Patents

Literature

50results about How to "Guaranteed Filtration Speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

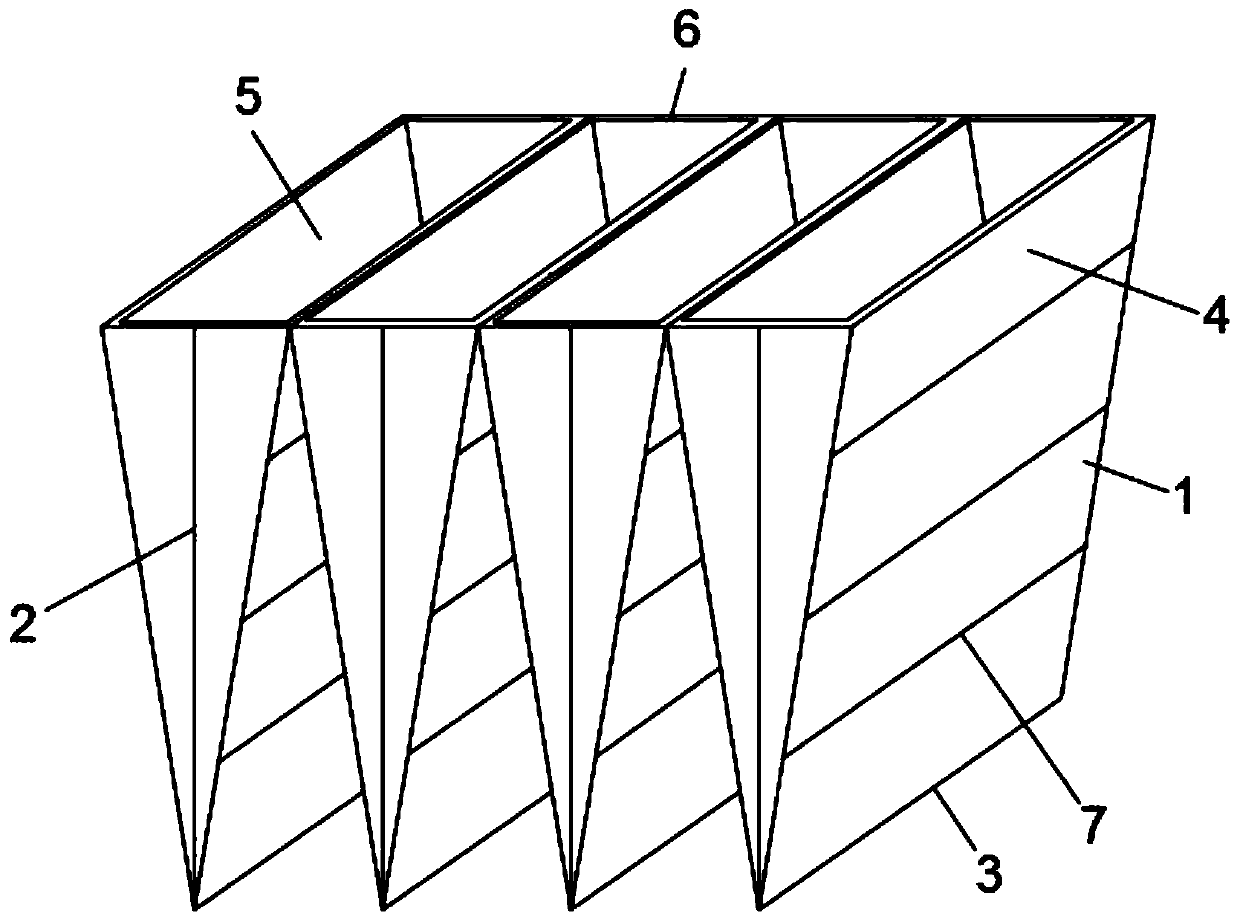

Quantitative filter paper and preparing method and application thereof

InactiveCN104878642AGuaranteed Filtration SpeedFast filtrationPaper/cardboardChemical/chemomechanical pulpFilter paperFiber

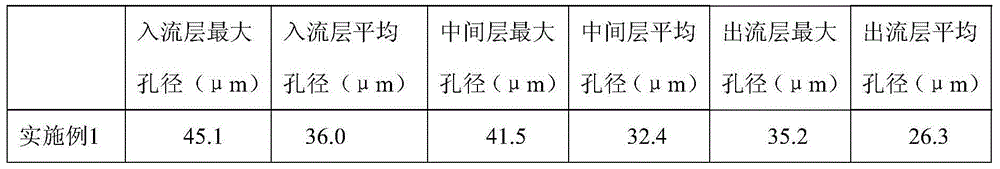

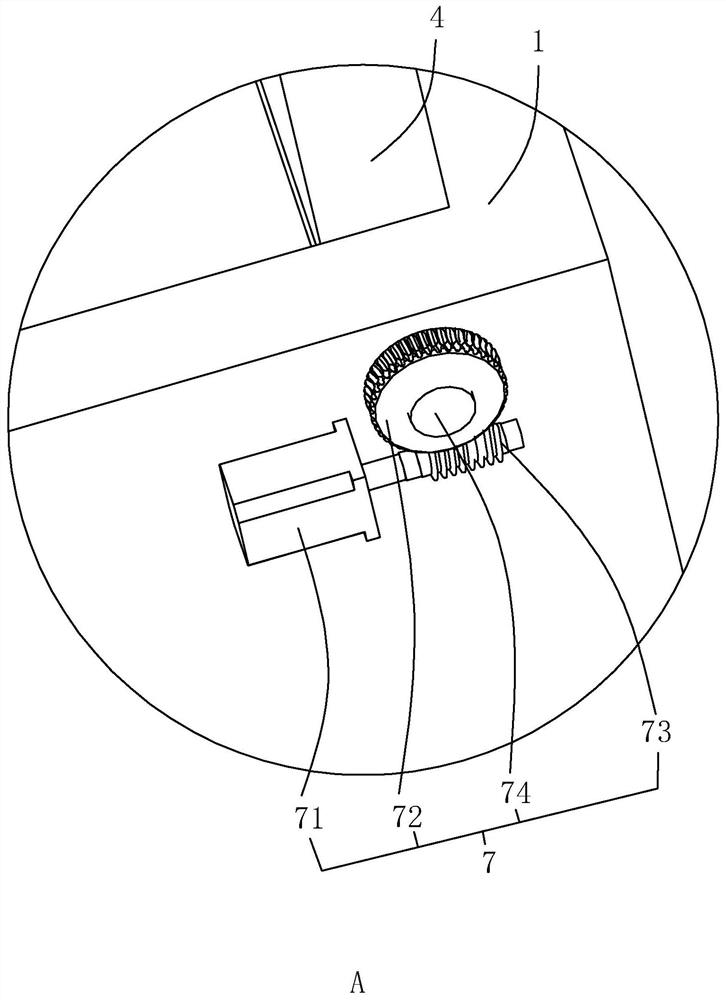

The invention discloses quantitative filter paper, comprising an inflow layer, a middle layer and an outflow layer. The inflow layer is made by forming, pressing and drying slurry 14 DEG SR to 17 DEG SR in beating degree; the middle layer is made by forming, pressing and drying pulp 19 DEG SR to 21 DEG SR in beating degree; the outflow layer is made by forming, pressing and drying pulp 23 DEG SR to 25 DEG SR; the inflow layer, the middle layer and the outflow layer are made of the pulp of same material. The invention further discloses a preparing method of and application of the quantitative filter paper. The layers have different beating degrees of the pulp, the different void distributions of the insides are ensured, and high filtering speed, high precision and high stability are integrated; the preparing method ensures that the fibers in the layers are tightly tangled together, no evident interface occurs, the three-layer composite filter payer manufactured with the pulp is in a complete structure, and smoothness of the separating process is ensured.

Owner:杭州特种纸业有限公司

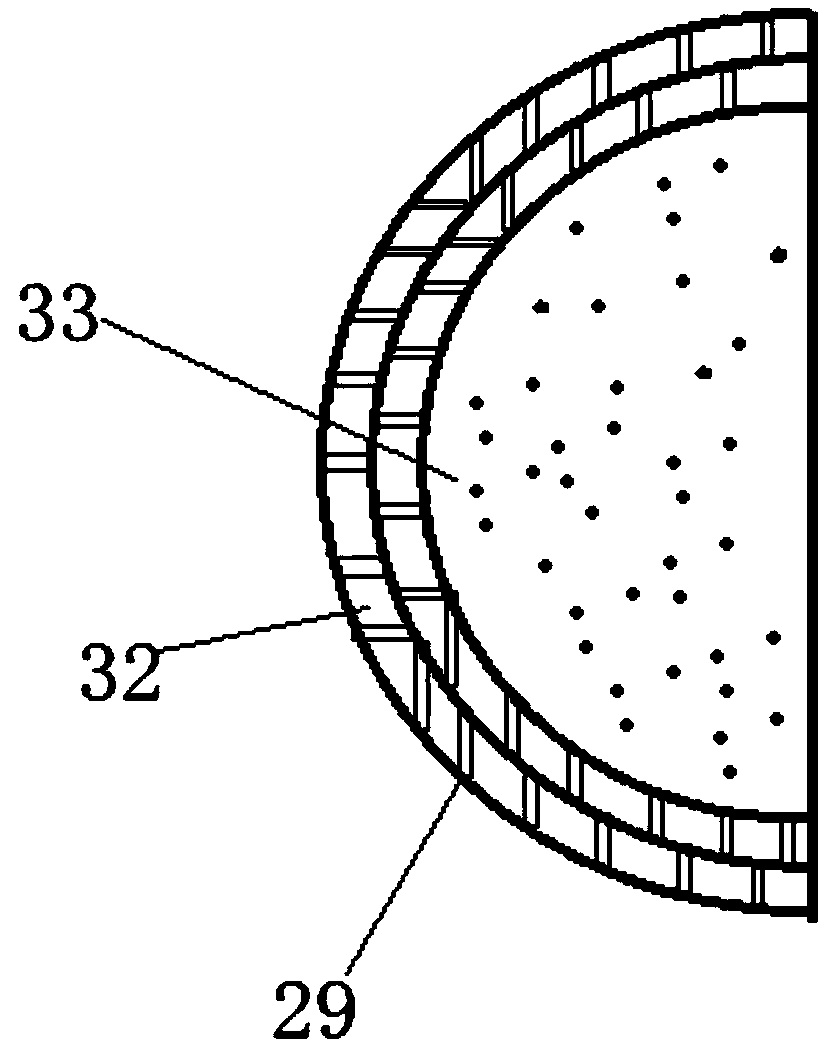

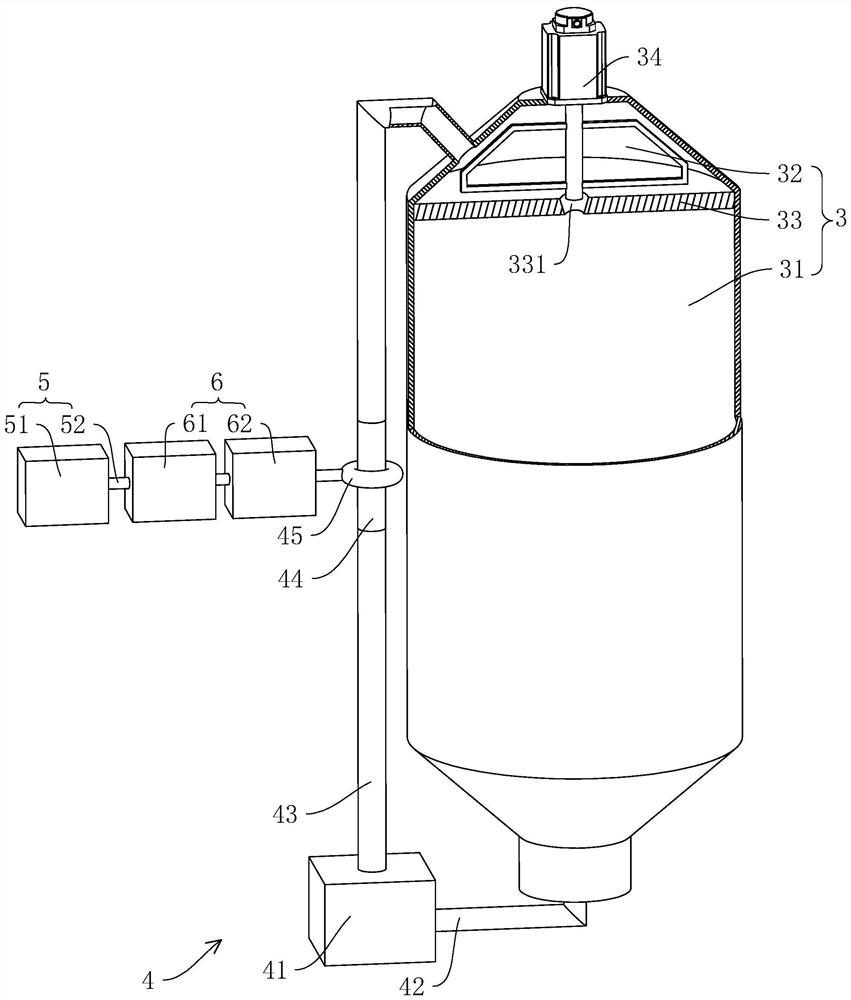

Method for preparing marsh gas through straw, excrement and kitchen waste

ActiveCN103451095AThorough responseImprove resource utilizationBioreactor/fermenter combinationsBio-organic fraction processingEngineeringPre treatment

The invention relates to a method for preparing marsh gas through straw, excrement and kitchen waste, and belongs to the technical field of renewable energy. The method comprises the following steps of: a, preprocessing, namely, feeding crushed straw, kitchen waste and excrement into a preprocessing tank; mixing; then transferring into a premixing tank to heat at a constant temperature; and uniformly mixing to obtain a mixture; and b, anaerobic fermentation, namely, feeding the mixture into at least one anaerobic fermentation tank to heat at the constant temperature; and agitating and fermenting to obtain the marsh gas and fermentation residues. The method has the beneficial effects that the operation is stable; the production efficiency of marsh gas is high; the production cost can be reduced; and mass popularization can be performed.

Owner:GUANGXI YUDA WATER PROCESSING ENVIRONMENTAL PROTECTION ENG CO LTD

Method for producing glucose bulk drug for injection by using rice

ActiveCN102703547AHigh biological potencyImprove saccharification puritySugar derivativesFermentationIon exchangeChemistry

The invention provides a method for producing a glucose bulk drug for injection by using rice. The method comprises the following steps of: soaking and defibrination, size mixing, liquefaction and slag removal, saccharification, primary decoloration and filtration, secondary decoloration and filtration, ion exchange, concentration and refining, primary crystallization, primary centrifugation, sugar solution, sugar concentration and decoloration, secondary sugar boiling and crystallization, secondary centrifugation, drying, packaging and the like. The method has the following advantages: (1), a two-time crystallization process is adopted, the quality is high, and a filtration speed is quick; (2), the problem that a raw material for producing an injection glucose in the south does not existis solved by using the rice as the raw material, and the blank of the production of a crystalline glucose in the south is filled; (3), the crystalline glucose produced by using the rice as the raw material has low-irritability in absorption property and is high in biological value; and (4), a breeding fermentation problem in a production procedure is solved successfully, the sugar concentration and the filtration are added, the quality of a finished product is greatly improved, and the clarity and the filtration speed of the product are guaranteed. The continuous feed and the continuous discharge can be carried out; the crystallization and fermentation contamination is stopped; the quality can be guaranteed; and the continuous production is guaranteed.

