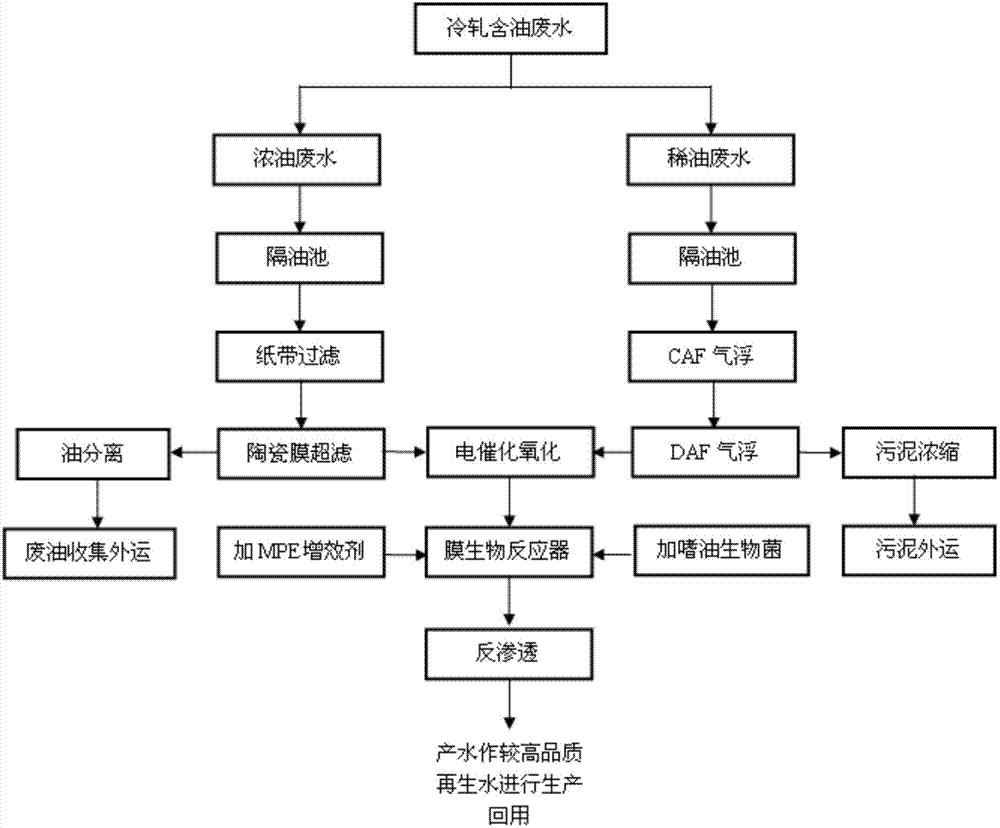

Cold rolling oily wastewater treatment process

A wastewater treatment and wastewater technology, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Significant economic and environmental benefits, improved wastewater reuse rate, stable treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Cold rolling thick oil wastewater mainly includes emulsion wastewater and thick oil alkali wastewater. The water quality is as follows: COD is 18000mg / L, oil content is 10000mg / L, SS is 5000mg / L; thin oil wastewater mainly includes thin oil alkali wastewater , the water quality is as follows: COD is 3000mg / L, oil content is 400mg / L, SS is 3000mg / L.

[0033] The above-mentioned dense oily wastewater is pretreated through a grease trap, a paper tape filter, and a ceramic membrane ultrafilter in sequence. Use a grease trap to collect dense oily wastewater, and use the oil skimming device in the grease trap to recover the upper oil slick; paper tape filtration is a security process for ceramic membrane separation, which can remove a part of suspended impurities, foam and sludge, which is very important for the operation of ceramic membranes. To optimize the effect; while the inorganic ceramic membrane uses the principle of sieving and filtration to intercept small particles...

Embodiment 2

[0043] Cold rolling thick oil wastewater mainly includes emulsion wastewater and thick oil alkali wastewater. The water quality is as follows: COD is 50000mg / L, oil content is 3000mg / L, SS is 1000mg / L; thin oil wastewater mainly includes thin oil alkali wastewater , its water quality is as follows: COD is 2000mg / L, oil content is 500mg / L, SS is 500mg / L.

[0044] The above-mentioned dense oily wastewater is pretreated through a grease trap, a paper tape filter, and a ceramic membrane ultrafilter in sequence. Use a grease trap to collect dense oily wastewater, and use the oil skimming device in the grease trap to recover the upper oil slick; paper tape filtration is a security process for ceramic membrane separation, which can remove a part of suspended impurities, foam and sludge, which is very important for the operation of ceramic membranes. To optimize the effect; while the inorganic ceramic membrane uses the principle of sieving and filtration to intercept small particles o...

Embodiment 3

[0055] Cold rolling thick oil wastewater mainly includes emulsion wastewater and thick oil alkali wastewater. The water quality is as follows: COD is 40000mg / L, oil content is 12000mg / L, SS is 8000mg / L; thin oil wastewater mainly includes thin oil alkali wastewater , its water quality is as follows: COD is 1000mg / L, oil content is 100mg / L, SS is 4000mg / L.

[0056]The above-mentioned dense oily wastewater is pretreated through a grease trap, a paper tape filter, and a ceramic membrane ultrafilter in sequence. Use a grease trap to collect dense oily wastewater, and use the oil skimming device in the grease trap to recover the upper oil slick; paper tape filtration is a security process for ceramic membrane separation, which can remove a part of suspended impurities, foam and sludge, which is very important for the operation of ceramic membranes. To optimize the effect; while the inorganic ceramic membrane uses the principle of sieving and filtration to intercept small particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com