Embedded-type sensor for detecting concrete chloride ion content and preparation method thereof

A technology of chloride ion content and sensor, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the chloride ion content of concrete cannot be detected in real time, the chloride ion concentration cannot be continuously detected, and the chemical reaction is irreversible, so as to reduce spillage and migration Loss, improve shrinkage cracking performance, improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

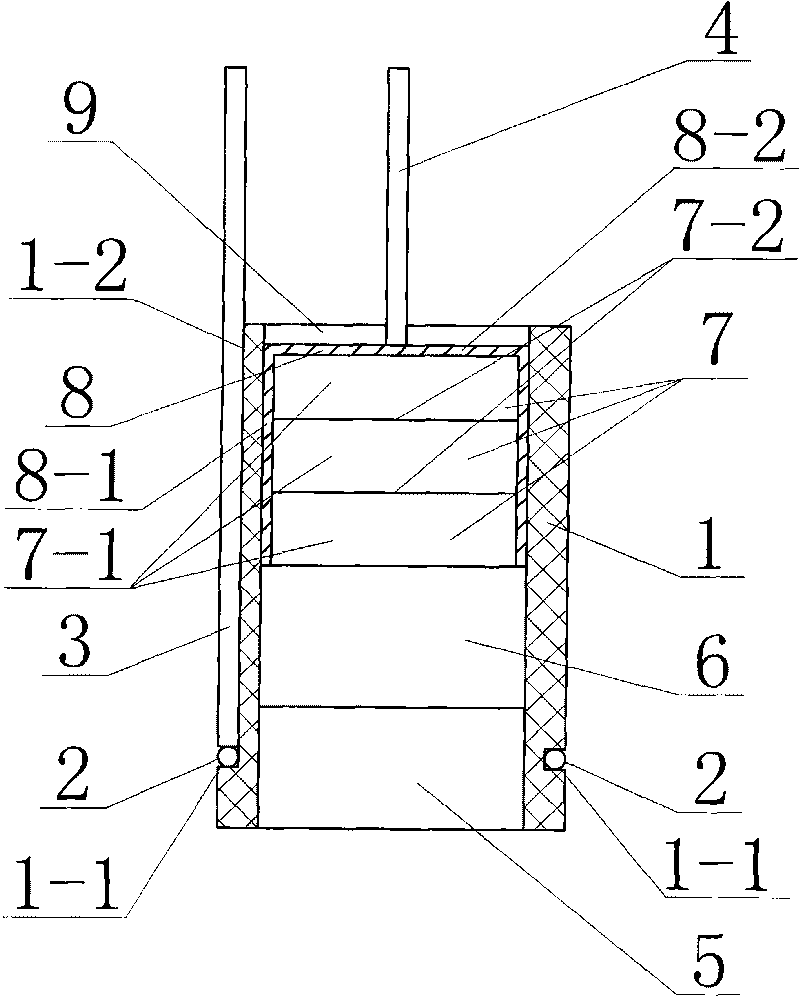

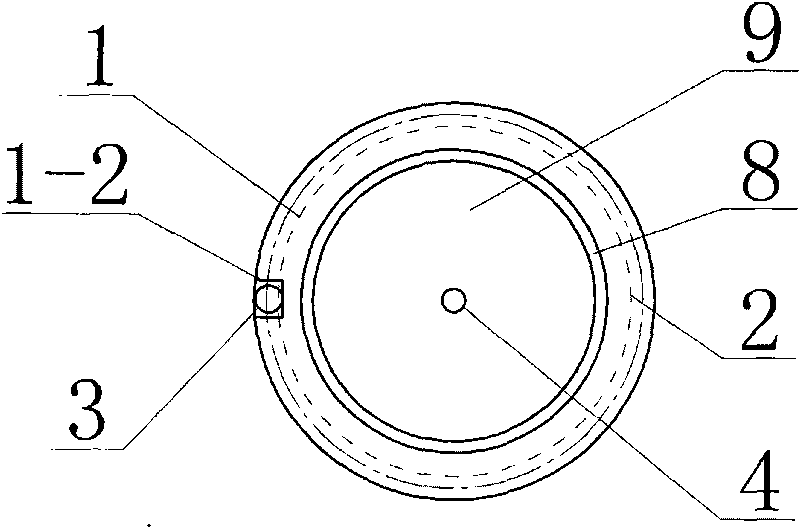

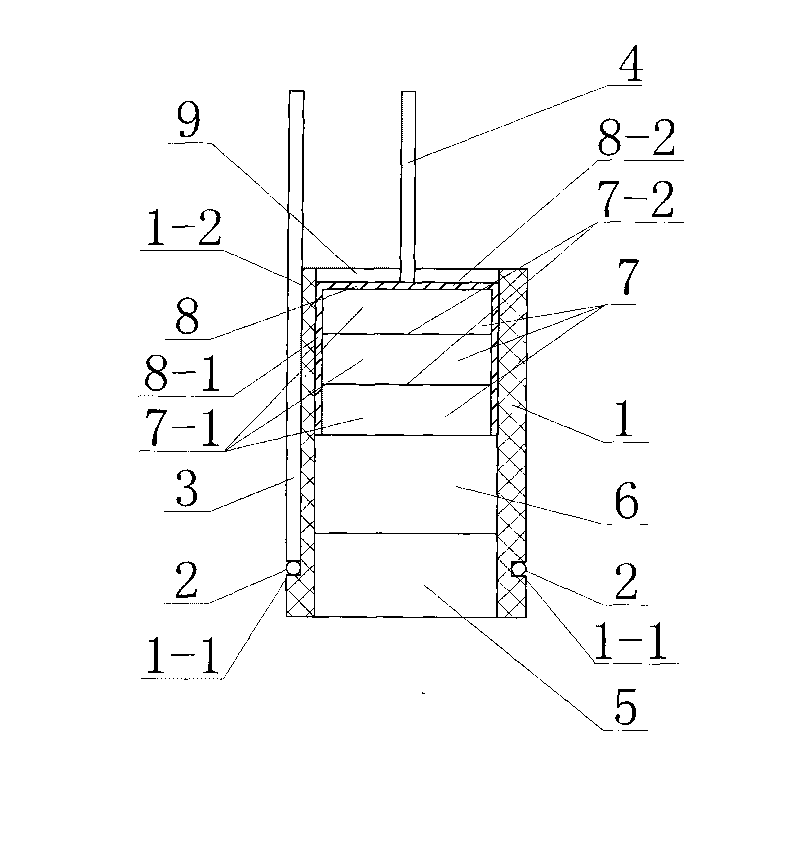

[0026] Specific implementation mode one: as Figure 1~2As shown, the embedded sensor for detecting the chloride ion content of concrete in this embodiment includes a sensor cylinder 1, an annular silver wire 2, an input copper wire 3, an output copper wire 4, a micro-expansion fiber cement semi-permeable membrane layer 5, an alkaline Gel layer 6, manganese dioxide layer 7, metal barrel body 8 and insulating sealant layer 9, the lower part of the outer wall of the sensor cylinder 1 is provided with an annular groove 1-1 along the circumferential direction of the sensor cylinder 1, the The outer wall of the sensor cylinder 1 has an axial groove 1-2 along the height direction, and the annular groove 1-1 communicates with the axial groove 1-2, and the annular silver wire 2 is sleeved on the sensor cylinder In the annular groove 1-1 of 1, the lower part of the input copper wire 3 is located in the axial groove 1-2, and the lower end of the input copper wire 3 is fixed with the annu...

specific Embodiment approach 2

[0028] Specific implementation mode two: as figure 1 As shown, the length of the sensor cylinder 1 in this embodiment is 30-50 mm. In such a design, the sensor barrel 1 is designed to be small in size, which is convenient for embedding the sensor in concrete. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: as Figure 1~2 As shown, the material of the sensor cylinder 1 in this embodiment is made of hard PVC plastic. With such a design, the hard PVC plastic has good insulation, is easy to process, and is waterproof and moisture-proof. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com