alum;

[0024] The foaming agent comprises the following raw materials: 8 parts of sodium alkylpropanesulfonate, 8 parts of sodium alkylsulfonate, 4 parts of cetyltrimethylammonium nitrate, ...

Embodiment 2

[0030] A sewage treatment agent for an oil production plant, which comprises the following raw materials in parts by weight: 80 parts of demulsifier, 60 parts of flocculant, 60 parts of foaming agent, 50 parts of flotation agent, 35 parts of bactericide, anti-corrosion and scale inhibitor 20 parts, 20 parts of oxygen scavenger,

[0031] The demulsifier includes the following raw materials: 20 parts of fatty alcohol polyoxyethylene ether, 20 parts of polyethylene polyamine polyoxypropylene polyoxyethylene ether, 16 parts of secondary octylphenol polyoxyethylene ether, 12 parts of propylene oxide, 6 parts of ethylene oxide, 6 parts of potassium hydroxide;

[0032] The flocculant comprises the following raw materials: 30 parts of zirconium sulfate, 16 parts of aluminum sulfate, 14 parts of alum;

[0033] The foaming agent comprises the following raw materials: 16 parts of sodium alkylpropanesulfonate, 16 parts of sodium alkylsulfonate, 10 parts of cetyltrimethylammonium nitrate,...

Embodiment 3

[0039] A sewage treatment agent for an oil production plant, comprising the following raw materials in parts by weight: 60 parts of a demulsifier, 45 parts of a flocculant, 45 parts of a foaming agent, 35 parts of a flotation agent, 25 parts of a bactericide, and a corrosion inhibitor 15 parts, 15 parts of oxygen scavenger,

[0040] The demulsifier includes the following raw materials: 15 parts of fatty alcohol polyoxyethylene ether, 15 parts of polyethylene polyamine polyoxypropylene polyoxyethylene ether, 12 parts of secondary octylphenol polyoxyethylene ether, 8 parts of propylene oxide, 5 parts of ethylene oxide, 5 parts of potassium hydroxide;

[0041] The flocculant comprises the following raw materials: 20 parts of zirconium sulfate, 13 parts of aluminum sulfate, 12 parts of alum;

[0042] The foaming agent comprises the following raw materials: 12 parts of sodium alkylpropanesulfonate, 12 parts of sodium alkylsulfonate, 8 parts of cetyltrimethylammonium nitrate, and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com