Power battery safety detection method and system and storage medium

A technology of power battery and detection method, which is applied in the direction of battery/fuel cell control device, measuring device, measuring device, etc., to improve the speed of safety detection, reduce the amount of data calculation, and ensure the effect of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

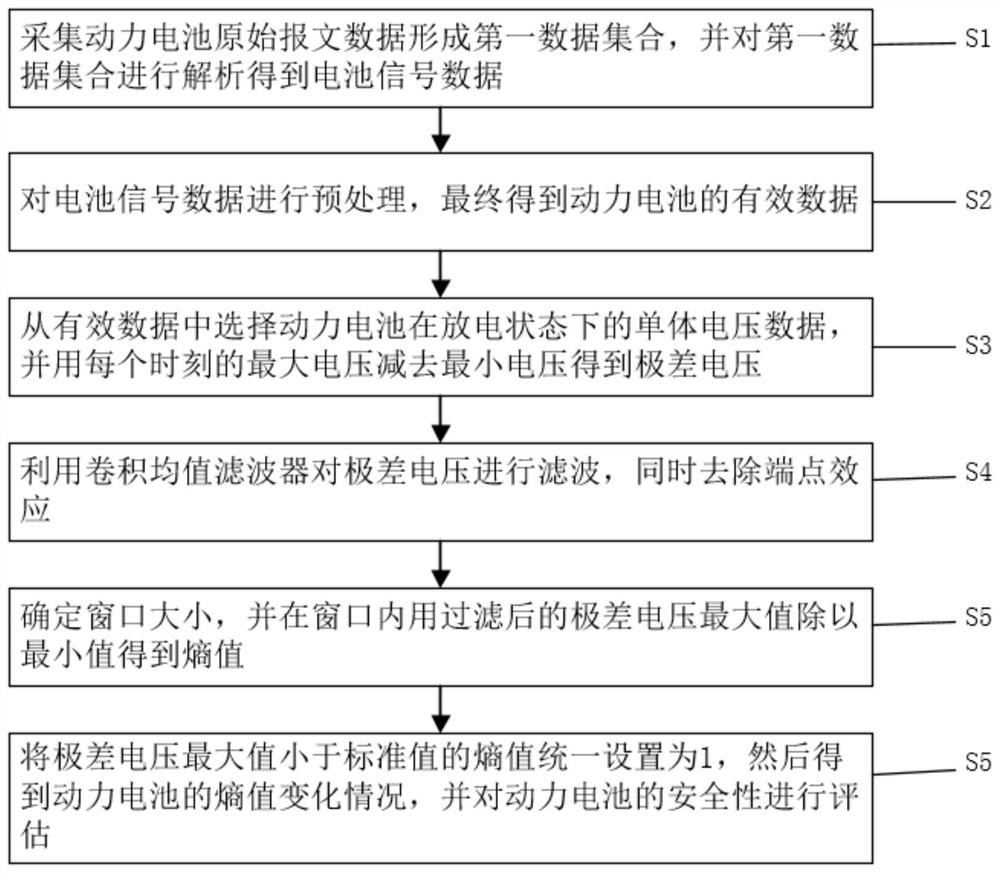

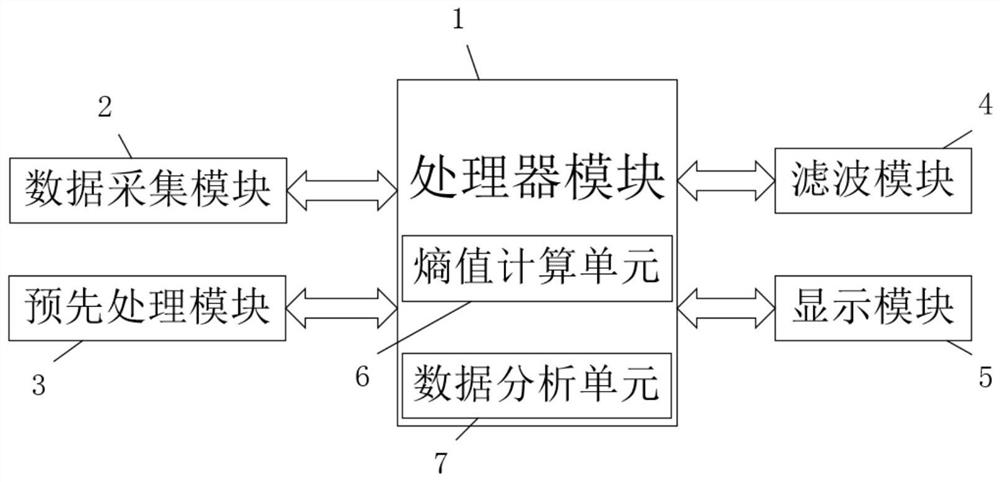

[0042] This embodiment is basically as attached figure 1 Shown: a power battery safety detection method, comprising the following steps:

[0043] Step S1, collect the original message data of the power battery to form a first data set, and analyze the first data set to obtain battery signal data;

[0044] Step S2, preprocessing the battery signal data, cleaning the battery signal data, deleting abnormal characters and invalid data, and eliminating data with a voltage value greater than 6V or less than 1V, and finally obtaining valid data of the power battery, including time Time , charge and discharge state Charge_Status and voltage matrix V three signals;

[0045]Step S3, select the single voltage data of the power battery in the discharge state from the valid data, and subtract the minimum voltage from the maximum voltage at each moment to obtain the range voltage;

[0046] Step S4, using a convolution mean filter to filter the extreme difference voltage, and remove the en...

Embodiment 2

[0065] This embodiment is basically the same as Embodiment 1, the difference is that the above-mentioned power battery safety detection system also includes a reminder module, which is connected with the vehicle-machine system of the electric vehicle. The on-board system of the car sends a reminder message to remind the user.

[0066] The specific implementation process of this embodiment is the same as that of Embodiment 1, the difference is that:

[0067] The fourth step is to uniformly set the entropy value corresponding to the maximum value of the range voltage less than 0.05V to 1, and then obtain the entropy value change of the power battery, and arrange the calculated entropy values according to the interval of 10 seconds. If the entropy value If the entropy value has been in a stable state, it is determined that the safety of the power battery is qualified. If the entropy value changes drastically, it is determined that the safety of the power battery is unqualified....

Embodiment 3

[0070] This embodiment is basically the same as Embodiment 1, the difference is that the power battery safety detection system also includes a prediction module, which is used to analyze the collected operating data and combine the power battery safety detection results this time to predict the occurrence of power battery failures. The time of the security question and suggest the time for the next security check to the user.

[0071] The specific implementation process of this embodiment is the same as that of Embodiment 1, the difference is that one step is added:

[0072] Step 5: After the safety test results of the power battery, the prediction module is started. Using the collected operating data and combined with the safety test results of the power battery, it calculates and analyzes the time when the safety problem of the power battery occurs, and proposes the following to the user. A predictive time to do a security check.

[0073] Through the set prediction module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com