Deep treatment method of tannery wastewater

A technology for tanning wastewater and advanced treatment, applied in animal processing wastewater treatment, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc. problems, to achieve the effect of reducing disposal costs, moderate operating costs, and prolonging the backwash cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

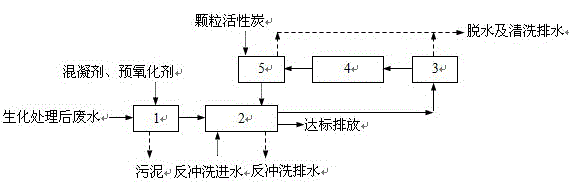

Method used

Image

Examples

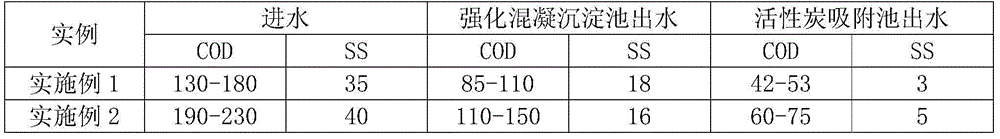

Embodiment 1

[0039](1) The tannery wastewater is biochemically treated in the secondary sedimentation tank, and the effluent from the secondary sedimentation tank biochemical treatment flows to the coagulation sedimentation tank 1 for enhanced coagulation and sedimentation, and at the same time, add sodium hypochlorite at the inlet of the coagulation zone of the coagulation sedimentation tank. and polyferric chloride. The reaction time t in the coagulation zone of the enhanced coagulation sedimentation tank 1 =15min, the surface load of the sedimentation zone q=1.0m 3 / (m 2 h), effective residence time t 2 =3h;

[0040] (2) The waste water after coagulation and sedimentation is lifted to the granular activated carbon adsorption tank by the lifting pump, and the wastewater flows through the activated carbon layer from top to bottom, and the filtration speed of the empty bed of the activated carbon adsorption tank is controlled to v=2.5m / h, and the thickness of the filter layer is h=3m ,...

Embodiment 2

[0046] The advanced treatment method of the tannery wastewater of the present embodiment comprises the following steps:

[0047] (1) The effluent from the secondary sedimentation tank after biochemical treatment flows to the enhanced coagulation sedimentation tank (the enhanced coagulation sedimentation tank is the pre-oxidation contact area, coagulation reaction area and precipitation separation area from front to back), and at the same time, the pre-oxidation contact area is Add ozone to the coagulation inlet, add polyferric chloride at the coagulation inlet, the enhanced coagulation sedimentation tank pre-oxidation contact zone residence time t 1 =30min, residence time t in the coagulation reaction zone 2 = 10min, surface load q = 1.0m in the sedimentation zone 3 / (m 2 h), effective residence time t 3 =3h.

[0048] (2) The waste water after coagulation and sedimentation is lifted to the granular activated carbon adsorption tank by the lifting pump, and the wastewater fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Methylene blue value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com