Owner:北京佳沃臻诚科技有限公司

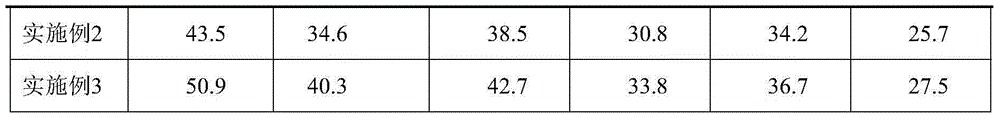

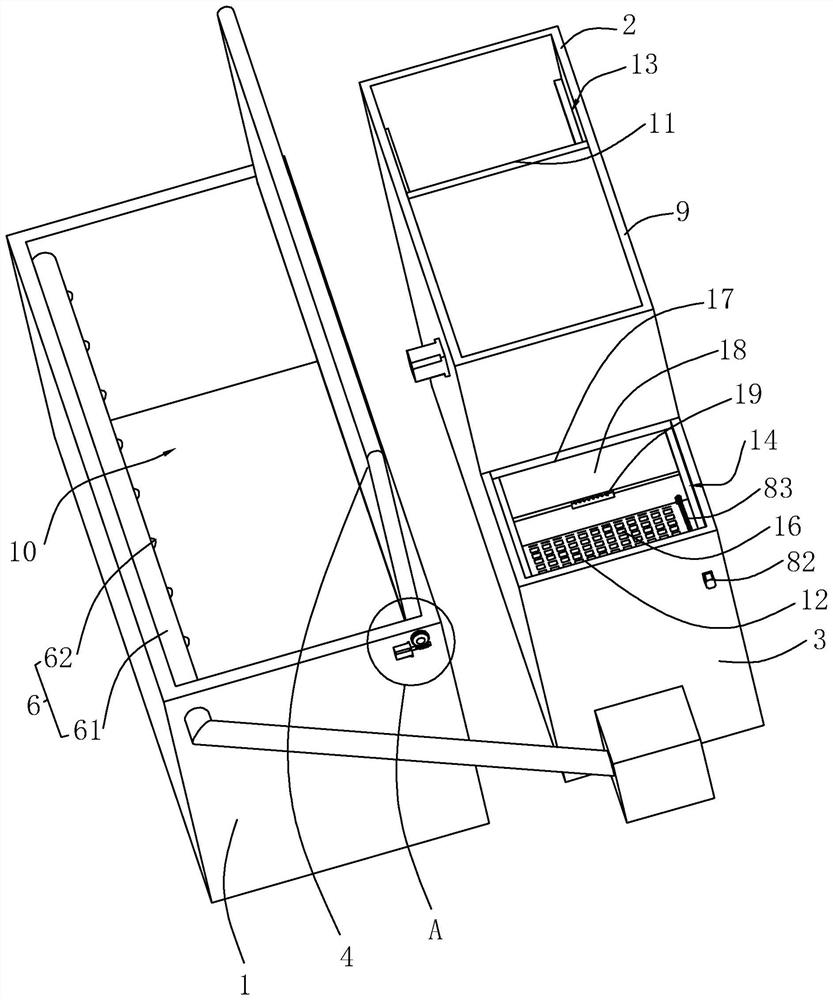

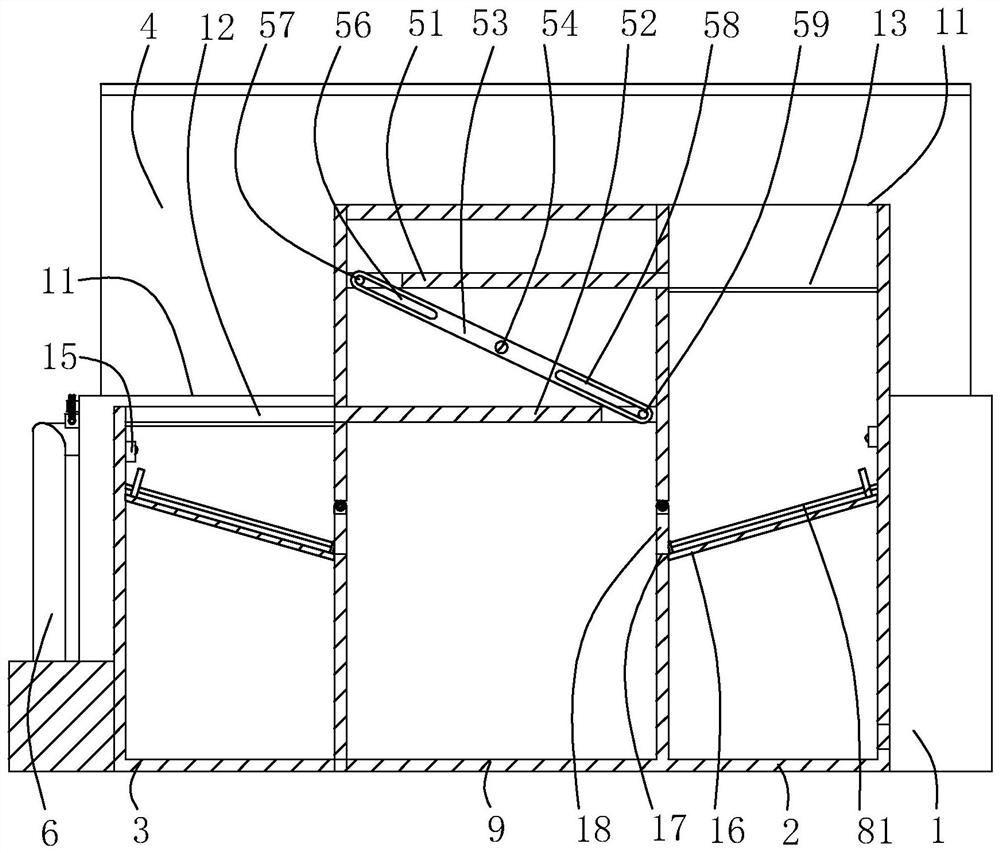

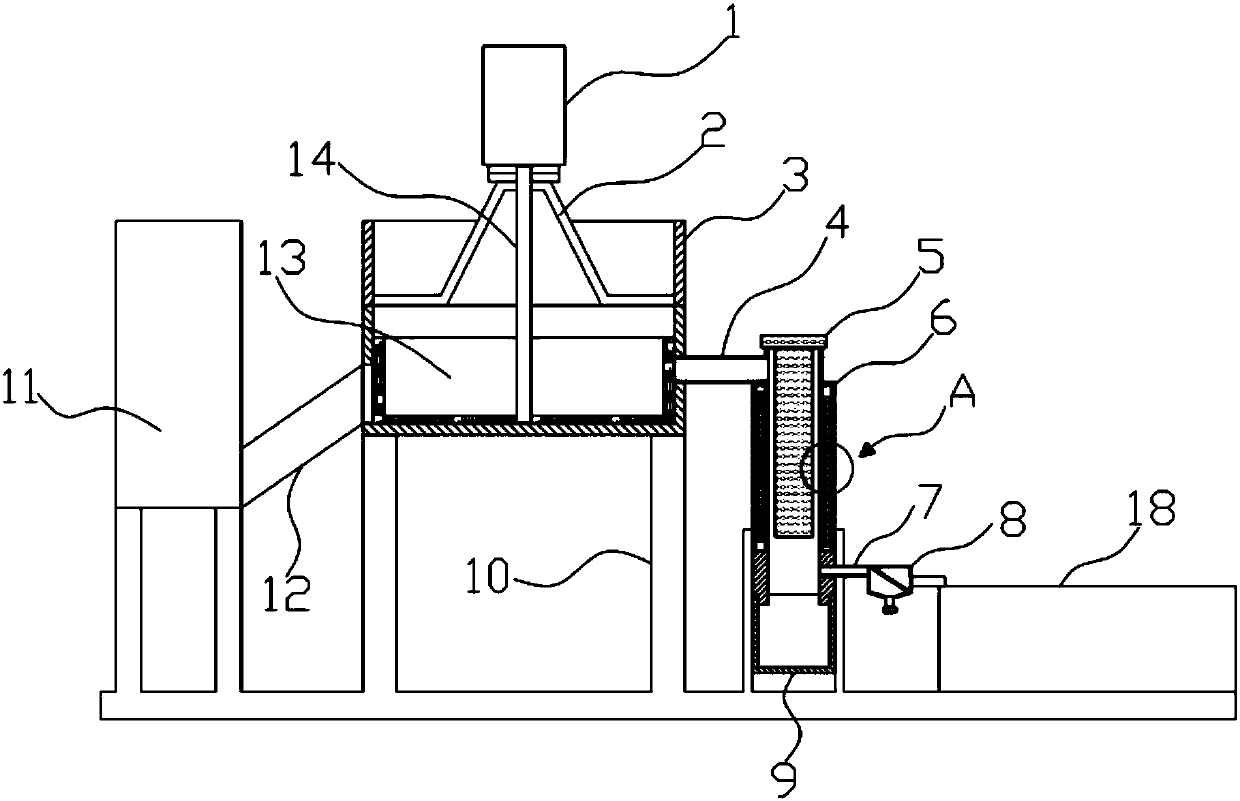

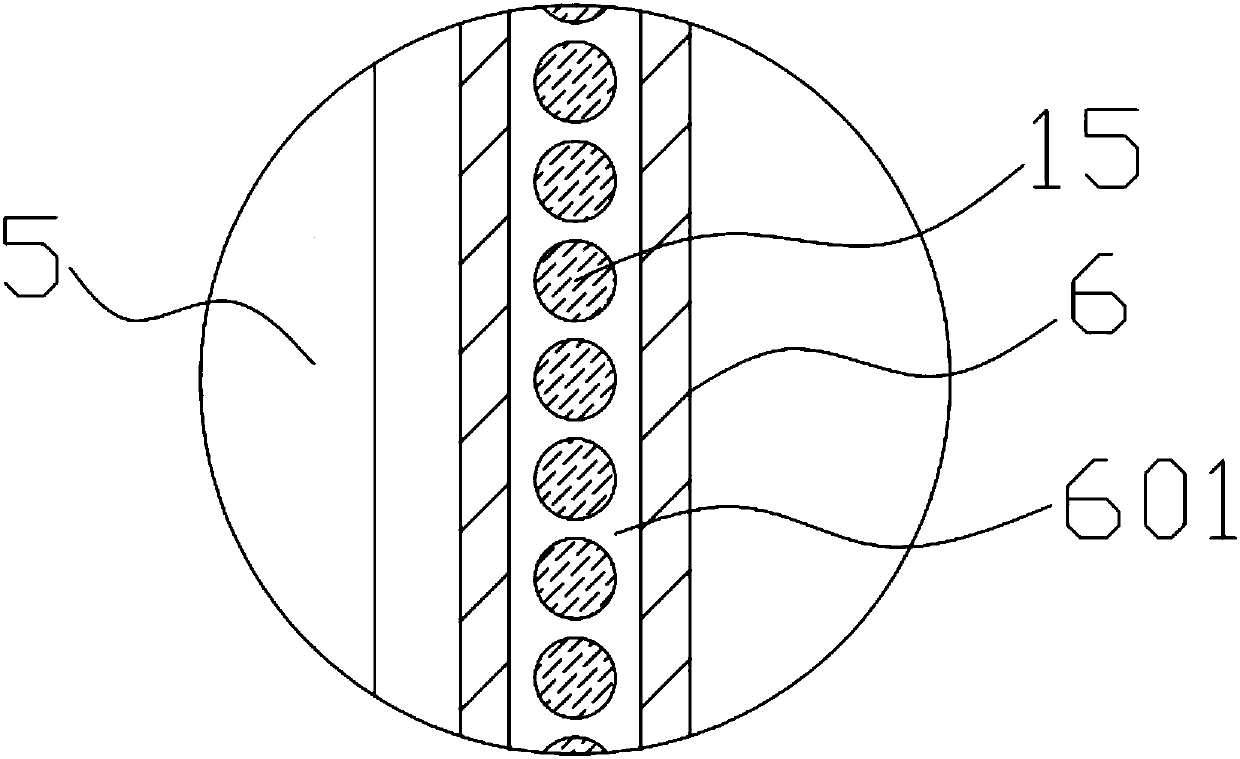

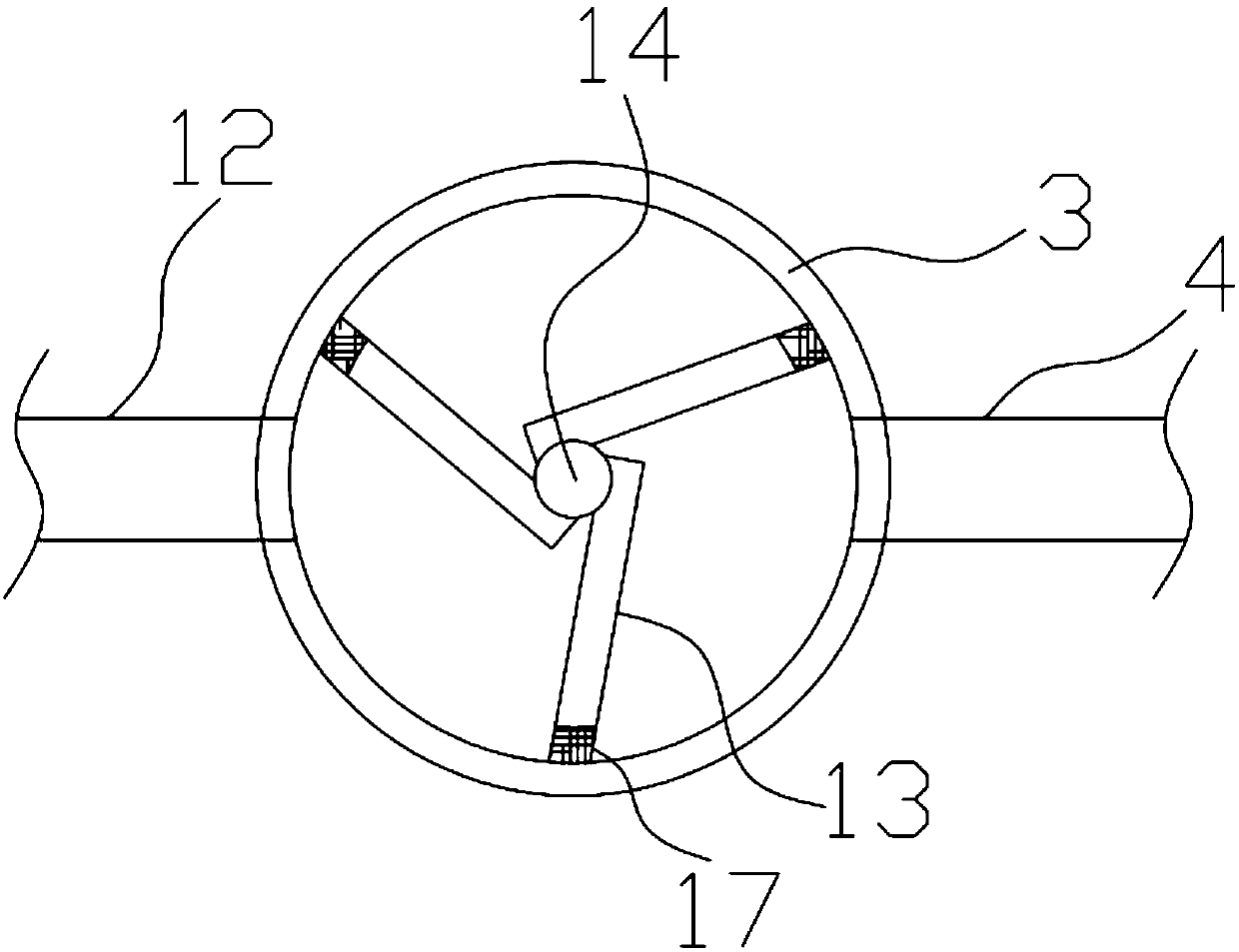

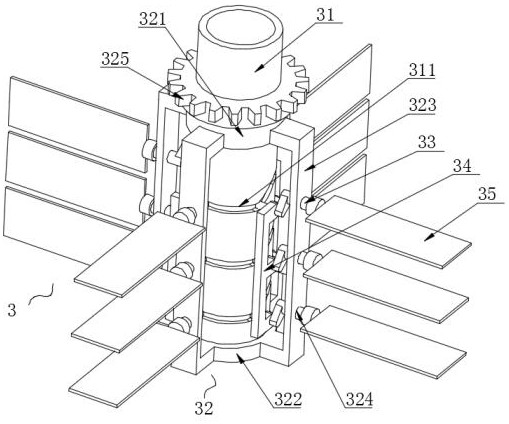

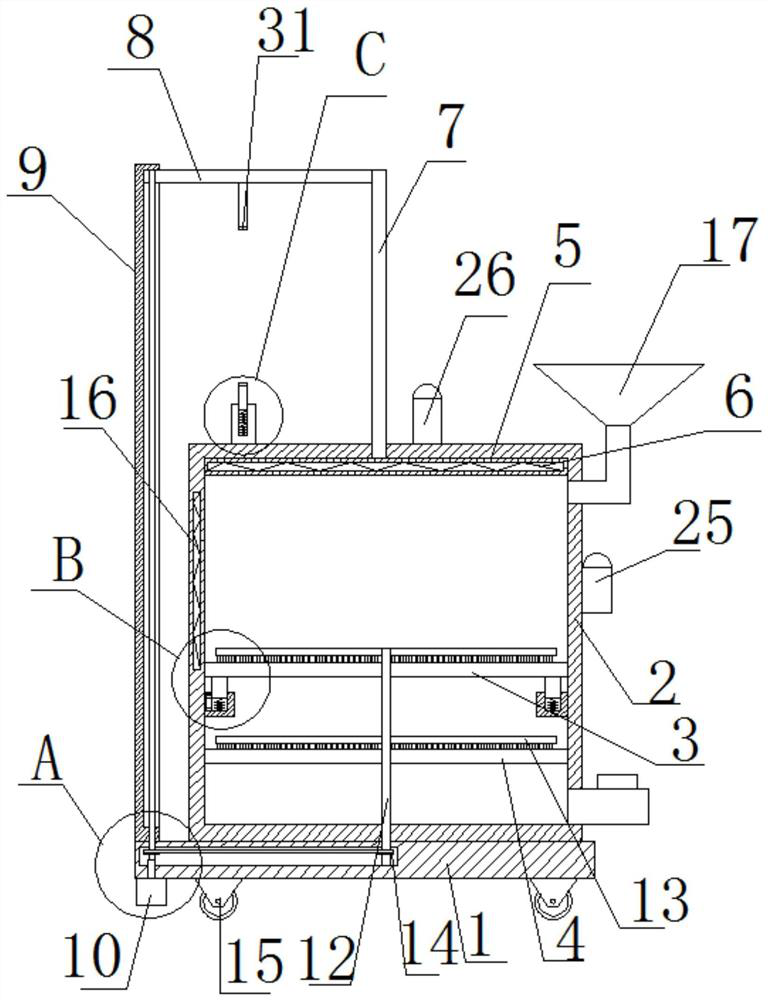

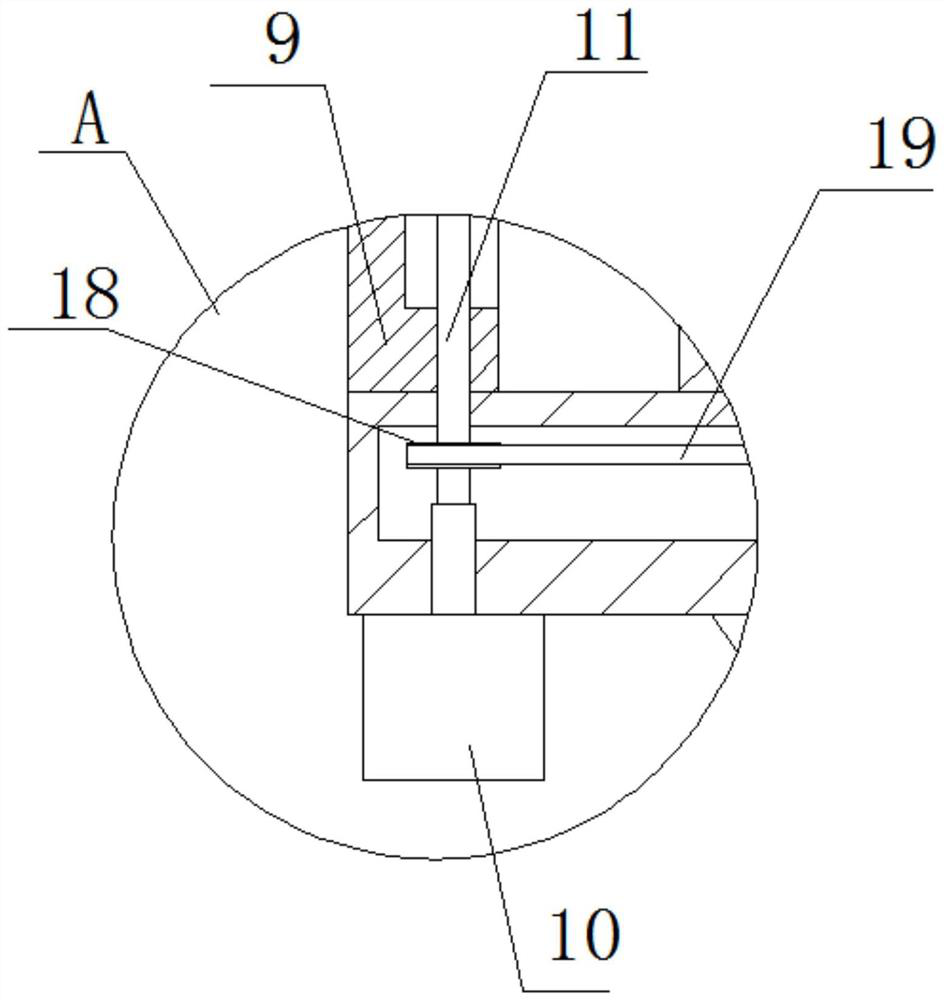

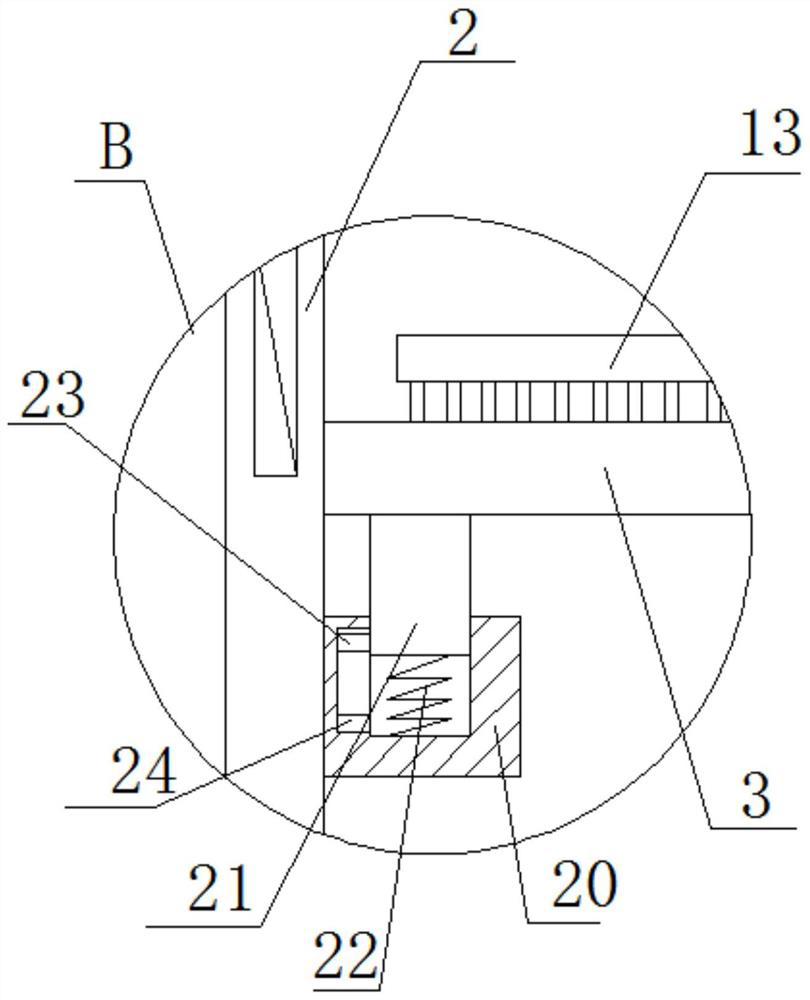

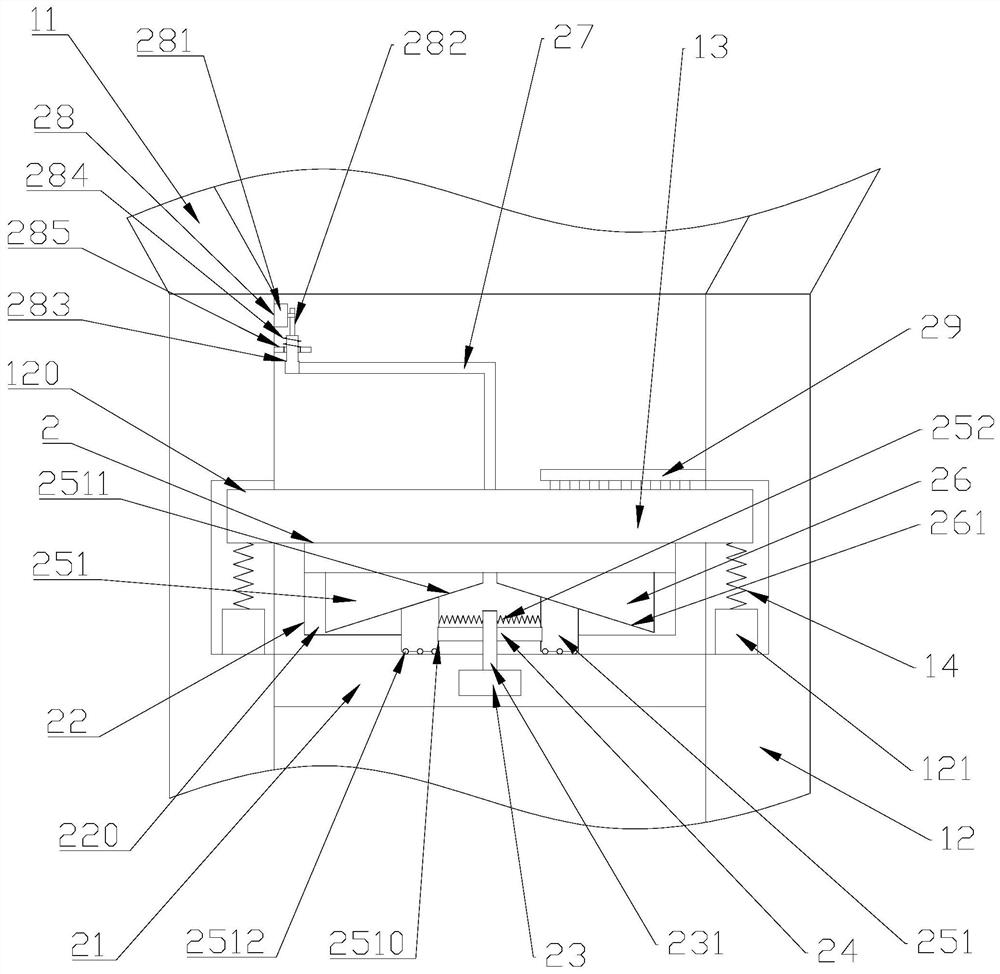

Rainwater collecting and recycling system of green building

ActiveCN111608229AGood energy saving effectLow costGeneral water supply conservationWatering devicesEngineeringRainwater harvesting

The invention relates to the technical field of rainwater collection and utilization, in particular to a rainwater collecting and recycling system of a green building. The rainwater collecting and recycling system of the green building comprises a planting box, a first water collecting box, a second water collecting box, a shielding mechanism, a baffle, an irrigation mechanism and a driving mechanism which are arranged on a roof, wherein the planting box is used for planting plants; the planting box is provided with an opening, the baffle rotates to shield the opening, and the driving mechanism is used for driving the baffle to rotate; a first water collecting opening is formed above the first water collecting tank, and a second water collecting opening is formed above the second water collecting tank; and the shielding mechanism comprises a first shielding plate and a second shielding plate, the first shielding plate and the second shielding plate are both movable, the first shieldingplate is used for moving to open or close the first water collecting opening, and the second shielding plate is used for moving to open or close the second water collecting opening. The rainwater collecting and recycling system of the green building has the following effects that 1, the rainwater collecting and recycling system of the green building has the advantage of good energy-saving effect;and 2, the cost is saved.

