Waste machine oil/tire oil/plastic oil distillation device and technique

A technology for distillation equipment and tire oil, which is applied in the field of waste engine oil, tire oil, plastic oil distillation equipment and technology, can solve the problems of endangering the safety of operators, low calorific value, and large loss of economic benefits, etc., to achieve resource saving and Energy, easy installation and operation, and the effect of eliminating secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

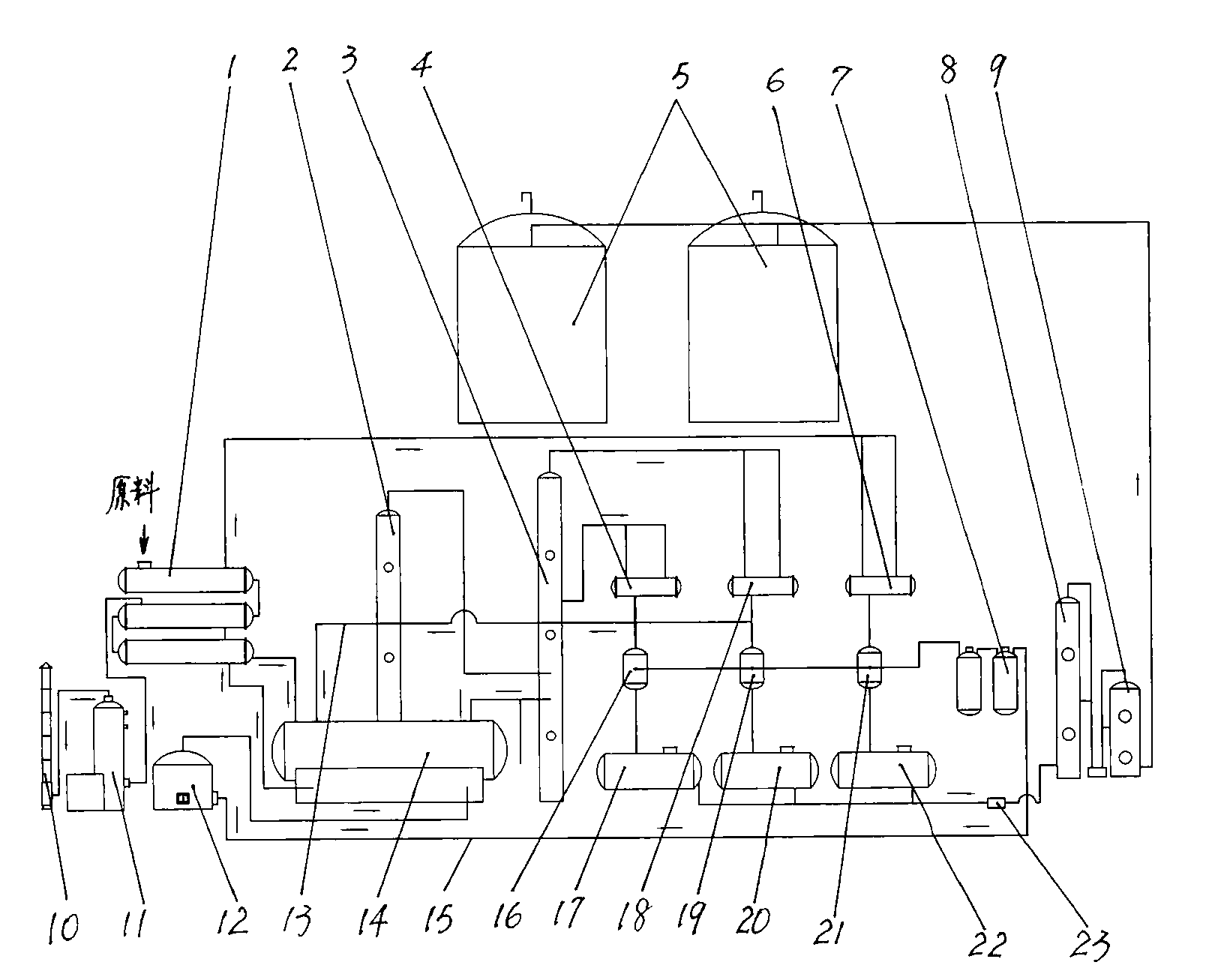

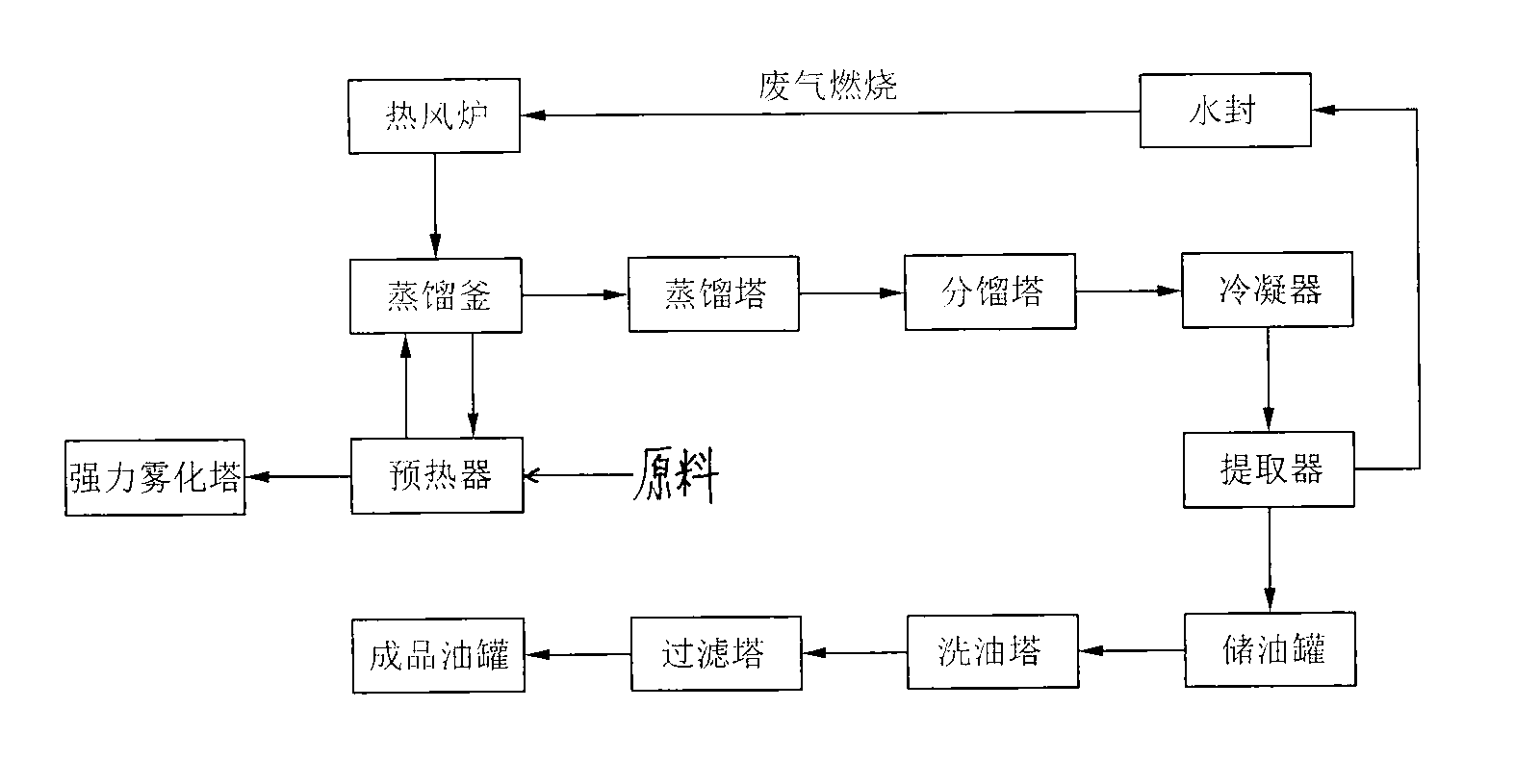

[0011] as attached figure 1 As shown, the equipment consists of a preheater 1, a powerful atomizing tower 11, a hot blast stove 12, a distillation still 14, a distillation tower 2, a fractionation tower 3, tube and tube condensers 4, 18, 6, oil storage tanks 17, 20, 22. Extraction tanks 16, 19, 21, oil washing tower 8, filter tower 9 and product oil tank 5, the oil outlet of preheater 1 is connected with the oil inlet of distillation kettle 14, the air outlet of hot blast stove 12 is connected with distillation kettle 14 The inlet of the flue is connected, the outlet of the preheater 1 is connected to the powerful atomization tower 11, and the outlet of the powerful atomization tower 11 is connected to the chimney 10 through the induced draft fan to discharge the treated waste gas; the distillation tower 2 Located above the still 14, the oil and gas outlet at the top of the distillation tower 2 is connected to the fractionating tower 3, and the reflux port at the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com