Curve temperature control type secondary fermentation process for mulberry wine

A technology for secondary fermentation and mulberry wine, applied in the field of fruit wine brewing, can solve the problems of incomplete sugar conversion, long clarification time, long cycle, etc., and achieve the effect of improving the clarity of wine body and shortening the secondary fermentation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

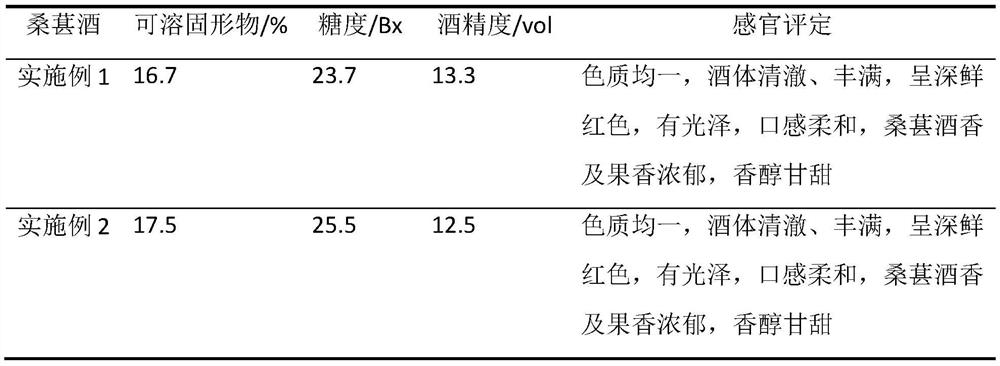

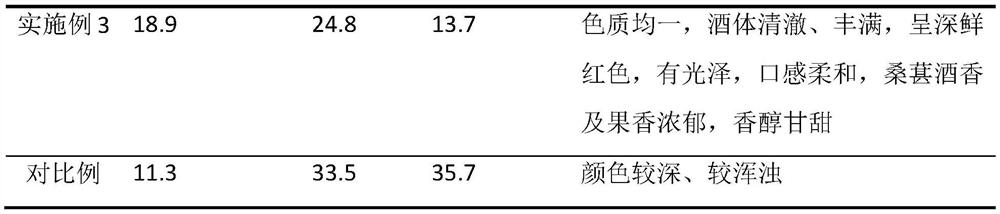

Embodiment 1

[0043] The mulberry wine curve temperature control type secondary fermentation process of the present embodiment comprises the following steps:

[0044] (1) Feeding: After the fermented liquid after initial fermentation is coarsely filtered, it is poured into an open tank;

[0045] (2) Fermentation: control the temperature at 25°C, and ferment for 3 days in the open; after the fermentation is completed, the sugar conversion rate of the fermented liquid reaches 90%;

[0046] (3) Initial tank: pour the fermented liquid in step (2) into the first airtight fermenter, control the temperature at 20°C, and continue to ferment for 3 days; after the fermentation is completed, the sugar conversion rate of the fermented liquid reaches 93%;

[0047] (4) Secondary tank inversion: pour the fermented liquid in step (3) into the second airtight fermenter, control the temperature at 18° C., and continue to ferment for 3 days; after the fermentation is completed, the sugar conversion rate of th...

Embodiment 2

[0059] The mulberry wine curve temperature control type secondary fermentation process of the present embodiment comprises the following steps:

[0060] (1) Feeding: After the fermented liquid after initial fermentation is coarsely filtered, it is poured into an open tank;

[0061] (2) Fermentation: Control the temperature at 26.5° C., and open the fermentation for 4 days; after the fermentation is completed, the sugar conversion rate of the fermented liquid reaches 91%;

[0062] (3) Initial tank: pour the fermented liquid in step (2) into the first airtight fermenter, control the temperature at 23° C., and continue to ferment for 4 days; after the fermentation is completed, the sugar conversion rate of the fermented liquid reaches 93.5%;

[0063] (4) Secondary tank inversion: pour the fermented liquid in step (3) into the second airtight fermenter, control the temperature at 20°C, and continue to ferment for 4 days; after the fermentation is completed, the sugar conversion ra...

Embodiment 3

[0075] The mulberry wine curve temperature control type secondary fermentation process of the present embodiment comprises the following steps:

[0076] (1) Feeding: After the fermented liquid after initial fermentation is coarsely filtered, it is poured into an open tank;

[0077] (2) Fermentation: control the temperature at 28° C., and open the fermentation for 4 days; after the fermentation is completed, the sugar conversion rate of the fermented liquid reaches 92%;

[0078] (3) Initial tank: pour the fermented liquid in step (2) into the first airtight fermenter, control the temperature at 25° C., and continue to ferment for 4 days; after the fermentation is completed, the sugar conversion rate of the fermented liquid reaches 94%;

[0079] (4) Secondary tank inversion: pour the fermented liquid in step (3) into the second airtight fermenter, control the temperature at 23° C., and continue to ferment for 4 days; after the fermentation is completed, the sugar conversion rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com