Owner:广东广美建设工程有限公司

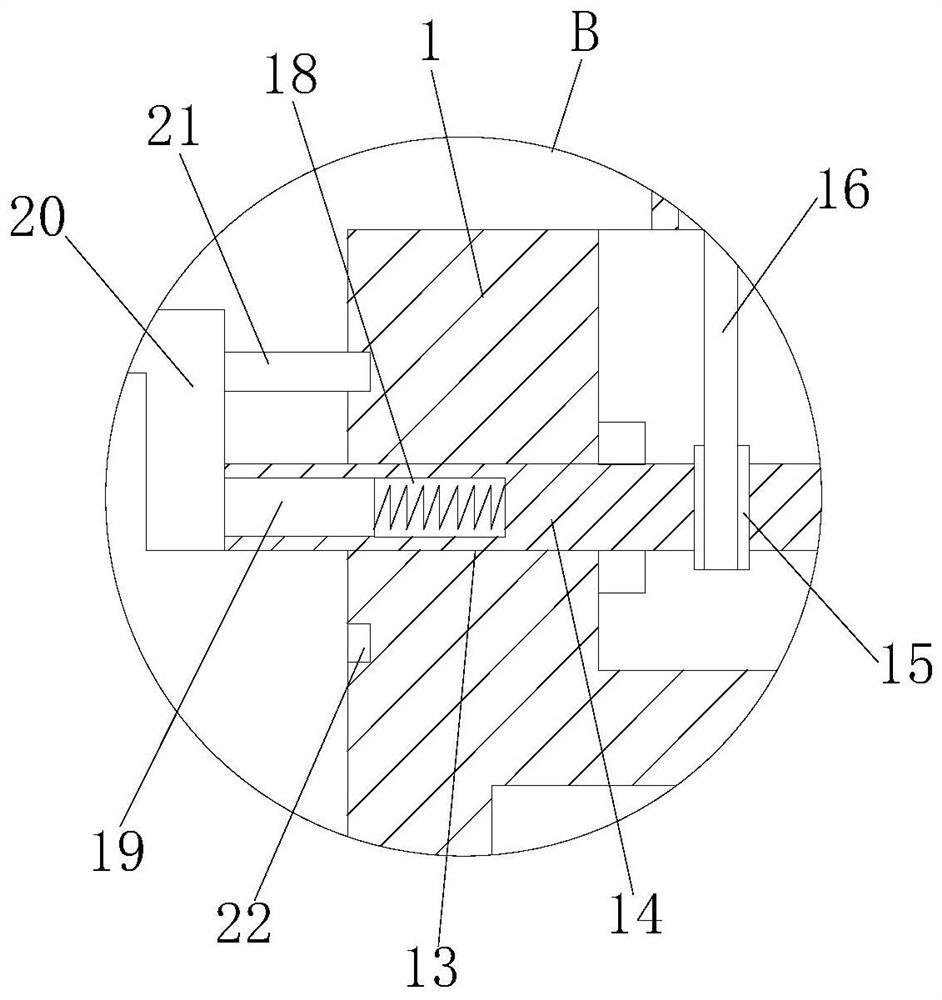

Cutting fluid recovering device for machining

InactiveCN107584327AGuaranteed Filtration SpeedAvoid accumulationMaintainance and safety accessoriesGratingEngineering

The invention discloses a cutting fluid recovering device for machining. The cutting fluid recovering device comprises a bracket, wherein a second collecting box, a separating cabin and an absorbing cabin are successively fixed on the bracket; the second collecting box is connected with the bottom of one side of the separating cabin through a guide slot; the middle part on the other side of the separating cabin is connected with the top end of the absorbing cabin through a guide pipe; a filtering box and a third collecting box are successively connected with the bottom of the absorbing cabin through a liquid draining pipe; a filtering plate is fixed on the upper part in the separating cabin; a rotating shaft of a motor extends into the separating cabin and is fixed with a grating plate; anabsorbing column is arranged in the absorbing cabin; a wire is arranged in an interlayer; the bottom of the absorbing cabin is in threaded connection with the top of a first collecting box. Accordingto the invention, the filtering plate, the grating plate, the absorbing column and the filtering box are adopted for treating the cutting fluid in turn, so that the impurities in the cutting fluid can be effectively removed, the device has a self-cleaning function, the recycling efficiency of the cutting fluid is guaranteed and the maintenance frequency is reduced.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

