Oil production block produced water reinjection method

A technology for producing water and blocks, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve problems such as pore and throat blockage, substandard reinjection water quality, and reduced injectability of injection water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

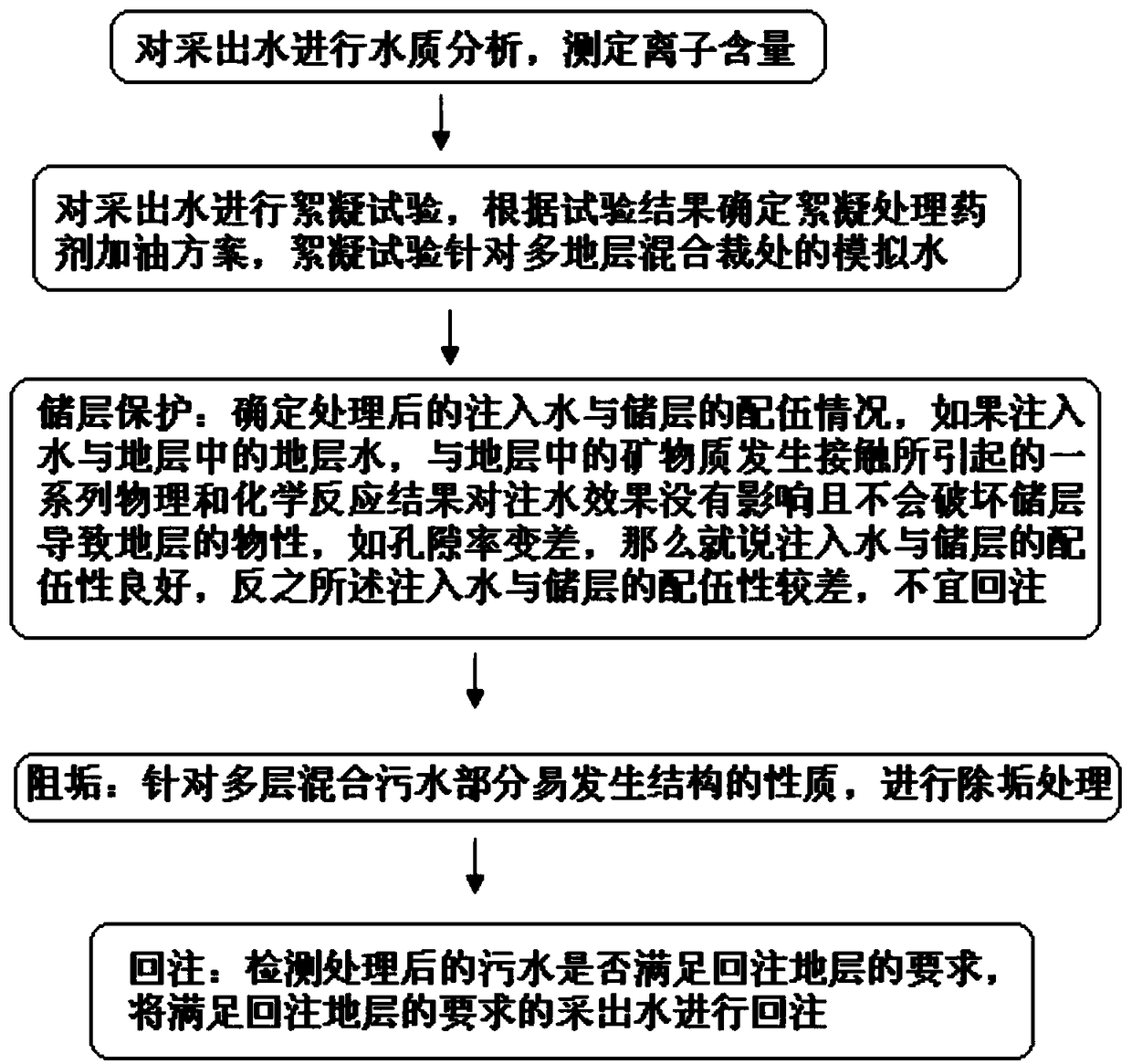

[0038] This embodiment is carried out for an oilfield in Hebei, and the method for reinjection of produced water in the oil production block includes:

[0039] (1) Carry out water quality analysis to produced water, measure ion content, and described ion comprises cation, Na + , K+ , Ca 2+ , Mg 2+ , Ba 2+ ,Sr 2+ , Fe 2+ , Fe 3+ , the anion Cl - , CO 2 2- , HCO 3 - ,OH - , SO 4 2- , content of sulfuric acid reducing bacteria, saprophytic bacteria and iron bacteria, average corrosion rate, scaling amount, suspended solids content and oil content;

[0040] (2) Carry out flocculation test to produced water, determine flocculation treatment agent refueling scheme according to test result, described flocculation test is aimed at the simulated water of multi-layer mixed cutting place;

[0041] (3) Reservoir protection: Determine the compatibility between the treated injected water and the reservoir. If the injected water contacts the formation water in the formation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com