Fermentation technology for organic fertilizer

A fermentation process and organic fertilizer technology, applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems of increasing product cost, production environment pollution, production operation environment pollution, etc., and achieve the goal of ensuring the fermentation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

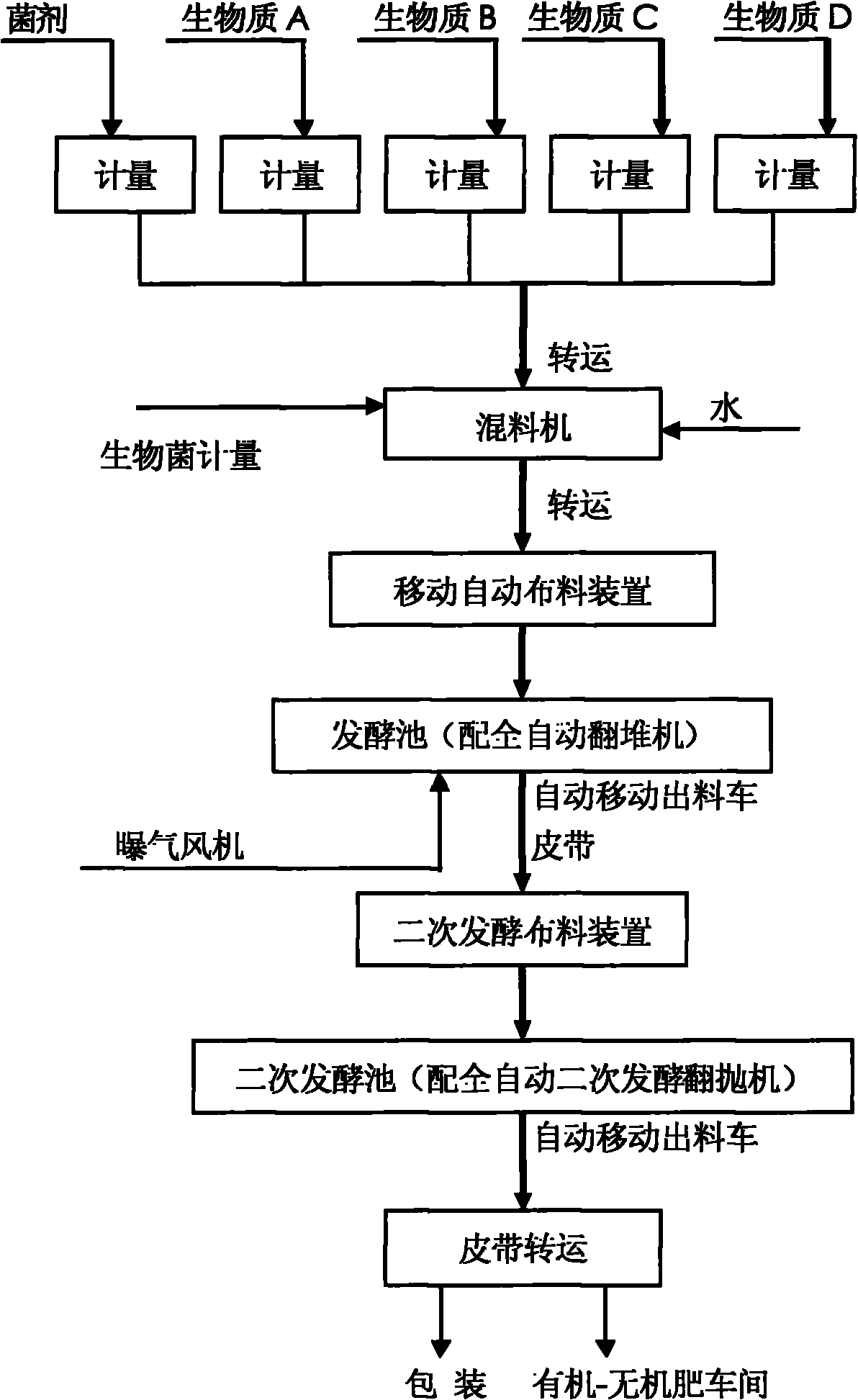

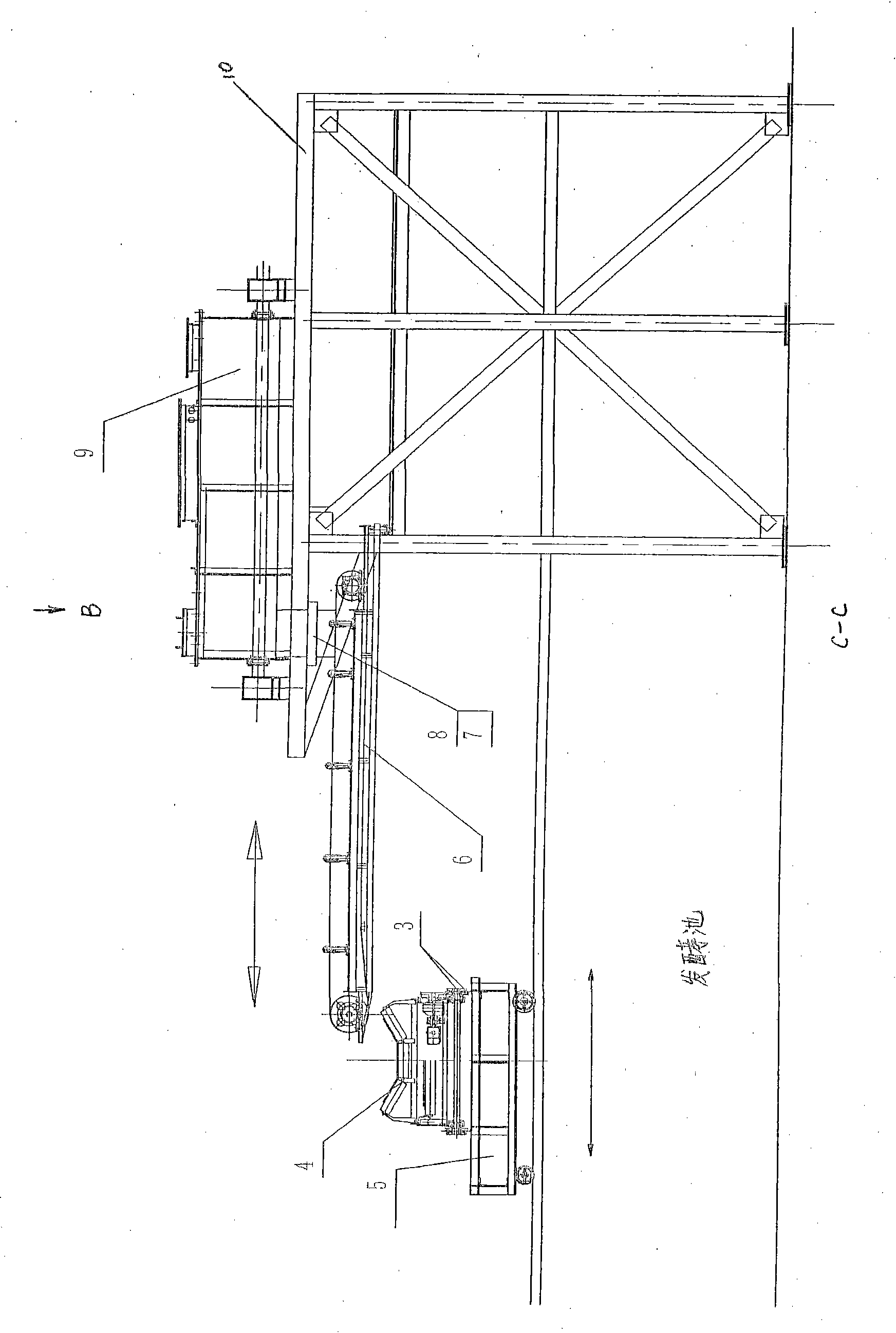

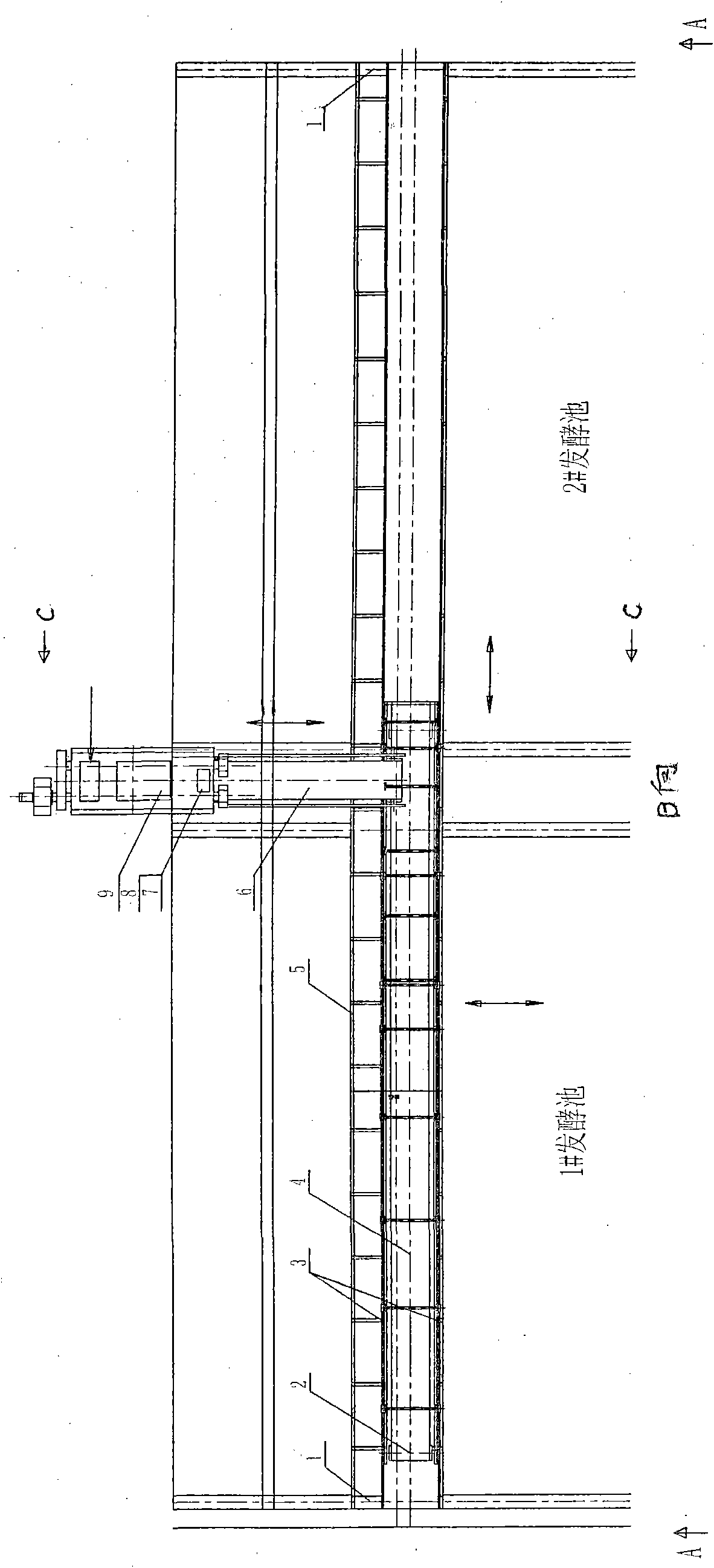

[0026] 1. Different kinds of fermented materials required for production are automatically metered by the metering screw through their respective silos, and then added to the fermented material transfer belt. The setting of the production load can be directly input through the computer, and the system can run automatically. After that The fermented material is then transferred to the mixer, and the amount of water to be added is set according to the amount of fermented material input. In the mixer, the water and the fermented material are fully mixed. The material is fed into the telescopic belt of the mobile automatic distribution device through the automatic discharge port at the lower end of the mixer, and then transferred to the mobile distribution belt of the mobile automatic distribution device, and then distributed into the fermentation tank from the mobile distribution belt.

[0027] 2. The turning and throwing machine performs turning and throwing once or twice a day i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com