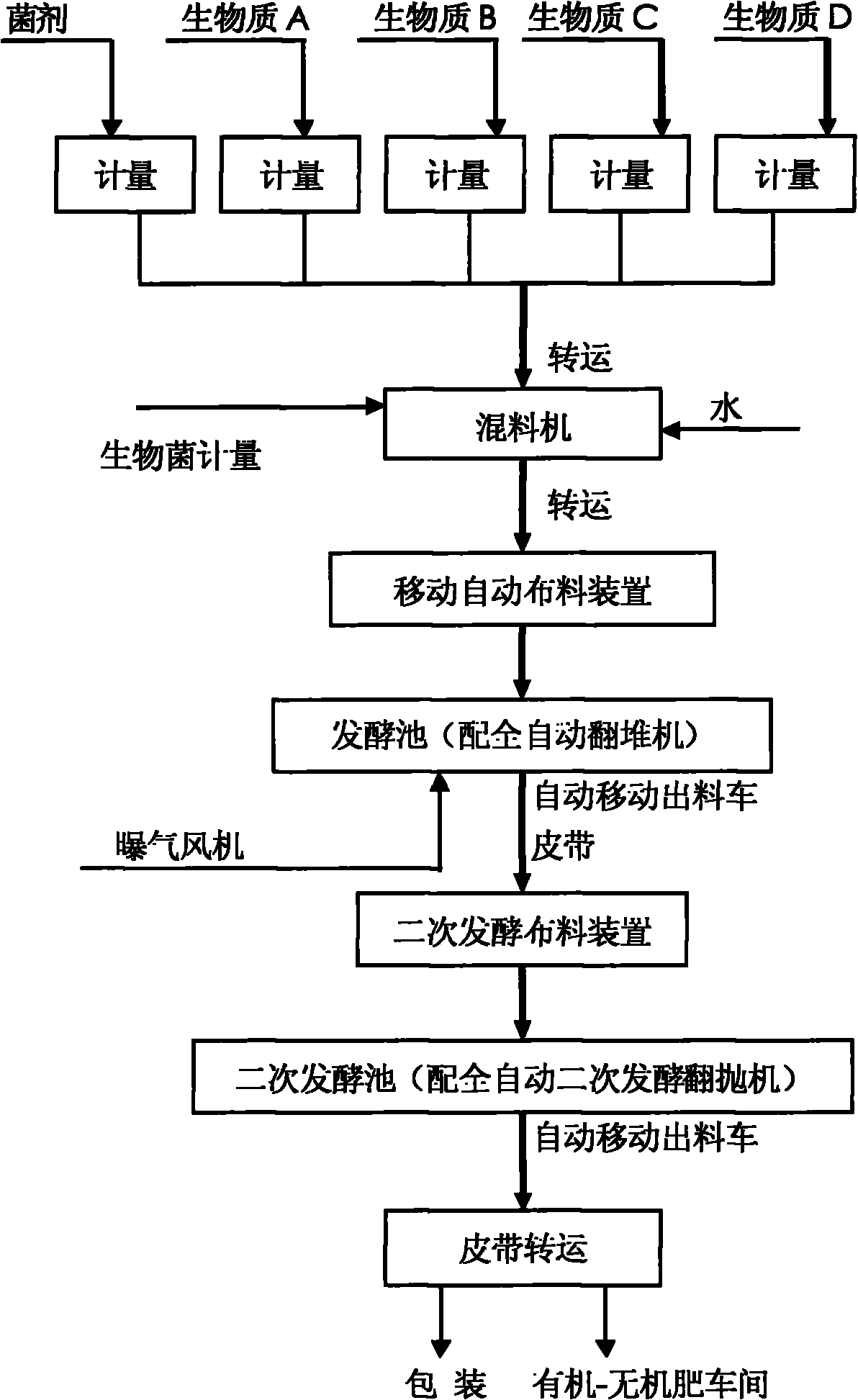

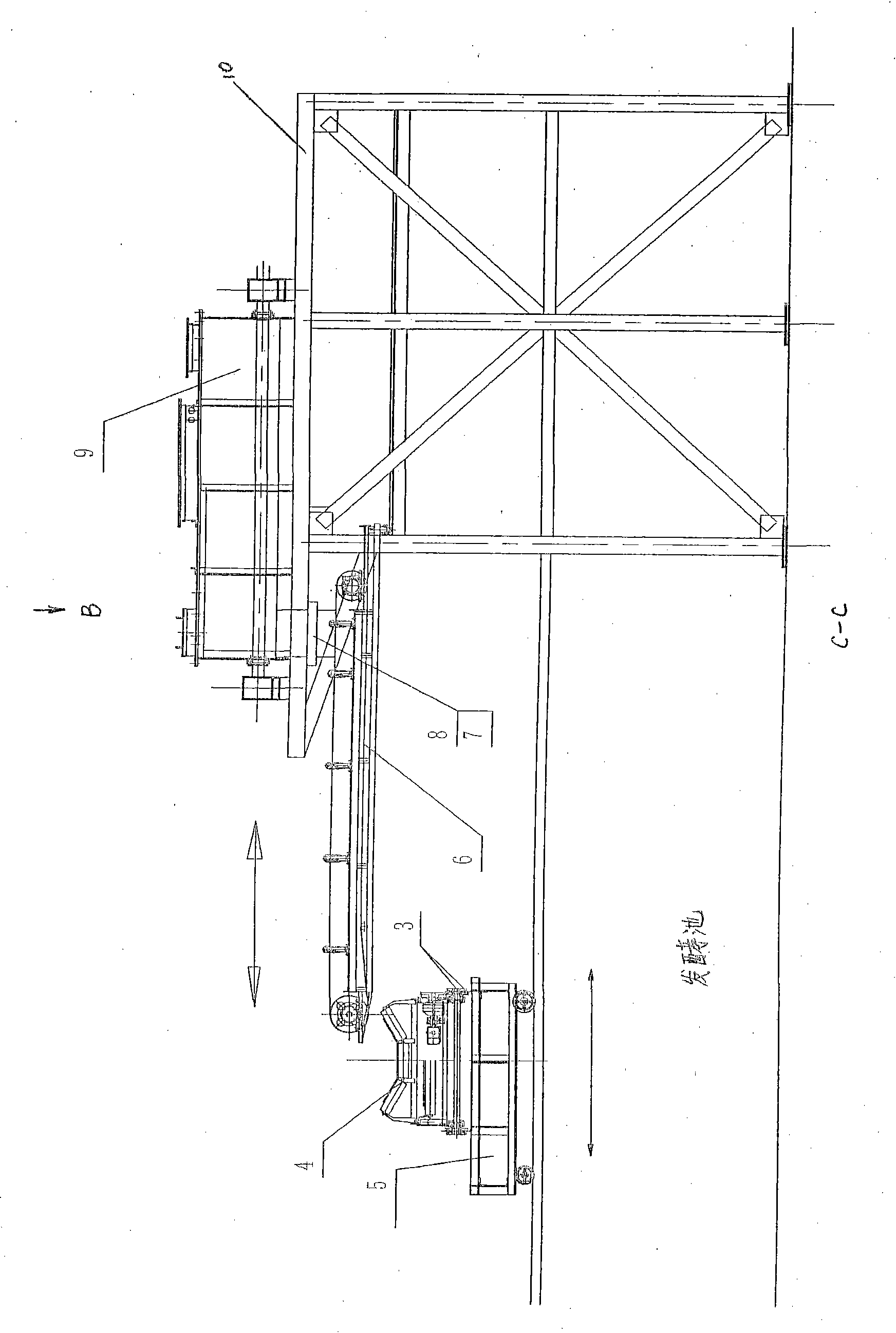

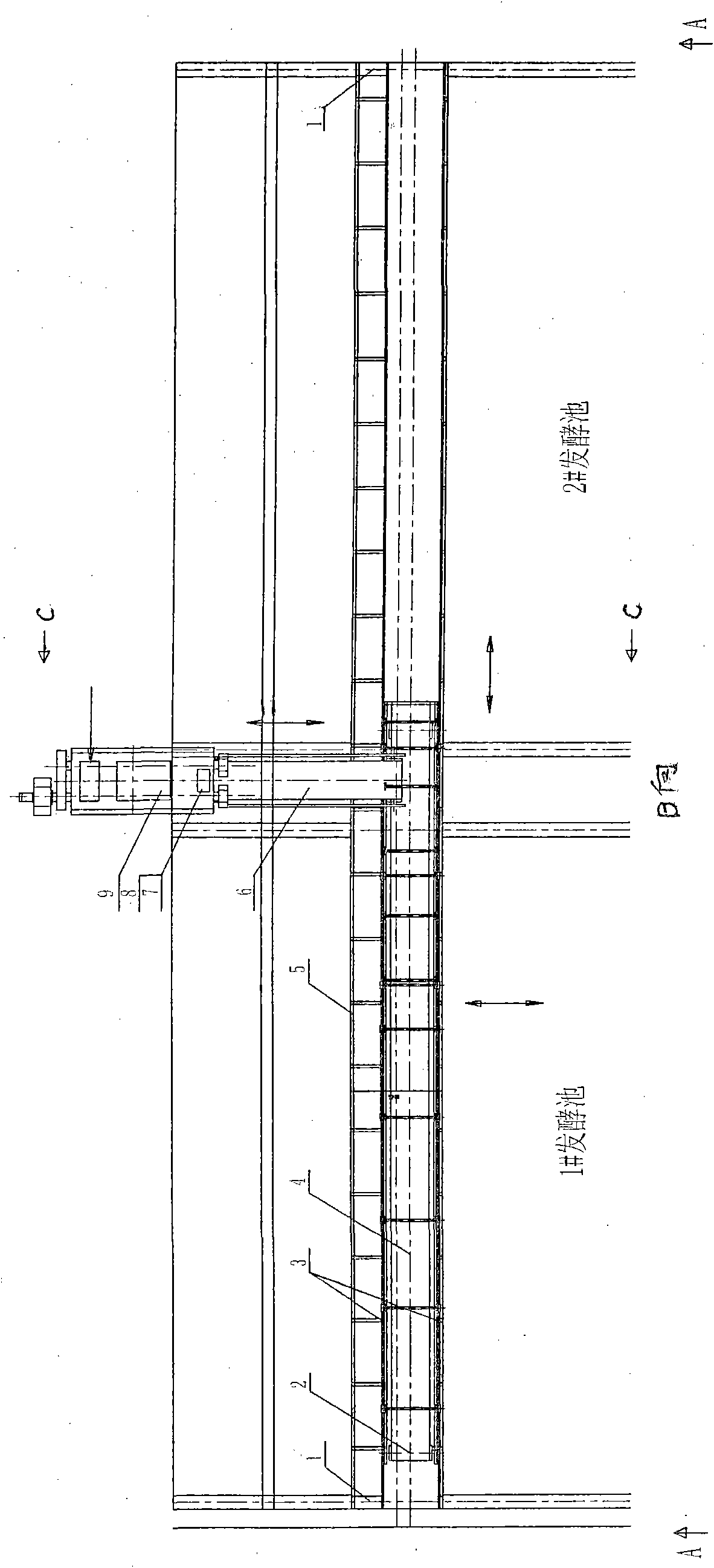

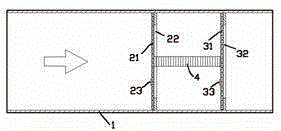

Fermentation technology for organic fertilizer

ActiveCN102060584AControl the fermentation speedGuaranteed Filtration SpeedBio-organic fraction processingOrganic fertiliser preparationBLENDER/MIXERAutomatic control

The invention discloses a fermentation technology for an organic fertilizer, comprising the following steps: after different fermentation materials are metered, causing the materials to enter a blender mixer; adding the mixture into a mobile automatic material distribution device to be distributed into a fermenting vat; turning and throwing everyday in the fermenting vat to guarantee the fermentation speed; after reaching the fermentation period of the organic fertilizer, carting, carrying out secondary material distribution to a secondary fermenting vat; and fermenting to obtain the organic fertilizer. In the fermentation technology, no forklifts are required to distribute and discharge materials, thus eliminating the mechanical loss brought by forklift operation, improving the product yield, and eliminating the pollution on the production environment by the forklift. All technical control points in the device can be automatically controlled by a programmable logical control (PLC) system, thus the manual production cost is lowered, the operation environment is improved, and the production continuity is guaranteed. Various different organic fertilizer varieties can be stored in bulk for providing guarantee for product diversification. The pressure for a product library can be lowered, and temporary packaging or formula packaging can be carried out as required.

Owner:YUNNAN YUNYE FERTILIZER

Sewage filtering system

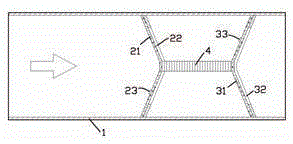

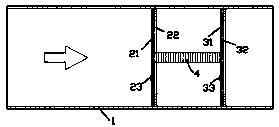

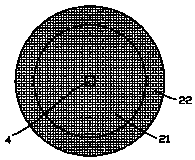

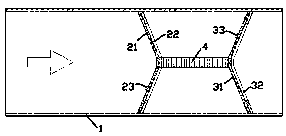

ActiveCN105561660ASignificant filter effectGuaranteed filtering effectMembrane filtersStationary filtering element filtersFilter systemSewage

The invention provides a sewage filtering system which comprises a filtering pipe. A front filter net and a rear filter net are arranged inside the filtering pipe in a tensioned manner, each of the front filter net and the rear filter net is made of soft iron wires which all can move transversely, a front annular plate and a rear annular plate which extend inward in the radial direction of the inner wall of the filtering pipe are arranged in the filtering pipe and stick close to the front filter net and the rear filter net respectively, a bar-shaped electromagnet is arranged on a central connecting line of the front filter net and the rear filter net, the front filter net and the rear filter net are symmetric according to the middle section of the electromagnet, a front piezometer and a rear piezometer are arranged on the front sides of the front filter net and the rear filter net respectively, and the front piezometer, the rear piezometer and the electromagnet are jointly coupled to a controller outside the filtering pipe. The sewage filtering system can actively adjust mesh size of the filter nets according to the size of impurity particles in the process of primary filtering of particle impurities in sewage, thereby taking both filtering speed and filtering effect into consideration.

Owner:广东金碧蓝环境科技有限公司

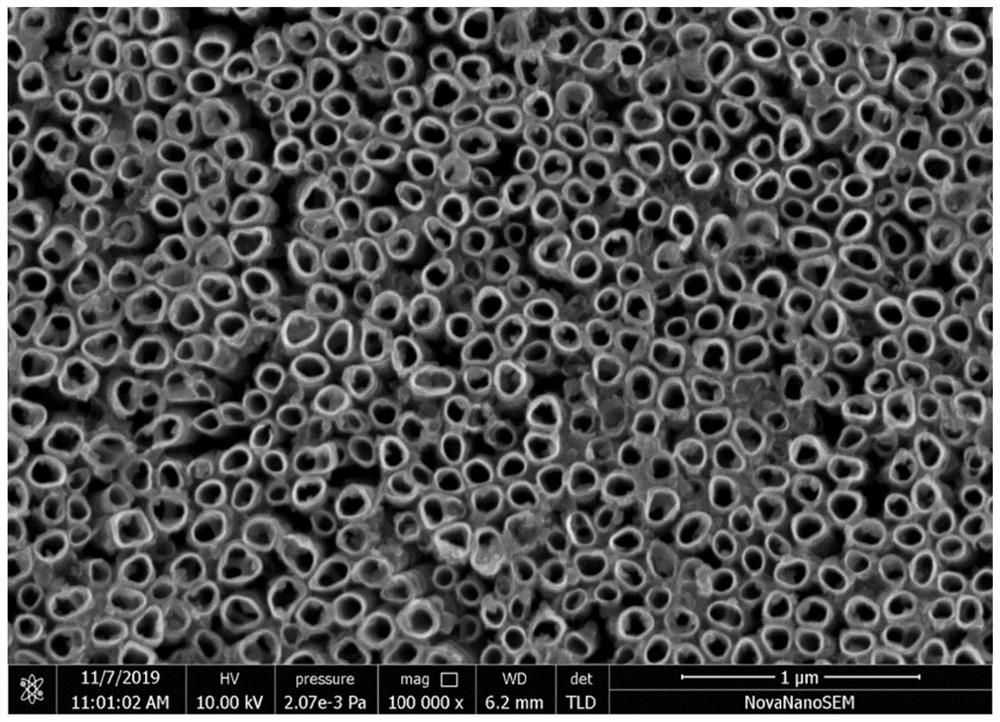

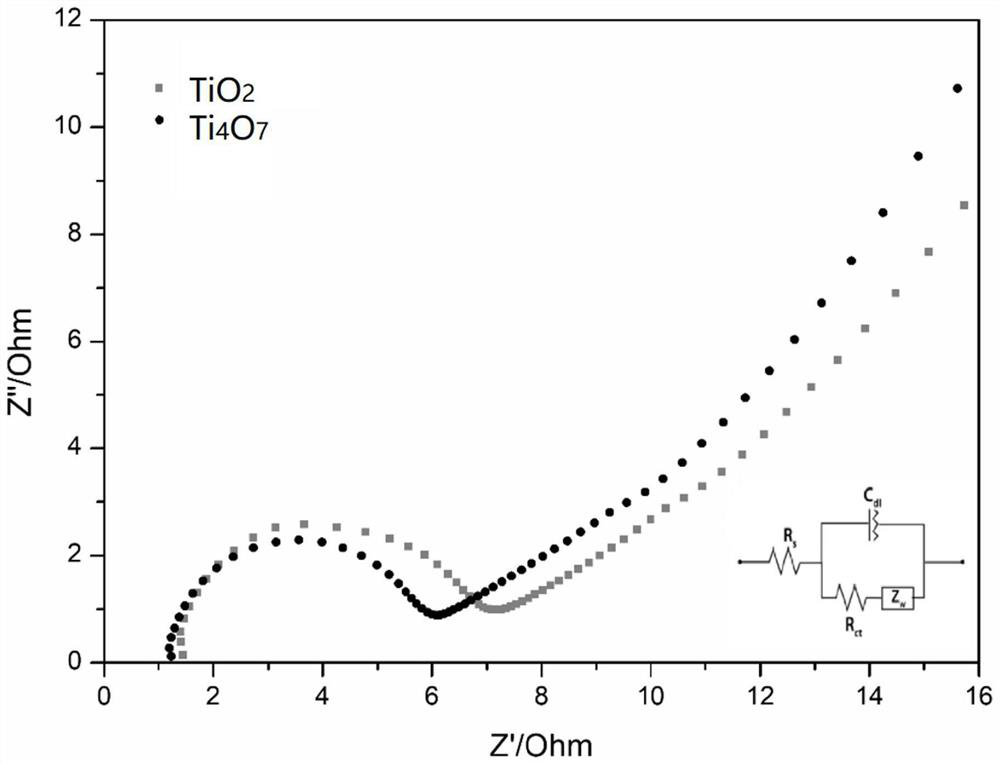

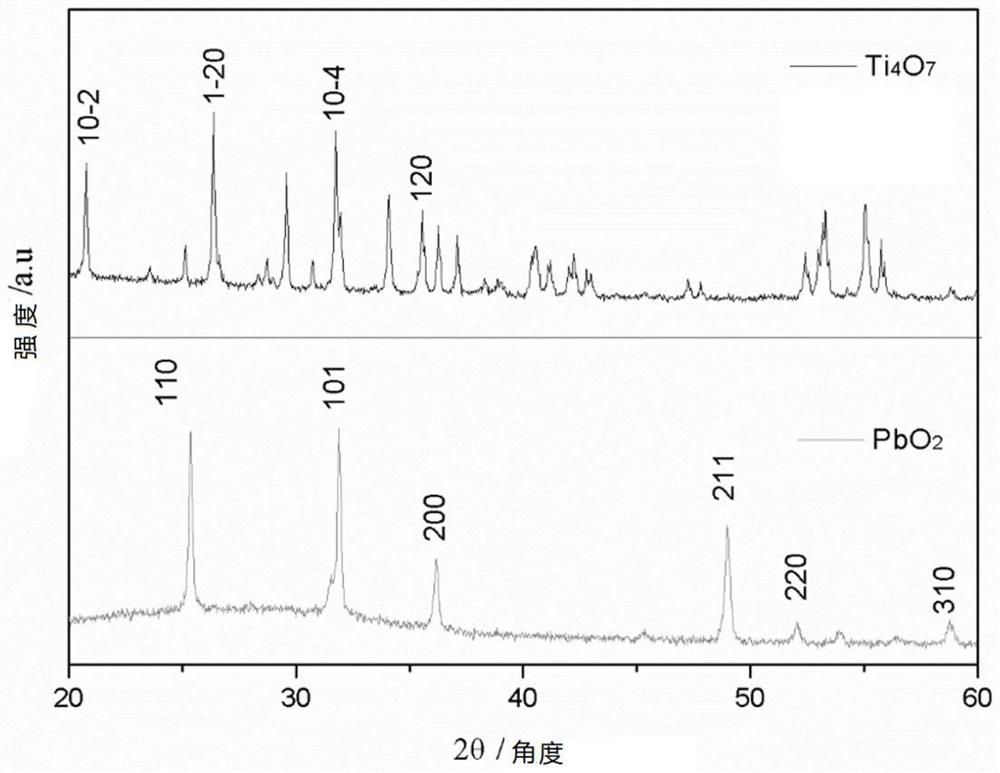

Preparation and application of porous titanium-based titanium black nanotube lead dioxide electrode

ActiveCN112250145AImprove conductivityImprove catalytic performanceWater/sewage treatment by oxidationTio2 nanotubeLead dioxide

The invention discloses preparation and an application of a porous titanium-based titanium black nanotube lead dioxide electrode, which belong to the field of material preparation. The electrode takesporous titanium as a matrix, titanium black nanotubes are arranged on the surface of the matrix and the surfaces of pore walls of the matrix to serve as middle layers of the electrode, and PbO2 layers are coated on tube cavities and the surfaces of the titanium black nanotubes; meanwhile, the preparation method of the electrode is simple, a porous titanium plate is used as the matrix, titanium black nanotubes are formed on the surface of the matrix and the surfaces of pore walls by adopting an anodic oxidation-annealing-high-temperature gas-phase reduction method to serve as an intermediate layer of the electrode, and then the lead dioxide layer is loaded in a suction filtration penetration type electrodeposition mode to prepare the corresponding electrode; and the prepared electrode canbe applied to degradation of pollutants in a water body.

