Composition for producing bio-organic fertilizer by fermenting livestock and poultry manure and preparation method of composition

A bio-organic fertilizer, livestock and poultry manure technology, applied in the direction of bio-organic part treatment, organic fertilizer, fertilizer mixture, etc., can solve the problems of uncontrollable fermentation speed, overheating, shortening the fermentation time of organic fertilizer, etc., and improve crop rhizosphere microorganisms. , enhance the utilization rate and survival rate, improve the effect of resistance to pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

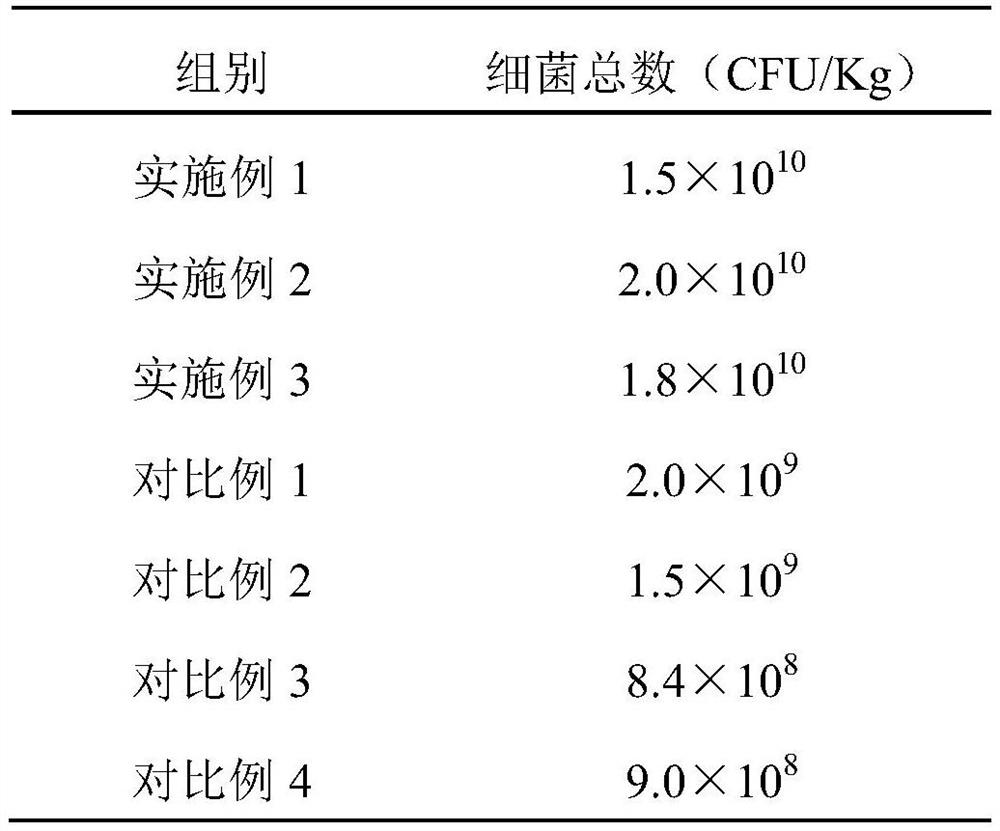

Embodiment 1

[0024] Embodiment 1. A composition for fermenting livestock and poultry manure to produce bio-organic fertilizer and its preparation method

[0025] Formula: 300g of hydroxypropyl methylcellulose, 100g of alginate and 100g of polyanhydride;

[0026] Compound enzyme: 300g alkaline protease, 100g lipase, 100g cellulase and 100g pectinase;

[0027] Composite bacteria: 500g of Bacillus subtilis powder, 300g of Bacillus megaterium, 300g of Bacillus nitrogen-fixing GD powder, 100g of JF Bacillus powder, 300g of Enterococcus faecalis powder, 100g of Candida powder and Marsh red fake Single cell bacteria powder 100g.

[0028] Preparation:

[0029] S1. Preparation of the slow-release layer: Take the formulated amount of hydroxypropyl methylcellulose and dissolve it in 600 mL of 10 mg / mL NaOH aqueous solution, and add the formulated amount of alginate, polyanhydride and 10 ml of epoxy Chloropropane, slowly added, reacted at room temperature for 8 hours, neutralized with dilute hydroc...

Embodiment 2

[0031] Example 2, a composition for fermenting livestock and poultry manure to produce bio-organic fertilizer and its preparation method

[0032] Formula: 400g of hydroxypropyl methylcellulose, 100g of alginate and 200g of polyanhydride;

[0033] Compound enzyme: 400g alkaline protease, 200g lipase, 200g cellulase and 200g pectinase;

[0034] Composite bacteria: 800g of Bacillus subtilis powder, 500g of Bacillus megaterium, 500g of Bacillus nitrogen-fixing GD powder, 300g of JF Bacillus powder, 500g of Enterococcus faecalis powder, 300g of Candida powder and Marsh red fake 300g of single cell bacteria powder.

[0035] Preparation:

[0036] S1. Preparation of the slow-release layer: Take the formula amount of hydroxypropyl methylcellulose and dissolve it in 1200ml of 10mg / mL NaOH aqueous solution. Under the condition of stirring in an ice bath, add the formula amount of alginate, polyanhydride and 20ml epoxy Chloropropane, slowly added, reacted at room temperature for 6 hour...

Embodiment 3

[0038] Example 3, a composition for fermenting livestock and poultry manure to produce bio-organic fertilizer and its preparation method

[0039] Formula: 500g of hydroxypropyl methylcellulose, 200g of alginate and 300g of polyanhydride;

[0040] Compound enzyme: 500g alkaline protease, 300g lipase, 300g cellulase and 300g pectinase;

[0041] Composite bacteria: 1000g of Bacillus subtilis powder, 600g of Bacillus megaterium, 600g of Bacillus nitrogen-fixing GD powder, 500g of JF Bacillus powder, 600g of Enterococcus faecalis powder, 500g of Candida bacteria powder and marsh red fake 500g of single cell bacteria powder.

[0042] Preparation:

[0043]S1. Preparation of sustained-release layer: Dissolve 1000ml of 10mg / mL NaOH aqueous solution in 1000ml 10mg / mL of hydroxypropyl methylcellulose, and add alginate, polyanhydride and 60ml of epoxy Chloropropane, slowly added, reacted at room temperature for 10 hours, neutralized with dilute hydrochloric acid, stirred for 60 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com