Owner:NANJING UNIV OF SCI & TECH +1

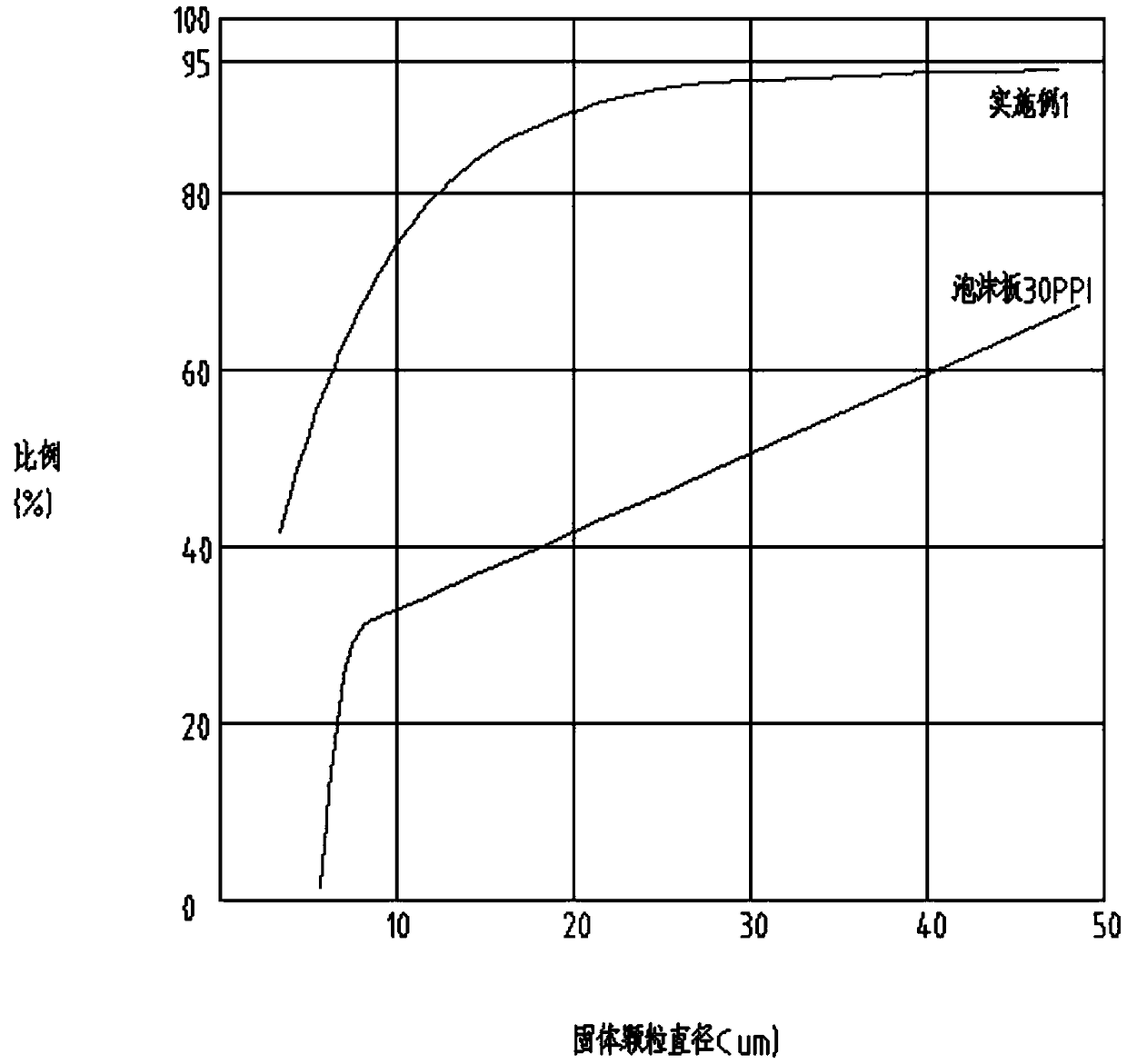

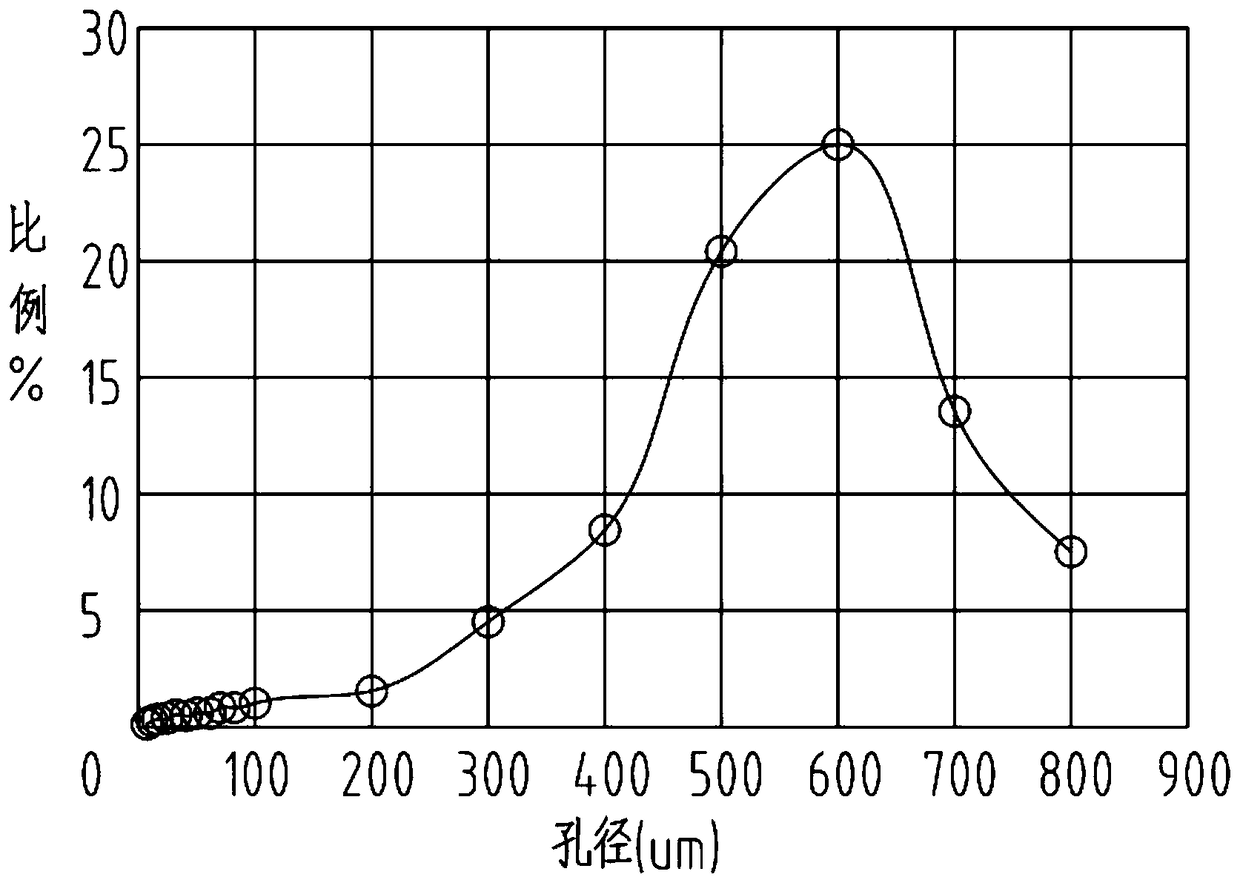

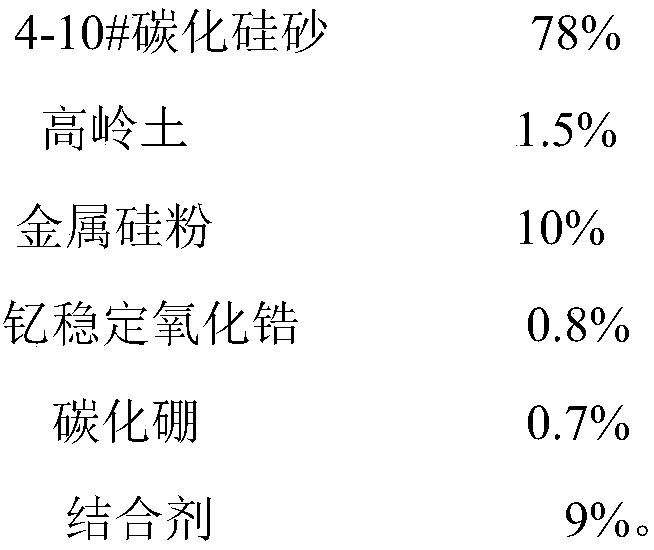

Silicon nitride combined silicon carbide ceramic filter and manufacturing method thereof

ActiveCN108751998AHigh bonding strengthHigh porosityMembrane filtersFiltration separationPrillThermal impact

The invention discloses a silicon nitride combined silicon carbide ceramic filter and a manufacturing method thereof. The ceramic filter is prepared from silicon carbide sand, kaolin, metal silicon powder, an additive and a binder in certain proportion. The manufacturing method comprises the following steps: 1, ball-milling kaolin, metal silicon powder and the additive to obtain small materials; 2, adding the binder into silicon carbide to uniformly mix, adding the small materials to uniformly mix to obtain a material mixture; 3, bundling the material mixture, uniformly mixing to obtain particles; 4, adding the particles into a mould to press and form, thereby obtaining porous wet blank; 5, drying the wet blank to obtain dry blank; 6, putting the dry blank into a nitriding furnace to sinter, thereby obtaining a primary sintered product; 7, soaking the primary sintered product into metal silicon powder suspension liquid, taking out and continuously sintering. The ceramic filter is highin particle bonding strength, does not have slag, is resistant to a high temperature, is good in thermal impact resistance and thermal stability, is high in filter precision, is high in aperture ratioand is intensive in gas hole diameter distribution. The method is simple, is convenient to operate, and is low in preparation cost.

Owner:HANJIANG HONGYUAN XIANGYANG SILICON CARBIDE SPECIAL CERAMICS

Method for measuring fiber falling performance of textile

ActiveCN111103231AReduce entryProtection of rights and interestsUsing mechanical meansMaterial analysisFiberProcess engineering

The invention discloses a method for measuring the fiber falling performance of a textile. The method comprises the following steps: combining the front surface of one textile sample with the back surface of another textile sample to form a closed combined sample; and after washing under specified conditions, uniformly collecting the fibers in the washing liquid in a filtering area, with the sameshape as the fiber falling rating sample photo, of the filtering cloth, then comparing the covering condition of the fibers collected on the filtering cloth on the filtering cloth with the fiber falling rating sample photo and evaluating the fiber falling performance grade of the textile. The invention specifically provides the method for testing and evaluating the fiber falling performance of thetextile, a method basis is provided for measuring the fiber falling performance of the textile, the fiber falling textile on the market can be scientifically and fairly evaluated, the market is standardized, the rights and the interests of consumers are guaranteed and the blank in the corresponding field is filled. The method is reasonable in process, easy to operate, convenient and easy to learnand suitable for laboratories of various detection institutions and various enterprises.

Owner:TIANFANG TIANJIN STANDARD TESTING TECH CO LTD

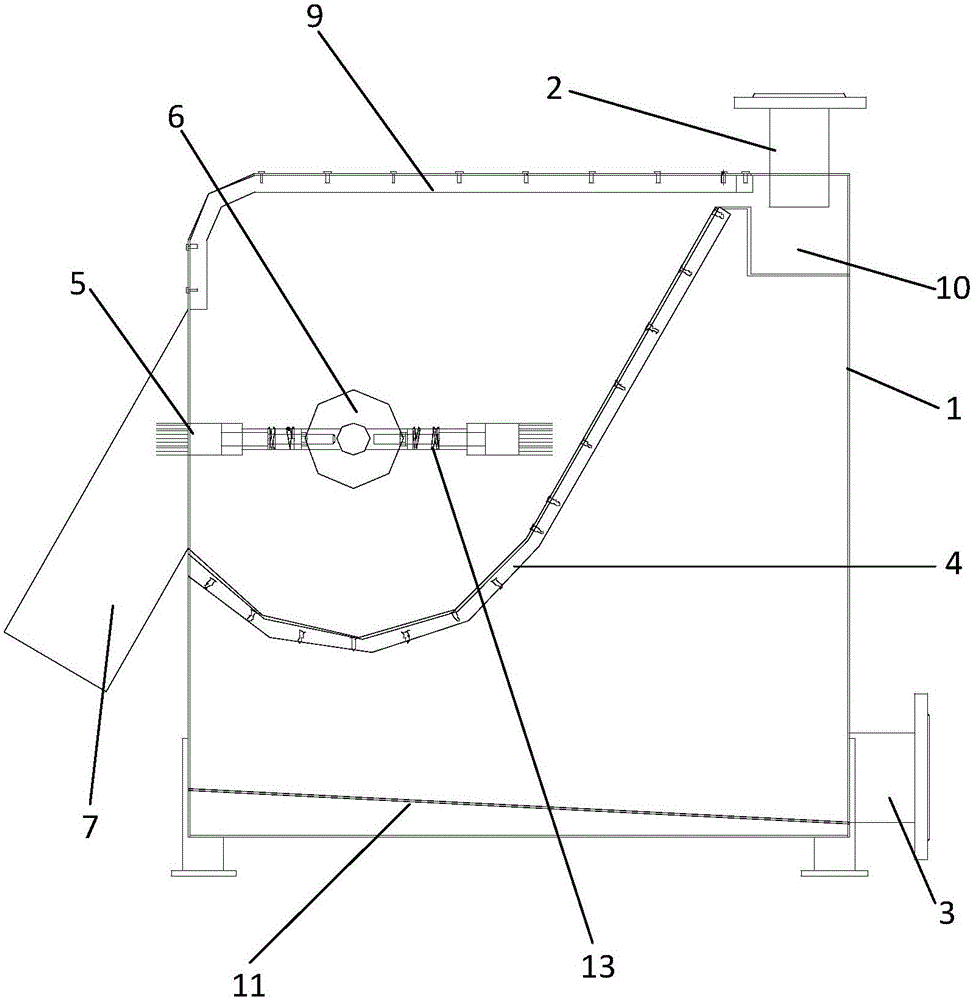

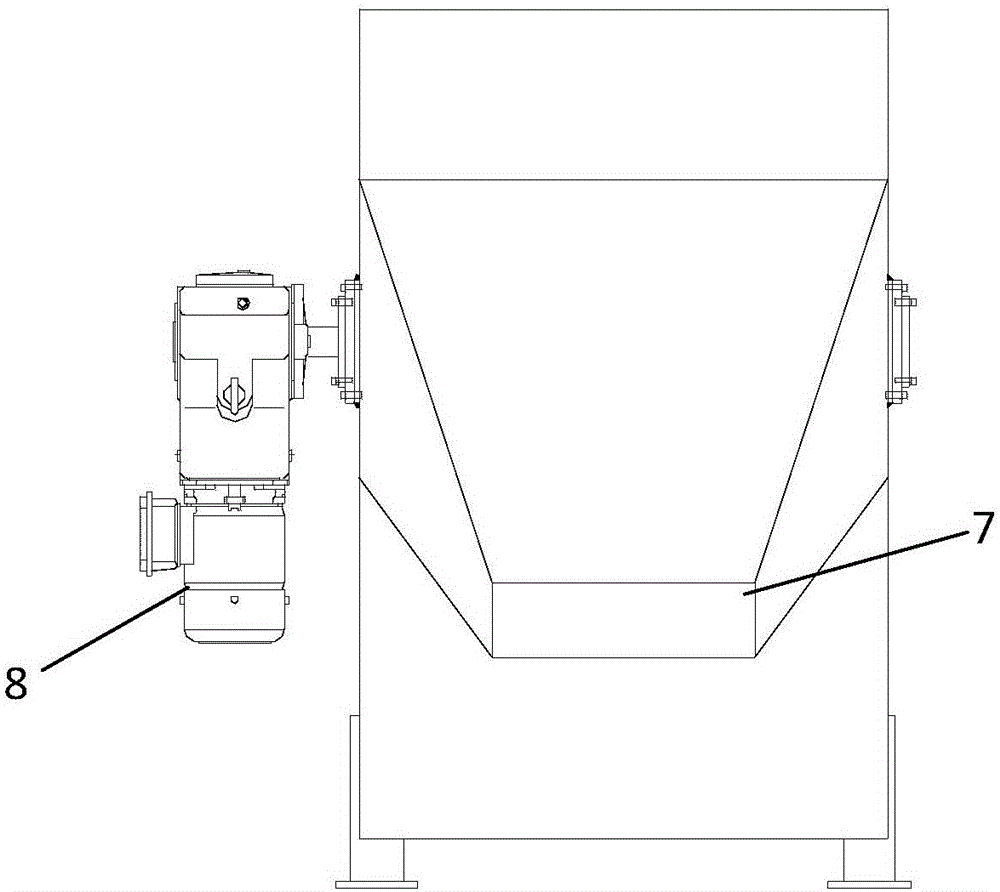

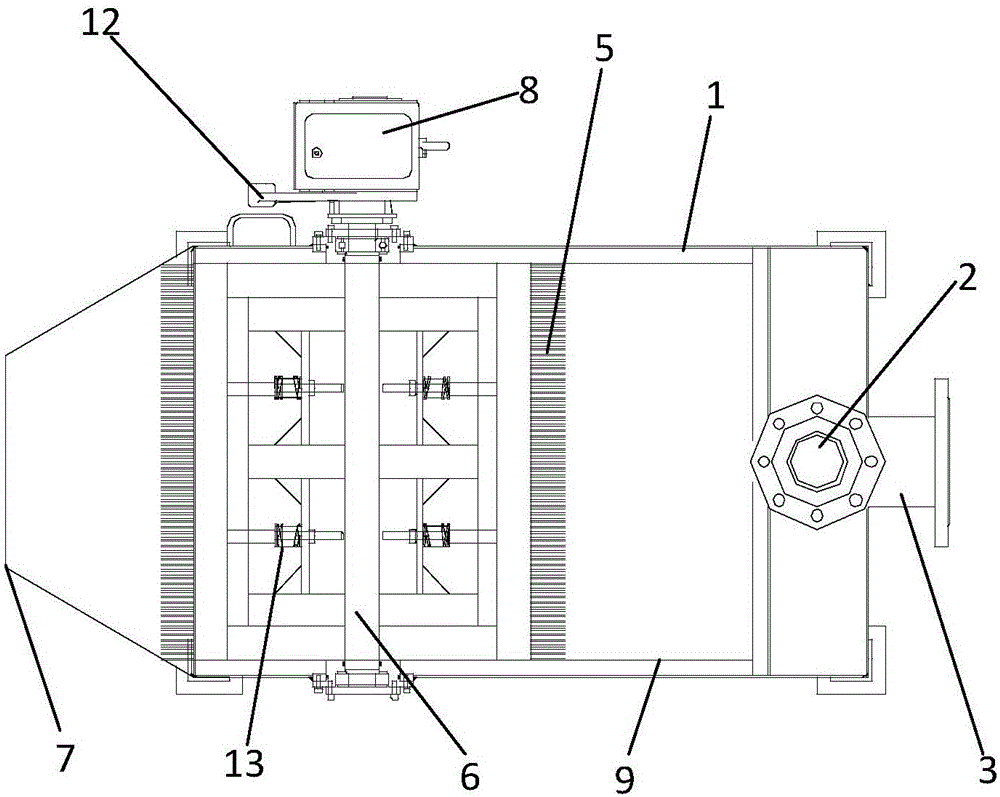

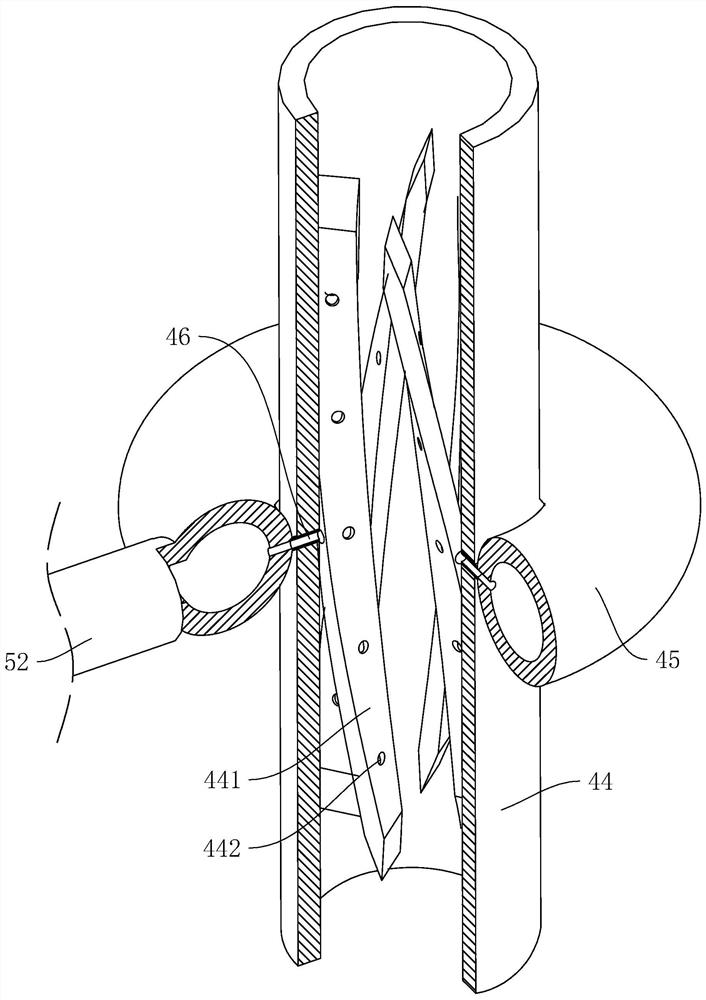

Superfine grille capable of achieving self sewage disposal

InactiveCN105129882AImprove securityGuaranteed Filtration SpeedWater/sewage treatmentSlagDrive motor

The invention relates to the field of sewage treatment, in particular to a superfine grille capable of achieving self sewage disposal. The superfine grill is composed of an outer wall, a water inlet, a water outlet, a superfine grill body, a cleaning brush, a rotating shaft, a slag outlet, a driving motor, a water distributing weir and necessary fastening parts. According to the technical scheme, an existing arc-shaped grille is improved, the existing open-type grille is designed to be of a closed structure, the problems that when the grills is used, field assembly is troublesome, the occupied area is large, the treatment efficiency is low, and transportation is inconvenient are solved, and the usage safety is enhanced; meanwhile, the cleaning brush is additionally arranged in a cleaner, impurities remained on the grille in sewage can be removed at any time while the sewage is filtered, the filtering speed is guaranteed, and the filtering efficiency is improved; in addition, the usage load of the grille is reduced, and the service life of the cleaner is prolonged.

Owner:ZDLX ENVIRONMENT TECH CO LTD

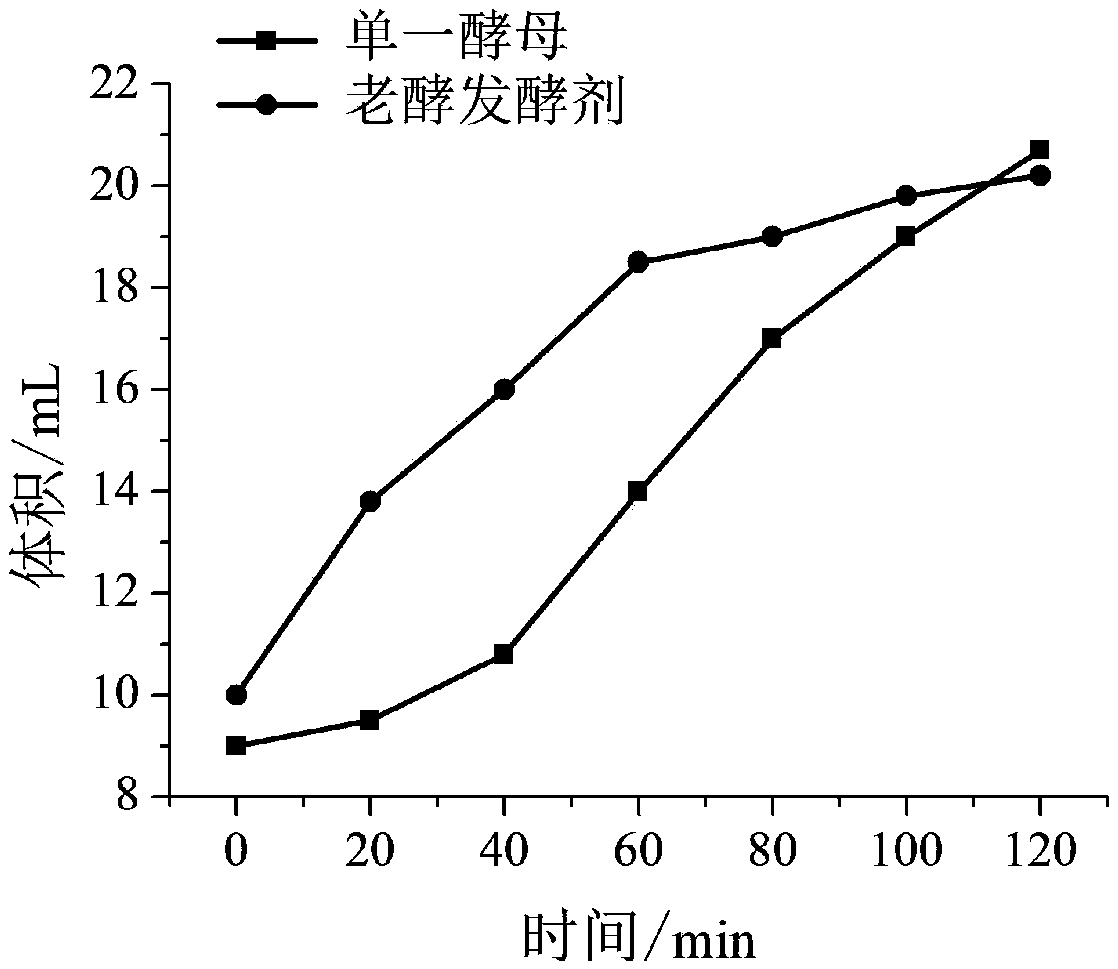

Direct-injection old yeast steamed bun fermentation agent capable of improving steamed bun flavor and preparation method and application thereof

The invention relates to a direct-injection old yeast steamed bun fermentation agent capable of improving steamed bun flavor. The direct-injection old yeast steamed bun fermentation agent is composedof short lactobacillus powder, lactobacillus plantarum powder, active dry yeast and fungal amylase in the mass ratio of 0.5-1:0.5-1:0.5-2:0.002-0.01. The fermentation agent can directly replace the traditional old yeast fermentation agent, and is directly used for dough fermentation and steamed bun making to improve the fermentation speed of the traditional old yeast and give steamed buns rich unique flavor. The fermentation agent is simple in preparation procedure, high in vitality and stable in quality, facilitates quality monitoring and can be used for industrial production of the steamed buns.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing marsh gas through straw, excrement and kitchen waste

ActiveCN103451095BThorough responseImprove resource utilizationBioreactor/fermenter combinationsBio-organic fraction processingFecesEngineering

The invention relates to a method for preparing marsh gas through straw, excrement and kitchen waste, and belongs to the technical field of renewable energy. The method comprises the following steps of: a, preprocessing, namely, feeding crushed straw, kitchen waste and excrement into a preprocessing tank; mixing; then transferring into a premixing tank to heat at a constant temperature; and uniformly mixing to obtain a mixture; and b, anaerobic fermentation, namely, feeding the mixture into at least one anaerobic fermentation tank to heat at the constant temperature; and agitating and fermenting to obtain the marsh gas and fermentation residues. The method has the beneficial effects that the operation is stable; the production efficiency of marsh gas is high; the production cost can be reduced; and mass popularization can be performed.

Owner:GUANGXI YUDA WATER PROCESSING ENVIRONMENTAL PROTECTION ENG CO LTD

Waste gas separation and dust removal device

ActiveCN112191053AWell mixedTo achieve the purpose of removing dustHuman health protectionUsing liquid separation agentDust controlElectric machinery

The invention discloses a waste gas separation and dust removal device, and particularly relates to the technical field of waste gas treatment. The waste gas separation and dust removal device comprises a rack, a dust removal cylinder is arranged on the upper portion of the inner side of the rack, a filter cylinder is detachably connected to the middle of the bottom end of the dust removal cylinder, and a dust removal mechanism is arranged in the dust removal cylinder and comprises a guide column; the upper end of the guide column and the middle of the upper end of the rack are fixedly mounted, a plurality of grooves are formed in the outer side of the guide column, and each groove comprises a lower portion. Through arrangement of the dust removal cylinder, the filter cylinder, the dust removal mechanism, an inner column, a dust scraping mechanism, a motor, a straight gear, an exhaust fan, an air inlet pipe, a water tank and a circulating pump, industrial waste gas is introduced into the dust removal cylinder to form a large number of bubbles, the bubbles are crushed and mixed with water, the industrial waste gas and the water can be fully mixed, and the dust removal purpose is achieved, and removal is more thorough; and meanwhile, dust on the inner wall of the filter cylinder is scraped off through a scraping blade, so that the filtering speed and the filtering effect are guaranteed.

Owner:SUZHOU JINGTIAN AIREN ENVIRONMENTAL TECH CO LTD

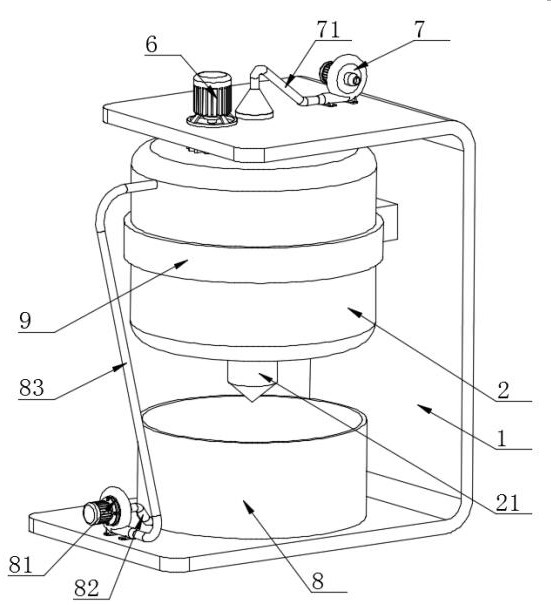

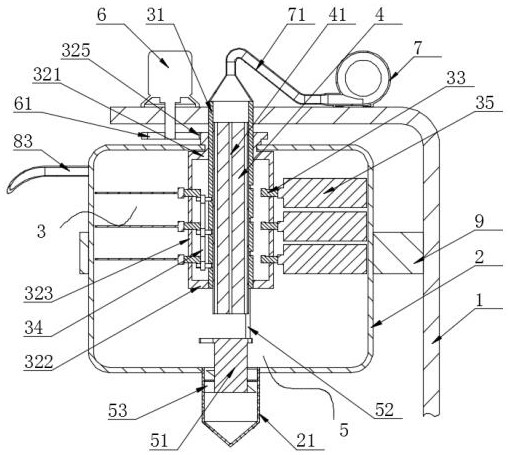

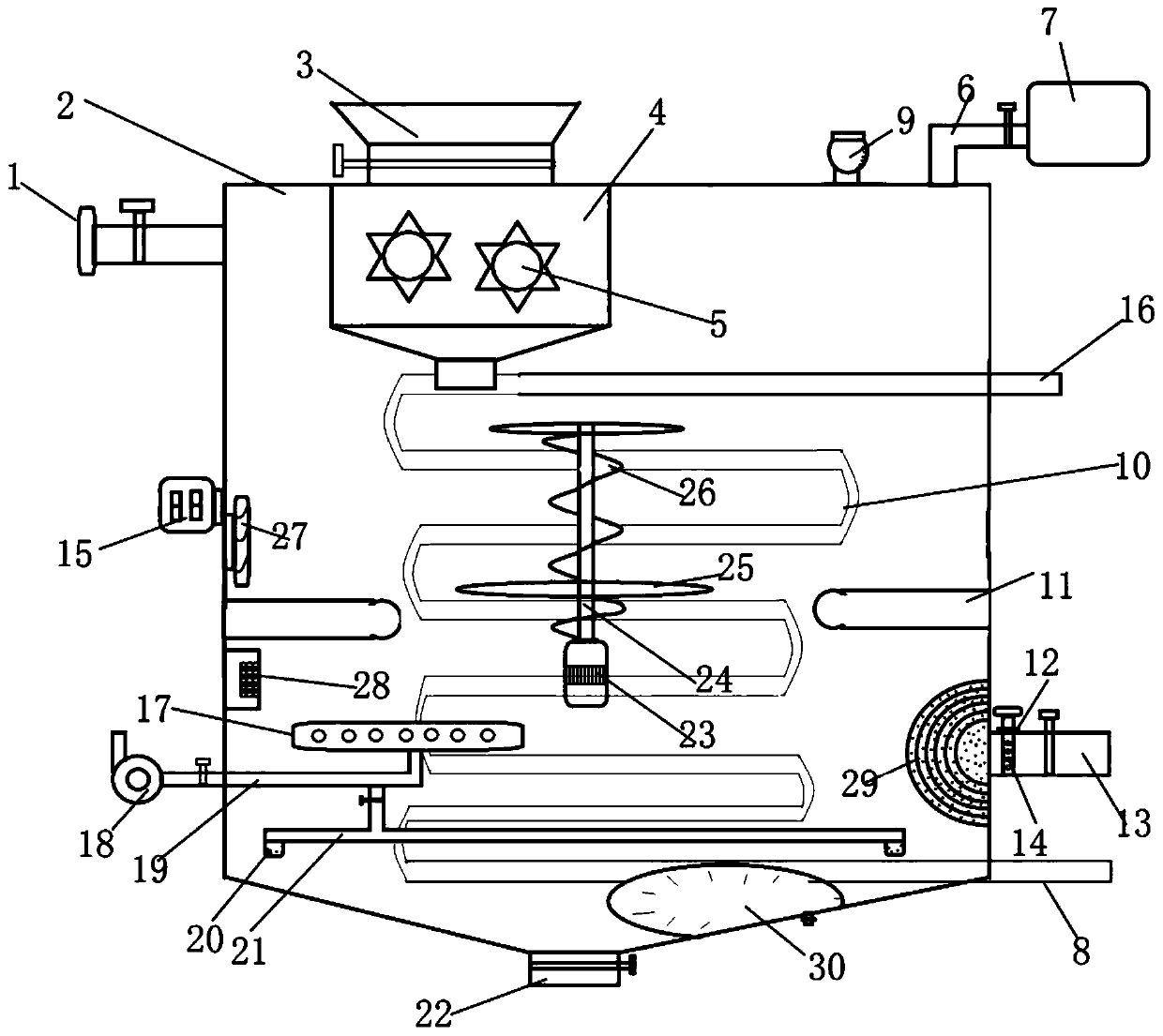

Efficient and environment-friendly kitchen waste treatment equipment

The invention discloses efficient and environment-friendly kitchen waste treatment equipment. The efficient and environment-friendly kitchen waste treatment equipment comprises a housing, wherein a rotary shaft is arranged inside the housing; the top end of the rotary shaft passes through the housing to upwards extend; the top end of the rotary shaft is fixedly connected with a drive device; a first cavity is arranged inside the rotary shaft; a gas inlet tube is arranged in the first cavity; the other end of the gas inlet tube is connected with an air blower at the upper side of the housing; a plurality of air distributing rods are uniformly and fixedly connected on the side wall, inside the housing, of the rotary shaft; a second cavity is arranged on each air distributing rod; and each second cavity communicates with the first cavity. The efficient and environment-friendly kitchen waste treatment equipment has the beneficial effects that the air blower is utilized for blowing air into the first cavity, and then, air uniformly enters the second cavity and is sprayed out from the air outlet, so that sufficient mixing of air and waste is realized, and the fermentation effect is effectively improved; and the rotary shaft drives a horizontal rod to rotate, and a slide block of the horizontal rod gets away from the rotary shaft after applied with centrifugal force, so that a mixing bump is driven to change a mixing range.

Owner:ANHUI XINHONG ENVIRONMENTAL PROTECTION EQUIP TECH

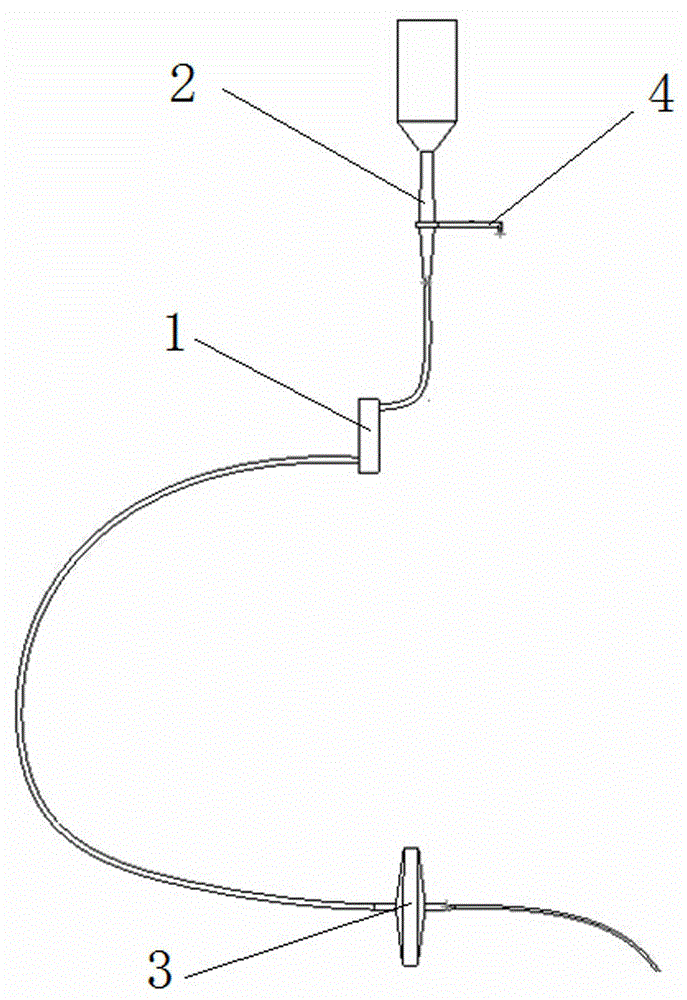

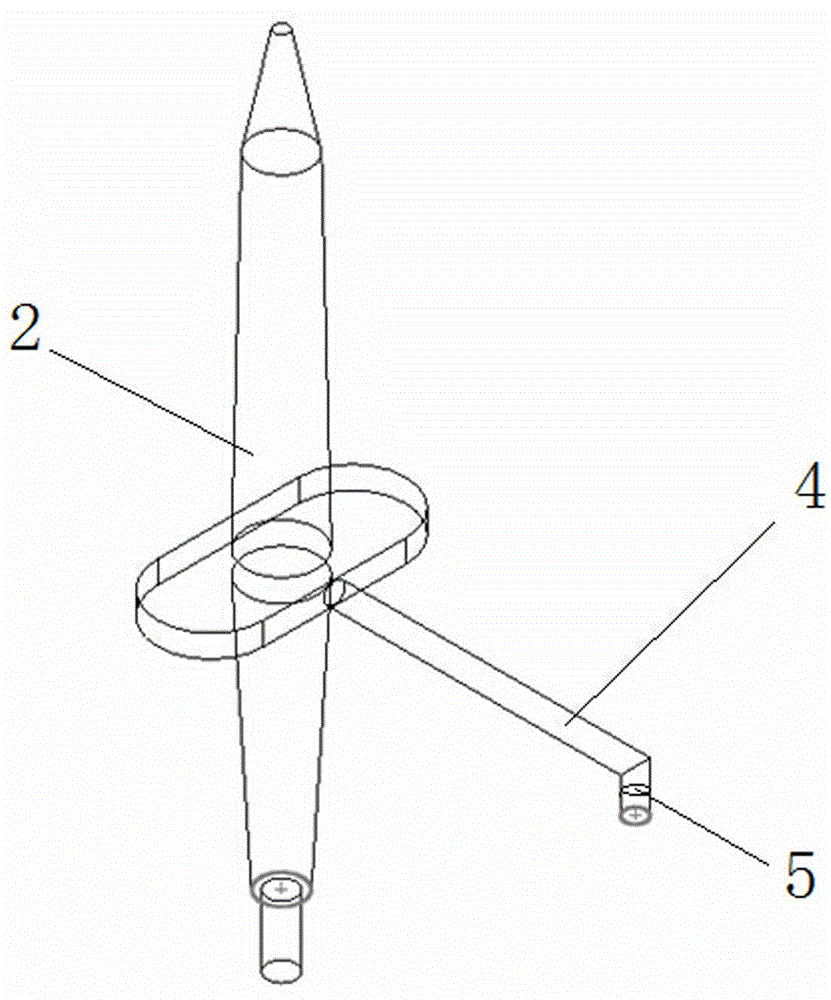

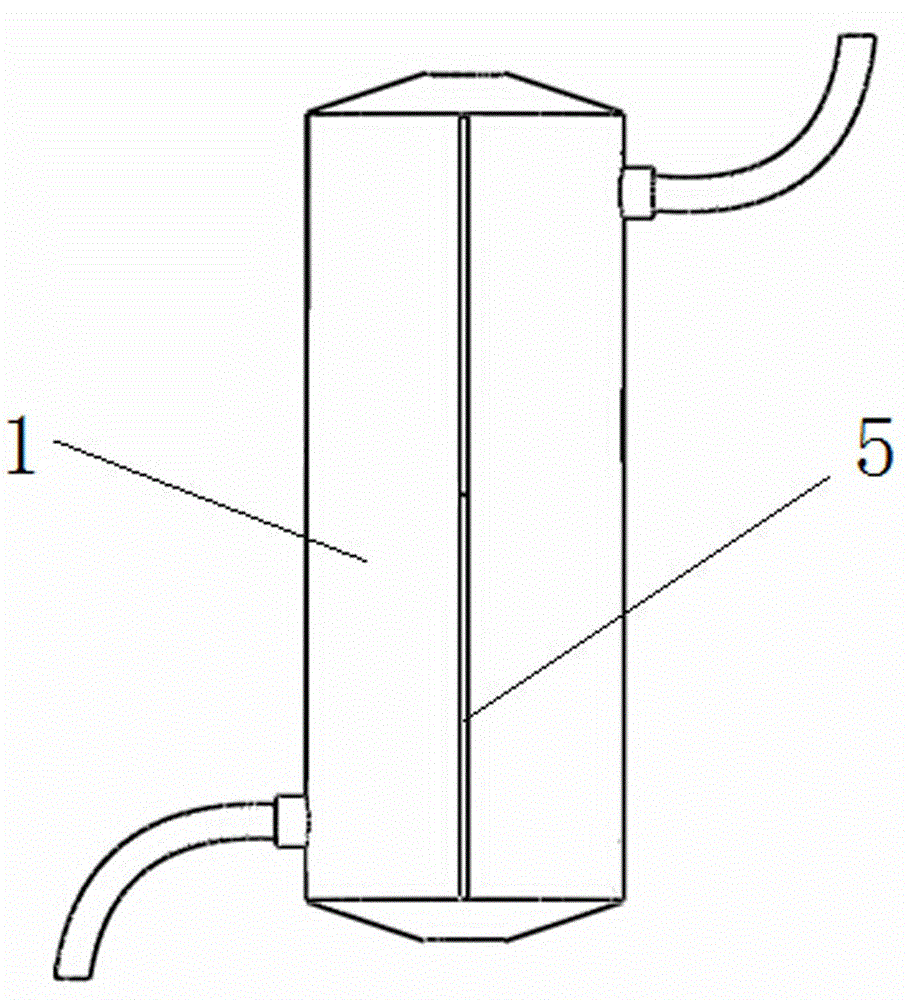

High-efficiency and low-resistance impurity particle filter system for venous transfusion

The invention particularly discloses a high-efficiency and low-resistance impurity particle filter system for venous transfusion, solving the problem that an existing venous transfusion filter system is unreasonable in structure design and poor in filter effect, thus causing potential safety hazards. The high-efficiency and low-resistance impurity particle filter system for venous transfusion comprises a murphy's dropper, wherein the murphy's dropper is provided with an air filter and a liquid medicine filter which are communicated with the murphy's dropper; the air filter is communicated with the right side of the upper part of the murphy's dropper, and the opening of an air inlet pipe of the air filter is downward; the liquid medicine filter is communicated with the left side of the lower part of the murphy's dropper; each of the murphy's dropper and the liquid medicine filter is internally provided with composite filter cloth which is vertically placed; the two pieces of composite filter cloth respectively divide the murphy's dropper and the liquid medicine filter from left to right; each composite filter cloth is made by bonding woven filter cloth and a polydimethylsiloxane filter membrane, and the end part of the air inlet pipe of the air filter is provided with horizontally placed composite filter cloth. The filtering effect of the venous transfusion is improved by the high-efficiency and low-resistance impurity particle filter system, and then the potential safety hazards are completely eradicated.

Owner:ZHONGBEI UNIV

Filter-bag non-woven fabric hot-melting structure

InactiveCN109847481AImprove sealingGuaranteed Filtration QualityDispersed particle filtrationEngineeringHot melt

The invention discloses a filter-bag non-woven fabric hot-melting structure. The filter-bag non-woven fabric hot-melting structure comprises a bag-type filter composed of a plurality of filter bag monomers; an outer frame framework is arranged on the periphery of the bag-type filter; a bag opening of each filter bag monomer is fixed with a supporting framework; the outer wall of each support framework is fixed on the inner wall of the outer frame framework; each filter bag monomer is formed by bonding two filter cloths; two sides of the two filter cloths are formed by hot melting through sidebonding wires; and the lower sides of the two filter cloths are formed by hot melting through lower bonding wires. The filter-bag non-woven fabric hot-melting structure has the advantages that the filter bag non-woven fabrics are bonded through ultrasonic hot melting, the bonding strength is higher than the bonding strength of gluing or sewing, the sealing performance is better, and leakage is avoided in a filtering process. A non-woven cloth strip is arranged on each filter bag monomer, so that when gas is blown into the filter bag monomer, the outer walls of the filter bags cannot be in contact with each other or be adhered with each other, and thus a sufficient filtering area of the filter bags is guaranteed.

Owner:深圳市万维空调净化工程有限公司

sewage filtration system

ActiveCN105561660BSignificant filter effectGuaranteed filtering effectMembrane filtersStationary filtering element filtersFilter systemSewage

Owner:广东金碧蓝环境科技有限公司

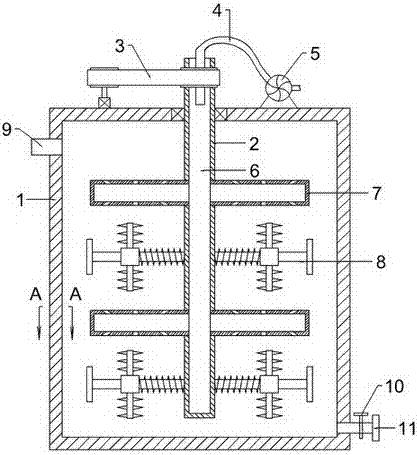

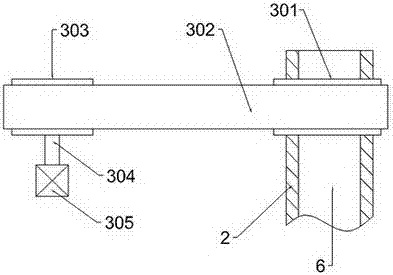

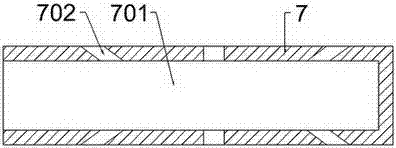

Method and device for heat exchange warming by biological fermentation

InactiveCN110550809AGuaranteed living environmentGuaranteed growth and fermentationTreatment using aerobic processesWater/sewage treatment by irradiationEngineeringCrusher

The invention discloses a method and a device for heat exchange warming by utilizing biological fermentation. The device comprises a water inlet pipe, a fermentation box, a crusher, a gas collecting tank, a medicament strain adding pipe, a heat exchange pipe, an aerator and a blow-off pipe; the water inlet pipe is arranged on the side wall of the fermentation box; a straw garbage feeding pipe is arranged at the top end of the fermentation box; the crusher is mounted in fermentation box, a crushing roller is arranged in crusher, the crushing roller is connected with an external motor; the medicament strain adding pipe is arranged on the side wall of the fermentation box; an electrode bar is arranged in the fermentation box and is connected with an external power supply; an ultraviolet lampand a heater are arranged on the inner wall of the fermentation box, an air bag is arranged at the bottom end of the fermentation box; a stirring motor is arranged in the fermentation box; the heat exchange pipe is arranged in the fermentation box; and the aerator is connected with a spray row through an air delivery pipe. The device is simple in structure, low in cost, convenient to use and beneficial to popularization, and resource waste is avoided.

Owner:佛山市易于嘉农业科技有限公司

White vinegar production equipment and white vinegar production process

PendingCN113214957AGuarantee the quality of fermentationGood aerobic environmentVinegar preparationAir pumpProcess engineering

The invention relates to white vinegar production equipment. The white vinegar production equipment comprises a fermentation tank, a material pumping device and an oxygen supply device, wherein the material pumping device comprises a material pump, a feeding pipe and a discharging pipe, two ends of the feeding pipe respectively communicate with a feeding hole of the material pump and the fermentation tank, and two ends of the discharge pipe respectively communicate with a discharge hole of the material pump and the fermentation tank; and the oxygen supply device comprises an air pump and an air inlet pipe, and the two ends of the air inlet pipe communicate with the air pump and the discharging pipe correspondingly. When raw materials circulate in the fermentation tank, the feeding pipe and the discharging pipe, the raw materials can be mixed with air, so that the mixing uniformity of the raw materials and the air is effectively improved, and the fermentation quality of the raw materials is ensured.

Owner:苏州好唯加食品有限公司

Multi-stage multifunctional oil filter

InactiveCN112807800ASpeed up filteringAvoid cloggingStationary filtering element filtersScreen filterBrush

The invention belongs to the field of oil filters, particularly relates to a multi-stage multifunctional oil filter, and aims to solve the problems that an existing oil filter is single in function and low in oil filtering efficiency. The multi-stage multifunctional oil filter comprises an oil filtering tank, a hollow pressing plate is slidably mounted in the oil filtering tank, and a pushing plate is fixedly mounted at the top of the hollow pressing plate; a transverse plate is fixedly mounted on one side of the pushing plate, a vertical plate is slidably mounted on the outer side of the transverse plate, a bottom plate is fixedly mounted at the bottom of the vertical plate, the top of the bottom plate is fixedly connected with the bottom of the oil filtering tank, a first-stage filter screen and a second-stage filter screen are mounted in the oil filtering tank, a rotating rod is rotatably mounted on the top of the bottom plate, and four brushes are fixedly mounted on the outer side of the rotating rod; and the bottoms of the four brushes make contact with the tops of the first-stage filter screen and the second-stage filter screen correspondingly. Pressure is applied to oil, the oil filtering speed is increased, the tops of the first-stage filter screen and the second-stage filter screen are cleaned through the four brushes, blockage is avoided, the filtering speed is guaranteed, and meanwhile the heating and alarming functions are achieved.

Owner:新乡市大唐鑫锐液压设备有限公司

High-concentration alcohol fermentation method

InactiveCN102250965AAddressing Vitality DeclineSolve the problem of fermentation abilityBiofuelsMicroorganism based processesBiotechnologyHigh concentration

The invention discloses a high-concentration alcohol fermentation method, which comprises the following: a step of distiller's yeast cultivation, in which yeasts are cultured at 31 DEG C and the concentration of distiller's yeast fermented liquor is 2 to 3 percent lower than that of saccharified fermented liquor in fermentation; a step of fermentation, in which an early fermentation stage is mainly to culture fermentation capacity (to enrich zymase of yeasts), the fermentation temperature is kept between 34 and 35 DEG C till the concentration of the alcohol is 8 percent, then the temperature is reduced to 33 DEG C till the end of the fermentation, at least 200ppm of free amino nitrogen is kept in a fermentation tank, the metabolism of the yeasts is promoted, and the number of the yeasts in the fermentation tank is ensured; and a step of adding saccharifying enzyme, in which 2 / 3 of saccharifying enzyme is added into a saccharification tank first, the rest saccharifying enzyme is added 8 to 10 hours later, and thus, the post saccharification can be performed at a higher speed in the later stage of fermentation in the presence of the saccharifying enzyme and the fermentation speed is ensured. In the invention, two problems of fermentation concentration and fermentation period, which influence fermentation concentration, are solved, the high-concentration alcohol fermentation can be realized, the fermentation effect of the alcohol is desirable, and the fermentation period is short.

Owner:HENAN TIANGUAN GRP

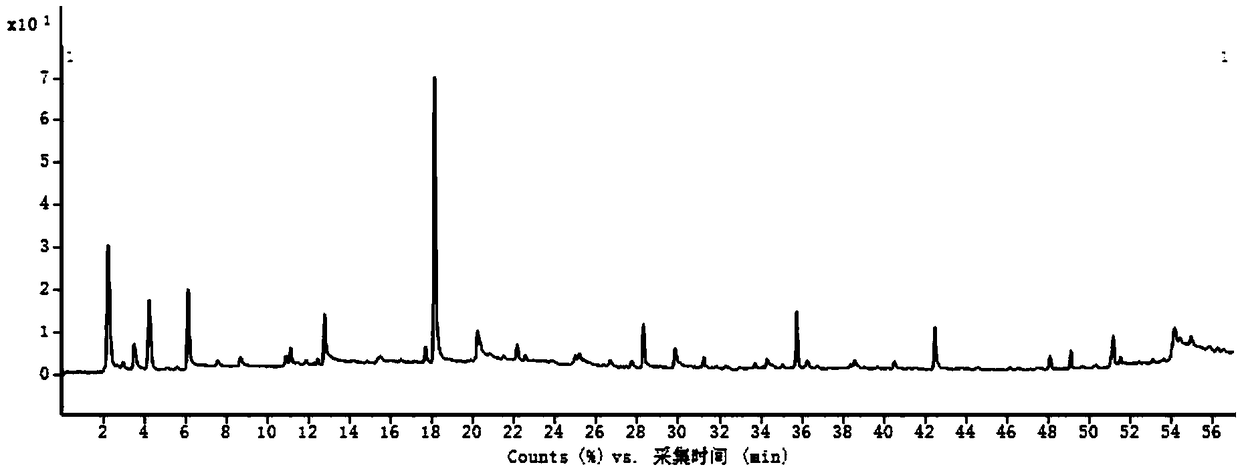

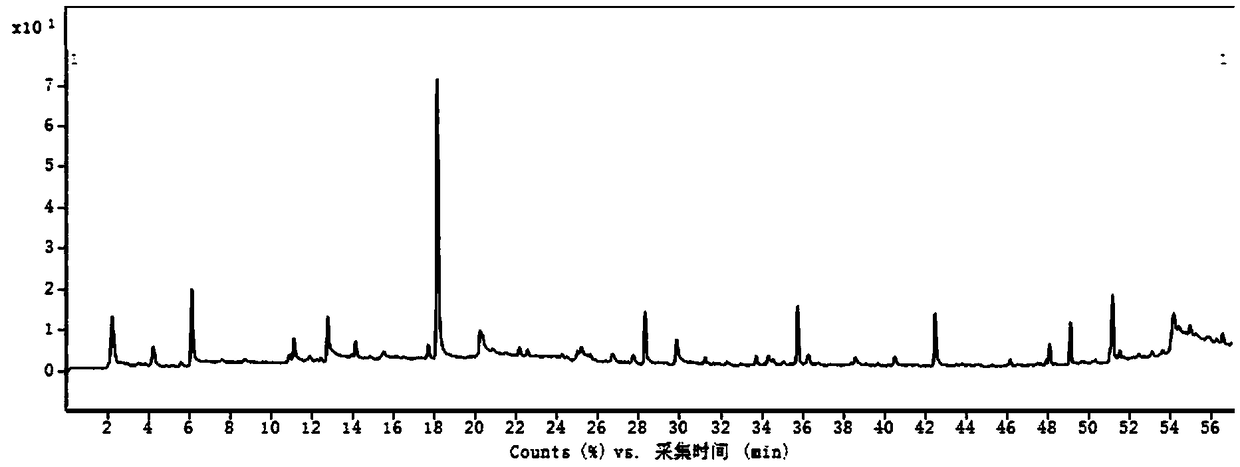

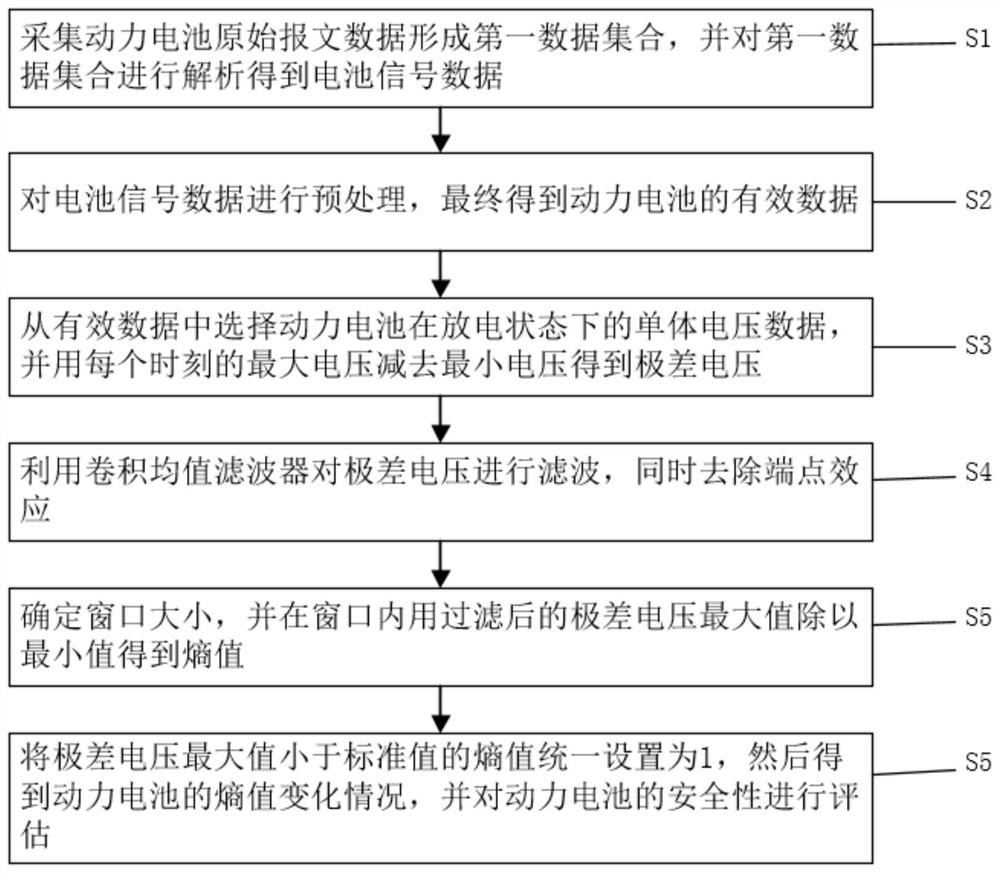

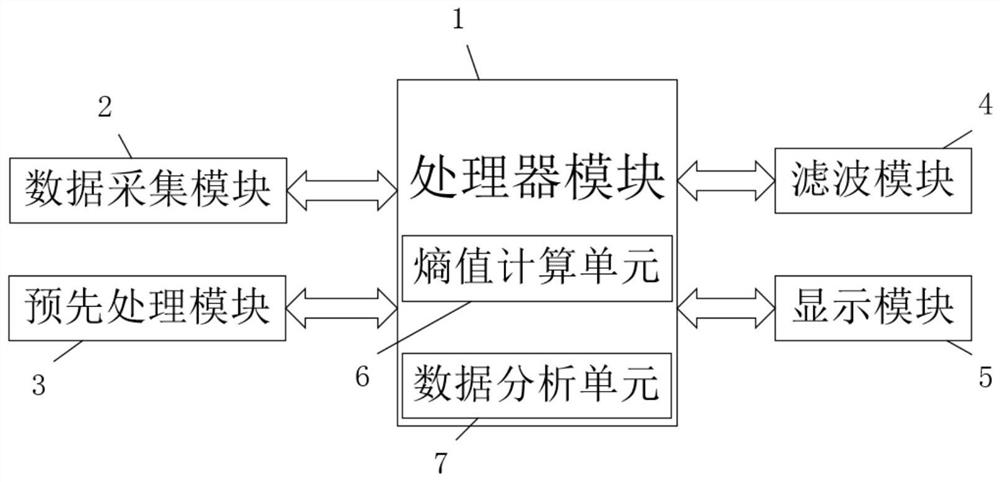

Power battery safety detection method and system and storage medium

InactiveCN114415032AKnow your health statusReal-time understanding of health statusElectrical testingVehicular energy storagePower batteryData acquisition module

The invention relates to the technical field of power battery safety detection, and discloses a power battery safety detection method and system and a storage medium, and the system comprises a processor module, and a data collection module, a preprocessing module, a filtering module and a display module which are connected with the processor module. Historical operation data of the power battery are collected, single voltage data in a discharging state are adopted to calculate range voltage, and then the change condition of entropy is calculated, so that the safety of the power battery is evaluated accurately and quickly. The method has the beneficial effects of quickly and accurately detecting the health state of the power battery, ensuring the use safety of the power battery and improving the driving safety of the electric automobile.

Owner:CHINA AUTOMOTIVE ENG RES INST

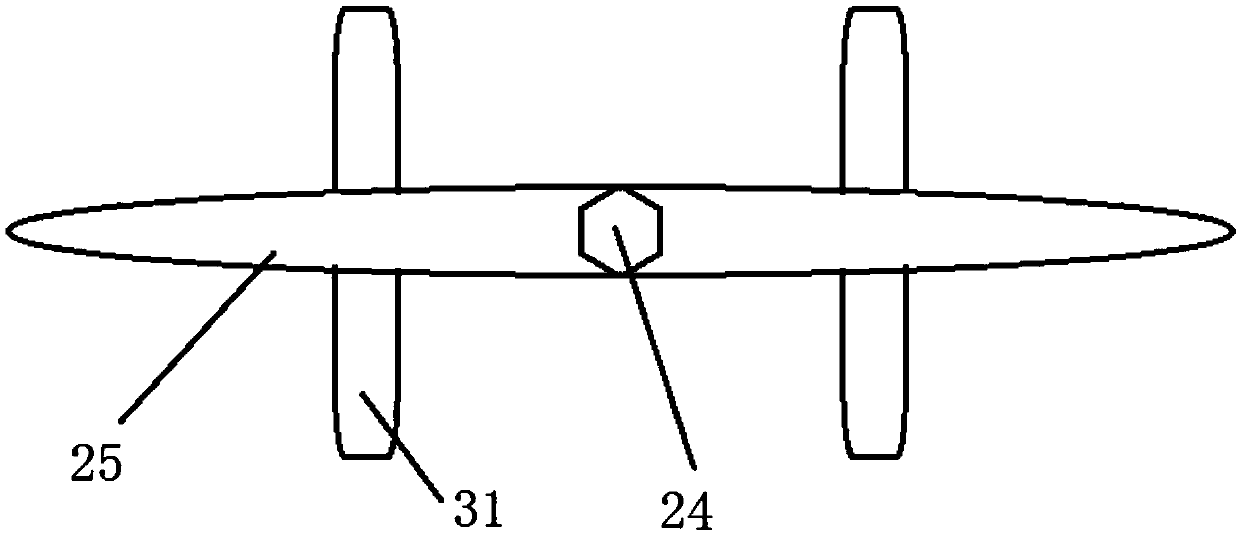

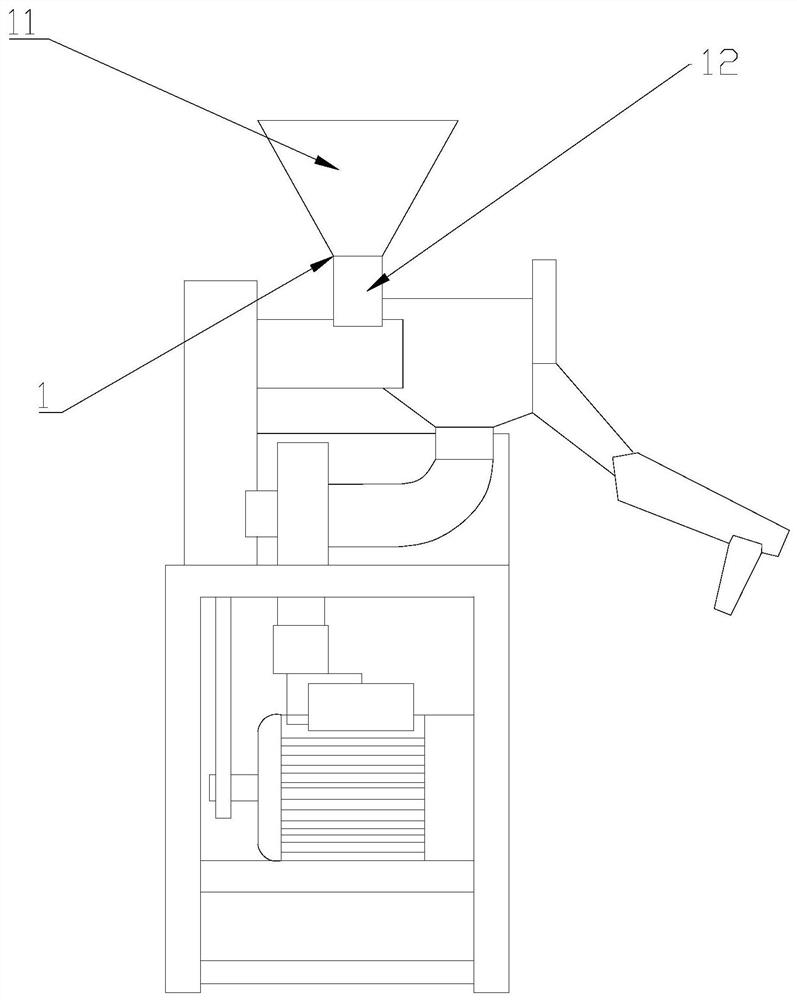

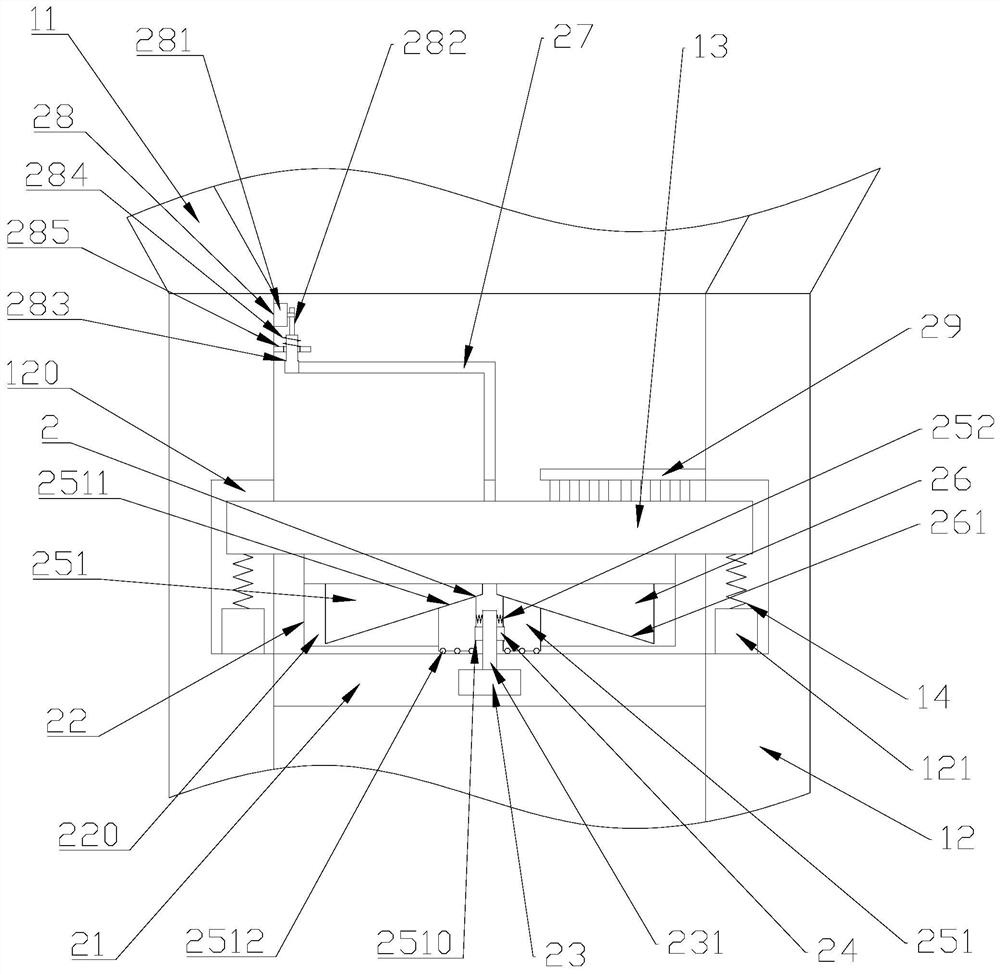

Rice mill

ActiveCN111744581ASpeed up filteringGuaranteed Filtration SpeedSievingScreeningAgricultural engineeringSieve

The invention discloses a rice mill. The technical scheme of the rice mill is characterized by comprising a feeding device for feeding and a vibration assembly, wherein the feeding device comprises afeeding hopper, a feeding pipeline and a filter plate; the feeding hopper adopts a funnelshaped structure; one end of an opening of the feeding hopper is connected to one end of the feeding pipeline;a sliding groove is formed in the inner wall close to one side of the feeding hopper, of the feeding pipeline, and is formed in an extension manner in the circumferential direction of the inner wall of the feeding pipeline; two sliding blocks which are symmetrically arranged about the axis of the feeding pipeline are arranged in the sliding groove in a sliding manner; the outer wall of the filterplate extends into the sliding groove; sieve pores which are penetrated in the thickness direction and are used for screening rice are formed in the filter plate; an elastic piece is arranged on eachsliding block; and two ends of each elastic piece are separately arranged on the filter plate and the corresponding sliding block. The invention aims to provide the rice mill which can filter impurities, and can guarantee the falling speed of the rice.

Owner:WENZHOU UNIVERSITY

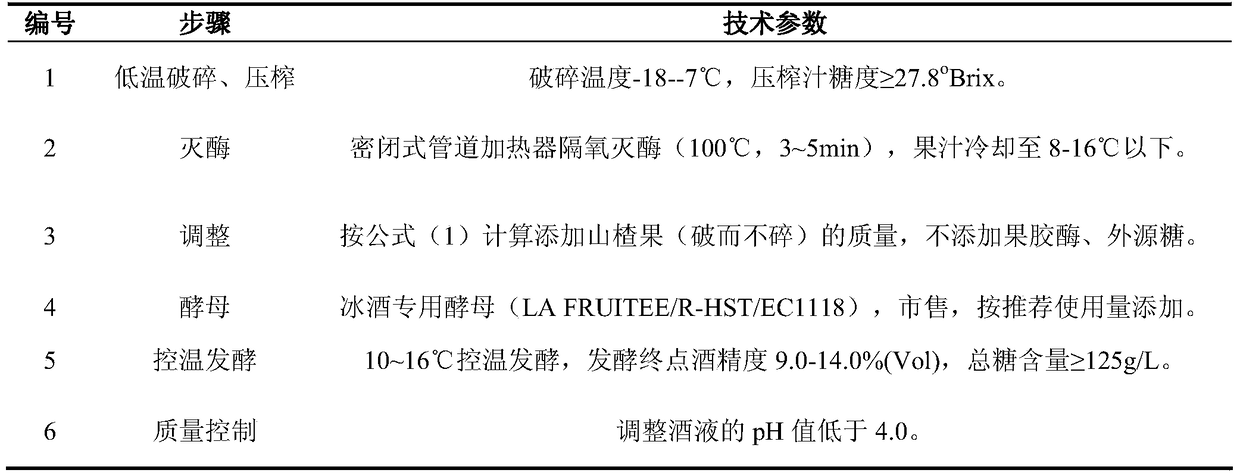

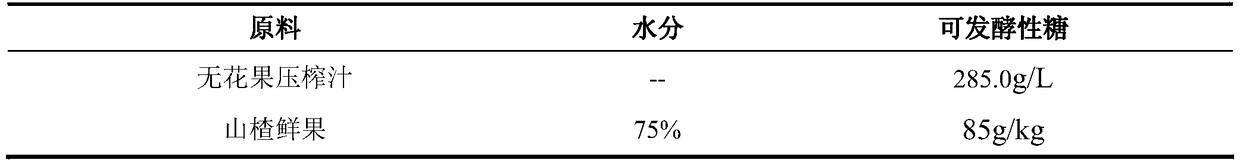

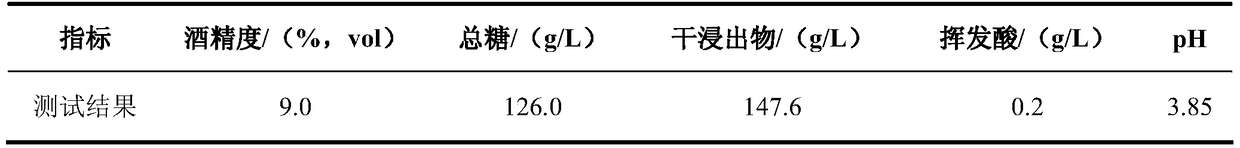

Ice fig wine and brewing method thereof

ActiveCN108998325AChange the way of processing, storage and transportationHigh economic valueAlcoholic beverage preparationPectinaseFruit juice

The invention relates to an ice fig wine and a brewing method thereof. The ice fig wine is prepared by taking fresh fig as a raw material and adding crushed and unbreakable whole hawthorn fruits to afig squeezed juice to be used as a fermentation auxiliary material. For the first time, the fig is used as the raw material for brewing ice wine; the fermentation process is completed by glycolysis ofnatural sugar, so the mellow property of the product is improved; the methanol content in the fermented wine can be effectively controlled without addition of pectinase, so the product quality can beimproved; the activity of fig protease can be passivated by a high temperature and short time method, so the microbial pollution is reduced; a closed pipeline heater can effectively reduce the fruitaroma loss and juice browning, and the non-biological stability of the fruit wine can be significantly improved; low temperature fermentation is beneficial to yeast aroma production, the leaching rateof nutrients and antioxidant ingredients in the hawthorn fruits is improved, and the quality of the ice wine is improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Preparation process of bacillus licheniformis[v]

PendingCN111197013AIncrease the number ofQuality improvementBacteriaMicroorganism based processesBiotechnologyBacillus licheniformis

The invention discloses a preparation process of bacillus licheniformis. The method comprises seed culture and fermentation culture, wherein the seed culture comprises liquefaction and sterilization;the fermentation tank culture comprises inoculation and fermentation culture; the process steps are rigorous; through detailed description of each step and solidification of environmental parameters in each step, the occurrence probability of maldevelopment of bacillus in the fermentation cultivation process is reduced; the bacillus licheniformis fermentation technology guarantees that the numberand the quality of the fermented bacillus licheniformis are far higher than those of fermentation results in the prior art, the environment in the preparation process of the technology is a sterile environment, the infectious microbe rate in the produced product is low, the product quality is high, and the bacillus licheniformis prepared through the technology is long in quality guarantee period and can be stored for a long time.

Owner:南宁汉和生物科技股份有限公司

A new type of water sulfate adsorption material

ActiveCN107774229BAperture controllableGuaranteed Filtration SpeedOther chemical processesWater contaminantsSulfate radicalsFiltration

Owner:河北太和洁源水务科技发展有限公司

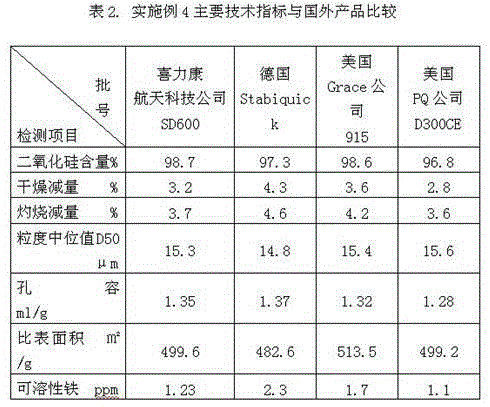

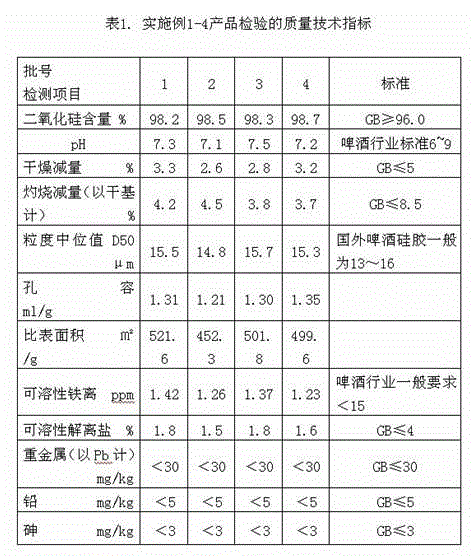

Food additive silica gel and production process of food additive silica gel

InactiveCN103204509BImprove adsorption capacityGuaranteed Filtration SpeedSilicon compoundsFood additiveIon content

Owner:烟台喜力康航天科技有限公司

Novel water body sulfate adsorbing material

ActiveCN107774229AAperture controllableGuaranteed Filtration SpeedOther chemical processesWater contaminantsFiltrationSULFATE ION

The invention provides a novel water body sulfate adsorbing material. The novel water body sulfate adsorbing material has a controllable pore size, can ensure a filtration velocity of water and play avery good adsorption role on sulfate ions, has no energy consumption in a treatment process, only needs gravity filtration, and is simple and environment-friendly; the adsorbing material can be replaced when the filtration velocity cannot meet requirements after being used for a period of time; the replaced adsorbing material can be used as a culture medium for plants, and the sulfate ions can beabsorbed by the plants as a fertilizer.

Owner:河北太和洁源水务科技发展有限公司

A photo frame sap material automatic turning mechanism

InactiveCN111252494BFlipGuaranteed Filtration SpeedConveyorsSupporting framesDust controlStructural engineering

The invention belongs to the technical field of photo frame production equipment, in particular to an automatic overturning mechanism for sap material of a photo frame. Aiming at the problems that the existing overturning equipment is inconvenient to adjust when in use, cannot adapt to materials of different sizes, and is inconvenient for dust removal, the present invention The following scheme is proposed, which includes a workbench. Two fixed plates are fixedly installed on the top of the workbench. Two rotating rollers are installed on the side of the two fixed plates close to each other. The same conveyor belt is arranged on the two rotating rollers. The workbench There are two side plates fixedly installed on the top of the two side plates, sliding plates are installed on both side plates, baffle plates are fixedly installed on the sides of the two slide plates close to each other, and one side of the baffle plate in the two baffle plates is fixedly installed There are stops. The invention can adapt to different sizes of sapwood, can process dust, shake off the dust on the filter net, ensure the filtering speed of the filter net, and can adjust the height of the conveyor belt to adapt to sapwood processing equipment of different heights .

Owner:洪敏燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com